Here are the key points from the Measure Stage:- Time stamps are used to track time from receiving to entering data - Samples were taken in April-July to measure receiving times- Gaps exist with some receipts taking >30 mins or >3 hours - Receivers sometimes forget time stamps - Inventory accuracy does not directly correlate with data entry time- Involving Tony and Ari after 3:30pm can help reduce delays - Timing and accuracy metrics will help identify root causesThe stage gate is approved pending addressing the timing gaps to fulfill customer needs of on-time delivery and minimizing shortages. Continued data collection and analysis is needed

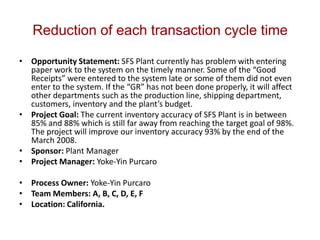

- 1. Reduction of each transaction cycle time • Opportunity Statement: SFS Plant currently has problem with entering paper work to the system on the timely manner. Some of the “Good Receipts” were entered to the system late or some of them did not even enter to the system. If the “GR” has not been done properly, it will affect other departments such as the production line, shipping department, customers, inventory and the plant’s budget. • Project Goal: The current inventory accuracy of SFS Plant is in between 85% and 88% which is still far away from reaching the target goal of 98%. The project will improve our inventory accuracy 93% by the end of the March 2008. • Sponsor: Plant Manager • Project Manager: Yoke-Yin Purcaro • Process Owner: Yoke-Yin Purcaro • Team Members: A, B, C, D, E, F • Location: California.

- 2. Reduction of each transaction cycle time • Financial Savings: This project will not have actual amount of the financial savings, but it will provide the improvement of the inventory accuracy. • Primary Metric: Improving inventory accuracy by reaching 93% by the end of March. Currently: Between 85% and 89% hit accuracy. • Secondary Metrics: To help the plant stays within the budget. • Currently: Some invoices that supposed to be paid last month but paid in this month. • Goal: Try to pay all of the bills within the same month. • Other Benefits: To better manage the inventory and to better manage the plant budget.

- 3. Project Summary Customers: Internal customers: Production department, shipping department and production planner. External customer: customer, CSR, sales, logistics Product or Service: We have improved the wait time for a PO that needs to be received. PO or materials receive in timely manner. Defect/Error: Key Dates Kick-off: Define: Measure: Analyze: Improve Control Target 1/28/08 1/28/08 2/28/08 3/15/08 4/1/08 5/1/08 Completed Scope: To enter all the paper work such as purchase orders and receivers to the system within a short period. To improve inventory by reaching target of 98%. Out of Scope: Paper work did not enter to system on time which created a conflict between production, shipping and customer. Project costs: This project cost us about $1000. We bought three time stamp clock to keep track the time from receiving to entering the system.

- 4. Validation of the Solution – Time entered into SAP 100% April 90% May 80% June 70% July August % of orders 60% Reduced >3 hrs & within 3 hrs to 0 50% 40% 30% 20% 10% 0% Within 30 min Within 1 hr Within 2 hrs. Within 3 hrs. 3 hrs >

- 5. Validating the new process Improvement in transaction cycle time does not mean an improvement in Inventory accuracy

- 6. Project Highlights Define Who are the Measure • customer? Plant Manager • Production Customer Service End use Customer 1. Shortages – complaint from customer. 2. When information was not entered in timely manner, production won’t be able to process the process order. 3. Inventory issue – spend hours on finding the if the receivers were entered properly. • • Analyze Measured by purchasing a time stamp •Short handed A “Receiving Analysis” has been done for this project. •Lack of organization 20 days sample were taken randomly from April to July. These samples were separated into five categories information entered within 30 min, within 1 hr, within 2 hrs, within 3 hrs & greater than 3 hrs . Within 30 minutes: April 26% May 58% June 76% July 48% •Lack of training (who is the backup?) Improve 1. Implemented three time stamps. 2. We are still using the time stamp for keeping track the time. 3. Have more employees involve in entering the paper work. 4. Train more employees to do the transaction to eliminate the “Short handed” problem. 5. Quality assurance and the supervisor will help entering the data to SAP Control 25 bill of ladings will be randomly audited Email team leaders if the document was not stamped “forget to enter” or “overlooked the document” will be documented for improvement purposes.

