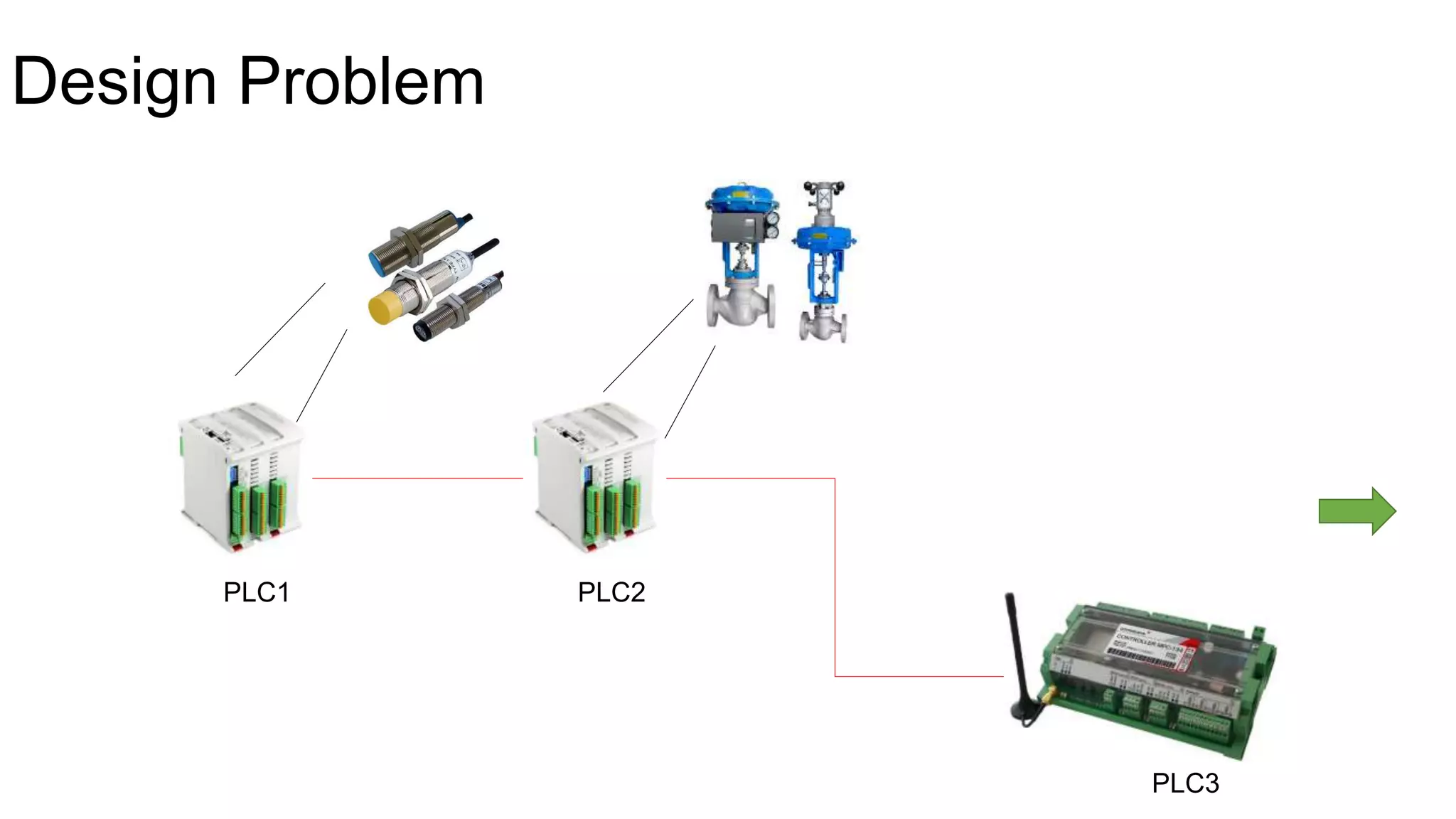

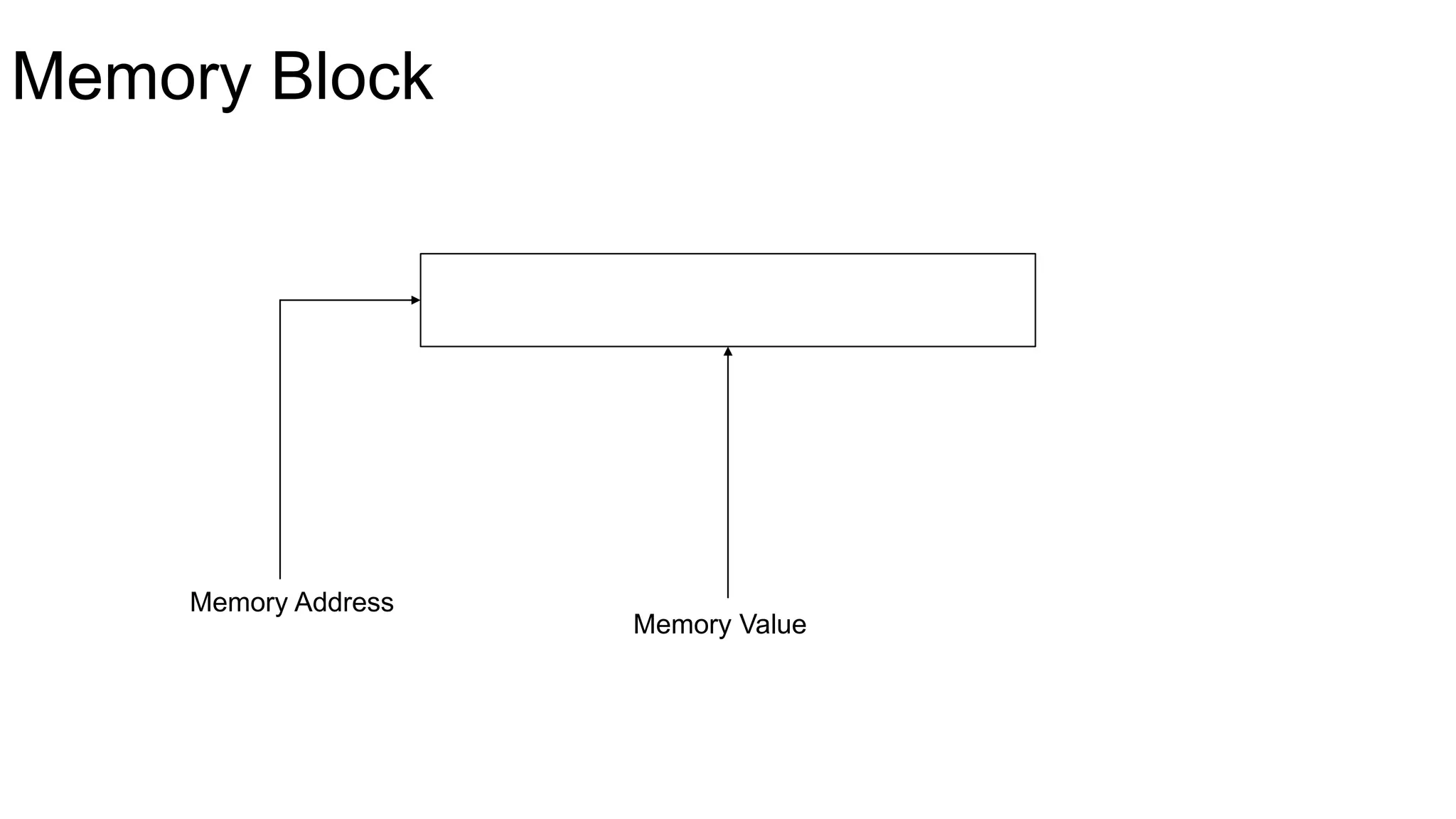

