TITLE PAGETABLE OF CONTENTSContentsTITLE PAGE1TABLE O

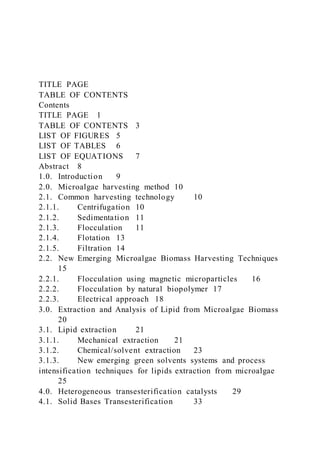

- 1. TITLE PAGE TABLE OF CONTENTS Contents TITLE PAGE 1 TABLE OF CONTENTS 3 LIST OF FIGURES 5 LIST OF TABLES 6 LIST OF EQUATIONS 7 Abstract 8 1.0. Introduction 9 2.0. Microalgae harvesting method 10 2.1. Common harvesting technology 10 2.1.1. Centrifugation 10 2.1.2. Sedimentation 11 2.1.3. Flocculation 11 2.1.4. Flotation 13 2.1.5. Filtration 14 2.2. New Emerging Microalgae Biomass Harvesting Techniques 15 2.2.1. Flocculation using magnetic microparticles 16 2.2.2. Flocculation by natural biopolymer 17 2.2.3. Electrical approach 18 3.0. Extraction and Analysis of Lipid from Microalgae Biomass 20 3.1. Lipid extraction 21 3.1.1. Mechanical extraction 21 3.1.2. Chemical/solvent extraction 23 3.1.3. New emerging green solvents systems and process intensification techniques for lipids extraction from microalgae 25 4.0. Heterogeneous transesterification catalysts 29 4.1. Solid Bases Transesterification 33

- 2. 4.2. Solid Acids Transesterification 35 4.3. Heterogeneous transesterification of algae oil 36 5.0. Reactors 44 5.1. Influence of reactor design and operating conditions 44 6.0. Conclusions 51 References 54 LIST OF FIGURES Figure 1: Flowsheet for biodiesel production from microalgae. Some intensified process techniques highlighted may reduce some downstream steps as it would render the dewatering step unneeded. i.e. MAE – Microwave assisted extraction (MAE), Enzyme assisted extraction (EAE), Ultrasound assisted extraction (UAE), Surfactant assisted extraction 27 Figure 2:Flow sheet of an oscillatory baffled reactor and it mixing features. Also illustrating the solid acid catalyst PrSO3H-SBA-15 undergoing no oscillation but sedimentation and or with about 4.5Hz oscillation traped in the baffles. Figures exuracted from (Eze et al., 2013) 47 Figure 3: Diagram of membrane reactors for producing biodiesel in transesterification reaction through (a) Solid acid catalyst

- 3. and (b) base catalysts.49 LIST OF TABLES Table 1: Performance comparison of flotation techniques14 Table 2: Performance comparison of filtration methods15 Table 3: Performance of flocculation using biopolymer17 Table 4: performance comparisons for microalgae biomass harvesting by various electrical methods operated in just 1 hour19 Table 5: Reported catalyst used for heterogenous transesterification reaction on various feedstocks30 Table 6: The effect of calcination temperature on the performance of WO3/ZrO2 catalyst (Jothiramalingam & Wang, 2009).39 Table 7: Literature review on biodiesel production via heterogenous catalyst41

- 4. LIST OF EQUATIONS Equation 1: Chemical equation showing production of biodiesel from any bio oil 32 Equation 2: Reaction mechanism of transesterification via base catalyst (denoted Y) in the equation. 33 Abstract The dwindling rate of our fossil fuel reserves and general believe of major contribution of CO2 emissions which is linked to the climate change due to the burning of such carbon sources in engines either for locomotion or power generation have geared both the academic and industrial research towards the new routes for renewable and sustainable fuels. However, microalgae as one of the third-generation biomass feedstock has recently been proven to be one of the best option considered employable for biodiesel production. But one of the crucial

- 5. challenges not yet explicitly attended to is the method of harvesting, lipids extraction and heterogenous catalyst for transesterification reaction for oil conversion to biodiesel. Herein. we reported several techniques for microalgae biomass harvesting, both the conventional and new emerging ones, as this helps in building ideas for improvement in the field. We also present a critical review on the work done on areas of lipid extraction from microalgae biomass and its conversion to biodiesel through heterogenous catalysis. it covers the progress made in this fields from the last decade, available systems for heterogenous catalysis, mechanism of the reactions and optimal process conditions. Lastly, we discuss on the reactors employed in the transesterification, effects of reactors design and way forward. 1.0. Introduction In our world, today, the demand for energy is on the increase. Fossil fuel reserves are running out. The persistent fluctuation and increase in price of fossil fuels and its adverse effect on the ecosystem through the emission of greenhouse gases makes it imperative that we seek alternative, sustainable and more environmental friendly energy source. The demand for safe alternative sources of energy such as biofuel is more pressing than ever before. Top on the list of such sustainable renewable energy is the feedstock energy source. A good source of feedstock energy is the Microalgae commonly referred to as the

- 6. third-generation feedstock (Patrícya et al., 2014; Wawrik & Harriman, 2010). Various bio-products, such as biofuel and bio- hydrogen can be manufactured from Microalgae. Microalgae also have higher biomass yield and lower carbon footprint requirement compared to other plants (Besson & Guiraud, 2013; Farooq et al., 2015). In making microalgae based biofuel production commercially available and economically viable, the challenge of what method to use in harvesting microalgae and lipid extraction must be taken into consideration. Most harvesting methods can be capital intensive, uneconomical, and produce some level of environmental pollution. Harvesting microalgae can require as high as 20-30% of total biomass production budget (Grima et al., 2003; Mata et al., 2010; Verma et al., 2010) or 50% of the cost of producing biofuel (Muradov et al., 2015). Also, it has been proposed that world usage of biodiesel could increase to two or three times in most part of the globe by year 2020 and numerous influencing factors have not been fully addressed. Bio-oils or oils as the origin implies contains a key compound called triglyceride esters which when react with any monohydric alcohol (i.e. methanol) would form a group of compounds called mono-alkyl esters i.e. biodiesel. However, scientist around the world suggested the use of lower monohydricalcohols (i.e. CH3OH to C3H8O), without any explicit justification of which gives the best performance and requirements in terms of its viscosity as specified by ASTM or related international agencies. Similarly, finding the best catalyst and optimized operating reaction conditions is of a great challenge to biofuel industries. Homogenous catalysis offers faster biodiesel production with even moderate reaction conditions, but faced with recovery or separation problem after the transesterification process. These above highlighted challenges have triggered scientists at both industries and academics to seek alternative means, while emphasizing on the feedstock flexibility, and green catalytic systems. Lately, both microalgae and microalgae emerged as a

- 7. better option for the biodiesel feedstock. Also, some green catalyst discussed herein emerged as a better candidate heterogenous catalysis for the transesterification process. We therefore present a critical review in these areas and lastly, the reactors involved.2.0. Microalgae harvesting method Show et al., (2015) inferred in their work that, when considering a preferred harvesting procedure two important issues must first be determined; the attributes of the microalgae considered and the condition of their growth. The efficiency of any harvesting method chosen will depend largely on the specie of microalgae, size of the microalgae, its morphology and composition of the medium employed. Some harvesting techniques commonly used are centrifugation, flocculation, filtration and sedimentation. 2.1. Common harvesting technology 2.1.1. Centrifugation Centrifugation is the application of a centrifugal force of higher intensity than the gravitational force to increase the rate of separation a suspension. Common centrifugation methods include Solid-bowl decanter, nozzle-type centrifuge, Hydro- cyclone, and solid ejecting disc (Milledge & Heaven, 2013). The challenge with the methods above despite their efficiency at harvesting majority of the microalgae cell types are high energy, capital and operational cost required to carry them out (requirement) (Grima et al., 2003; Milledge & Heaven, 2013; Yuan et al., 2009).Centrifugation can harvest averagely between 12-25% of microalgae biomass with an energy consumption of 50-75kW (Milledge & Heaven, 2013). The only justification for this high cost and large amount of energy is that sufficient biofuel of over 90% of the microalgae biomass must be harvested. 2.1.2. Sedimentation Sedimentation is the process by which solids are separated from liquids by capitalizing on differences in the density of the solids