- 7. The Define Stage deliverables Santa Fe Springs Plant has realized that the delay on receiving raw materials to the system caused a major problems Problems: Unable to proceed the process order in the production department, inaccurate inventory and shortages Production department: When the raw material was not entered to the system on time, the process order can’t not be done. The production line has to stop. Inventory: When the materials that supposed to be entered before the cycle count but didn’t enter to the system until the cycle count has been performed, the inaccurate inventory shows. Shortages: When the materials didn’t receive at the right time, shortages on the order will be occurred. The timing of entering information to the system is important as it will create all the problems as above; and all these problems waste employees energy and time on the investigation.

- 8. Voice of the Customer • Who are the customers of this process? – Plant Manager • Complain about the poor inventory control due to the delayed on good receipts • Stay within the plant budget – Production • Can’t create process order. No products will be produced in the production line. – Customer Services department • Can’t fulfill the customer’s orders. Complaints come from different directions such as the sales department and the customers Measure how long it takes to enter inventory into SAP • End Use Customer wants and needs: • Customer wants the right product, right quantity and the product in the right place. The order needs to ship out on time as promised. What the customer needs is to avoid the shortage and delayed.

- 9. Voice of the Process R e c e iv in g P ro c e s s P r o d u c t s t r an s fe r fr o m o t h e r p lan t s Aft e r r e c e iv e r v e r ifie d t h e m at e r ial an d q u an t it y , t h e r e c e iv e r s ig n e d an d d at e t h e d o c u m e n t . 55 m in u t e s D o c u m e n t w ill b e t u r n e d in t o t h e s h ip p in g le ad e r 5 m in u t e s Le ad e r w ill d o t h e "GR " fo r all t h e r e c e iv in g fr o m o t h e r p lan t s F r o m im m e d iat e ly t o 15 m in u t e s By the end of the s h ift , all o f t h e r e c e iv in g d o c u m e n t s w ill b e file d .

- 10. Voice of the Process Receiving Process for Components Components such as bottles, cartons, pails, drums and etc. After receiver verified the material and quantity, the receiver signed and date the document. Document will be turned in to the front desk and 20 minutes Administrative will enter the information to SAP Less than 10 minutes If material was delivered after the administrative left, the supervisor, Tony and the QA, Ari will help enter the information. Then, we file all the documents that have been entered. Within the same day. More than 30 minutes.

- 11. Define Stage and Gate Voice of the Customer: Voice of the Process: All of the P.O. must be entered within the same day as it is delivered. All of the deliver P.O. should have two time stamps – Time in and the Time Entered. EXCEPTIONAL: Materials such as bottles, cartons, and the materials transfer from other plants need to be entered within 30 minutes. Materials transfer from other plants enter by the receiver in the shipping department. When a P.O. that is delivered by UPS or Fedex should have a P.O. number as “Reference Number” on the label. The administrative assistant is responsible for entering the information. If all of the P.O. entered to the system on time, the production department should not have any problems with the process order. Components such as cartons, bottles, caps, pails, drums, pallets and etc. enter by the administrative assistant in the office. The administrative assistant works from 6:30 AM to 3:30 PM. She will make sure all of the materials are received in the system before she 3:30 PM. If the materials were delivered after 3:30 PM, Tony and Aril perform the Goods Receipt in SAP. What we are trying to do here is to make sure all of the delivered materials received within the same day.

- 12. The Measure Stage deliverables The plant bought three time stamps to keep track all the delivered materials and the time from being received to enter to the system All of the bill of lading, packing list have two time stamps. The administrative assistant and the receivers have been trained for performing the “Good Receipts” procedures. We have been using the time stamp machines since April and we had randomly picked 20 – 23 bill of ladings for samples. They are five categories of timing for the receiving: Information enter within 30 minutes, 1 hour, 2 hours, 3 hours and more than 3 hours. The results we have are on the following slide.

- 13. Performance- Customer’s point of view Receiving times entered by Administrative Assistant 100% April May June July 90% 80% 70% % of orders 60% Why does it take longer than 30 min to enter? 50% 40% 30% 20% 10% 0% Within 30 min Within 1 hr Within 2 hrs. Within 3 hrs. 3 hrs >

- 14. Process Performance Inventory accuracy and entering data doesn’t correlate?