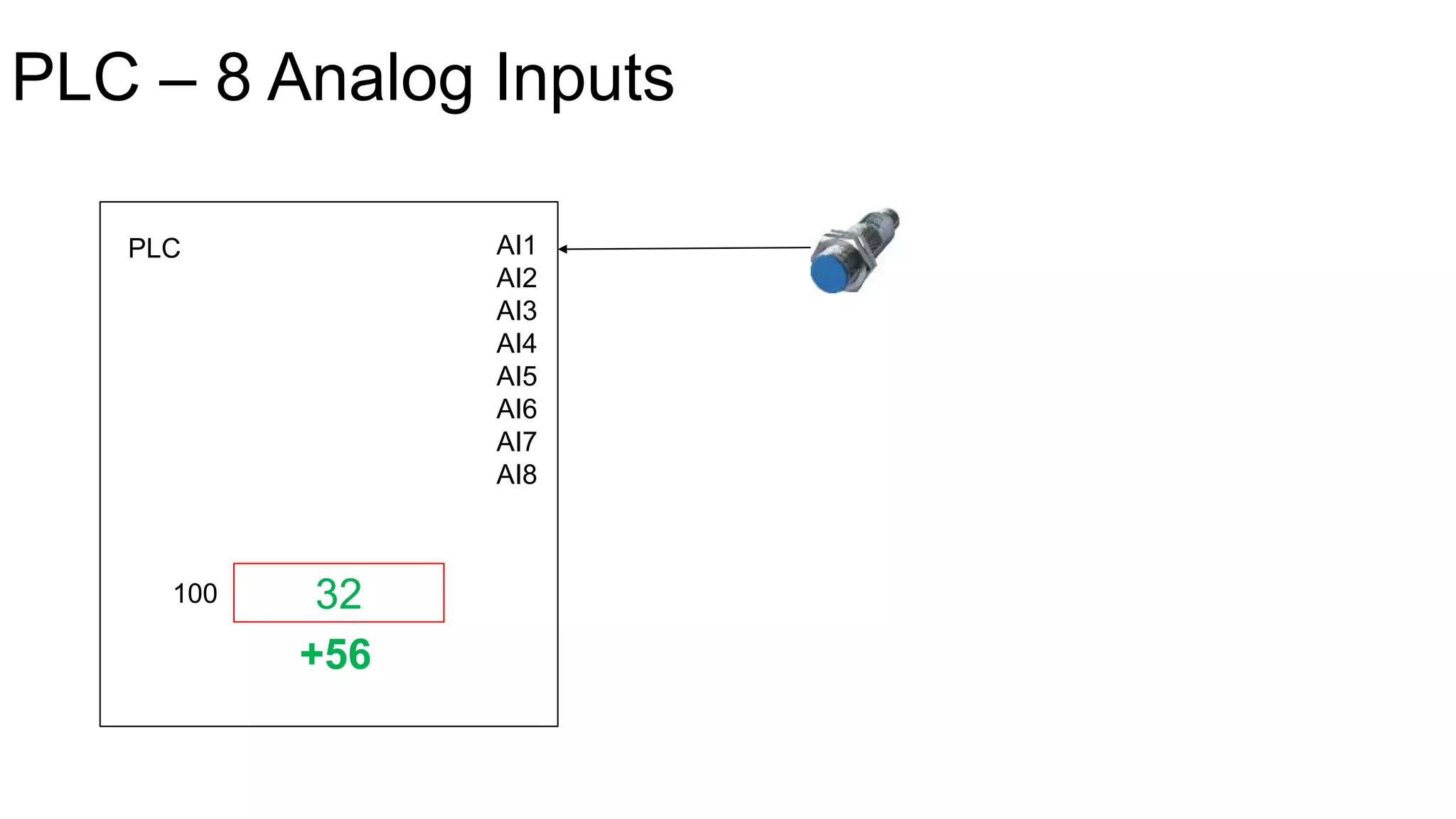

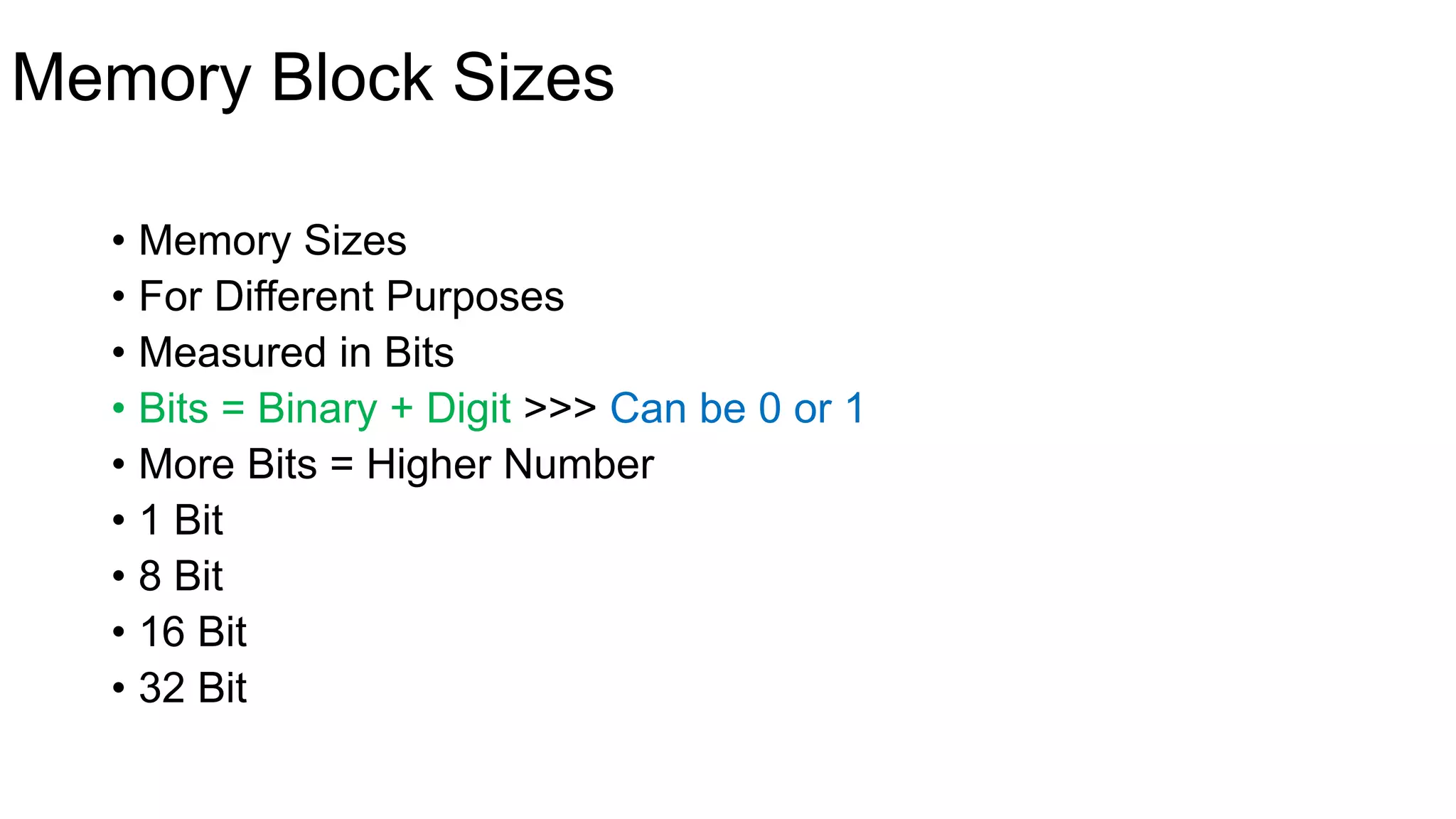

