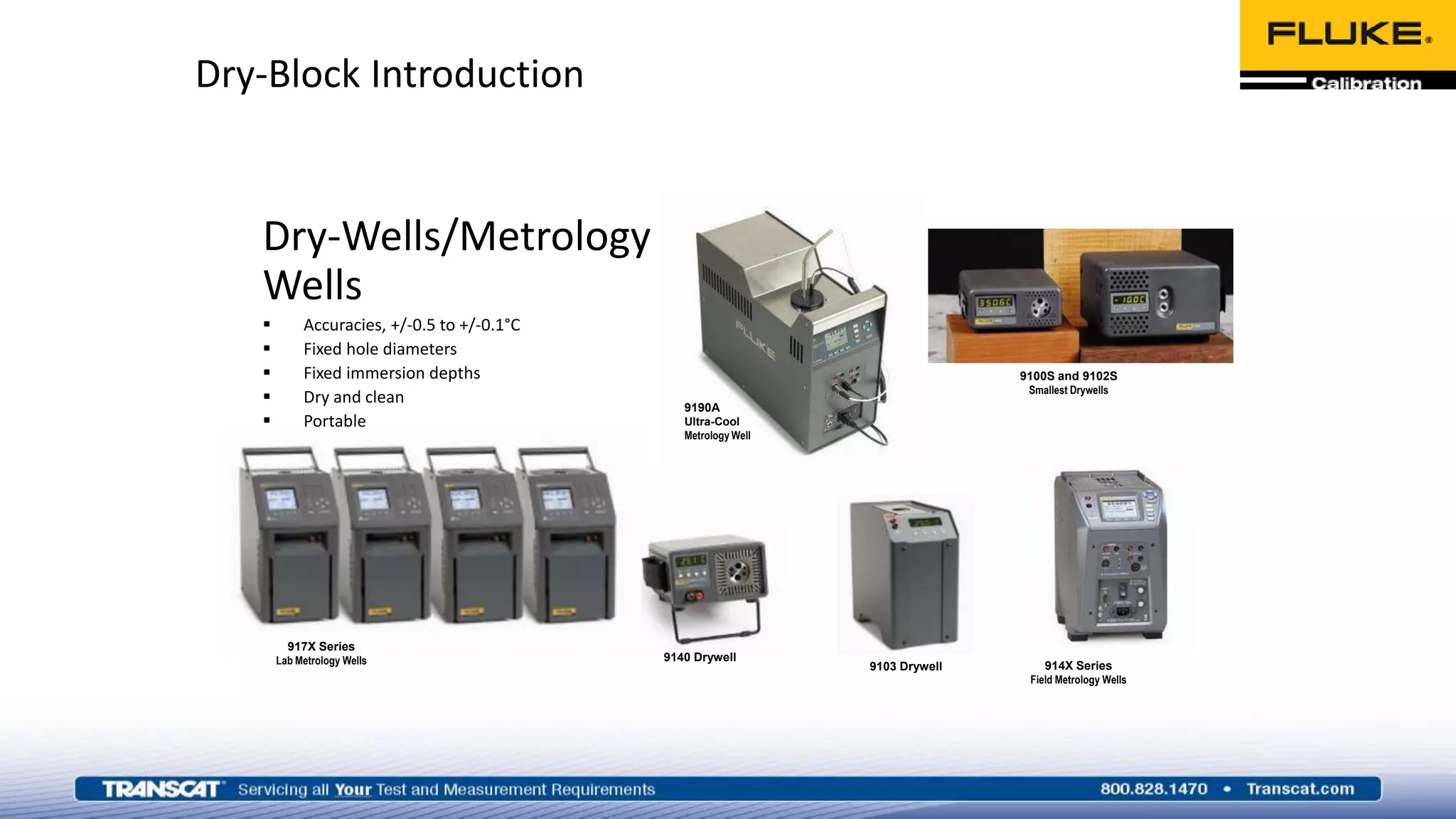

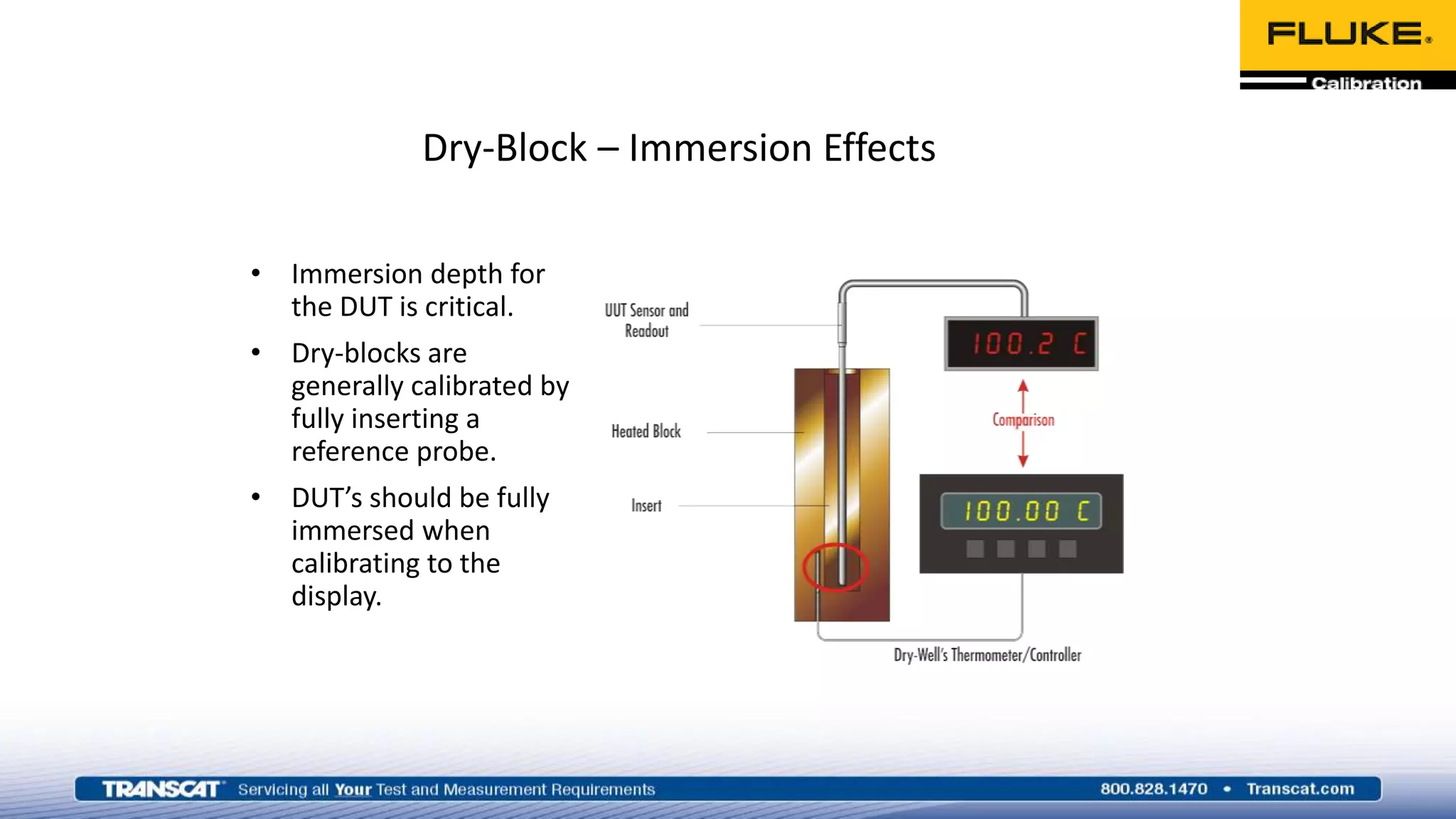

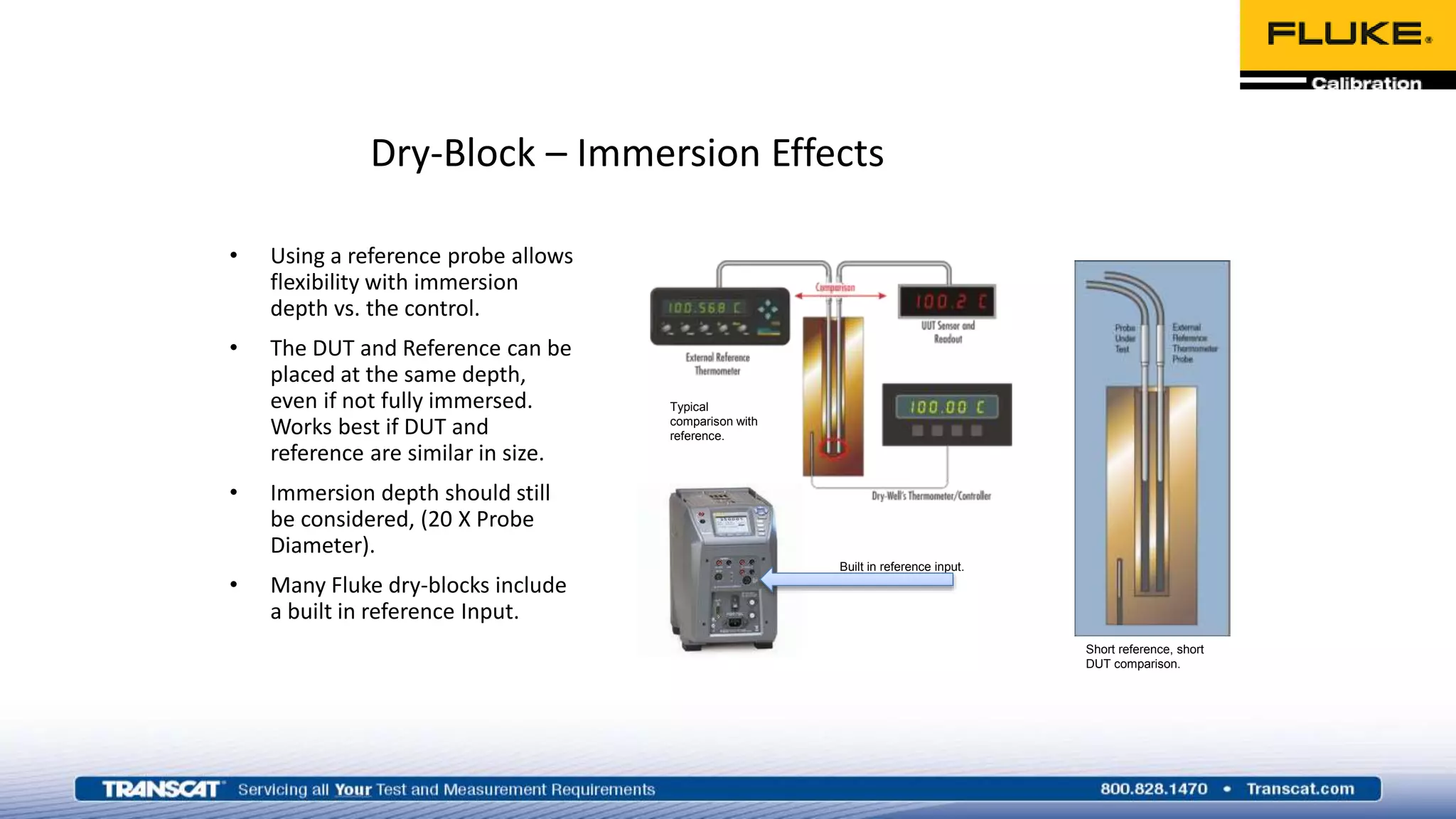

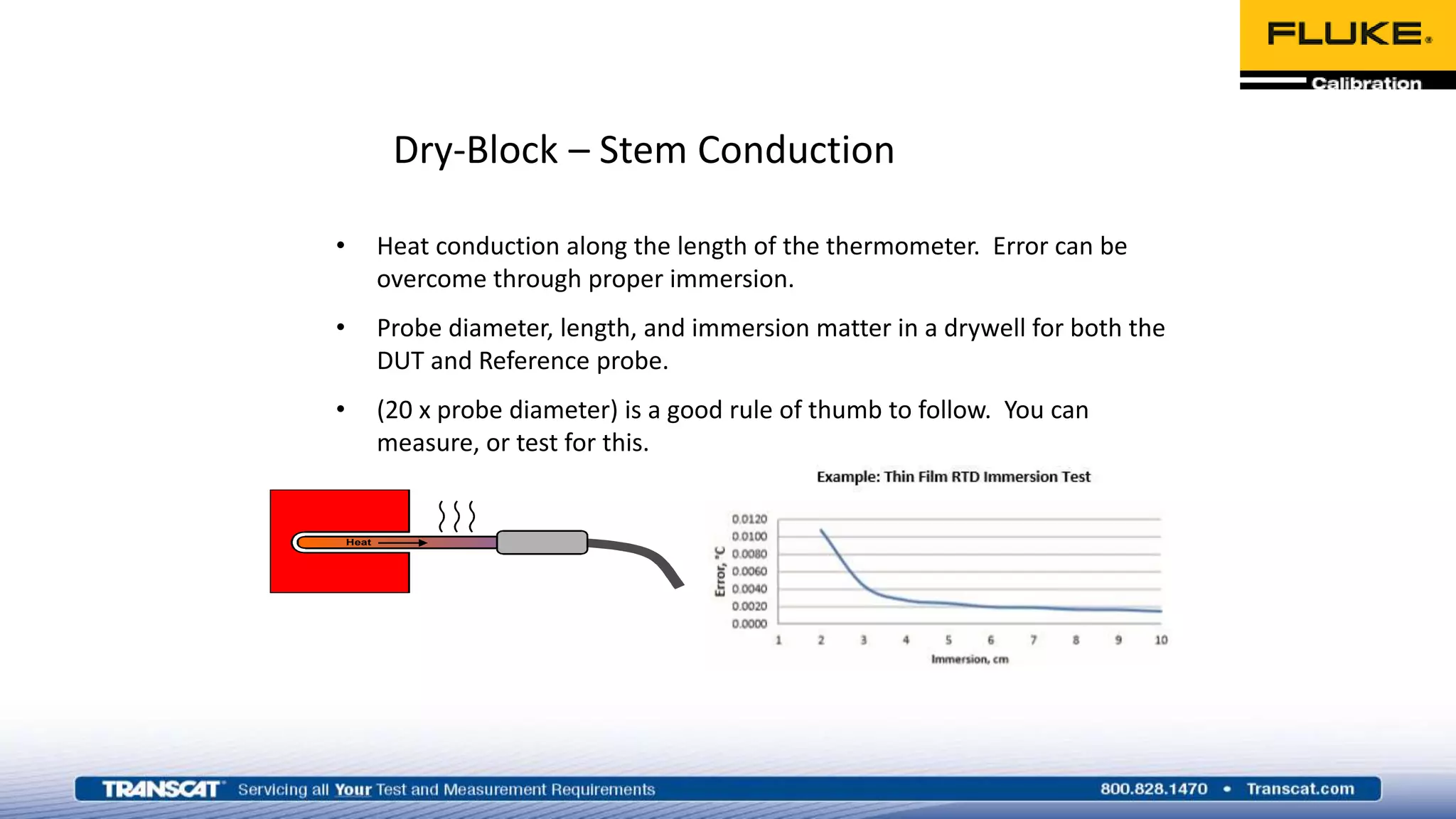