- 8. to obtain an effluent of clear liquid (Milledge & Heaven, 2013). Most wastewater treatment facilities use sedimentation for sludge treatment. Sedimentation is the most cost effective and least complicated method for harvesting microalgae biomass, especially heavy microalgae suspensions. Two difficulty with using sedimentation for microalgae biomass harvesting is that for solids with little difference in their densities the process can be excruciatingly slow and the dry solids concentration of microalgae biomass that can be harvested is about 0.5-3% (Grima et al., 2003; Milledge & Heaven, 2013; Yuan et al., 2009). Golueke & Oswald, (1965) reported that using alum as a coagulant in a flocculation-sedimentation process an of 85% microalgae biomass harvest was achieved. 2.1.3. Flocculation Flocculation seldom used alone but in conjunction with other methods (Brennan et al., 2010) such as coagulation- flocculation and flotation-flocculation. Flocculation through aggregation improves particle size of microalgae suspension and speeds up rate of suspension settling (Mata et al., 2010; Milledge & Heaven, 2013). Auto-flocculation, physical flocculation, bio-flocculation and physio-chemical flocculation are four types of flocculation commonly in use. Auto-flocculation usually cuts the flow of carbon dioxide (CO2) to the microalgae system when the pH of the culture is above 9, therefore the microalgae flocculate on its own (Vandamme et al., 2013). Although auto-flocculation can be a slow, unreliable process and also requires the presence of calcium and magnesium ions many researchers have published results of up to 90% microalgae recovery harvest (Baya et al., 2016; Gerardo et al., 2015; Milledge & Heaven, 2013; Ras et al., 2011). Bio-flocculation is a technique in which microorganism are used in the treatment of wastewater. Such microorganisms include fungi and bacteria (Gerardo et al., 2015; Vandamme et al., 2013). Bio-flocculation is a technique yet to be fully

- 9. comprehended but it is well documented that it improves the abilities of microalgae to form in suspension (Salim et al., 2011; Zhou et al., 2013). Zhou et al., (2013) reported almost 100% success harvesting microalgae cells of Chlorella vulgaris UMN235 by employing palletization-assisted bio-flocculaton. Their further recommended in their study that adding 20g/L glucose and of spores in BG-11 medium is desirable for palletization. Two locally isolated fungi being used as bio- flocculants are; Aspergillus sp. UMN F01 and Aspergillus sp. UMN F02. More so, a bio-flocculant from Bacillus licheniformis CGMCC 2876 was discovered to be an excellent harvester with 96% efficiency. This level of efficiency results from reduction in the negative charge of Desmodesmus sp. to about zero surface charge (Ndikubwimana et al., 2015). From the findings of the studies above, it can be clearly seen that bio- flocculation in conjunction with other techniques such as flotation and electrical approach can be used to solve the challenge of high quantity of bio-flocculants and time required to efficiently harvest high amount of microalgae using bio- flocculation. 2.1.4. Flotation Microalgae have low densities; this characteristic can be explored during harvesting using flotation method (Gerardo et al., 2015; Show et al., 2015). Air bubbles enhance the movement of microalgae particles upwards. Microalgae cells become hydrophobic when surfactant or coagulants are added into the system. Addition of surfactant or coagulants expands the mass transfer between the air and microalgae particles improving particles separation (Gerardo et al., 2015; Uduman et al., 2010).Some readily available surfactants in use are aluminum sulfate (Al2(SO4)3), iron (III) sulfate (Fe2(SO4)3), cetyltrimethylammonium bromide (CTAB), chitosan, and iron (III) chloride (FeCl3). High efficiency harvesting rates between 70 and 99% of microalgae biomass by flotation has been reported in some studies (Aulenbach et al., 2010; Barrut et al.,

- 10. 2012; Coward et al., 2014; Show et al., 2015). Flotation harvesting method requires low initial equipment cost and shorter period compared to others (Gerardo et al., 2015; Show et al., 2015). The choice of surfactants and its effect on reusability of culture and biofuel manufacturing has only been reported by few researchers as of today. Recent studies have shown an increase in the production of biomass and support for the growth of C. vulgaris – an outstanding discovery using iron (III) chloride (FeCl3) (Farooq et al., 2015). The challenge with this process is that ferric acid which is a residue of the iron (III) chloride has a negative impact on the oxidative stability of biodiesel, upon completion of the harvesting process it has to be separated from the biomass. It is worthy of mention that studies by Farooq et al., (2015); Kim et al., (2011); Kim et al., (2013) have implied that cytotoxicity from residual alum from the alum used as surfactant inhibits the growth of microalgae. Hence the effect of surfactants need to be properly studied and understood before harvesting microalgae to be used for production of biofuel and culture recyclability. Other flotation techniques have been reported. Some of these are; dispersed air, micro-flotation, foam flotation, dissolved air, vacuum gas, electro-flotation, and ozone flotation. A comparison of these techniques is displayed in Table 1. Table 1: Performance comparison of flotation techniques Flotation Techniques Strains Harvesting efficiency (%) References Foam flotation Tetraselmis sp. 93 (Garg et al., 2014) Chlorella sp

- 11. NR (Coward et al., 2014) Microflotation Dunaliella salina 99 (Hanotu et al., 2012) Vacuum gas Mixed culture 23 (Barrut et al., 2012) Dissolved air Mixed culture 90 (Phoochinda & White, 2003) C. zofingiensis 91 (X. Zhang et al., 2014) Column flotation Chlorella sp 90 (Liu et al., 2006) Flocculation flotation C. vulgaris 93 (Lei et al., 2015) Dispersed air Spirulina platensis 80 (Kim et al., 2005) Electro-flotation Mixed culture NR (Sandbank, 1979) Ozone flotation Microcystis

- 12. 90 (Benoufella et al., 1994) *NR – Not reported 2.1.5. Filtration Filtration is the separation of a solid-liquid mixture of microalgae using a semi-permeable membrane with small pores that allow the passage of the liquid but retains the solid microalgae (Gerardo et al., 2015; Show et al., 2015). Microalgae with low density such as Chlamydomonas sp., Chlorella sp. and Scenedesmus sp. can easy have their biomass harvested using filtration method (Gerardo et al., 2015; Rickman et al., 2012; Show et al., 2015). One problem with filtration however is that clogging and fouling brought by settled cells that can reduce the solid content due to low volumes of liquid that is able to pass through the filter used (Huang et al., 2012; Show et al., 2015). Two filtration setups are common, which are; the dead-end and the tangential flow. Dead-end setup made up of cartridge filtration, horizontal filter press, belt filter and vacuum drum filter are carried out in batch modes. These methods can harvest 5-37% mean solid content. Cross-flow filtration which is an alternative name for tangential flow filtration was created to overcome the challenge of fouling and decrease the accumulation of cake layer such that the filtration time is accelerated (Gerardo et al., 2015). Shear movement (Morineau- Thomas et al., 2002; Nurra et al., 2014), back-flushing (Baerdemaeker et al., 2013), supplementation of coagulant (Hwang et al., 2013), and alteration of membrane surface (Baerdemaeker et al., 2013) have been reported by many studies as ways of minimizing membrane fouling. Table 2 is a summary of the outcome obtained from using each filtration method in microalgae biomass harvesting. Table 2: Performance comparison of filtration methods Filtration Techniques Strains

- 13. Harvesting efficiency (%) References Vacuum filter Coelastrum sp. NR Belt filter Mixed culture NR (Grima et al., 2003) Ultrafiltration Scenedesmus quadricauda NR (Zhang et al., 2010) Chlorella sp. 94 (Hwang et al., 2013) Deep-bed filtration Mixed culture NR Vacuum filter Spirulina sp. NR (Goh, 1986) Ultrafiltration Dunaliella sp. 99 (Mixson et al., 2014) *NR – Not reported2.2. New Emerging Microalgae Biomass Harvesting Techniques Many scientific studies have been carried out to enhance microalgae biomass harvesting, which include reducing the energy requirement and operational cost. Recent approaches being developed to harvest microalgae

- 14. biomass include flocculation employing magnetic microparticles (Seo et al., 2015; Vergini et al., 2015), flocculation using natural biopolymer (Banerjee et al., 2014; Rahul et al., 2015), sedimentation involving polymers (Zheng et al., 2015), magnetic membrane filtration (Bilad et al., 2013) as well as electrical approaches which includes electro-coagulation- filtration (ECF) (Gao et al., 2010) and electrochemical harvesting (ECH) (Misra et al., 2015). 2.2.1. Flocculation using magnetic microparticles Seo et al., (2015) examined four different magnetic particles, namely pure copper, iron (III) nitrate nonahydrate, copper/carbon composite and polyvinylpyrrolidone (PVP). Vergini et al., (2016) also examined the application of iron oxide magnetic microparticles (IOMPs). Both studies reported microalgae biomass harvesting using flocculation with the various magnetic particles aforementioned (Seo et al., 2015; Vergini et al., 2015). By using various methods and different materials these magnetic particles can be coated. Some coating methods are polyol method, sol-gel processing, thermal reduction, and spray pyrolysis (Athanassiou et al., 2006; Grouchko et al., 2009; Yan et al., 2007; Yanhui et al., 2009; Jacob et al., 2006; Jung et al., 2011; Li & Liu, 2009; Li et al., 2011; Qian et al., 2012; Wang & Asefa, 2010; Xu et al., 2003). A 99% harvesting efficiency of Chlorella sp. KR-1 was achieved by Seo et al., (2015) using polyvinyl-pyrrolidone (PVP) and iron nitrate with 0.8 () ratio at 10mg/mL. Vergini et al., (2015) on their part reported a 91% efficiency in harvesting D. tertiolecta using iron oxide magnetic microparticles (IOMPs) during 5 min of harvesting. The harvesting procedure was carried out for a certain period using cylindrical neodymium magnets (NdFeb) as an external magnetic field. Judging from the reports by Seo et al., (2015) and Vergini et al., (2015) , a conclusion can be reached; that flocculation using magnetic particles brings about cost effectiveness, as far as the magnetic microparticles can achieve full functionality via one-step