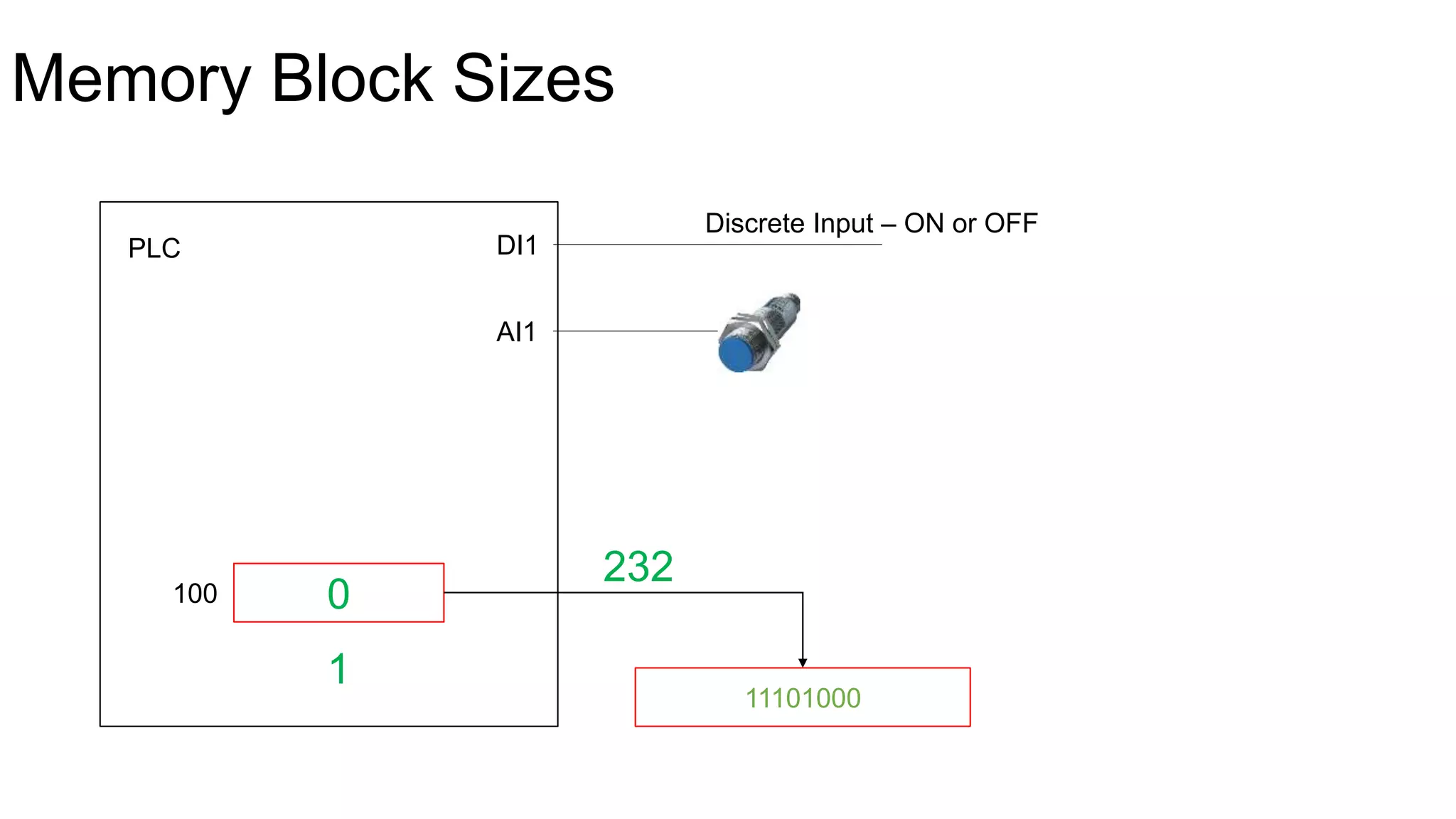