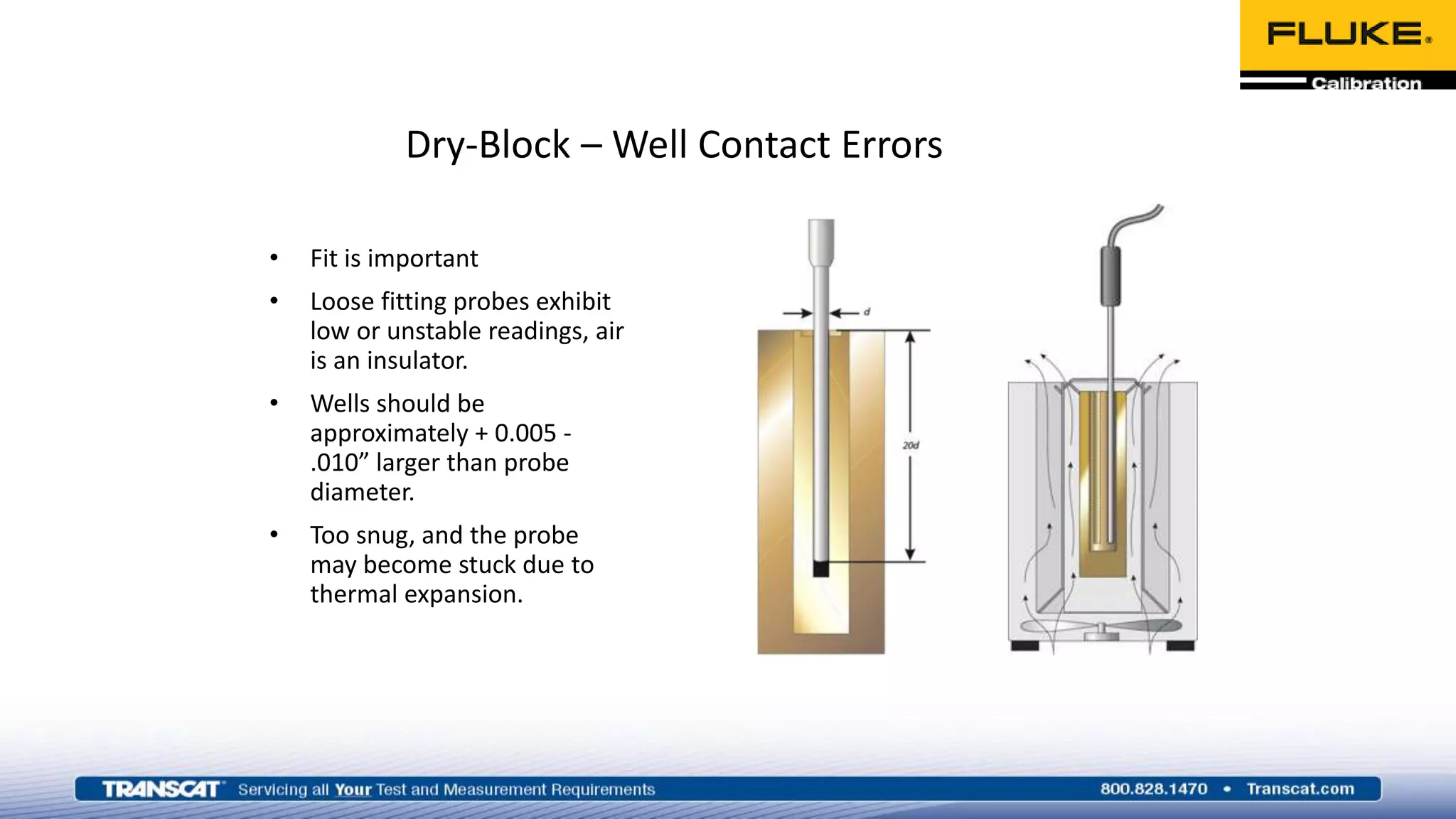

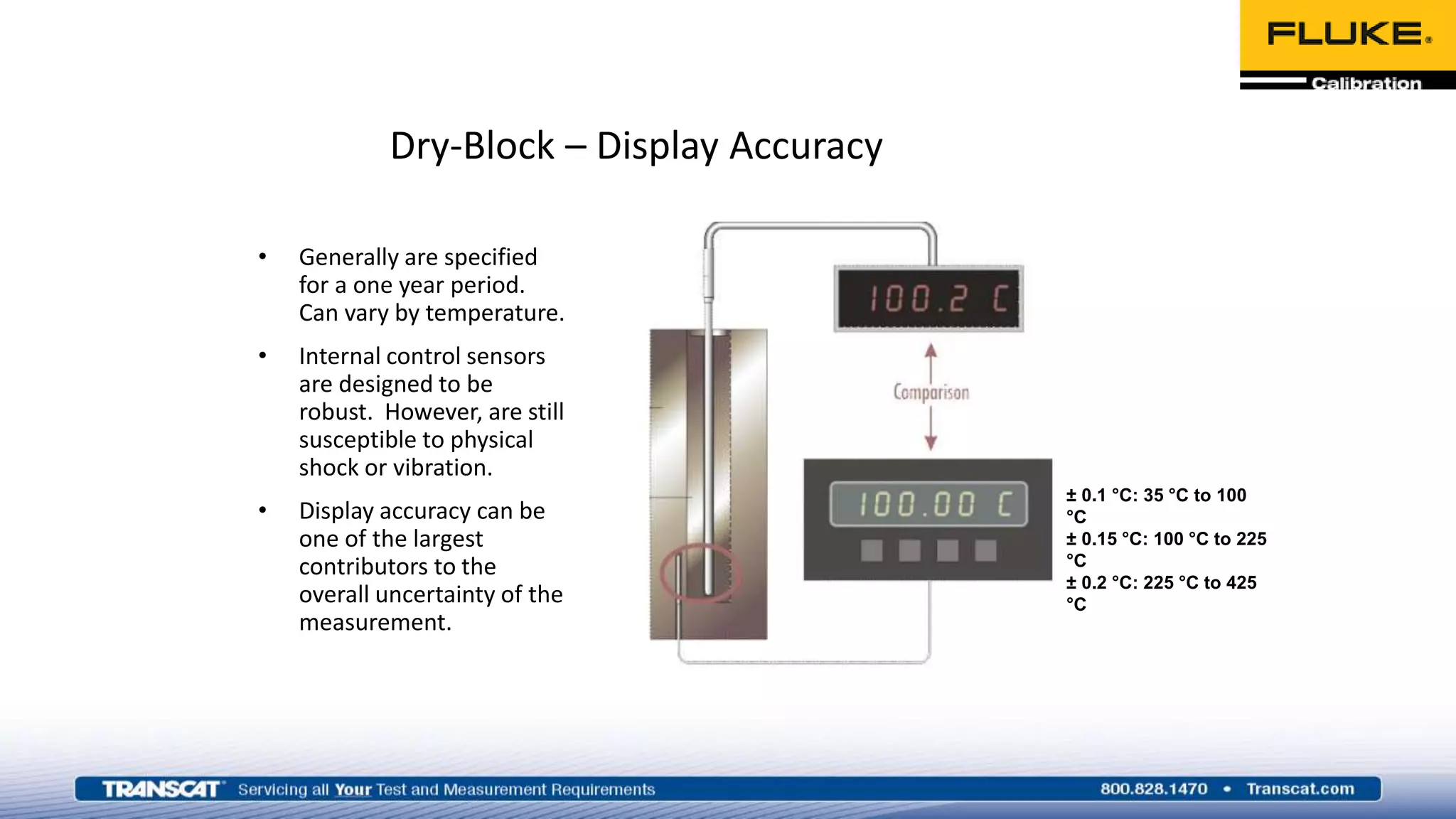

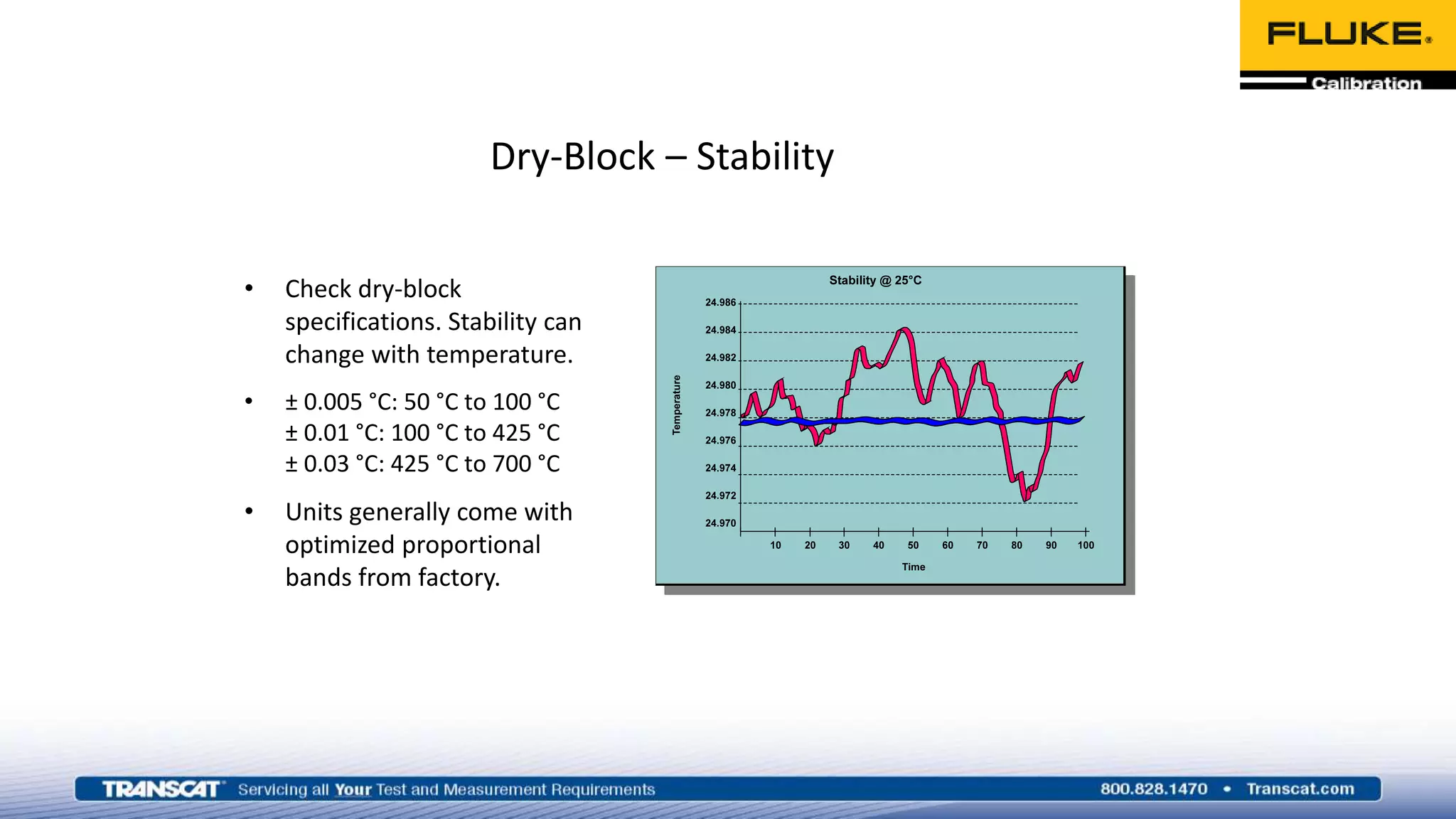

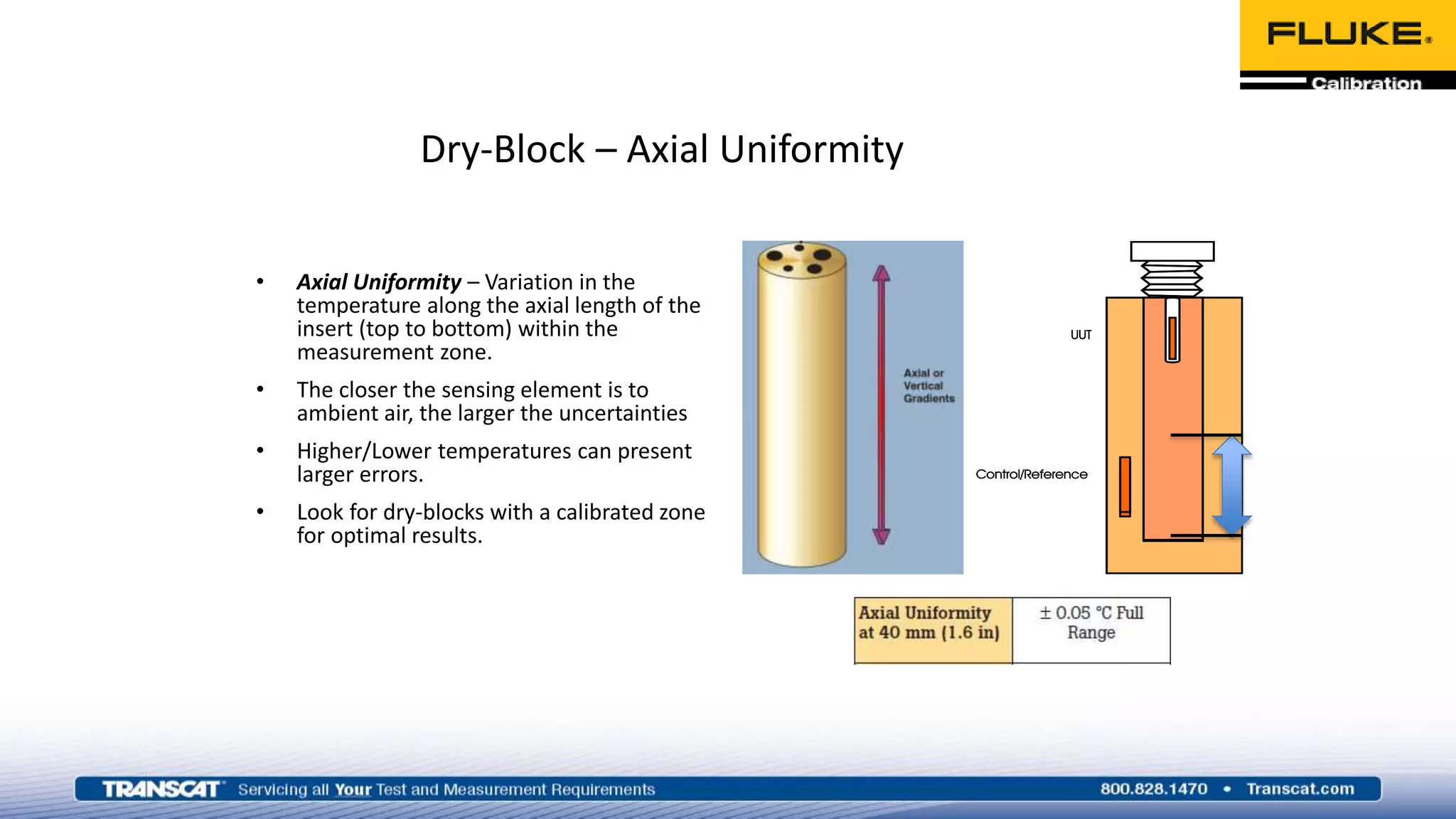