- 15. synthesis. It is worthy of note that harvesting efficiency is affected by the dose of each particular magnetic flocculant. Vergini et al., (2015) reported a minimal increase of 16% when the concentration if IOMPs changed from 6.2mg/L (75%) at the beginning to 62mg/L (91%). Furthermore, Seo et al., (2015) in their study reported that increasing the dose of PVP/Fe (0.33) while reducing the ratio had resulted in reduced harvesting efficiency (31.4%). 2.2.2. Flocculation by natural biopolymer Biopolymers are organic flocculants manufactured by microalgae, bacteria, and plants haven undergone the process of cationization using (3-chloro-2-hydroxypropyl) trimethylammonium chloride (HPTAC). Polymeric substances which are a kind of organic flocculant when linked with different colloidal particles to produce floc formation have bee n described as efficient harvesters. An optimized dosage of 60mg/L of cationic inulin resulted in 88.61% harvesting efficiency within 15 min was reported by Rahul et al., (2015) while harvesting isolated Botryococcus sp., this study further showed that cationic inulin is a potent flocculant. In another study by Banerjee et al., (2014), the potency of cationic cassia gum to harvest Chlamydomonas sp. CRP7 and Chlorella sp. CB4 was reported. An harvesting efficiency of 93% was reported for Chlamydomonas sp CRP7 within 15 min when a 80 mg/L optimized flocculant dosage was used. On the other hand, the harvesting efficiency for Chlorella sp. CB4 was 92% within 30 min of introducing a 35 mg/L dosage of optimized flocculant. Finally, these studies showed a similar trend when the flocculant efficiency increased and the chlorophyll content decreased. Table 3 contains a summary of the performance of flocculation using biopolymer. Table 3: Performance of flocculation using biopolymer Biopolymer Strains

- 16. Optimum concentration (g/L) Harvesting efficiency (%) References bCatinic cassia gum Chlorella sp. CB4 0.035 92 (Banerjee et al., 2014) aCatinic cassia gum Chlamydomonas sp. CRP7 0.08 93 (Banerjee et al., 2014) aCatinic inulin Botryococcus sp. 0.06 88.61 (Rahul et al., 2015) a – run time = 15 min, b – run time = 30min 2.2.3. Electrical approach Various researchers have worked on the use of electric approach in biomass harvesting. Methods such as electro-coagulation- filtration (ECF) (Syafaini et al., 2017), magnetically induced membrane filtration (MMV) (Bilad et al., 2013) and electrochemical using non-sacrificial electrodes (Misra et al., 2015) have been studied. The electrical approach for biomass harvesting is environmentally friendly, not restrained to certain microalgae species only, safe, and cost effective. A comparative study on the treatment of water containing microalgae using aluminium and iron electrodes by Gao et al., (2010) in an electro-coagulation-filtration (ECF) system reported that aluminum electrodes performed better than the iron electrode for harvesting. Micro-cystis aeruginosa, as seen in their harvesting efficiencies which was about 100% for aluminum and 78.9% for iron. The study further showed that

- 17. increasing operating time resulted in increased harvesting efficiency. Gao et al., (2010) also studied the impact of initial pH on the harvesting efficiency, the best efficiency was observed for pH values between 4 and 7 where efficiency of 100% was observed. The alkaline broth resulted in the lowest percentage efficiency. As the initial pH values increased from 8 to 9, and then 10, the harvesting efficiency reduced from 99% to 90% and then 87.2% respectively. To improve the shear-rates at the liquid-membrane interface membrane vibrating system was used. From the result of polyvinyldene fluoride (PVDF) at two different porosities of 9% and 12% w/w, PVDF-12 presented a greater efficiency for harvesting Phaeodactylum tricornutum and C. vulgaris, which was higher than 97% (Bilad et al., 2013). Reduced harvesting efficiency was observed when using PVDF-9, this was suspected to be a result of the shortcoming of the membrane itself. Misra et al., (2015) reported the use of electrochemical method in the harvesting of Scenedesmus obliqus FR75119.1 using carbon plates. This study was interested on the effects of applied current, initial pH and electrolyte addition. When a current of 1.5 A was supplied for half an hour, the electrochemical harvesting (ECH) attained 55.4% efficiency. This finding was in consonance with that by Gao et al., (2010) in which the harvesting efficiency relied on the applied current and conductivity of the broth. Adding electrolytes, for instance sodium chloride (NaCl) would increase conductivity and reduce power consumption (S. Gao et al., 2010). The highest harvesting efficiency reported was 83% when 6 g/L of NaCl was added. The study further buttressed the report that initial pH within the acidic range for example pH 5 produced the highest harvesting efficiency of 73% while initial pH in the alkaline region between7–9 had produced a lower harvesting efficiency in the ECH system. From the aforementioned studies, it can be concluded for the electrical method, the alkaline broth had the worst performance

- 18. and that addition of electrolyte was vital in making the process economically sustainable. Table 4shows a summary for performance comparisons for microalgae biomass harvesting by various electrical methods. Table 4: performance comparisons for microalgae biomass harvesting by various electrical methods operated in just 1 hour Electrical approach Strains Initial pH Harvesting efficiency (%) References Electrochemical harvesting Scenedesmus obliqus 9 65 (Misra et al., 2015) 7 66 5 73 Electro-coagulation-floatation Microcystis aeruginosa 10 87 (S. Gao et al., 2010) 9 90

- 19. 8 99 4 100 3.0. Extraction and Analysis of Lipid from Microalgae Biomass Lipids are a major component of microalgae. Microalgae can contain between 2-60% lipids out of its total dry weight depending on the condition of growth and the type of specie being examined. Lipids extracted from microalgae have attracted major interest for their fatty acids and triglycerides which can be converted into alcohol esters through esterification. The oils derived through this process are called ester fuels, when blended with diesel stocks these oils have produced efficiency of about 30% without degrading engine performance (Razzak et al., 2013). A group of researchers have successfully demonstrated a modified engine that can run on 100% of these fuels (Xu et al., 2008). Microalgae serve as special chemical production sites using the instrument of photosynthesis. After over four decades of studying these microorganisms, they finally displayed their abilities to produce different varieties of complex compounds and fossil fuels. The extraction of fatty acids from microalgae or lipid synthesis which usually results in hydrocarbons with 16 to 22 carbon chain length requires that oxygen be available (Hu et al., 2008). Lipid content and distribution in the cell are affected by some elements, some of which are; (a) CO2

- 20. concentration (b) temperature (c) intensity of light, (d) the nutrient concentration and (e) the relative proportion of salt - salinity. In algae, carbon compounds such as triglycerides-which are nonpolar lipids act as reservoirs of energy. However, the function of cell and chloroplast membrane formation is that of two polar lipids - phospholipids and glycolipids which are found inside the cell (Razzak et al., 2013). In as much as biodiesels can be manufactured from conversion of polar lipids, conventionally the non-polar triglycerides such as feedstocks are still the favored option. Therefore, non-polar lipids remain the most important algal product of interest. The conditions under which an algae grows during the growth phase will determine greatly the lipid concentration and productivity (Razzak et al., 2013). The total lipid content can differ between species beginning at 4.5% for very low and 80% for very high (Xu et al., 2008).3.1. Lipid extraction We can not emphasize enough the fact that lipid extraction from microalga to be used as biofuel is not only a strenuous process, but it is both energy intensive and cost demanding. To convert microalgae into diesel fuel that research into better ways for the extraction from dry biomass of lipids and further refining is pivotal. The challenge here is that the specific condition to achieve this is yet to be fully laid out (Chisti, 2007, 2008). To extract lipid from biological cell, chemical means, physical means or a combination of both means are employed. Cell disruption is mostly needed for releasing lipid and sugar contents within the cells of microalgae, to be used in the production of biodiesel and ethanol. Mechanical cell disruption can lead to extraction of an immense amount of lipid from microalga when accompanied by chemical solvent extraction. Furthermore, literatures have reported other mechanical processes which include: freezing, bead milling, osmotic shock, homogenization, high pressure, sonication. Also alkali and organic solvent extraction which is a chemical procedure was