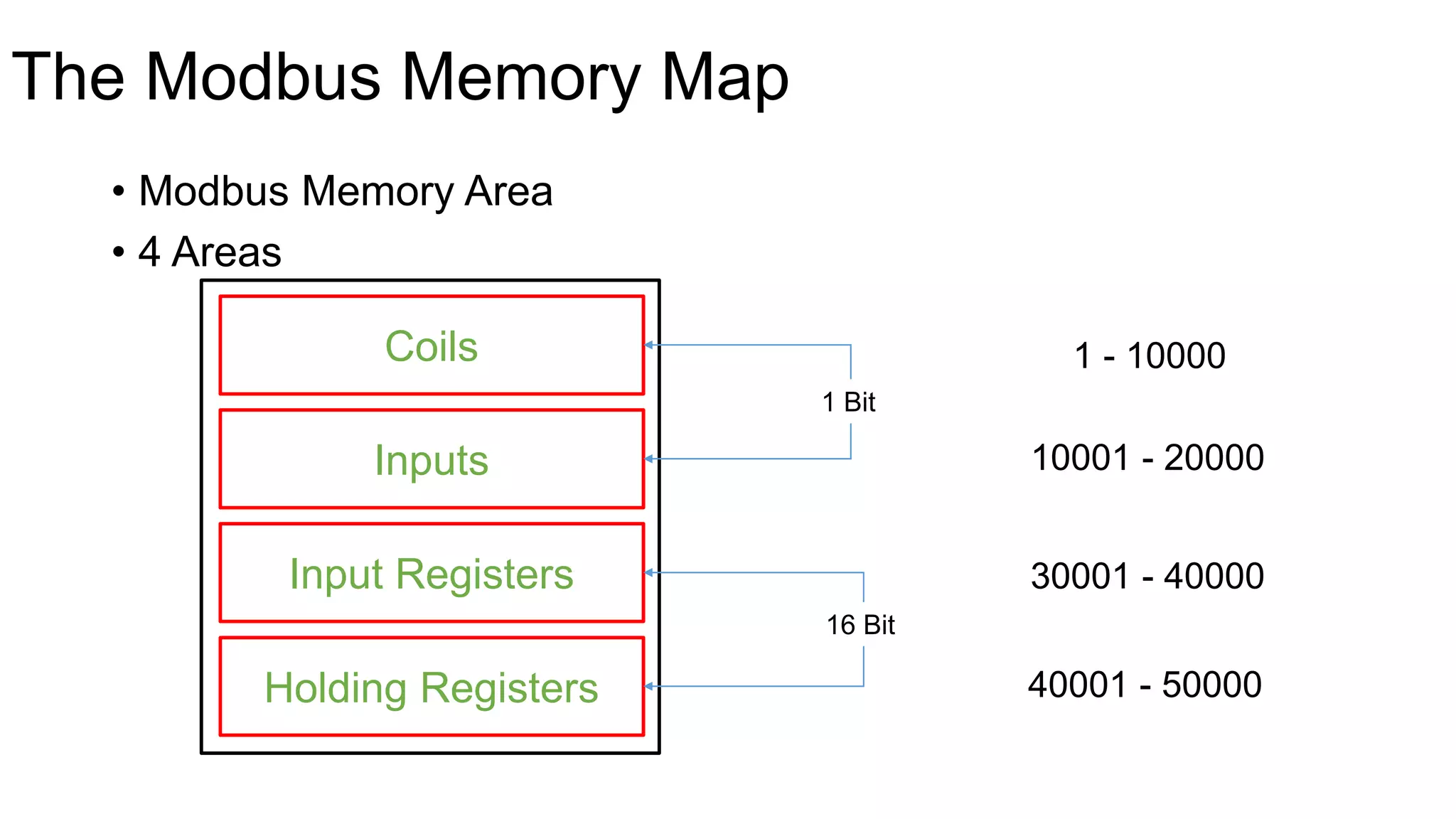

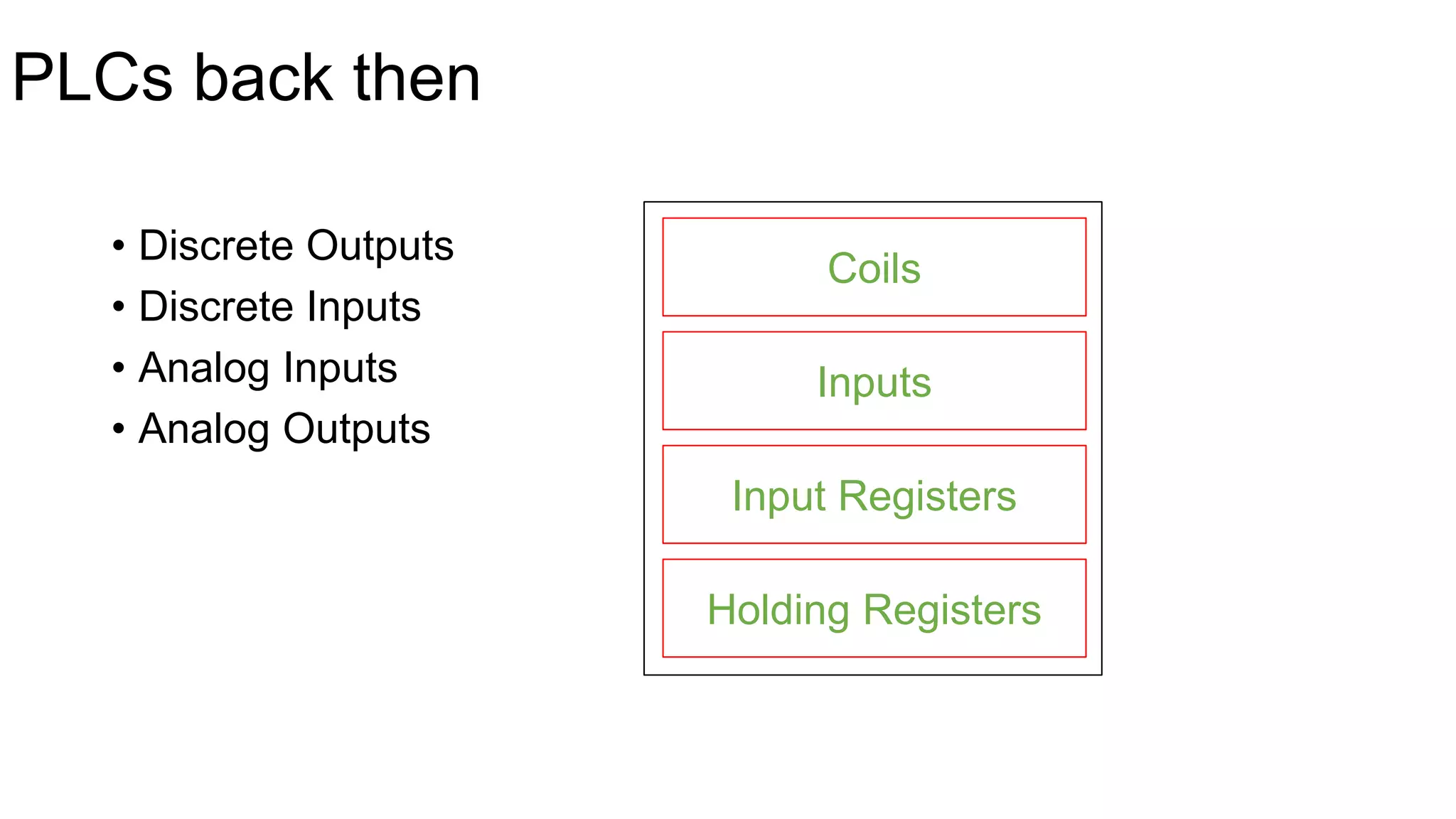