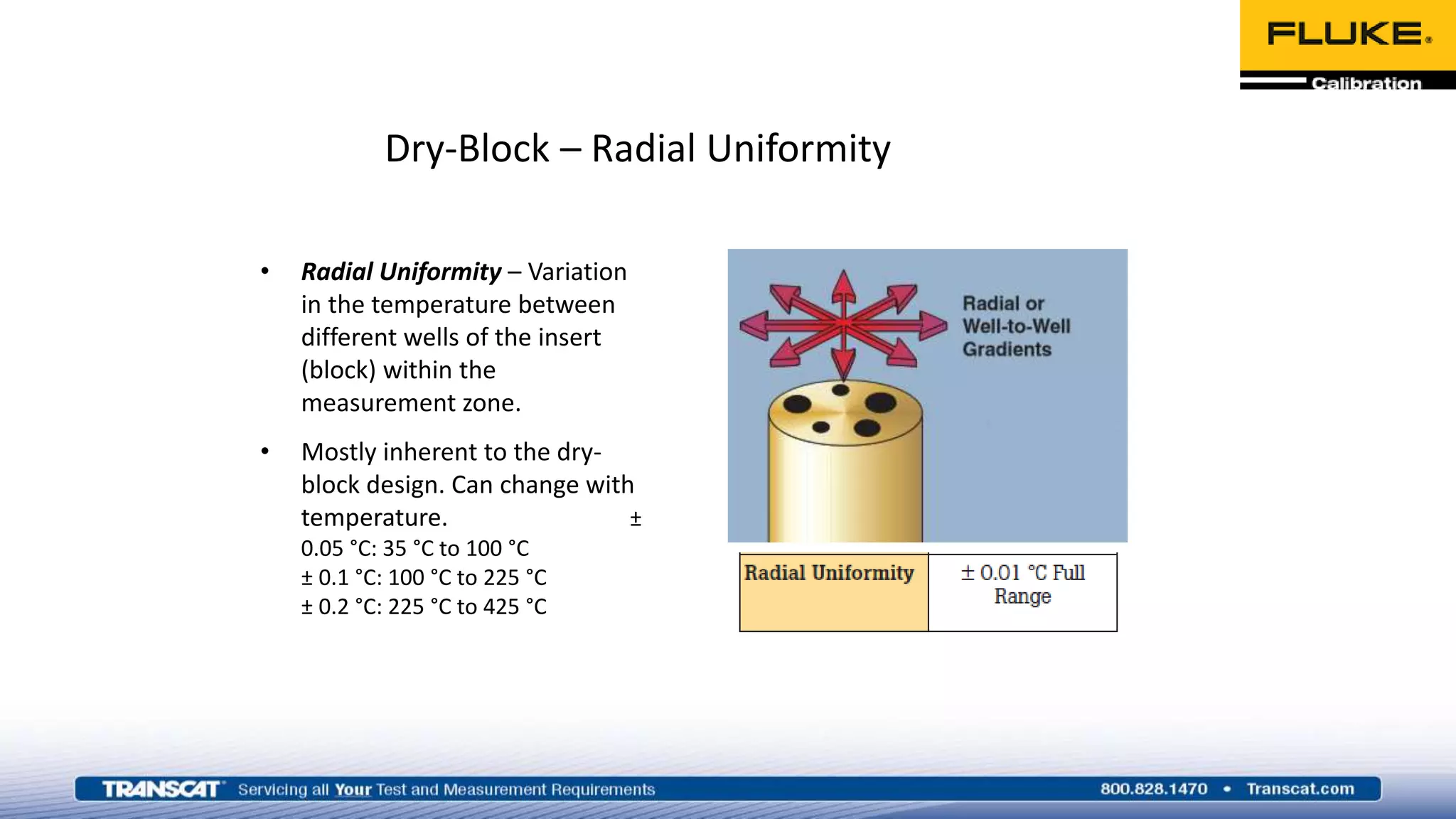

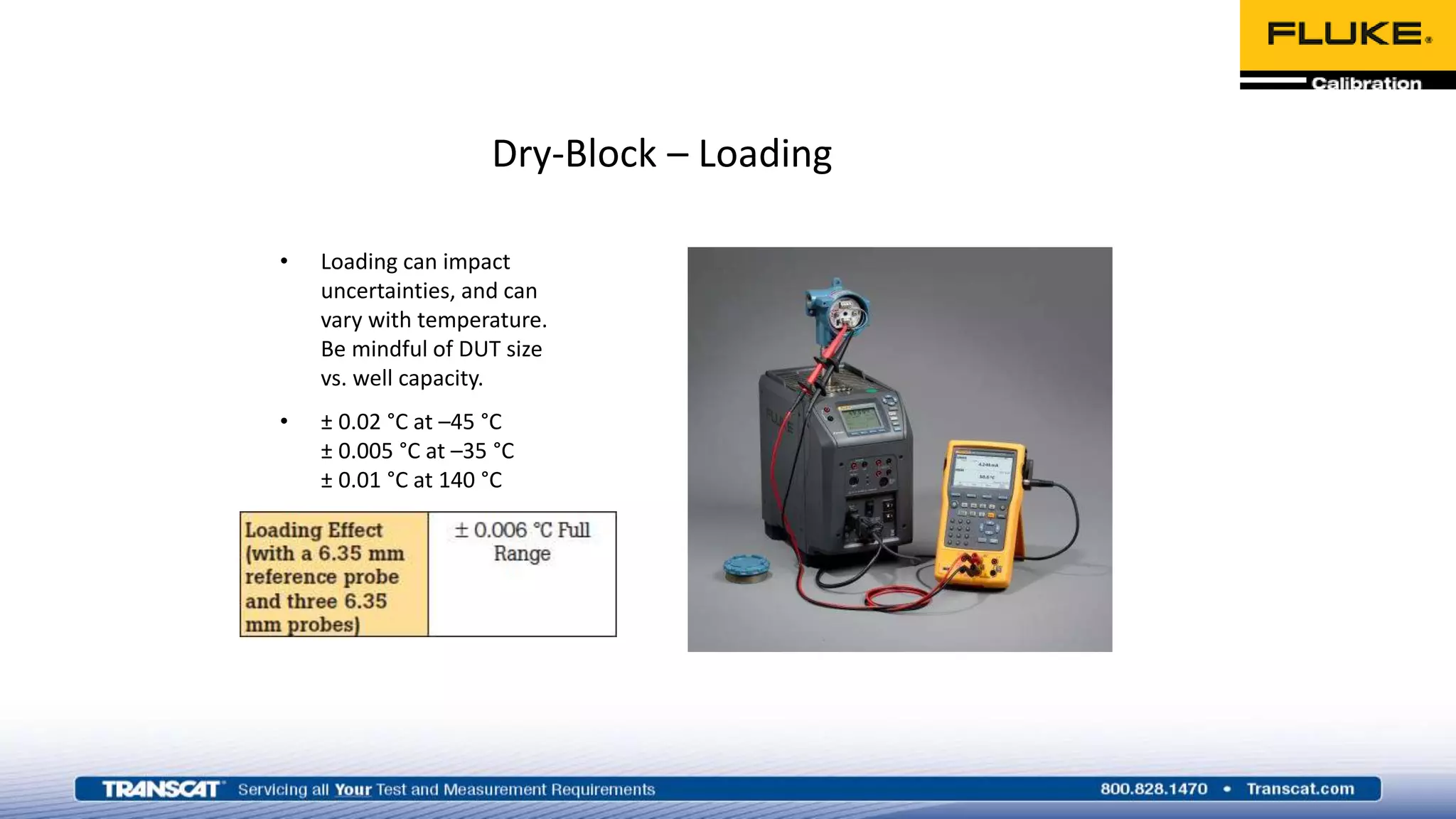

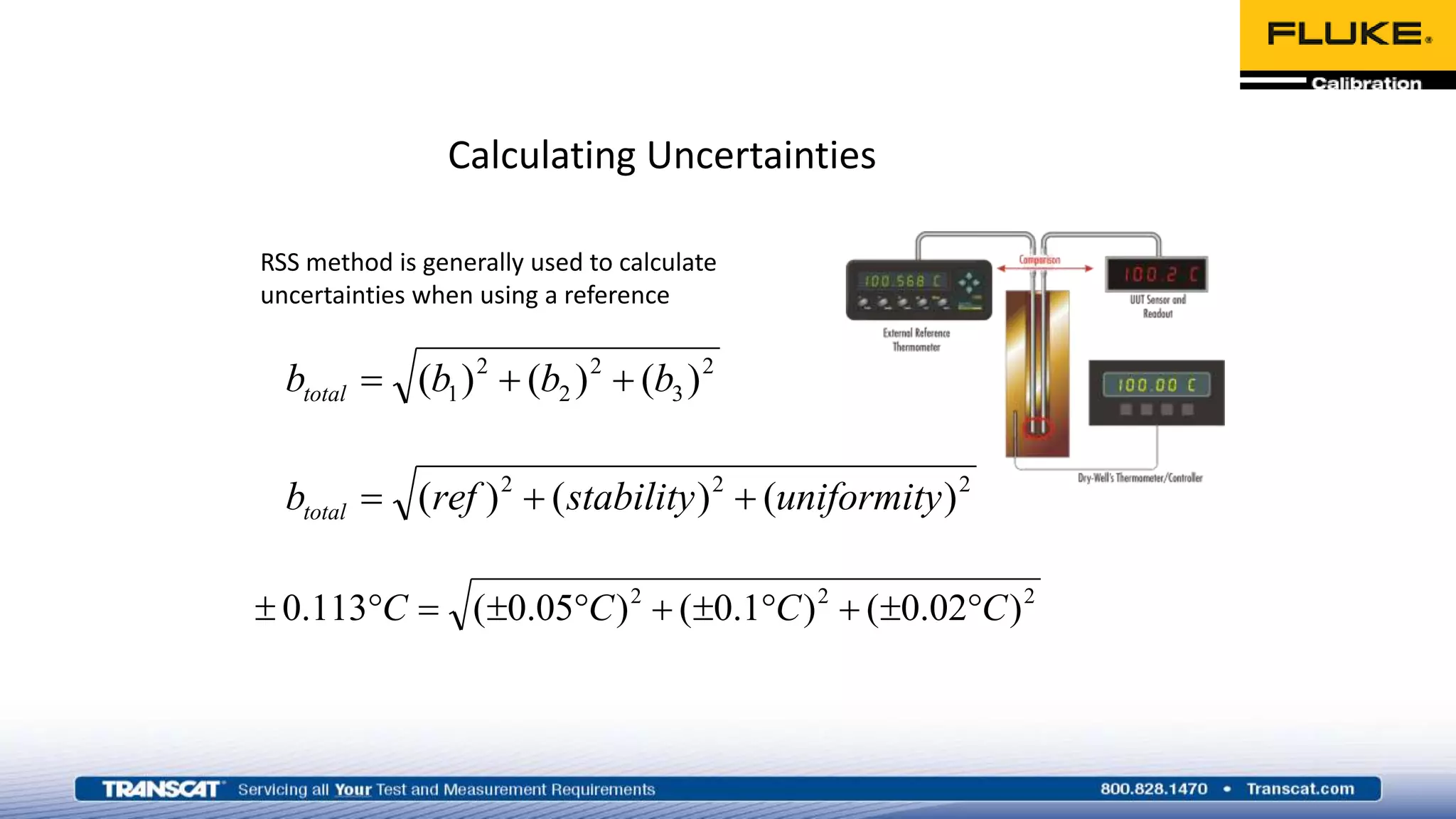