- 21. also advanced. (Chisti, 2007, 2008; Razzak et al., 2013). 3.1.1. Mechanical extraction When a dense suspension of microalgae or other organisms is vigorously stirred together with the purpose of extracting the lipid in the mills cell disruption occurs. Cell disruption could happen to the suspended cells when they come into contact with energetic glass beads with powerful crushing ability during stirring. Hopkins (Razzak et al., 2013) reported that vigorous agitation by several small sized glass beads or ceramic beads was observed while mixing the cells and the beads. A bead mill is a simple arrangement of an enclosed grinding chamber having at its center a shaft that rotates. The discs fixed to the shaft transfer energy of motion to the tiny beads within the enclosure, bringing about a collision between them. The chamber contains a sieve or a slot in the direction of the rotating shaft through which the beads cannot pass. The beads accelerate radially, creating streams with varying speed and establishing high- tangential forces. The suspension is channeled into the grinding column through an external pump. Recently, the use of ultrasound for disrupting microcell has increased just as that used during microalgae as well as microbial processes. Assuming perfect conditions, such an arrangement can generate strong ultrasonic wave pressures in the liquid media it transverse leading to the creation of tiny bubbles. When these bubbles increase in size they generate cavitation when they collapse and generate huge violent shock waves of energy breaking cell wall membrane (Samarasinghe et al., 2012). Converti et al., (2009) demonstrated that ultrasound can be used (mod. UP100H, Hielscher, Teltow, Germany). Converti et al., (2009) achieved total extraction of the microalgae fatty components by a combined use of ultrasound along with chloroform/methanol. the microalga of Scenesdesmus almeriensis contains lutein Cerón et al., (2008) were successful at extracting the lutein from it. The authors also experimented with three methods of disrupting a cell viz-a-viz

- 22. (a) bead mill (with ceramic beads of 28 mm diameter, rotation speed of 120 rpm and, 2L volume), (b) mortar with pestle (125mL volume), (c) a combination between them and (d) ultrasound (Pselecta Ultasons unit). They reported the preferred option as the use of bead mill with alumina as disintegrating agent, among the treatments tested with regards to industrial use in the ratio 1:1 w/w for 5 min. Another study into lipid extraction was carried out by Neto et al., (2013) the cell disruption step was carried out using sonication bath pretreatment, after which vortex mixing was done and solvent extraction was performed using n-hexane. Neto et al., (2013) verified that increased lipid extraction using this method was obtained from the alga biomass when compared with the regular solvent extraction using hexane. These authors put forward the hypothesis that extraction time and solvent consumption were reduced when ultrasound was used to assist the process of lipid extraction because the solvent had greater penetration of the cell arrangement (Mercer & Armenta, 2011). Similar to other studied microbial cells, microalga can be hardened by freezing using liquid nitrogen or the method of freeze dryer. Frozen microalgae become brittle and easy to crush simply by the crushing action of the mortar and pestle. Low temperatures make ice crystals abrasive. Gouveia et al., (2007) in their own study, extracted lipids by freezing the microalga and then crushing mechanically, which was preceded by supercritical CO2 extraction. Firstly, the microalgae were manually crushed then moderately mixed with dry ice. The mixture was then crushed totally with the help of a disk vibratory mill (NV-TEMA, Labor-Scheibenschwingmuhle, type T100, 0.75 kW, 1000 V/min). Zheng et al., (2011) extracted lipids by using C vulgaris sp. The authors compared different processes through which lipids can be extracted. Some of the methods examined included (a) grinding in liquid nitrogen, (b) quartz and grinding under dehydrated condition, (c) quartz sand grinding under wet conditions, (d) enzymatic lysis by snailase, (e) bead milling, (f)

- 23. ultrasonication, (g) enzymatic lysis by cellulose, (h) microwaves, and (i) enzymatic lysis by lysozyme. Grinding in liquid nitrogen required a minimum of 2 min. 3.1.2. Chemical/solvent extraction Using solvent to extract oil usually comes after the algae cells have been mechanically disrupted and can be carried out through a two-solvent system. Mechanical disruption takes place a lot in the Lab setting, such disruption can be done by the process proposed by Bilgh and Dyer. This process entails the use of a chloroform/water/methanol method of extraction for accessing cell lipids. Non-polar (chloroform) and polar (methanol) two solvent systems are used for fractional lipid extraction from the cells. A major upside to solvent extractions is that it allows for high lipid harvest which can be refined further or used in its raw state. (Dote et al., 1994) studied how efficiently the algal cells of B. braunii could be converted into liquid fuels through liquefaction. Algal cells (~30 g) were charged to the autoclave while utilizing a catalyst (sodium carbonate) or not, 20 mL of distilled water was added to enable proper stirring because the amount of algal cells was inadequate to allow for proper stirring. The autoclave was later charged with nitrogen at 2 MPa after purging it using nitrogen, and then heated after sealing it in an electric furnace. Supercritical CO2 is also usable as a solvent in the extraction of lipids from microalgae. Some of the liquid and gas are held back due to the Supercritical CO2. Supercritical fluid extraction offers a ‘natural and ecofriendly’ option towards extracting product. This process is increasingly seen as an alternative to the usual techniques used for separation. It is an easier, faster and more reliable method. Also, the process utilizes less organic solvents, thereby reducing cost and harm. Supercritical CO2 presents some special attributes as a solvent. It is not harmful (Halim et al., 2012). Hence, Supercritical CO2 can be used as an appropriate solvent for extracting lipid from microalgae C

- 24. vulgaris, as clearly shown by (Gouveia et al., 2007; Mendesa et al., 2003). It was successfully demonstrated that microalgae that has been mechanically crushed delivered higher extraction yields using supercritical CO2 compared to others (Razzak et al., 2013). 3.1.3. New emerging green solvents systems and process intensification techniques for lipids extraction from microalgae A major setback for the commercial viability of algae-based fuels is the cost required for the process. In the process of producing biodiesel from microalgae a lot of difficulties is encountered; lipid extraction is one of such challenge, lipid extraction does not just require a significant quantity of energy and time but also causes environmental contamination due to the toxic solvents used. Furthermore, the quality of the lipid content maybe reduced by unwanted compounds such as chlorophyll dissolved in it as a result of the conventional solvents used during lipid extraction. To overcome this problem, green solvents and process intensification methods/techniques (green extraction technologies) promise improvements in the characteristics of energy reduction, eco- friendliness, non-toxicity and efficient lipid extraction. Hence, this section examines the prospects of green solvents and extraction techniques that may enhance the commercial viability of biodiesel production. Lipid extraction from microalgae is conventionally carried out by Folch et al. or Bligh and Dyer (Jeevan et al., 2017) after which lipid quantification through gravimetric estimation of lipid content is done. Folch et al. devised an easy method for extracting total lipids from animal tissues. However, the success of this method depends on the availability of mineral salts in the crude extract and use of large amount of solvent. If mineral salts are not present, majority of the acidic lipids are lost during the washing step. On the other hand, Bligh and Dyer devised a fast lipid extraction technique for estimating the lipid composition of

- 25. frozen fish tissue. This method works only for tissues wi th 80% water content, and the efficiency rely on the constancy of chloroform, methanol and water proportions according to the water content of the tissue. Chloroform and methanol are not just toxic and flammable but can also endanger our health and environment. These solvents reduce the quality of the final product by dissolving unwanted compounds (chlorophyll) during the extraction procedure (Archanaa et al., 2010). When this occurs, the quality of the lipid does not only drop but the biorefinery goal of a more cost friendly process is greatly hampered. Moreover, it goes without saying that for biodiesel production, preference has to be given to saponifiable lipids, which after transesterification are modified into fatty acid methyl esters (FAME) and not the whole lipids (Meng et al., 2009). Hence, those solvent systems for lipid extraction that can be sustained, non-toxic and improve lipid content yield without interference of non-lipid compounds should be looked into (Brennan et al., 2010). The importance of green solvent in the lipid extraction process has been discussed above. Furthermore, some new ‘green or process intensification techniques’ that encourage time and energy reduction, lower usage of solvent, reduction in the down-stream processing steps are vital for making the process viable. These techniques simplify the process and make it cost effective. For example, during biomass extraction the drying step could be skipped by using wet algae biomass extraction. In like vain, transesterification which is used for ester and glycerol production besides biodiesel process of wet algae biomass may prevent not just the dewatering and drying steps but also the lipid extraction process (in situ transesterification). The possibilities of green solvents and process intensification technologies and their influence can be compared with a traditional process for extraction and transesterification to biodiesel (Figure 1).