- 15. Measure Stage and Gate Customer’s perspective: Orders to be fulfilled and delivered at the right time and right place. Shortages should be minimized and quality needs to be consistent. Process performance: The receivers in shipping department keep forgetting to stamp the time on the paper. Instruction was sent to the supervisor that the time stamp on paper is necessary. 99% of the papers o Gap: There is a 30 minutes and more than three hours gap occur on the receiving process. Validate data is correct, repeatable, and reproducible: Which measurements/ metrics will help identify the root causes: The timing and the accuracy will be able to help us to identify the root causes. “Just do it” opportunities: After we had a meeting about who should enter the paper works after the administrative assistant left. We decided to have Tony and Ari help us with this task. We are trying to enter all the paper work on the same day as the materials delivered to our plant.

- 16. Identify the Root Causes Why does a gap of 30 minutes to greater than 3 hours gap occur in this process? Short handed Lack of training Lack of organization (who is the backup?)

- 17. Analyze Stage and Gate Root Causes: When the materials were not received in timely manner; often, it caused by short handed. We have noticed that when the employees were rushing on getting things done, mistakes such as entering the wrong quantities or overlooked the paper work happened. Lack of the sense of urgency is one of the reason why the materials were received late. Some employees have the attitude of “Don’t worry, we can do it later.” The word “later” could be tomorrow or two days later. Supporting data: 1. In April, we started using the time stamp that allowed me to keep track the timing from receiving the product to entering information to the system. The Good Receipt was performed within 30 minutes are – April: 26%, May: 58%, June: 76%, July: 48%. 2. We were short handed most of the time in July. The production assistant, the production scheduler, the inventory control were absented. Key factors that must be addressed in the solution: Being able to receive all of the materials that need to be received on the same day as they were delivered. “Just do it” opportunities: In the past, only the receivers and the administrative assistant enter information to the SAP. Now, we have the lab assistant and the manufacture supervisor to help us entering the data.

- 18. The Improve Stage - The Solution • • • • We are still using the time stamp for keeping track the time. Have more employees involve in entering the paper work. Train more employees to do the transaction to eliminate the “Short handed” problem. Components will be entered by the administrative assistant. Quality assurance and the supervisor will help entering the data to SAP if the administrative assistant left before the material is delivered.

- 19. 100% Validation of the Solution – Time entered into SAP April 90% May 80% June 70% July August % of orders 60% 50% Reduced >3 hrs & within 3 hrs to 0 40% 30% 20% 10% 0% Within 30 min Within 1 hr Within 2 hrs. Within 3 hrs. 3 hrs >

- 20. Improve Stage and Gate Process Change: Voice of the Process: Voice of the Customer: Make sure all the materials receive in the system no later than 30 minutes after they were delivered. 1. When the materials were delivered, check the accuracy on the bill of lading. 1. The production department did not complained about “Good Receipt” on our components. 2. Perform “Good Receipt” in SAP. 2. Production planner will be able to schedule the production plan more effectively. It is necessary to have to time stamps (Time in and time entered) on each bill of lading. All of the employees understood the process and the concept of keeping track the timing. The last person left the office makes sure there is no “undeceived” document. People in receiving department and administrative assistant were trained for the process. 3. Materials transfer from other plants will be received in shipping department and information will be entered no later than 15 minutes, usually. 4. Components will be entered by the administrative assistant. Quality assurance and the supervisor will help entering the data to SAP if the administrative assistant left before the material is delivered. 5. This process is a task NOT an optional step. 3. They are one less error that inventory control coordinator needs to investigate. 4. It save times on investigation. 5. Voice of the customer is unable to measure but can be heard physically.

- 21. How we will maintain the new process 25 bill of ladings will be randomly audited Email team leaders in receiving department and manufacturing supervisor if the document was not stamped “forget to enter” or “overlooked the document” will be documented for improvement purposes. Administrative assistant will be questioned if the document was entered after three hours. The reason will be documented for future improvement.

- 22. How we know it is working The process will be working when 80% of the transactions are entered into SAP within 30 minutes and 0 orders are greater than 1 hour This will be validated with monthly audits using the time stamps

- 23. Lessons Learned Reducing the transaction time might not be the best way to improve our inventory accuracy, but it definitely helps us to smoothing the process order for production line and improve the customer service Change the goal of the project at an earlier date

- 24. Sign Off • Approval completes the project for the Team. This transfers control of the project to the process owner. We agree that this project is complete and the control phase can be completed.. Date: Team Leader Date: Sponsor Date: Project Manager