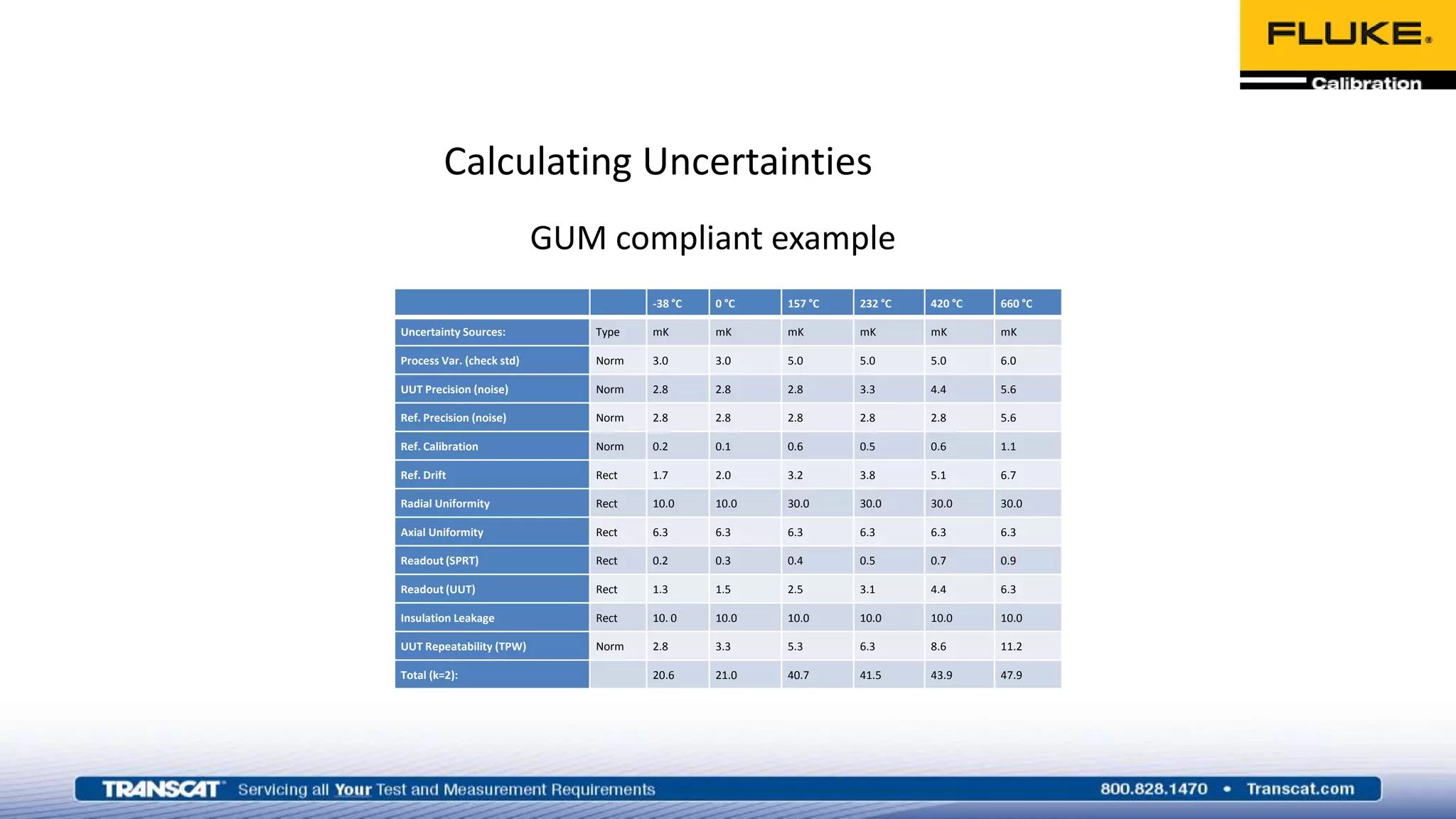

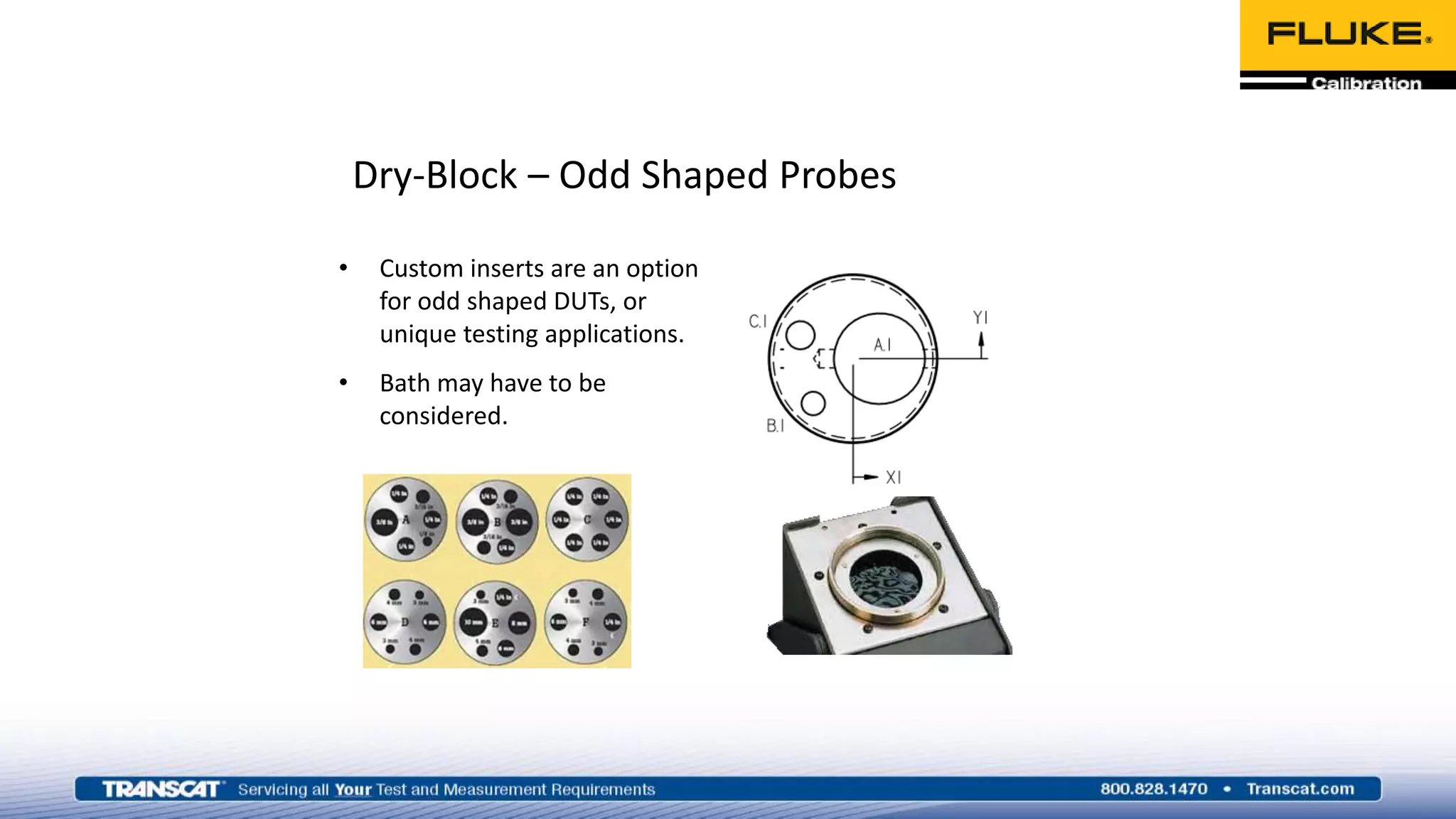

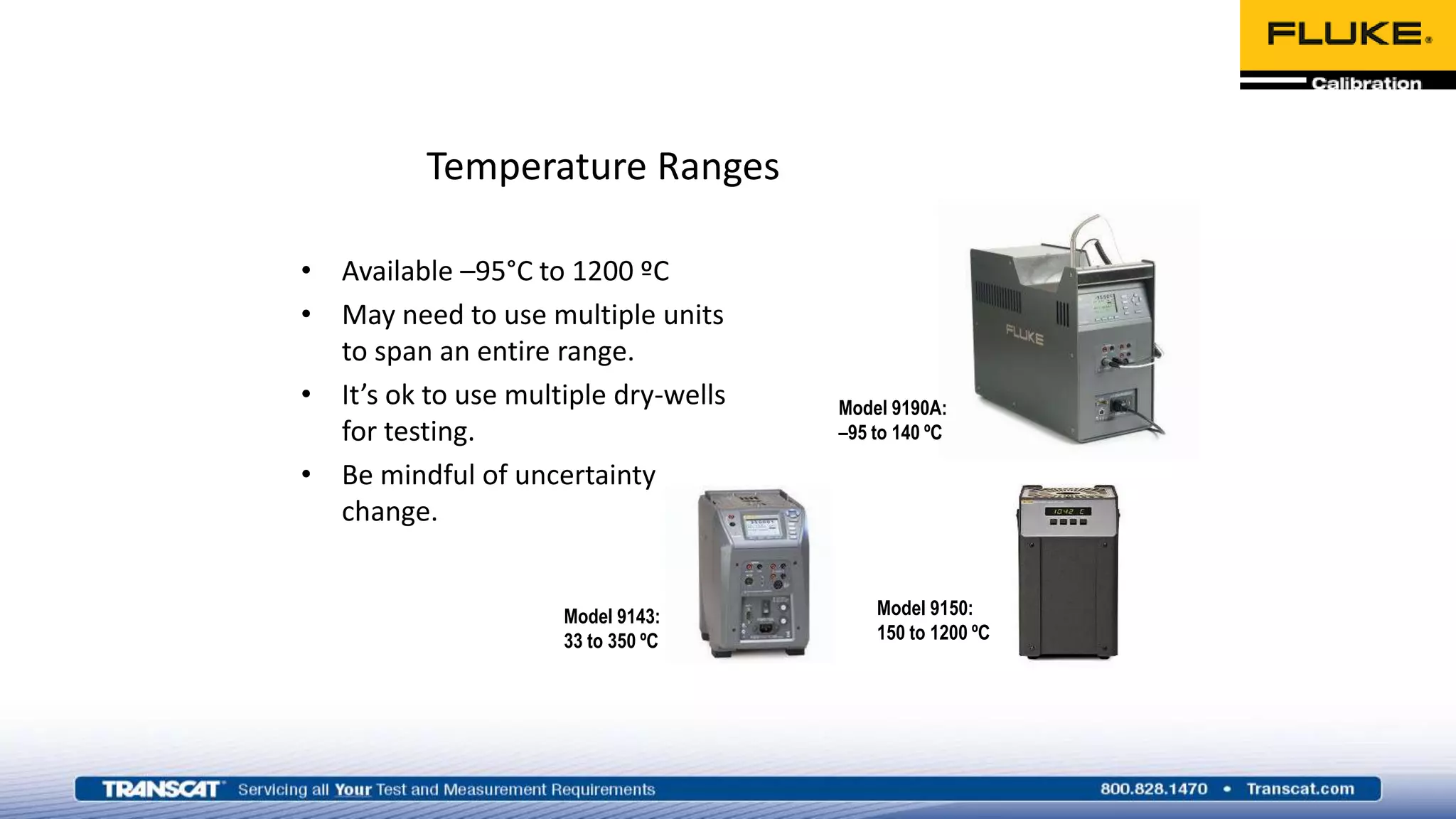

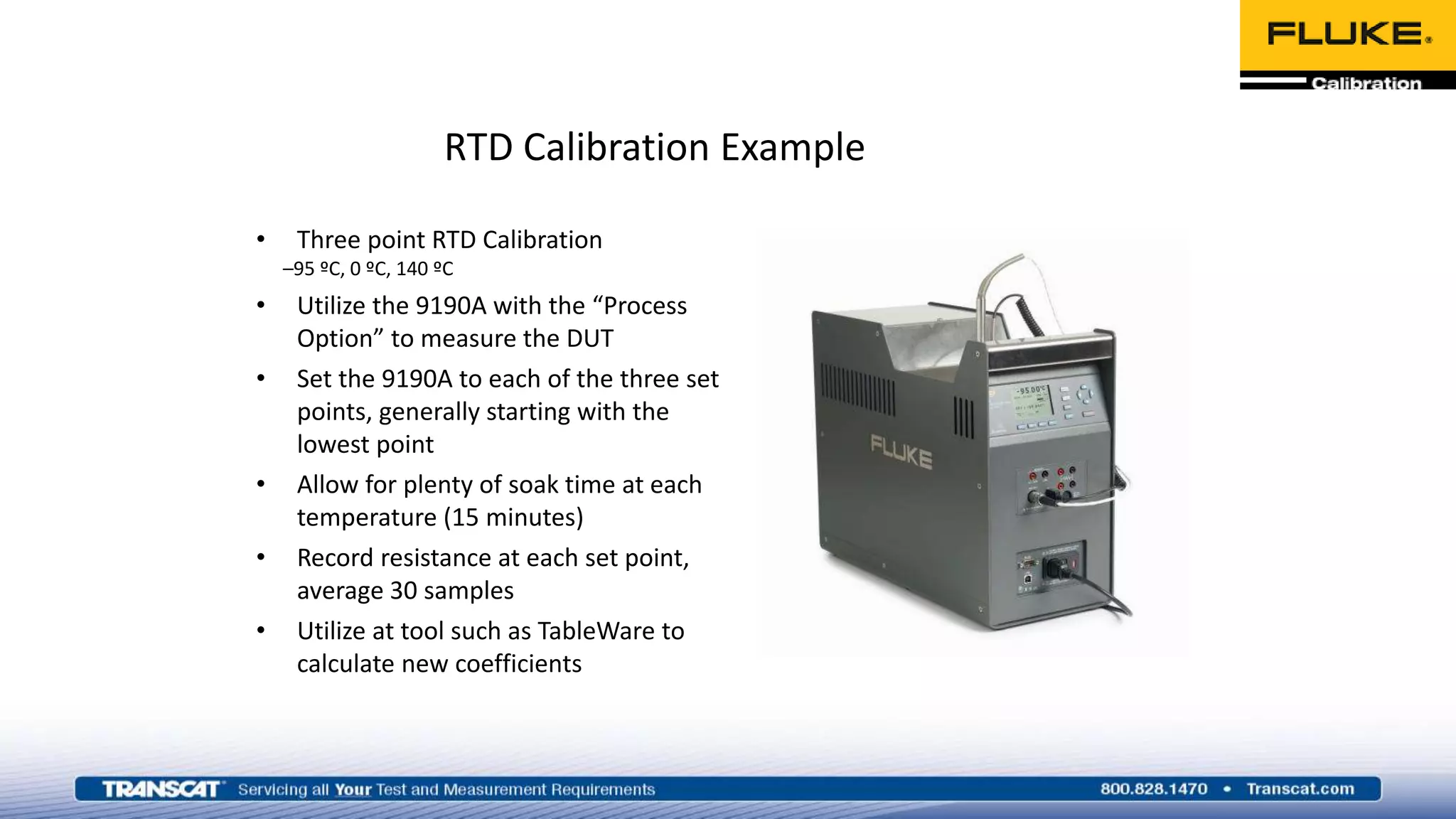