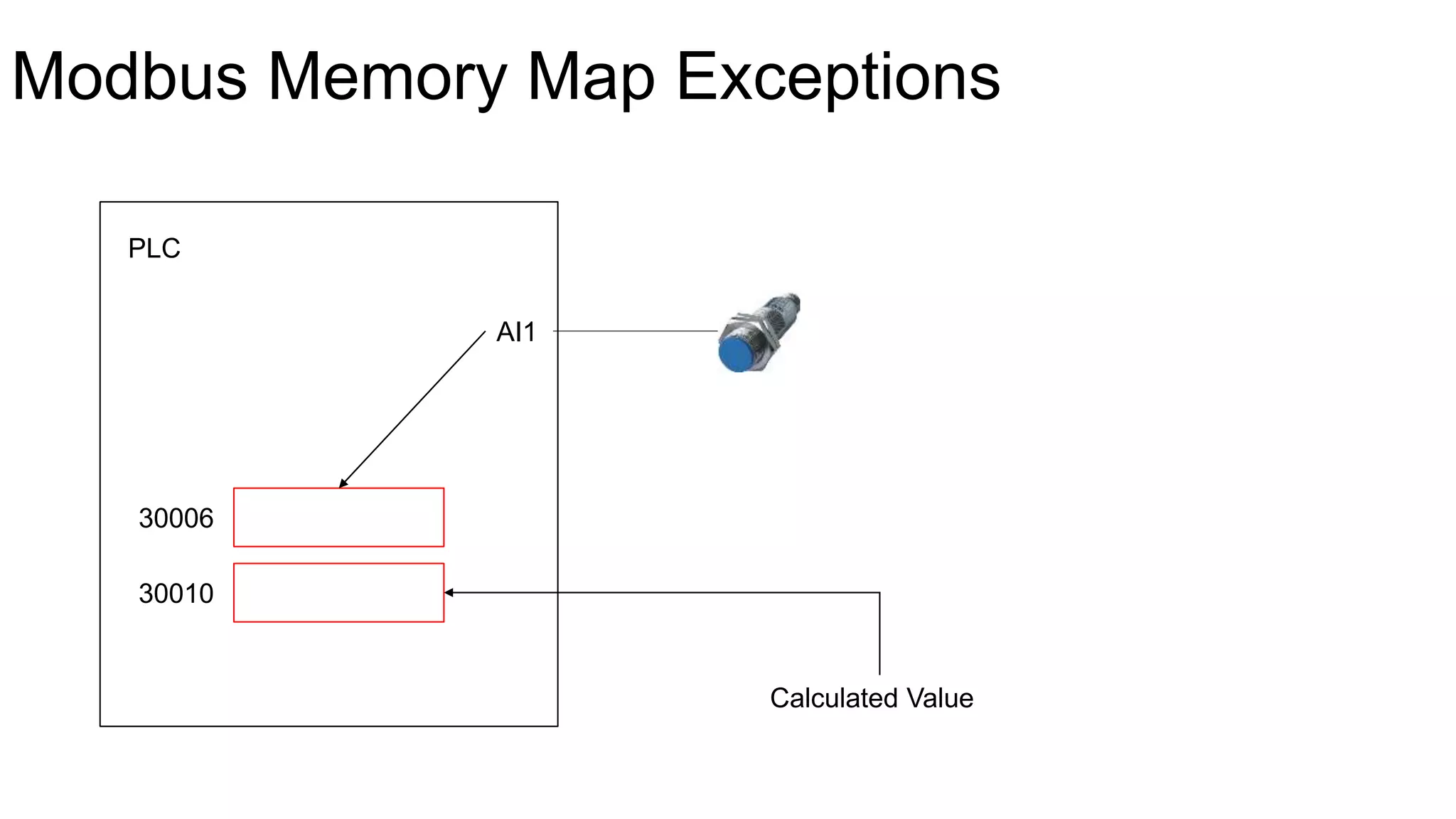

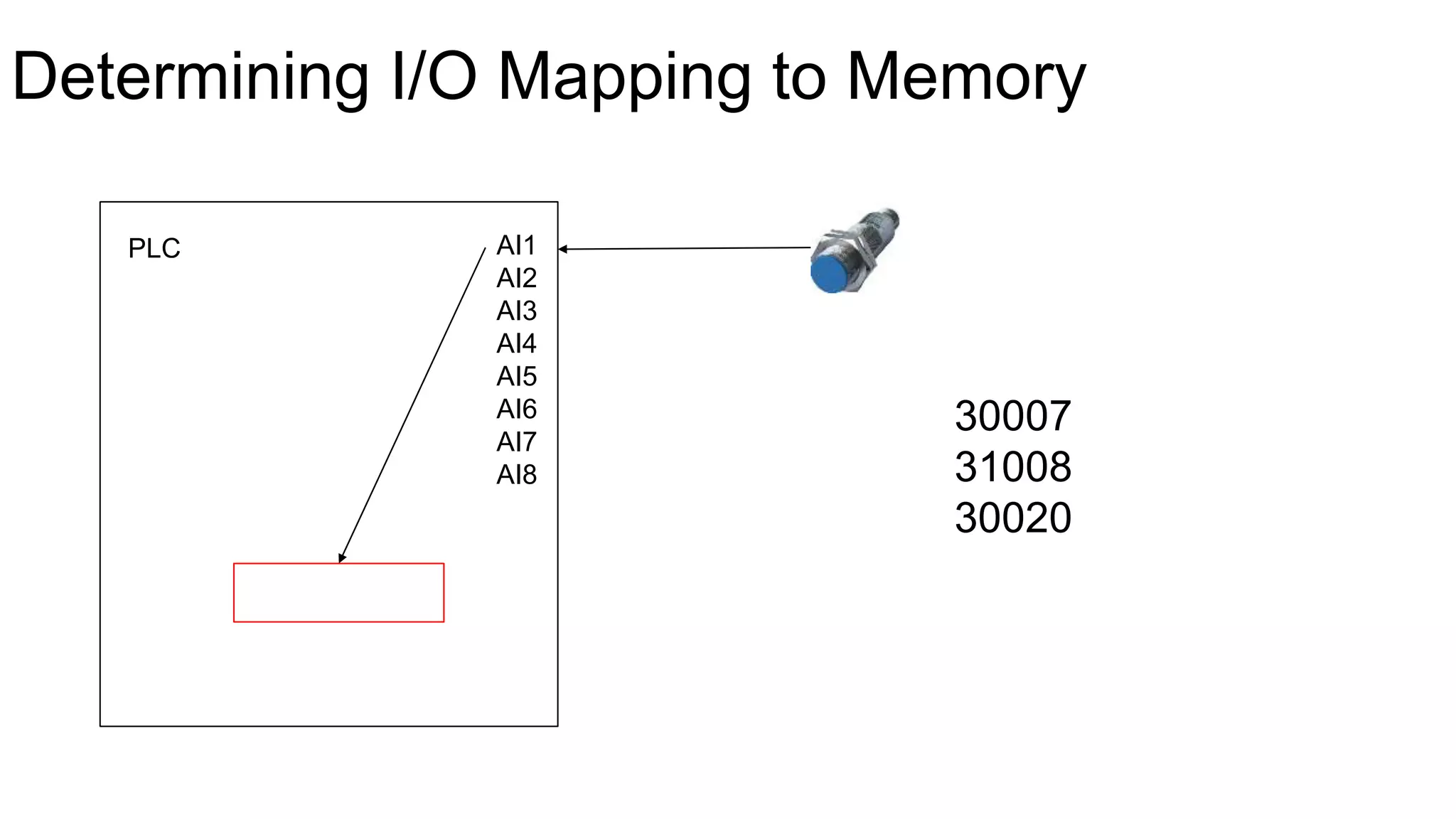