- 26. In-situ transesterification Other fuels Chemicals Conversion Separation of biodiesel and glycerol / FAME purification Biodiesel Glycerol Transesterification Cell disruption Extraction i.e., MAE, SAE, UAE, EAE Mechanical processing Grinding Drying/freeze drying Wet biomass Dry biomass Harvesting Cultivation of Microalgae Figure 1: Flowsheet for biodiesel production from microalgae. Some intensified process techniques highlighted may reduce some downstream steps as it would render the dewatering step unneeded. i.e. MAE – Microwave assisted extraction (MAE), Enzyme assisted extraction (EAE), Ultrasound assisted extraction (UAE), Surfactant assisted extraction 3.2. Lipid analysis Fluorophores are plants that exhibit fluorescence when light of a certain wavelength falls on it when in a non-polar environment. Nile Red is an example of such a plant and it causes lipid droplets in algal cells to fluorescents. Keith et al., (1987) determined the non-polar lipid content in algal cells using Nile Red dye. The authors using acetone with a concentration of 1 μg/mL examined Cell cultures previously

- 27. stained with Nile Red. The total lipids in Amphora coffeaeformis, Navicula sp., Tropidoneis sp., and Chlorella sp were gravimetrically determined by the average peak fluorescence as measured by a spectrofluorometer. For detection and characterizing the fatty acids (PAs) levels of biodiesel, different analytical techniques are available. There are also diverse techniques for quantifying fatty acid levels (PAs) in biodiesel. Gas chromatography (GC) and high performance liquid chromatography (HPLC) are two analytical methods often used for analyzing fatty acids and triglycerides. In comparing these methods chromatographic analysis alone should not be the focus but focus should also be placed on sample preparation. Although fatty acid analysis using HPLC has been on the increase in the past 10 years, the most used method still remains GC (Shantha et al., 1992). When complex mixtures that cut across a broad molecular range are analyzed gas chromatography-flame ionization detection {GC-FID} along with this standard technique has been very effective and fast (Carelli et al., 1997). Zuo et al., (2013) have exemplified that separation, quantification and analysis by GC can be very well carried out using fatty acids without the need for derivatization. However, while analyzing using GC, to improve the volatility and separation of the substances; derivatization of fatty acids can be carried out. This will also reduce tailings. The technology behind GC has seen recent improvements among which is the columns having bonded phases that give special separation opportunities reduced phase bleeding. However, derivatization can be used for situations requiring improved sensitivity. In recent studies separation and analysis of geometric isomers have been done using GC as well as for positional isomers. For diagnostic fragmentation of saturated and unsaturated AAS mass spectrometry (MS) has been proven as a potent technique. It is therefore worthy of note that GC and MS detection can be used together. MS can also be used for the analysis of branching positions in Pas (William, 1998). Otsuka & Morimura, (1966) showed the change in lipid

- 28. composition over different cell growth stages of synchronously grown cultures of Chlorella ellipsoidea. Using a silicic acid column chromatography was preceded by a methanol/ethanol/ether lipid extraction. Acid methyl ester fractions, after separation of polar and non-polar individual fatty acids were then obtained. These authors examined growing cultured cells at different stages. A change in the relative distribution of polar and non-polar fatty acids at every next growth stage was seen by the fatty acid profile. The kind of lipid, hydrocarbon and other complex oils produced by microalgae depends on its specie (Banerjee et al., 2002). Fatty acids in algae were discovered to be abundant in oleic acid (C18:1) and palmitic acid (C16:1). During cell division oleic acid is utilized for both cells under light and in the dark, this suggests that oleic acid in triglycerides contribute largely to the energy requirement for cell division.4.0. Heterogeneous transesterification catalysts Several researches were carried out and reported in other to explore the reactions of wide range of heterogeneous substance with the aim of mitigating the diverse challenges experienced when using homogeneous bases and liquid acids as alcoholysis catalysts (Choudhury et al., 2014; Dias et al., 2012; Kazemian et al., 2013). Presented in Table 5 is the list of various solid acids and bases reported from researchers as biodiesel producing catalysts. As shown in the table, ZrO2, MoO2, Al2O3, Si2O3, heteropoly acids and zeolite materials are catalysts categorized as solid acids (Anderson et al., 2009; Choudhury et al., 2014; Chouhan & Sarma, 2011; Dias et al., 2012; Kazemian et al., 2013; Martín & Grossmann, 2012). Having both Brønsted and Lewis acid sites was the bases for charactering the above-mentioned materials, which decides their reactivity in transesterification reactions. Shape selectivities could also affect the activities of zeolites and heteropoly acids. Materials with multi-dimensional pore structure stand a better chance in the formation of alkyl esters without necessarily cracking. Alternatively, solid bases mainly consist of oxides of

- 29. common metals, carbonates and basic zeolites. However, in biodiesel production, the most important active sites in these materials are the basic sites. Table 5: Reported catalyst used for heterogenous transesterification reaction on various feedstocks Catalyst Feedstock Reaction operating conditions Performance References Temp (0F) Catalyst loading wt% Time (hr) Methanol :oil Yield (%) Conv. (%) Solid Acids Heterogenous Catalysis WO3/ZrO2 Waste cooking oil 167 - 20 19:1 - 85 ( Park et al., 2010) Zeolite Y (Y756) 860 -

- 30. 0.37 6:1 27 NR (Brito et al., 2007) Starch/Carbon-based 176 10 8 30:1 92 (Lou et al., 2008) H3PW12O40.6H2O 149 4 14 70:1 87 (Cao et al., 2008) ZrO7H0.2PW12O40-ZrHPW 2 8 20:1 99 (Zhang et al., 2010)

- 31. Zs/Si 392 3 5 18:1 98 (Jacobson et al., 2008) SO42-/TiO2-SiO2 4 9:1 90 (Peng et al., 2008) SO42-/SnO2-SiO2 302 3 15:1 92 (Lam et al., 2009)

- 32. Solid Bases Heterogenous Catalysis CaMnO3 animal fat - - - - - NR (Dias et al., 2012) Calcined waste coral fragment-CaO Palm oil, Soybean oil, Rice bran oil, waste cooking oil - - 2 - 98 (Roschat et al., 2012) KF/CaO Chinese tallow seed oil 149 - 2.5 12:1 97 (Wen et al., 2010) KNO3/CaO Rape oil

- 33. 149 1 3 6:1 98 (Encinara et al., 2010) CaO/ZnO Ethyl butyrate 140 1.3 2 12:1 90 (Alba-Rubio et al., 2010) Li/MgO Soybean oil 140 9 2 12:1 94 NR (Wen et al., 2010) Kl/Mg-Al 158 5 8 20:1 90

- 34. (Tantirungrotechai et al., 2010) CaO/SiO3 140 5 8 16:1 95 (Samart et al., 2010) Na2SiO3 3 1 8:1 100 (Guo et al., 2010) PzOH/SiO2 167 4 12 60:1 90 (Kim et al., 2011) Mg-Al-hydrotalcite 446 5

- 35. 1 13:1 (Cristina et al., 2010) Sunflower oil 140 2 24 12:1 50 (Campo et al., 2010) Jatropha curcas oil 113 1 1.5 4:1 95 (Deng et al., 2011) CaO/Fe3O4 158 2 1.33 15:1 95 (Liu et al., 2010)

- 36. CaMgO 149 4 6 80 NR (Taufiq-Yap et al., 2011) CaZnO MgO-KOH Mutton fat 4 0.33 22:1 - 98 (Mutreja et al., 2011) Dolomite Canola oil 154 3 3 6:1

- 37. 92 NR (Ilgen, 2011) Palm oil 140 6 3 30:1 98 (Ngamcharussrivichai et al., 2010) Calcined mollusk & egg shell-CaO 10 2 18:1 90 (Viriya-empikul et al., 2010) Calcined egg shell-CaO 149 1.5 2 12:1 98 (Cho & Seo, 2010) KF/Ca-Al-hydrotalcite

- 38. 5 5 (Gao et al., 2010) CaO/Al2O3 148 - 5 99 (Zabeti et al., 2010) Calcined CaCO3-CaO 140 - 1 15:1 94 (Yoosuk et al., 2010) CaO 7 0.75 96

- 39. (Yoosuk et al., 2010b) Sunflower oil 176 1 5.5 6:1 91 (Verziu et al., 2011) 167 - 0.75 4:1 80 (Vujicic et al., 2010) Waste cooking oil 149 0.9 1 12:1 66 (Kouzu et al., 2017) K3PO4 140 4

- 40. 2 6:1 97 (Guan et al., 2009) Oil palm ash 5.4 0.5 18:1 72 (Chin et al., 2009) Calcined snail shell-CaO 2 8 6:1 87 99.6 (Birla et al., 2012) In the heterogeneous catalysis, though regarding if solid basic or acidic catalyst is employed, a number of factors such as amount of catalyst, degree of mixing or stirring, the on stream reaction time, oil/alcohol content, transesterification temperature and purity index of the feedstock has to be appropriately considered. Anderson et al., (2009) studied the distribution of the active material over the catalyst support which is believed to have influences on the activity of BaO/Al2O3 in alcoholysis, the author confirmed that higher distributions have higher activity. To avoid handling

- 41. difficulties, temperature close to boiling point of monohydric alcohol should be selected. More so, in other to have a complete conversion adequate reaction time needs to be provided (for example 1-3 hours). It is also important to monitor the extent of catalyst/reactants interaction therefore moderate mixing is very necessary, because the reaction would be very slow if the mixing rate is low, meanwhile the reaction may be difficult to handle as well as side reactions will be experienced when the mixing rate is high. However, oils with lesser percentage of fatty acids (such as algae oil with less than 1% fatty acid) are most desirable because the key impurities in majority of oils are the free fatty acids. The equilibrium process through which methanol (monohydric- alcohol) and triglyceride ester (bio-oil) reacts in ratio 3:1 to give a mole of glycerol and an equal amount of mono-alkyl esters (biodiesel) is known as transesterification (Equation 1). + Glycerol 3 Methanol Triglyceride Catalyst 3 Methyl acetate (Biodiesel) + Equation 1: Chemical equation showing production of biodiesel from any bio oil This reaction proceeds in three successive phases, each consisting of the production of biodiesel (mono-alkyl ester) and initiating alcoholic -OH group into the triglyceride ester chain. Hence, at the last phase of the reaction, glycerol would be produced. However, the ratio required of monohydric-alcohol to oil should be within 4:1 and 12:1 in other to speed up the