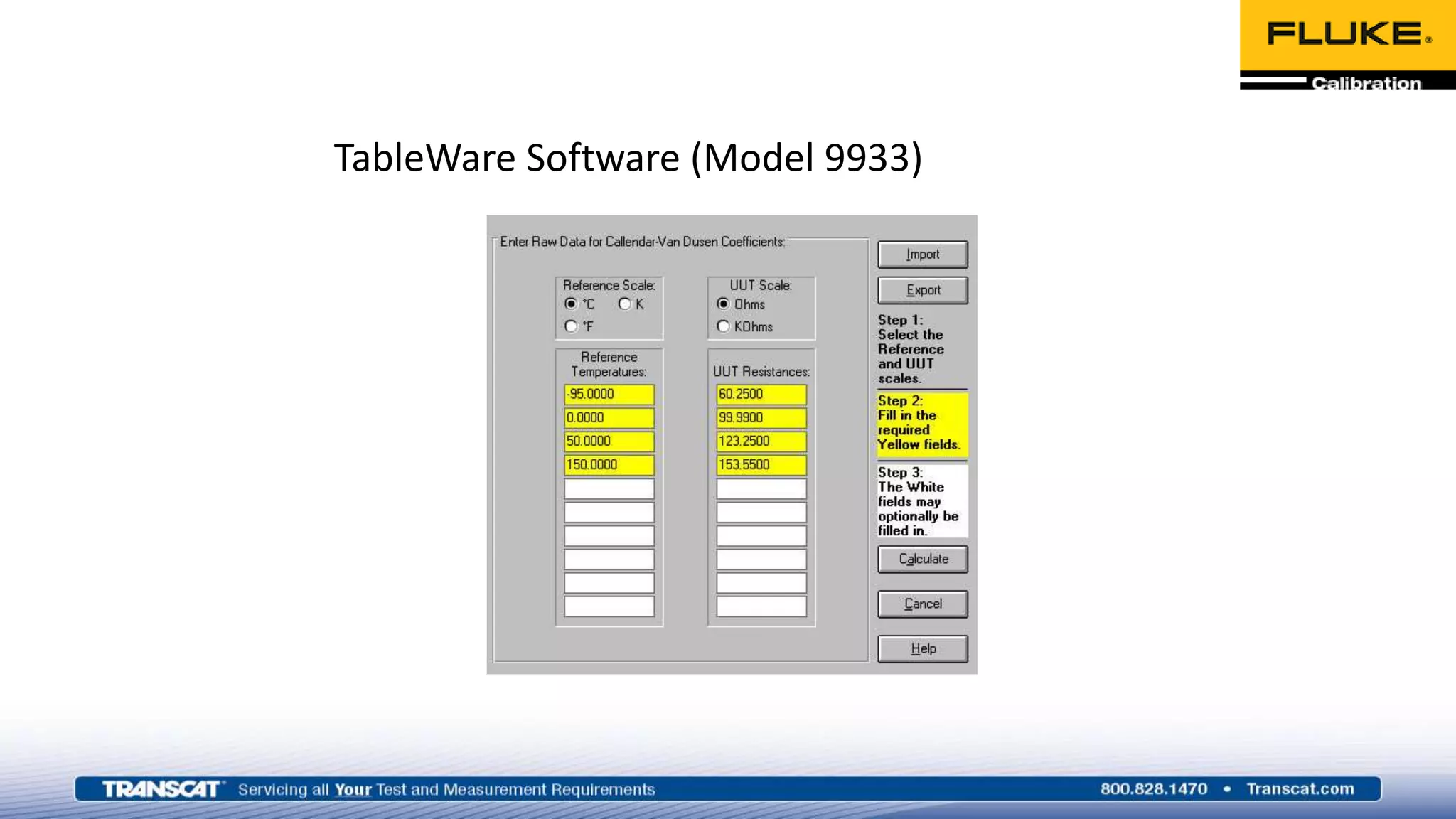

This document provides guidance on how to calibrate an RTD (resistance temperature detector) using a dry-block calibrator. It discusses potential sources of error from a dry-block like immersion depth, stem conduction, contact issues and temperature non-uniformity. It recommends fully immersing probes, maintaining consistent depths between the RTD and reference probe, and accounting for uncertainties. The document then walks through calculating uncertainties, addressing odd shaped probes, temperature ranges, and provides an example of a three-point RTD calibration using a dry-block and software.