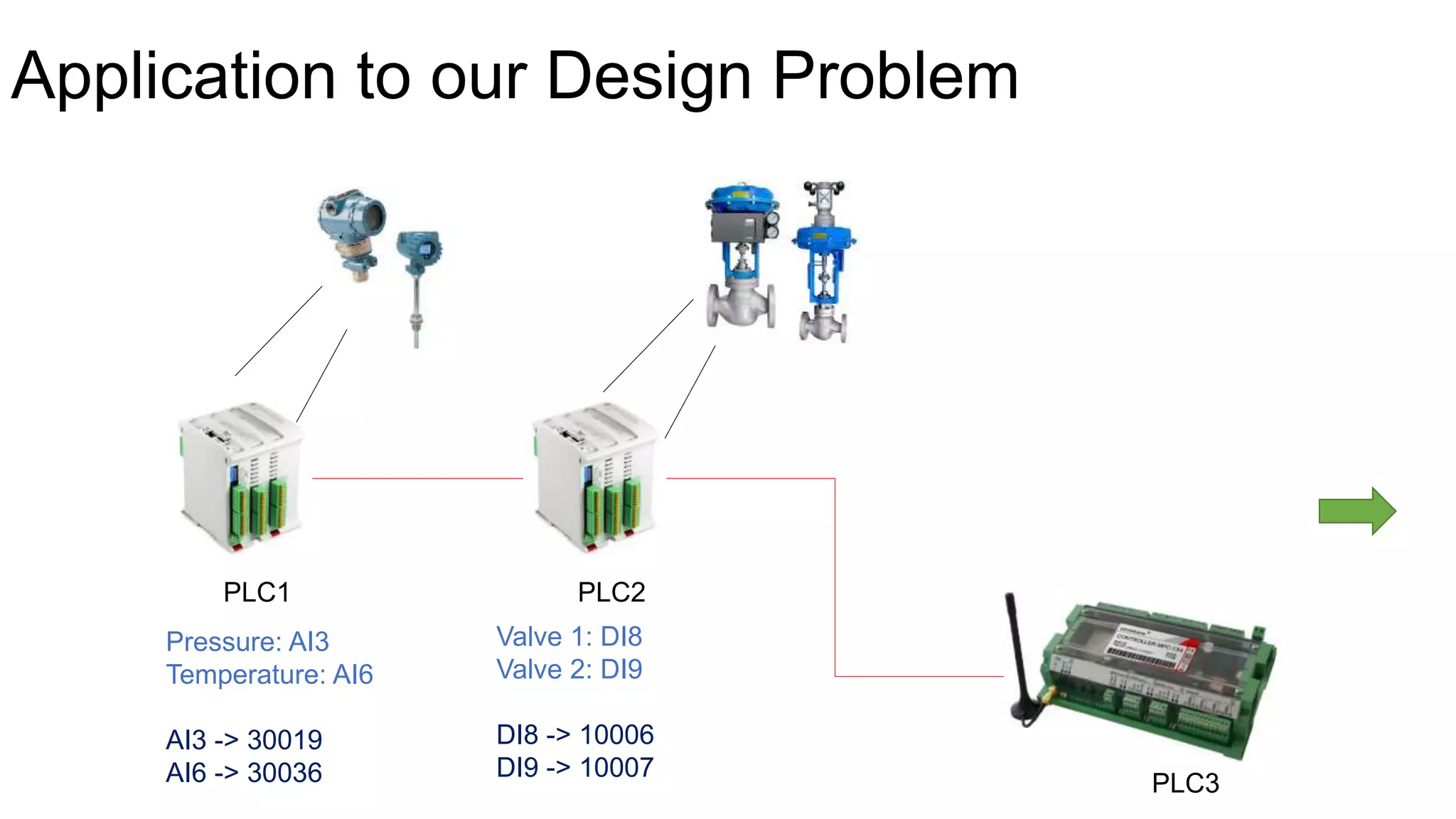

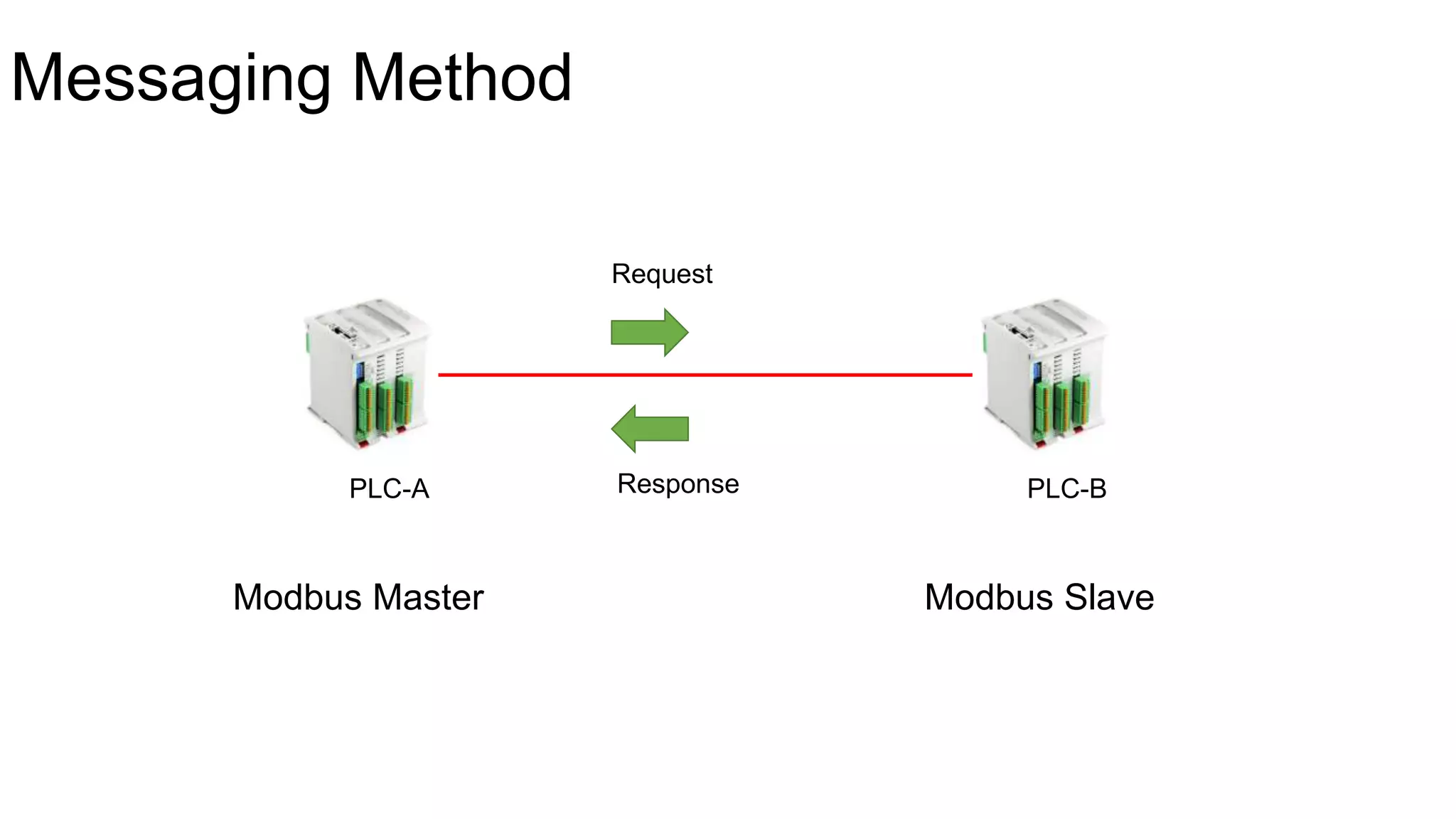

