A Comparison of 3D Printing Technologies Used to Make Investment Casting Patterns - Part 2

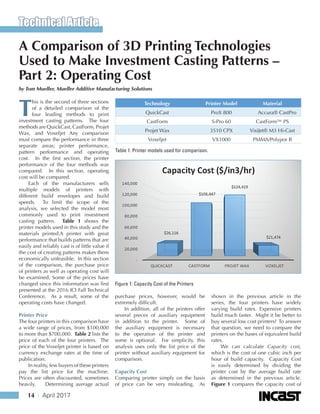

- 1. ® 14 ❘ April 2017 A Comparison of 3D Printing Technologies Used to Make Investment Casting Patterns – Part 2: Operating Cost by Tom Mueller, Mueller Additive Manufacturing Solutions T his is the second of three sections of a detailed comparison of the four leading methods to print investment casting patterns. The four methods are QuickCast, CastForm, Projet Wax, and Voxeljet Any comparison must compare the performance in three separate areas; printer performance, pattern performance and operating cost. In the first section, the printer performance of the four methods was compared. In this section, operating cost will be compared. Each of the manufacturers sells multiple models of printers with different build envelopes and build speeds. To limit the scope of the analysis, we selected the model most commonly used to print investment casting pattern. Table 1 shows the printer models used in this study and the materials printed.A printer with great performance that builds patterns that are easily and reliably cast is of little value if the cost of creating patterns makes them economically unfeasible. In this section of the comparison, the purchase price of printers as well as operating cost will be examined. Some of the prices have changed since this information was first presented at the 2016 ICI Fall Technical Conference. As a result, some of the operating costs have changed. Printer Price The four printers in this comparison have a wide range of prices, from $100,000 to more than $700,000. Table 2 lists the price of each of the four printers. The price of the Voxeljet printer is based on currency exchange rates at the time of publication. In reality, few buyers of these printers pay the list price for the machine. Prices are often discounted, sometimes heavily. Determining average actual purchase prices, however, would be extremely difficult. In addition, all of the printers offer several pieces of auxiliary equipment in addition to the printer. Some of the auxiliary equipment is necessary to the operation of the printer and some is optional. For simplicity, this analysis uses only the list price of the printer without auxiliary equipment for comparison. Capacity Cost Comparing printer simply on the basis of price can be very misleading. As shown in the previous article in the series, the four printers have widely varying build rates. Expensive printers build much faster. Might it be better to buy several low cost printers? To answer that question, we need to compare the printers on the bases of equivalent build rates. We can calculate Capacity cost, which is the cost of one cubic inch per hour of build capacity. Capacity Cost is easily determined by dividing the printer cost by the average build rate as determined in the previous article. Figure 1 compares the capacity cost of Technical Article Table 1: Printer models used for comparison. Technology Printer Model Material QuickCast ProX 800 Accura® CastPro CastForm S-Pro 60 CastForm™ PS Projet Wax 3510 CPX VisiJet® M3 Hi-Cast Voxeljet VX1000 PMMA/Polypor B Figure 1: Capacity Cost of the Printers

- 2. ® April 2017 ❘ 15 the four printers. Surprisingly, the least expensive printer has the highest capacity cost. The Voxeljet printer has the lowest capacity cost followed by the QuickCast printer. Elements of Pattern Cost Capacity cost only measures the cost of obtaining build capacity. Operating cost is how much it costs to run the printer after acquisition. Other than labor, there are three major elements of pattern cost; the cost of materials, depreciation and the cost of maintenance. • Material Cost - For purposes of this analysis, list prices of the materials supplied by the manufacturer of the printer were used. Manufacturers often sell at a discount and aftermarket material suppliers often supply less expensive materials. Given the difficulty of determining actual average prices, manufacturers’ list prices are used. Material cost for QuickCast patterns varies widely with the geometry of the pattern and has four components: 1. Resin used to build the internal support structure – the volume of resin used for internal support structure is approximately 13% of the pattern volume. 2. Resin used to build the skin – the volume of resin used to build the skin of the pattern is the surface area times the skin thickness 3. Resin used to build supports – the stereolithography process builds supports which attach the part to the build platform and act as a fixture. The amount of supports required varies dramatically from pattern to pattern and can vary significantly depending on how the part to be built is oriented in the build. 4. Resin undrained from the interior of the pattern – In the build process, liquid resin is trapped within the pattern. Drain and vent holes allow that liquid resin to be drained out after the build is complete. Draining is further encouraged by placing in the pattern in a centrifuge for several minutes. Nonetheless, it is virtually impossible to completely drain the pattern and some liquid resin will remain inside. It will be cured in place in the post cure process. It could easily be a percent or two of the pattern volume and for patterns with thin walls, it could be significantly higher For this analysis, it was assumed that resin volume consumed averaged 40% of pattern volume, although the actual percentage is likely higher. CastForm is the easiest material cost Table 2: Printer List Price System List Price 3D Systems ProX 800 $550,000 3D Systems S Pro 230 $475,000 3D Systems ProJet 3510 CPX $100,000 Voxeljet VX1000 PPB $735,625 Figure 2: Material Cost for the Printers Figure 3: Depreciation Cost per Cubic Inch of Patterns