- 42. reaction and generate more biodiesel within the shortest possible time. Furthermore, negative effect on the total biodiesel generated may be created as well as reduction in the general production of biodiesel as such the reaction may shift backwards all of which are as a result of values below the above-mentioned ratio. Nevertheless, at higher ratios, greater challenges may be posed as a result of the removal of excess alcohol. Other critical factors such as the degree of stirring and reaction temperature are greatly importance. Thus, to guarantee adequate interaction between reactants and catalyst particles sufficient stirring is necessary (Anderson et al., 2009; Chouhan & Sarma, 2011; Liu et al., 2008; Lotero et al., 2005; Ma et al., 2008). However, as for the reaction temperature, it must be close to the boiling point of that of monohydric alcohol, because slow reactions are favoured by lower temperatures, while handling difficulties is created by much higher temperatures.4.1. Solid Bases Transesterification More often than none, reactions that involve heterogeneous bases proceed via reactions of either the Brønsted or the Lewis basic sites of the catalyst generally with ether ethanol or methanol (monohydric alcohol). Hence, biodiesel is produced when the alkoxide mixture generated reacts with TAG (triglyceride - C55H98O6) ester in the oil and also yields glycerin in the next steps (Equation 2). + + Equation 2: Reaction mechanism of transesterification via base catalyst (denoted Y) in the equation.

- 43. The mode of action is Eley-Rideal type, but the extend of its basicity greatly determines on the speed of the reaction. An alkoxide group (RO-) is formed and H+ removed when the alcohol preferentially interacts with the basic sites, been the key active component which attacks the triglyceride ester at the intermediate phases. The formation of alkoxide species depends on strength the basic sites (i.e. the higher the strength of the basic sites, the more favored the production of the alkoxide species and vice versa). In the same way, cleavage and glycerol formation is favoured by stronger basicity and subsequently enhancing the overall rate of reaction. Solid basic catalysts i.e. zeolites, ZnO, CuO or other oxides of first row transition metals, compounds from group 2A elements and basic polymers (Table 5), particularly the oxides i.e. Calcium oxide, Magnesium oxide, strontium oxide, Barium oxide etc., and carbonates which is more prominent for example Calcium carbonate, Magnesium carbonate, Strontium carbonate and Barium carbonate, have been focus of research in the area of heterogenous catalysis for transesterification. Their basi city is associated with metal-oxygen ion pairs (i.e. M2+ -O2-) and varies in the order Ba > Sr > Ca > Mg for the oxides. As such these catalytic materials are easy to prepare, because they are inexpensive and showed low corrosion properties. The transesterification reaction of these heterogeneous base catalysts is determined by the severity of calcinations step which is a very important factor. The conversion gets reduced at high calcinations temperatures as a result decrease in active catalyst surface. For example, only 18% conversion yield was achieved in 8 hours of reactions for a sample of MgO calcined at 600OC. Meanwhile, at optimum conditions; lower calcination temperatures, the methanol/oil content being 12:1 and 5.0 wt % catalyst 92% high conversion yield was achieved (Chouhan & Sarma, 2011). This was also noticed over CaO. On the other hand, after repeated cycles of applications, the latter catalyst caused reusability problems. Transition elements such as Fe, Ce, Zr and La and Mixed oxides

- 44. of Ca have also been studied in transesterification. This has resulted to above 95% biodiesel yield. Although, to achieve sufficient shift of the equilibrium position forward, a relatively high ratio of methanol-oil (i.e. 6:1) could be needed. Sufficient transesterification time of about 10 hours’ reaction time may as well be required in addition to these materials. For instance, in 10 hours a CaTiO3 may yields up to 79% of biodiesel, while in the same reaction time (10hrs) CaCeO3 and CaZrO3 yields around 70 and 95% of biodiesel at 60OC using oil/methanol ratio of 1:6. Because of the adequate stability and dispersion properties of Al2O3 out of other support materials, it shows a higher activity and also permits improved interaction between the surface reactants (Anderson et al., 2009; Chouhan & Sarma, 2011; Ma et al., 2008). Basic zeolites and hydrotalcites are gradually more researched and recently more studied. Materials like oxides containing faujasites, zeolites and ETS-10 have basic cations which may be generated through thermal melting of their supported salts. Ion exchange with highly electropositive cations is as well essential in other to the promote transesterification activity. The hydrotalcites (MgeAl) has good basicity except for the dissolution problems that necessitate the materials to be carefully prepared. Co- precipitation preparation methods have thus far shown reliable stability. 4.2. Solid Acids Transesterification This category consists of catalysts that are more environmentally friendly and sustainable compared to homogeneous catalysts. This catalysts have shown very little or no recycling and corrosion problems. Nevertheless, to achieve better efficiency high porosity systems are needed. The porosity permits sufficient and appropriate adsorption-desorption and diffusion of the products and reactants. Hence, metal oxides or carbonates is less effective compared to acidic zeolites (see Table 5) as such the latter will be more preferable here. In other to address diffusional impediments, their structural and acidity properties should constantly be adjusted thereby enhancing and increasing biodiesel production (Borges et al., 2013; Macario et

- 45. al., 2008). Nevertheless, selecting the suitable silica alumina ratio alongside modifying the concentration is a difficult task with zeolites. High loading can result in the blockage of the pore systems meanwhile free metals such as Palladium or Platinum results in hydrogenolysis and then, dehydrogenation, as a result obstructing biodiesel production. The performance rating of organosulphonic acids and sulfated zirconias as materials for transesterification catalysts has been triggered due to several separation and environmental challenges related to sulfuric acid. The SO42- in an unsupported system could effortlessly be lost in the reaction medium and hence acidity decay which causes catalyst deactivation. Thus to solve this problem, it becomes necessary to incorporate porous silica or alumina as support material. ZrO2 generally exists as tetragonal, cubic and monoclinic phases. It is a well known fact that the tetragonal phase exerts greater transesterification activity compared to the other phases, particularly when doped with appropriate amount of amorphous Tungsten trioxide. In few cases, sulfated tin oxide or tungstatedzirconia may be used in place of sulfated zirconia with supported over alumina to achieve a comparable activity (Jothiramalingam & Wang, 2009). 4.3. Heterogeneous transesterification of algae oil After harvesting, plants extraction of its oil is usually the first followed by other significant step in production of biodiesel (Figure 1). The procedure to be embarked on should be such that will ensures reduction in the cost of extraction cost and at the same time ensures high oil production (Martín & Grossmann, 2012). Chemical and mechanical methods are the basic and popular techniques obtainable for algae today. The chemical methods commonly available include hexane solvent, soxhlet and supercritical fluid extraction while expeller press or ultrasound-assisted is the main available mechanical method. The chemical methods are of great health and safety concern because of the chemical implications meanwhile the mechanical method is energy intensive because drying of the algae is required (Martín & Grossmann, 2012). However, adopting

- 46. supercritical extraction method is also energy intensive because of the involvement of high pressure equipment used in this method which is usually expensive. Commercially, Origin Oil Company widely applies a single step process. This method entailed chronological steps of harvesting, concentration, and extraction oil from algae. It split the oil, biomass and water in a single step (generally in <1hr). This method does not need initial dewatering of the fresh algae, more so no heavy equipment or chemicals are required. The Cavitation Technologies Inc method is another novel technique. In other to produce cavity bubbles in the solvent the company employed its Nano-based reactor (Oilgae, 2017). For the bubbles near the cell wells to collapse, pulses are generated which breakdown the cell walls to synthesis oils into solvent used for the extraction. Another method which Nano-technologists would find very interesting is the Catilin's method (though still under research and development stage). In other to specially extract and sequester specific fuel-based compounds present in the algal lipid feed, specially developed mesoporous nanoparticles will be used. The T300 catalysts developed by the company will be used to trans-esterify the free fatty acids and triglycerides rich balanced algal oil into biodiesel. The major advantage in this case is that, the technology is potentially very efficient and involved heterogeneous catalyst as such reduces cost, ensures sustainability of the environment, recycling of the catalyst as well as highly purified biodiesel and glycerol (Oilgae, 2017). Osmotic shock and enzymatic extraction are some other methods used for the extraction of oil which are still under investigation, however, the later is considered to be costlier than the hexane extraction technique. The method uses precise enzymes molecules to breakdown the cell walls by a common solvent, thus allowing it to be easier to fractionate the oil. An estimation of 80,000 liters/acre of algae oil was recently recorded by Demirbas & Demirbas, (2011). These figures more than 30 times the quantity that could be obtained from other feedstocks such as palm oil. They revealed that common species

