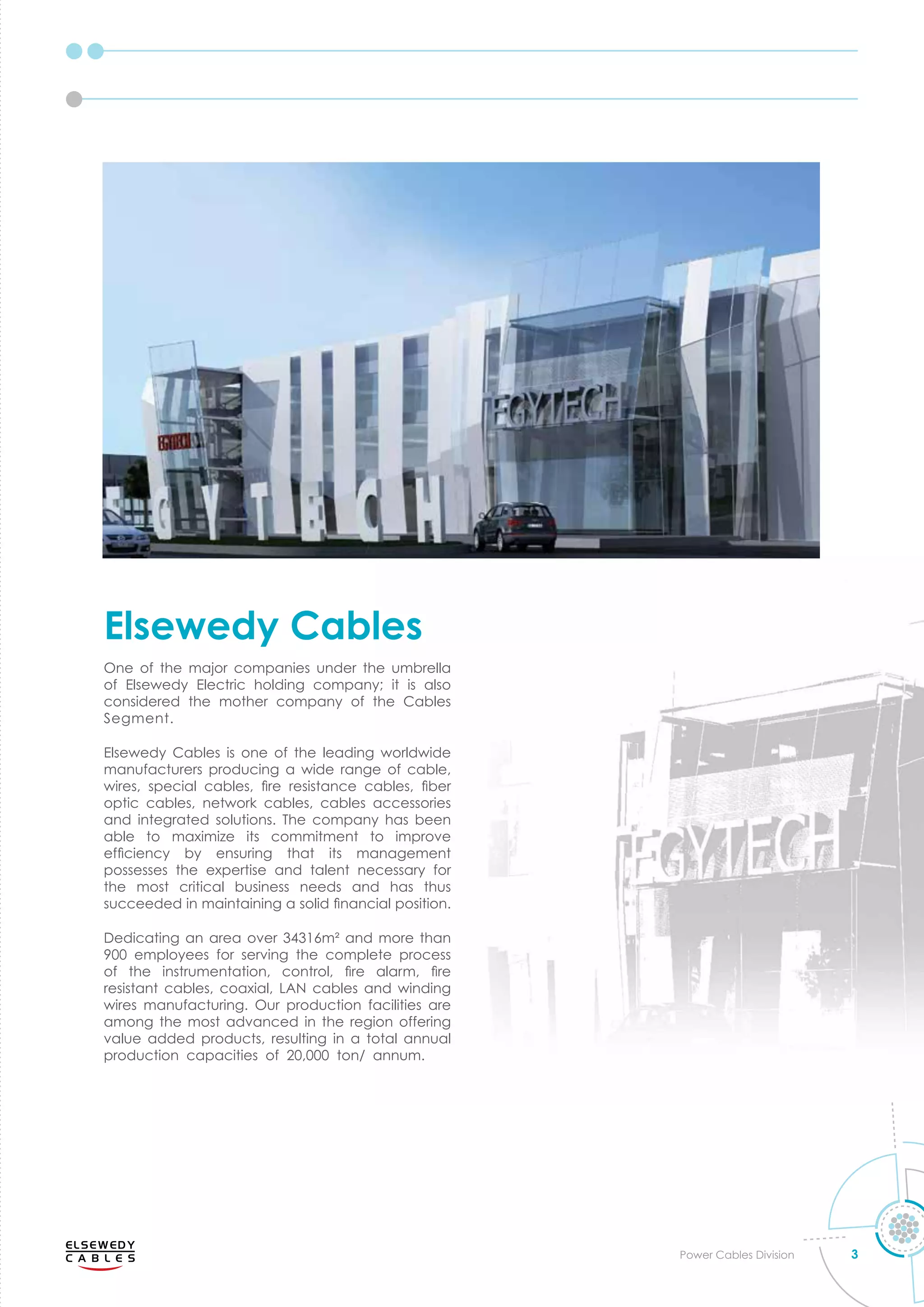

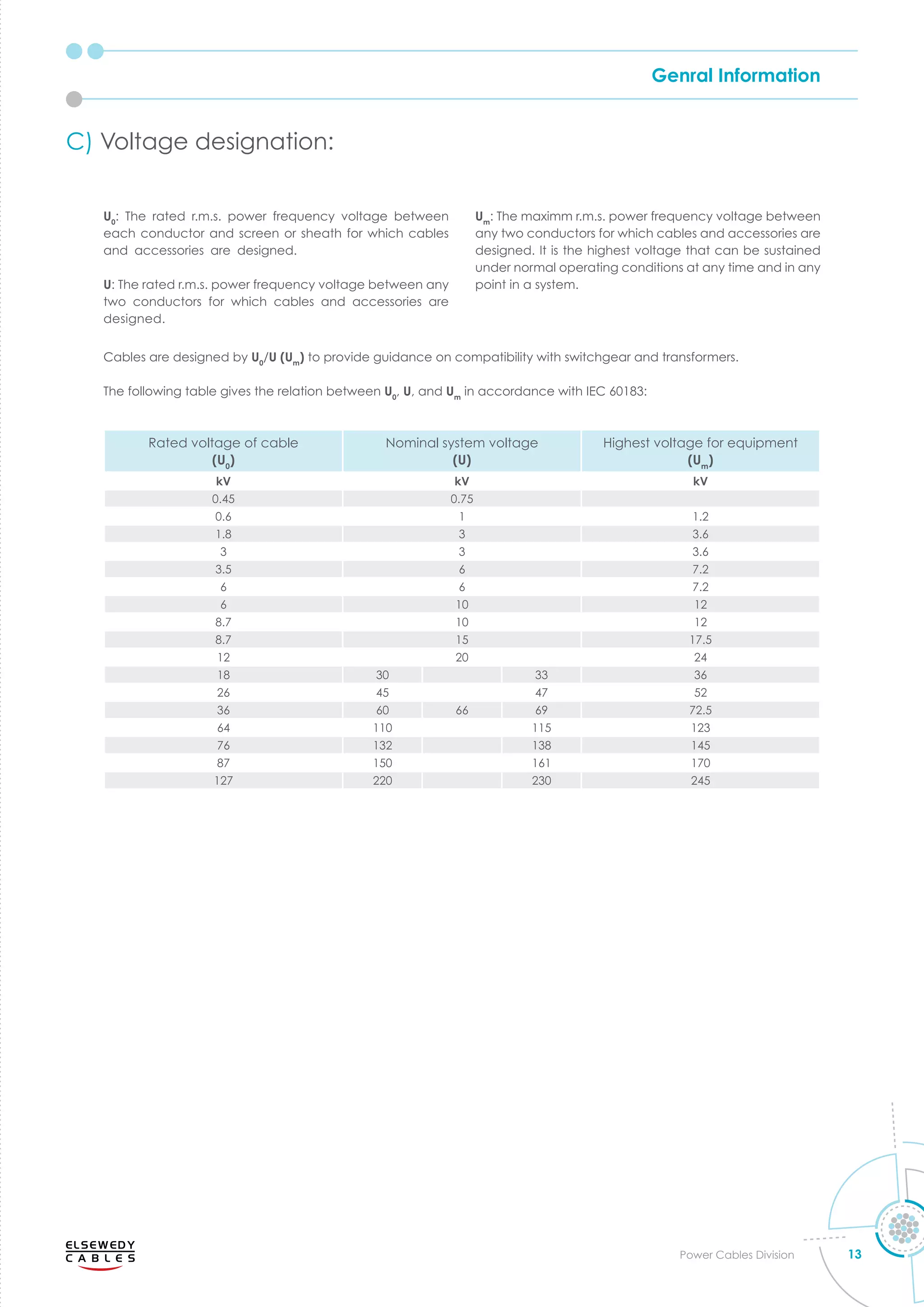

This document provides an overview of a catalog that contains technical information on overhead conductors and electrical power cables up to 220 kV. The catalog helps customers select suitable cables based on factors like voltage, current rating, short circuit current, weight and dimensions. Standards from organizations like IEC and BS that relate to power cables are also listed.

![Genral Information

14 Power Cables Division

1. Resistance

The conductor DC resistance values given in this

catalog are based on C. in case of the conductor

DC resistance is required at different temperature, the

following formula shall be used:

Rθ

= R20

[ 1 + θ(θ-20)] Ω/Km

where

Rθ

: conductor DC resistance at θ C m

R20

conductor C resistance at C m

θ o erating tem erature C

α tem erature coefficient C

= 0.00393 for Copper

= 0.00403 for Aluminum

To get AC resistance of the condcutor at operating

temperature the following fromula is used

m

where

Yp

and Ys

are proximity and skin effect factors

respectively

2. Inductance:

The self and mutual inductances are formoualted as

following:

mh/Km

where

L : Inductance mh/Km

K : Constant (as self inductance)

d : Conductor diameter mm

S : Axial spacing between cables in mm

trefoil and in case of at formation

multiply the spacing by 1.26

3. capacitance:

The capacitance is formulated as following:

μf/Km

where