- 3. ® 16 ❘ April 2017 Technical Article to calculate. It is simply the volume of the pattern times the cost per cubic inch of polystyrene powder. Any unused powder in the build is recycled. The Voxeljet analysis considered the price of PMMA powder, binder, and cleaner used to clean the print head during the build. The amount of wax required for infiltration depends on the surface area of the pattern. For this analysis, it was assumed that wax volume was 5% of the pattern volume. The Projet Wax system uses two different waxes, one for the pattern and one for the supports. The ratio of support wax to pattern wax varies with the geometry of the pattern and the build orientation. For this analysis, it was assumed that the amount of support wax used was 50% of the volume of pattern wax. Users have stated that this number is conservative. Figure 2 shows the cost per cubic inch of pattern volume for each of the four technologies. At $6.70 per cubic inch, the Projet Wax printer had by far the most expensive material cost, more than triple the cost of the next highest cost material, QuickCast. The least expensive material cost was PMMA from Voxeljet with a cost of $0.81 per cubic inch. • Depreciation – Depreciation is a significant expense in building patterns. More expensive printers will have a higher total depreciation cost, but they also will print more patterns. To get a true comparison, the depreciation cost per cubic inch built was calculated. For this analysis we will assume a straight line seven year depreciation. The monthly depreciation cost is then the printer cost divided by 84 (number of months in seven years). To compare from printer to printer, it is necessary to compensate for the volume of patterns built. For this analysis, it was assumed that each printer would be operated 16 hours per day for five days a week, or 320 hours per month. Multiplying the 320 hours by the average build rate will yield the total volume of parts built per month. The monthly depreciation is then divided by the volume of parts per month to get a depreciation cost per cubic inch. Figure 3 shows the depreciation cost per cubic inch of pattern for each of the four printers. Note that the cost depends on the number of hours per month the printer is used. As printing hours increase, cost per cubic inch decreases. The Project Wax printer has the highest depreciation per cubic inch of pattern built. • Maintenance Cost – A significant cost of running a pattern printing operation is the cost of maintenance. Determining actual maintenance costs would be extremely difficult. However, a reasonable approximation can be obtained by looking at the cost of the highest level maintenance contract offered by each manufacturer. For those customers who purchase the contract, it covers most if not all of their maintenance cost. To calculate Figure 4: Maintenance Cost per cubic inch of Pattern Figure 5: Total Non-labor operating cost per cubic inch of pattern.

- 4. ® April 2017 ❘ 17 the cost of maintenance per cubic inch, the monthly cost of the maintenance contract is divided by the total volume of patterns built per month (320 hours per month as calculated above). The result of those calculations is shown in Figure 4. Like depreciation cost, the more hours per month the printer is used, the lower the maintenance cost per cubic inch will be. CastForm has the highest maintenance costs. • Total Non-Labor Pattern Cost – To obtain total non- labor pattern cost, we can simply add the three previous costs together and is shown in Figure 5. The Projet has the highest cost per cubic inch of part volume followed by Castform, QuickCast, and Voxeljet. Note that the highest cost is more than 7 times the lowest cost. Observations Several observations can be made 1. The least expensive printer, the ProJet 3510 CPX has both the highest capacity cost and operating cost. 2. The most expensive printer, Voxeljet VX1000 has both the lowest capacity cost and operating cost. 3. Capacity cost, depreciation cost, and maintenance cost (but not material cost) are all dependent on the build rate. An increase in build rate will lower both capacity cost and operating cost. Build rate varies significantly depending on the number of parts being built, build orientation and the geometry of the parts being built. As was explained in the first article, average build rates is determined from actual data gathered on a number of machine runs. As more data is gathered, better estimates of average build rates will be determined. As a result, cost data may change. A great printer with low costs will be of no value if the patterns it creates cannot reliably be converted into acceptable castings. The ability to convert the patterns into acceptable castings is dependent on characteristics of the patterns. In the next issue, those characteristics will be examined.