- 47. of algae like Schizochytriumsp and Botryococcusbrauni could produce about 77% oil based on dry matter. They also showed in one of their model the oil per hectare yield of 100,000 liters for algae species as compared to just 446 liters for soy plants and 952 liters per hectare for sunflower plants. Furthermore, other scientist such as Vazhappilly & Chen, (1998), Volkman et al., (1989) and Yaguchi et al., (1997)also recorded closer trends. Algae oil is also discovered to contain unsaturated fatty acids for example omega-3's, omega-6, docosahexanoic and ecosapentanoic acids. Interestingly, these compounds can be isolated and used for other commercial purposes, thereby being of economic exploitability advantage (Wen & Chen, 2003). Transesterification of the oil into biodiesel follows after successfully extracting the oil. Similar conversion techniques used for other vegetable oils are also adopted for use in the conversion algae oils (Campbell, 2008; Demirbas & Demirbas, 2011; Miao et al., 2004; Xu et al., 2006). Algae specie, Chlorella protothecoides was used by Xu et al., (2006) for the production of biodiesel. The cells were removed via agitation together with washing with distilled water before using freeze drying process to dry. Pulverize of powdered cells with mortar will produce the oil after which extraction is done using n- hexane, the optimal parameters include equivalent catalyst concentration (i.e. according to oil weight), methanol/oil ratio (56:1) at temperature of 30 OC, which reduces product density from 0.912 to 0.864 during 4 hours on stream. Recently emphasis is given to the production processes using homogeneous catalysts with several evidences (Hu et al., 2008; Martín & Grossmann, 2012; Martın & Grossmann, 2009; Plata et al., 2010; Santacesaria et al., 2012; Wen et al., 2009). Meanwhile, shifting to the use of heterogeneous materials becomes necessary because the materials’ sensitivity towards fatty acids in the algae oil feed likewise due to low quality glycerol produced. Nevertheless, the two materials could be used in line with Figure 1. With the latter catalysts, lesser energy is needed for the removal of soap and glycerine (i.e.

- 48. during purification). In the separation process the catalysts are also removed easily and reused. Hence in the nearest future, the current used of homologous methods will be substituted by the heterogeneous process. Acids like Silicotungstic acid (H4SiW12O40), Phosphotungstic acid - PTA (H3PW12O40), CsPW (Cs2.5H0.5PW12O40), Phosphotungstic acid/Zirconia (H3PW12O40/ZrO2) and Phosphotungstic acid/Niobium oxide (H3PW12O40/Nb2O5) are commonly referred to as heteropoly acids, have been recorded to show great tolerance towards free fatty acid concentrations, producing large conversions of biodiesel at ordinary conditions such as that of vegetable oils (Alsalme et al., 2008; Katada et al., 2009; Talebian-Kiakalaieh et al., 2013). This groundbreaking potential can be harness in algae oils which has greater potential. However, under controlled conditions acidic zeolites like H-Beta, H-ZSM-5, H- MOR, H-ETS-10, H-ETS-4 having moderate acidic properties and adequate porosity permits more fast transesterification with limited side reactions interference for the vegetable oils (Borges et al., 2013; Macario et al., 2008) and also for the algae oils. Materials based on WO3/ZrO2 must be used at the right loadings and calcinations. The 15% weight of WO3/ZrO2 calcined at 932 OF is recommended, which gives 95% yield conversion for other oils (see Table 6). Therefore, using comparable preparations algae oil has more yield potentials under similarly constant conditions of the reaction. Table 6: The effect of calcination temperature on the performance of WO3/ZrO2 catalyst (Jothiramalingam & Wang, 2009). Conversion (%) Sample Calcination temperature (0F) 15 wt% WO3/ZrO2 5 wt% WO3/ZrO2 1

- 49. 1652 17 5 2 1292 25 5 3 1112 20 10 4 932 81 95 5 752 78 93 Likewise the heterogeneous bases are materials of great prospect (see Table 7). Mixed oxides with transition metals, oxides of Calcium, Strontium and Magnesium, and supported over silica or alumina were widely investigated for oils other than algae oil and their various properties well evaluated. Similarly, these materials can intensively be exploited for algae oils, hoping to mitigate challenges like thermal instability, dissolution, sintering, and recyclability problems by right parameters choices. Selecting suitable conditions of reaction and appropriate support materials is key to heterogeneous algae transesterification (Galadima & Muraza, 2014; Krohn et al., 2011; Santacesaria et al., 2012; Umdu et al., 2009) Duri ng the conversion of marine microalgae, the properties of aluminum oxide (Al2O3) doped magnesium oxide (MgO) and calcium oxide (CaO) were investigated by Umdu et al., (2009), by

- 50. controlling the concentration of methanol as well as the quantities of the active materials at 323 K. In their study, they discovered that unsupported calcium oxide and Magnesium oxide activity were negligible, while calcium oxide and aluminum oxide system produced the activity with the most potential, because of higher basic sites concentration and basic strengths. Finally, their conclusion was that just like other vegetable oils, algae could be converted to biodiesel successfully by the use of the named heterogeneous materials at low transesterification temperature. Likewise, there are no unwanted products which needed to be purified. Biodiesel was also generated by the catalysts at low temperatures for some eatable vegetable oils containing common impurities such as free fatty acids. Thus, it means that the materials have strong potentials for algae oils. A new fixed bed continuous reactor system was incorporated by McNeff et al., (2008) using porous titania, alumina and zirconia (including their mixed oxides) as heterogeneous alcoholysis catalysts at high temperature and pressure of 300-450 OC and (2500 psi) respectively, in addition to some feedstocks (such as microalgae, corn and soybean oils). The catalysts were proven very successful, particularly with algae oil Table 7. Table 7: Literature review on biodiesel production via heterogenous catalyst S/N Feedstock Catalyst Yield (%) References 1 1st Generation Soybean oil Li/MgO 94 (Borges & Díaz, 2012)

- 51. 2 ZrO2, TiO2 88 (McNeff et al., 2008) 3 Corn oil 4 Groundnut oil BaO/Al2O3 80 (Anderson et al., 2009) 5 Cotton seed oil 6 Palm oil CaO/ Al2O3 99 (Ramachandran et al., 2013) 7 Mutton fat MgO/KOH 98 (Mutreja et al., 2011)

- 52. 8 Sunflower oil ZrO2/La2O3 85 (Ramachandran et al., 2013) 9 Na-X zeolite 84 (Musyoka et al. 2012) 10 2nd Generation Yellow horn Cs2.5H0.5PW12O40 96 (Ramachandran et al., 2013) 11 Waste cooking oil MgO/ TiO2 92 12 Zeolite Y (Y756) 85 (Lam et al., 2010)

- 53. 13 H3PW12O40.6H2O 87 14 K3PO4 97 15 Chinese tallow seed oil KF/CaO (Borges & Díaz, 2012) 16 Jatropha curcas oil CaO/Fe3O4 95 17 Croton megalocarpus oil SnO2SO4/ZrO2 18 Algae oil ZrO2, TiO2 90 (McNeff et al., 2008)

- 54. 19 NiO, MoO3/ Al2O3 99 (Sani et al., 2013) 20 Pt-SAPO-11 83 21 NiO, MoO3/H-ZSM-5 98 22 Microporous TiO2 95 23 Niobium oxide (HY-340) 94 24 H-beta Zeolite 100

- 55. 25 Amberlst-15 98.5 (Dong et al., 2013) 3rd Generation 26 Microalgae's lipid Modified Al2O3 98 (Umdu et al., 2009) 27 Modified TiO2 96 (Chouhan & Sarma, 2011) 28 Porous TiO2 microsphere Under constant conditions percentage yields of biodiesel gotten from; algae was 90.2%, corn was 88.3% and soybean oils was 88.1%. More so, economical analysis of the process revealed that it was less expensive compared with the conventional homogeneous options. However, they encountered limited

- 56. interference because of the fatty acids. The reusability of the catalysts is also made possible because of their thermal stability. For the sake of increasing the biodiesel yield and reduce the fatty acids interference experienced with few heterogeneous base catalysts, some scientists (Dong et al., 2013), have recently introduced two steps in situ process. This process consists of a pre-esterification of the algae oil before the base-catalyzed transesterification. It could permit 98% recovery of the biodiesel, which is greater than the values obtained by a single-step catalytic in situ process. The reusability potential Amberlyst-15 (a heterogeneous material) was studied by Dong et al., (2013), where it was repeatedly employed eight times without activity decay. Up to 30% weight increases in ester yield is caused by catalyst loading, above this, its concentration does not affect the activities of transesterification. In the contrast, biodiesel production is negatively affected as a result of increase in methanol to algae oil ratio, with an optimal yield of 20%. The technology could serve as a more cost effective, environmentally sustainable method because of the optimal biodiesel produced and recyclable catalyst. Heterogeneous solid acids like NiO- MoO3/Al2O3, Pt-SAPO-11, NiOeMoO3/H-ZSM-5 and microporous TiO2 has recently been reported by (Sani et al., 2013) as being efficiently used for microalgae oil. In general, the conversions were within the range of 83 and 99% (see Table 7), these materials displaced great prospect for lower commercial and industrial cost of production compared with the homogenous system in addition the remarkable stability of catalysts and lack of reusability problems or corrosion. Many researchers (Giannakopoulou et al., 2010; Hara, 2010; Lim & Teong, 2010; MacArio & Giordano, 2013; Peng-lim et al., 2013; Perego & Millini, 2013; Rathore & Madras, 2007; Serrano et al., 2013; Sharma et al., 2011; Verma et al., 2011; Zhao et al., 2013) generally believed that the best future method for the production of biodiesel from algae or similar non-edible feedstock would be by heterogeneous catalysis. However,