C : Capacitance μf/Km

εr

: relative permittivity of insulation

material

D : Diameter over Insulation mm

d : Diameter under insulation mm

4. Insulation resistance:

The insulation resistance is formualted as following:

m

where

insulation resistance m

K : Constant depending on the

insulation material

d : diameter under the insulation mm

D : diameter over the insulation mm

5. Charging Current:

The charging current is the capacitive current which

o s through the dielectric la ers hen C oltage

is applied. The value can be calculated from the

following equation:

A/Km

where

Ic

: Charging current A/Km

U0

: Rated phase voltage V

ω : Angular of velocity (2πf)

f : Frequency Hz

C : Capacitance μf/Km

6. Dielectric losses

The dielectric losses of an AC cable are proportional

to the capacitance, the frequency, the phase voltage

squared and the power factor. The value can derived

from the following equation:

watt/Km/phase

where

Wd : Dielectric losses watt/Km/phase

f : Frequency Hz

C : Capacitance μf/Km

U0

: Rated phase voltage V

tanδ : Dielectric power factor

ω : Angular of velocity (2πf)

D) Technical data Cables arameters

L = K + 0.2 In( )

2S

d

—

C = ———————

18 In( )

D

d

—

εr

RAC

= Rθ

(1 + Yp

+ Ys

)

Rθ

= R20

[ 1 + α(θ-20)] Ω/Km

R = K ln(D/d)

Ic

= U0

ωC10-6

Wd

= ωCU0

2

tanδ 10-6](https://image.slidesharecdn.com/power-cables-catalogueelsewedy-221016110122-e67b5b58/75/power-cables-catalogue-Elsewedy-pdf-15-2048.jpg)