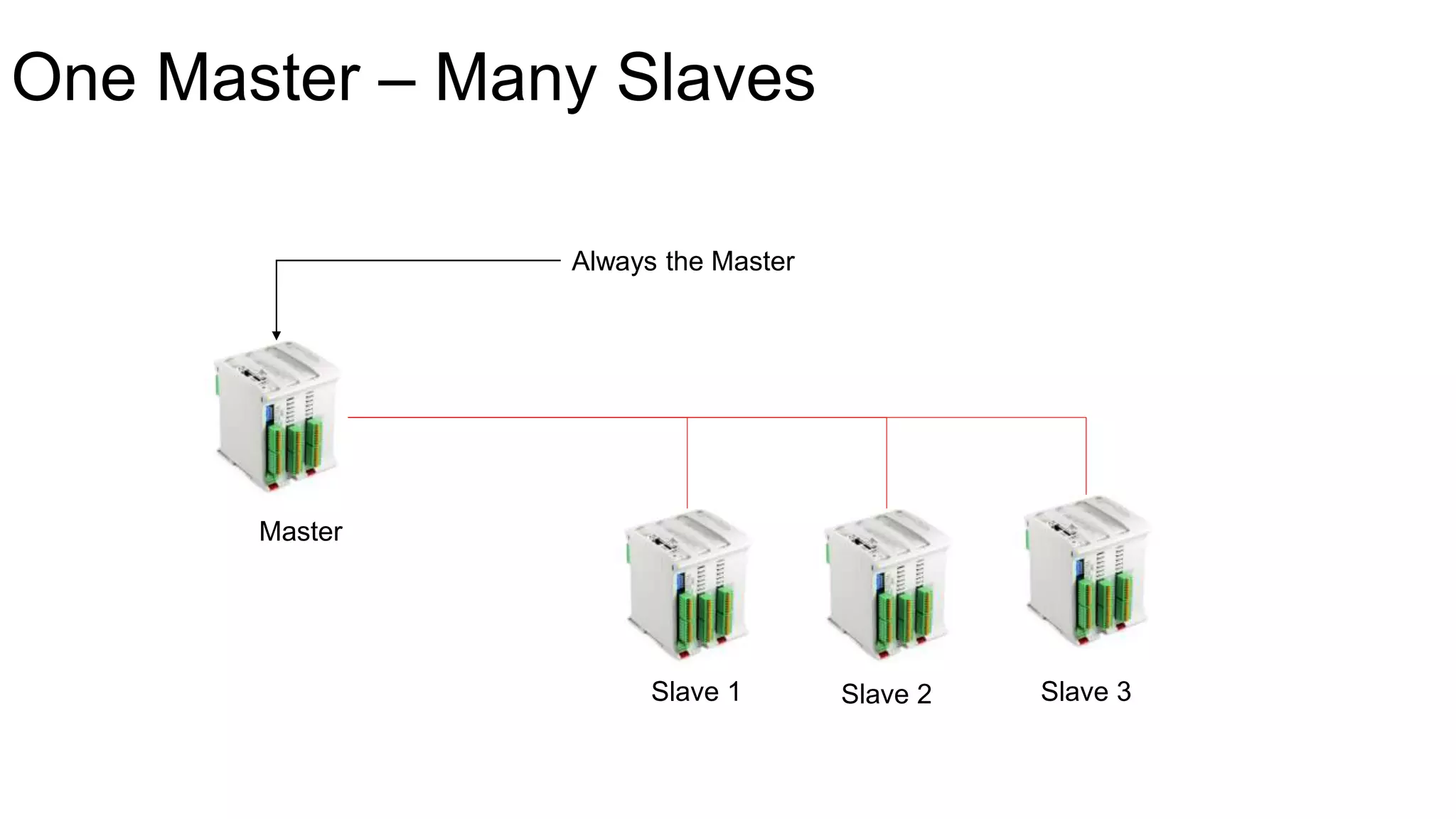