- 57. researchers need to integrate economic aspects with science, technology and policy issues in their studies so as to identify the technical and economical feasibility of this method. It is however interesting to note that, diesel range hydrocarbons and or gasoline (Harman-Ware et al., 2013; Kiss et al., 2006; Thangalazhy-gopakumare et al., 2012; Tran et al., 2010), animal feeds and fine chemicals including Hydrogenated Vegetable Oil (HVO) can also been produced using algae oil. The most important heterogeneous materials exploited in this regards are solid acid catalysts. Generally, the conversion processes involves cracking, hydrotreating and hydrodeoxygenatio n (Kiss et al., 2006; Savage et al., 2011). Out of the solid catalysts, the good materials evaluated for cracking reactions includes aluminum oxide (Al2O3), aluminum chloride (AlCl3), calcium oxides (CaO) and magnesium oxide (MgO), SAPO-5, SAPO-11 (Kiss et al., 2006), HZSM5, HBEA and USY. Meanwhile, heterogeneous systems which are mostly used for hydrotreating of bio-oils even at low temperature include NieMo/g-Al2O3, CoMo and NiMo-sulphides and their SiO2-Al2O3 supports though with limited stability challenges. They have interesting properties such as good thermal stability with catalyst poisons resistances in the reaction feed. Primary deoxygenation materials such as Al2O3, SiO2 and zeolites supported Nickel and/or noble metal catalysts can be used to convert fatty acids in the algae oil to liquid hydrocarbons of mostly diesel range. (Hu et al., 2013), recently pyrolyzed oil gotten from microcystis species (oil-riched blue - green algae) at temperatures ranges of 572-1292OF in a fixed bed reactor. Mostly at optimal temperature of 932OF, the liquid bio-oils generated were discovered contain gasoline and diesel range hydrocarbons at appreciable quantity. C6H6, C6H6O, C7H8O (Cresol), C4H5N, C8H7N, C5H5N, their families and substituted pyrazines were also identified at appreciable concentrations. Other researcher that used different species also had similar outcomes (Choi, Choi, & Park, 2012; Melligan et al., 2011; Miao et al., 2004; H. J. Park et al., 2012). 5.0. Reactors

- 58. Commercial industries and producers have suggested several techniques for culturing microalgae. Reviews such as (Chen et al., 2011; Eriksen, 2008; Grobbelaar, 2010; Kumar et al., 2011; Ugwu et al., 2008; Wang et al., 2012) listed the various technological solutions. Some of these methods used include tanks or pools of different type ranging from round ponds with arms that are movable, large open ponds, cascade systems with baffles, race way type ponds (tracks). Furthermore, fermenters (for heterotrophic and mixotrophic cultures), large bags, two stage systems (cultivation in the reactor in an internal system, the system of outside pond with paddle wheel, which enforces growth medium movement and simultaneously aerates the culture) are also employed (Olaizola, 2003) The ratio of the culture solution volume to the illuminated surface is a key factor to the design of reactors used to grow photosynthetic organisms. The reduction of unwanted consequences of self-shading or limited access to light from one cell to another is achievable through the proper selection of the culture solution irradiated surface (A) and volume (V) ratio. Nevertheless a raise in the values of the ratio of irradiated surface to the volume (A/V) is the parameter that is desirable for photobioreactors (Becker, 2007).5.1. Influence of reactor design and operating conditions The design of an innovative chemical reactor in other ease the continuous processing of viscous bio-oils is most likely to affect biodiesel production by commercially exploiting heterogeneous catalysts. Even though a lot of biodiesel production plants of most industries runs in batch mode and at an important scale of B7000 tons per year (Aransiola et al., 2014; Sakai et al., 2009). It becomes very important to employ continuous flow reactors that is heterogeneously catalyzed, so as to prevent the separation cases of homogeneous catalysts and drawbacks of batch mode (particularly raised the capital investment needed to operate at high volumes as well as raised the cost for labor of a start or stop process) (Stamenković, & Veljković, 2014) in addition, also raise the scale of operation

- 59. ranging from 8000 to 125 000 tons per year (Aransiola et al., 2014; Sakai et al., 2009). Varieties of process engineering solutions have been suggested for use in the continuous esterification of FFAs, as well as the use of fixed bed (Cheng et al., 2012) or microchannel-flow reactors (Kulkarni et al., 2007) pervaporation methods (de la Iglesia et al., 2007) and reactive distillation (Buchaly et al., 2012; Kiss et al., 2008). A depth review of biodiesel production using process intensification methods have been conducted elsewhere (Maddikeri et al., 2012; Qiu et al., 2010). Chemical conversion and separation steps are combined in a single stage in reactive distillation. As a result, the process flow sheets are made easier, cost of production is reduced, as well as catalyst lifetimes extension by continuously getting rid of water from the system. Nevertheless, the method is only relevant and usable when the pressure and temperature needed for reaction is suitable with that required for the distillation. Kiss et al. used a range of alcohols catalyzed by sulphated zirconia to demonstrate this approach for the esterification of dodecanoic acid (Kiss et al., 2008). However, their reactive distil lation was 100% selective, allowed lesser residence times compared to similar flow systems, in addition to this it didn’t need excess alcohol. The fact that it doesn’t need excess alcohol is a key improvement over the majorities of popular conventional biodiesel syntheses in which there is a reversible reaction between the alcohol and triglyceride, hence huge alcohol excesses are usually needed to accomplish full conversion (to ensure economic process viability, the excess alcohol should be separated and re-used after worth). In other to exploit the full potential of the integrated heterogeneous catalyst, every continuous flow reactor should be appropriately designed, however plug flow is an important characteristic because it allows effective management and monitoring of the product composition, thus minimizes its operational costs, downstream separation processes alongside associated capital investment. The conventional plug flow

- 60. reactors are poorly designed to lower reactions like TAG transesterification and FFA esterification, given that, specification such as very high length, diameter ratios are required to achieve good mixing, even though they are problematic because of their pumping duties together with large footprints, in addition to the difficulties in controlling and managing it. These difficulties are avoided in Oscillatory Baffled Reactors (OBRs) by oscillating the reaction fluid via orifice plate baffles to realize an effective mixing and plug flow,249 thus decoupling mixing from the net fluid flow in a scalable fashion, allowing long reaction times on an industrial scale, as such applied to homogeneously catalysed biodiesel production (Phan et al., 2012) OBR vortical mixing further provides an efficient, manageable methods of solid particles that are uniformly suspended and was utilized recently to entrain a PrSO3H-SBA-15 mesoporous silica within a glass OBR under an oscillatory flow for the continuous esterification of propanoic, hexanoic, lauric and palmitic acid (Figure 2) (Eze et al., 2013). There is an outstanding semi-quantitative consensus between the kinetics of hexanoic acid esterification in the Oscillatory Baffled Reactors and a conventional stirred batch reactor, in which the important predictor of solid acid activity was recognized to be the length of the fatty acid chain. Constant esterification inside the Oscillatory Baffled Reactors enhanced ester synthesis when compared to the batch operation because of the water by-product is constantly removed from the zone of catalyst reaction, proofing the flexibility of the Oscillatory Baffled Reactors for heterogeneous flow chemistry and key potential roles as a new clean catalytic technology. No Oscillation Oscillation Net flow out Baffled tube Net flow in

- 61. Oscillation Sedimentation Uniform suspension Upstroke Down stroke Figure 2:Flow sheet of an oscillatory baffled reactor and it mixing features. Also illustrating the solid acid catalyst PrSO3H-SBA-15 undergoing no oscillation but sedimentation and or with about 4.5Hz oscillation traped in the baffles. Figures exuracted from (Eze et al., 2013) In the production of biodiesel by TAG transesterification with methanol phase equilibrium considerations are significant, given that the alcohol and reactant are usually immiscible, while the FAME product is miscible, obstructing retarding reaction and mass transport. More complexity and production cost is added due to the need to separate and purify the product phase, which comprises of a mixture of solid catalyst, unreacted oil, biodiesel and glycerol (Lee et al., 2014). These challenges could be lessened by using membrane reactors (Baroutian et al., 2011; Falahati & Tremblay, 2012; Xu et al., 2014). where the semi-permeable material of which the reactor walls are made is designed to permit the passage of the FAME or glycerol phase, whereas the oil-rich or MeOH emulsion is retained for more reaction. However, a MCM-41 supported p-toluenesulfonic acid catalyst was used by Xu et al., (2014) to pack a ceramic membrane tube for the transesterification of a recirculating soybean oil and methanol feed (Figure 3a). It is worthy of note that membrane reactor produced higher biodiesel compared to a homogeneous p-toluenesulfonic acid catalyst under similar conditions in batch mode (84% against 66%). Furthermore, recycling of catalyst showed just a little reduction of activity, generally at the end of the third cycle with about 92% of