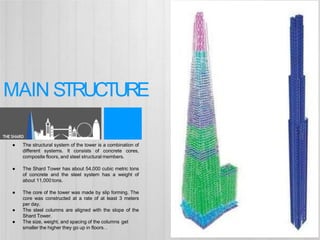

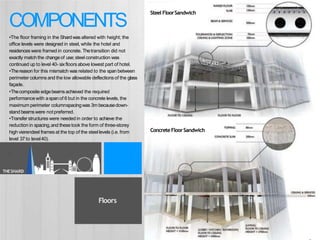

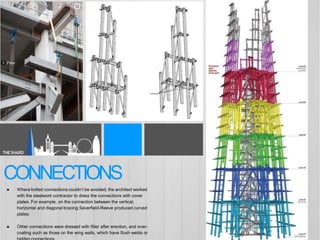

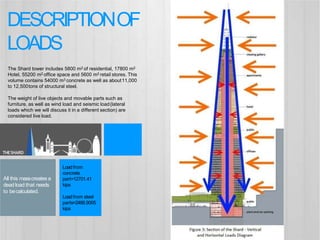

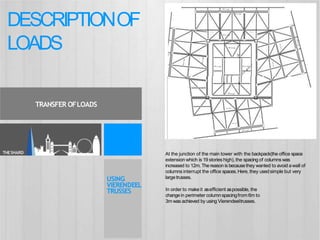

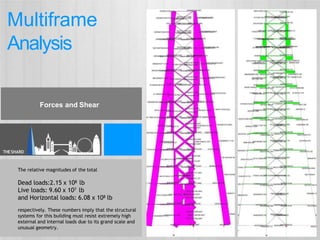

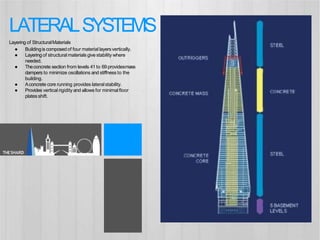

The Shard is a 310m tall skyscraper in London consisting of offices, hotels, apartments and retail space. It uses a combination of concrete and steel structures, with a concrete core providing stability. Over 54,000 cubic meters of concrete and 11,000 tons of structural steel were required. Complex transfer structures such as vierendeel trusses were needed to reduce column spacing as the building design transitioned between material types. Extensive analysis and testing was performed to ensure the tower could withstand the immense external and internal loads placed upon it.