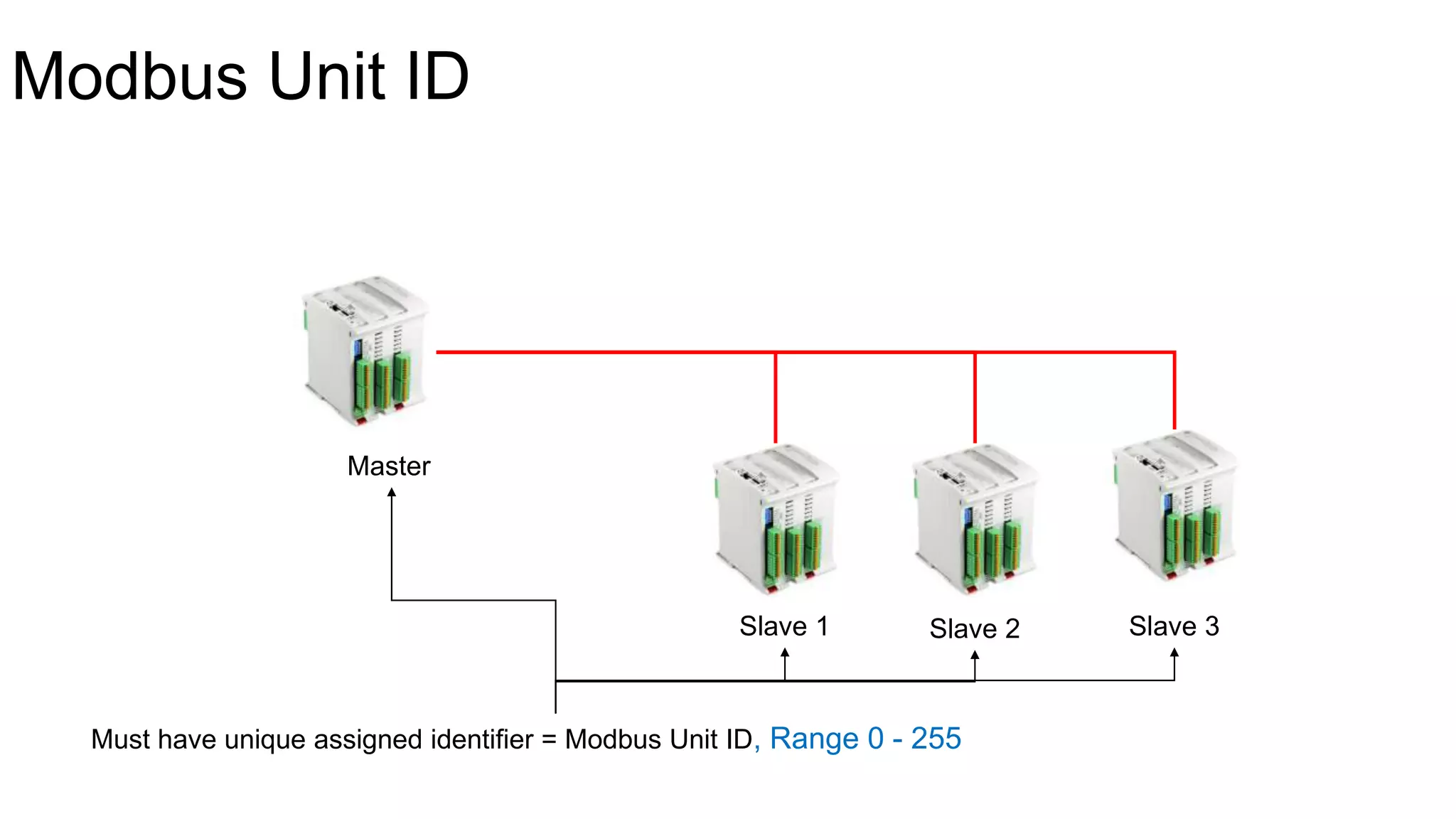

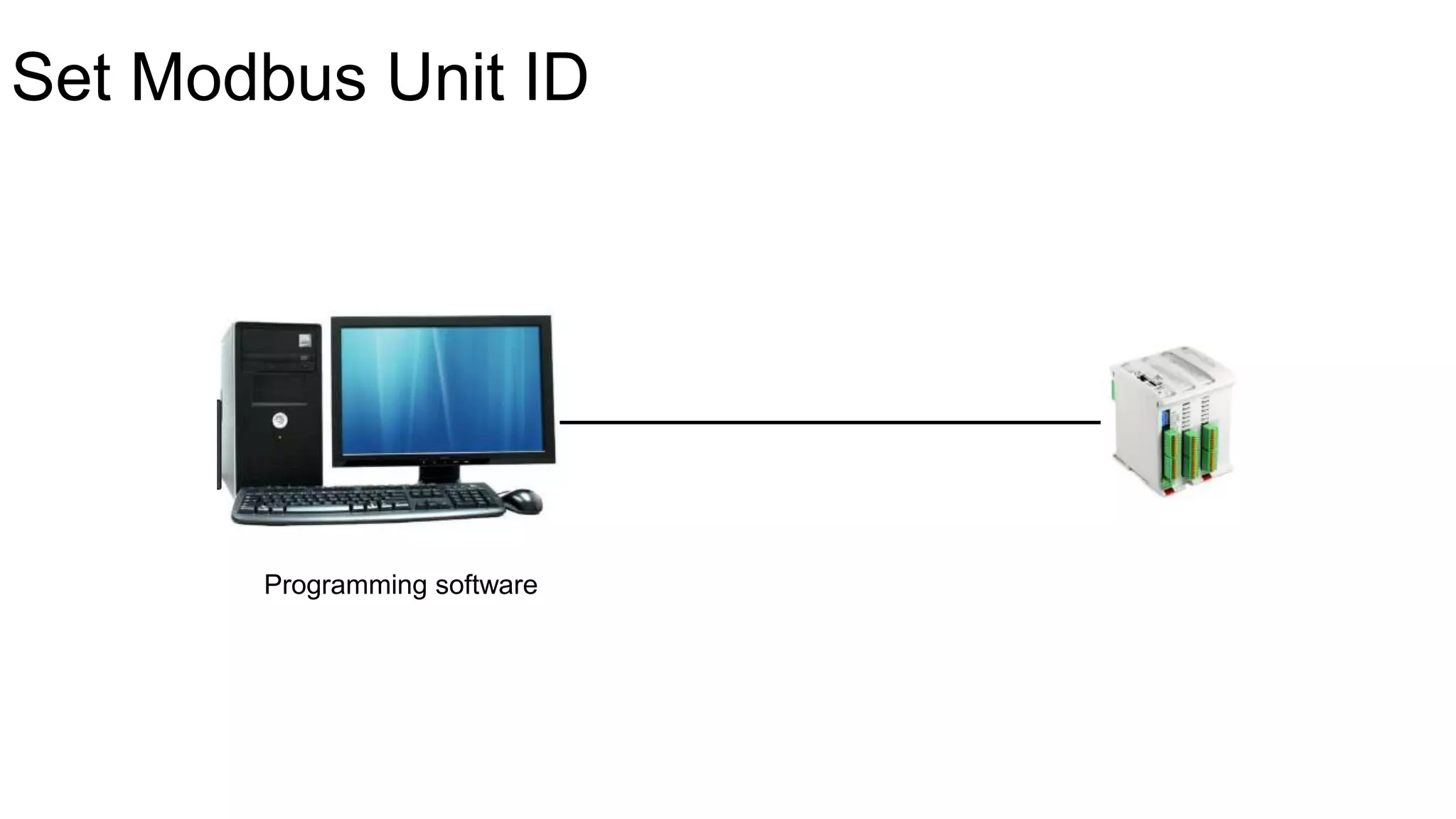

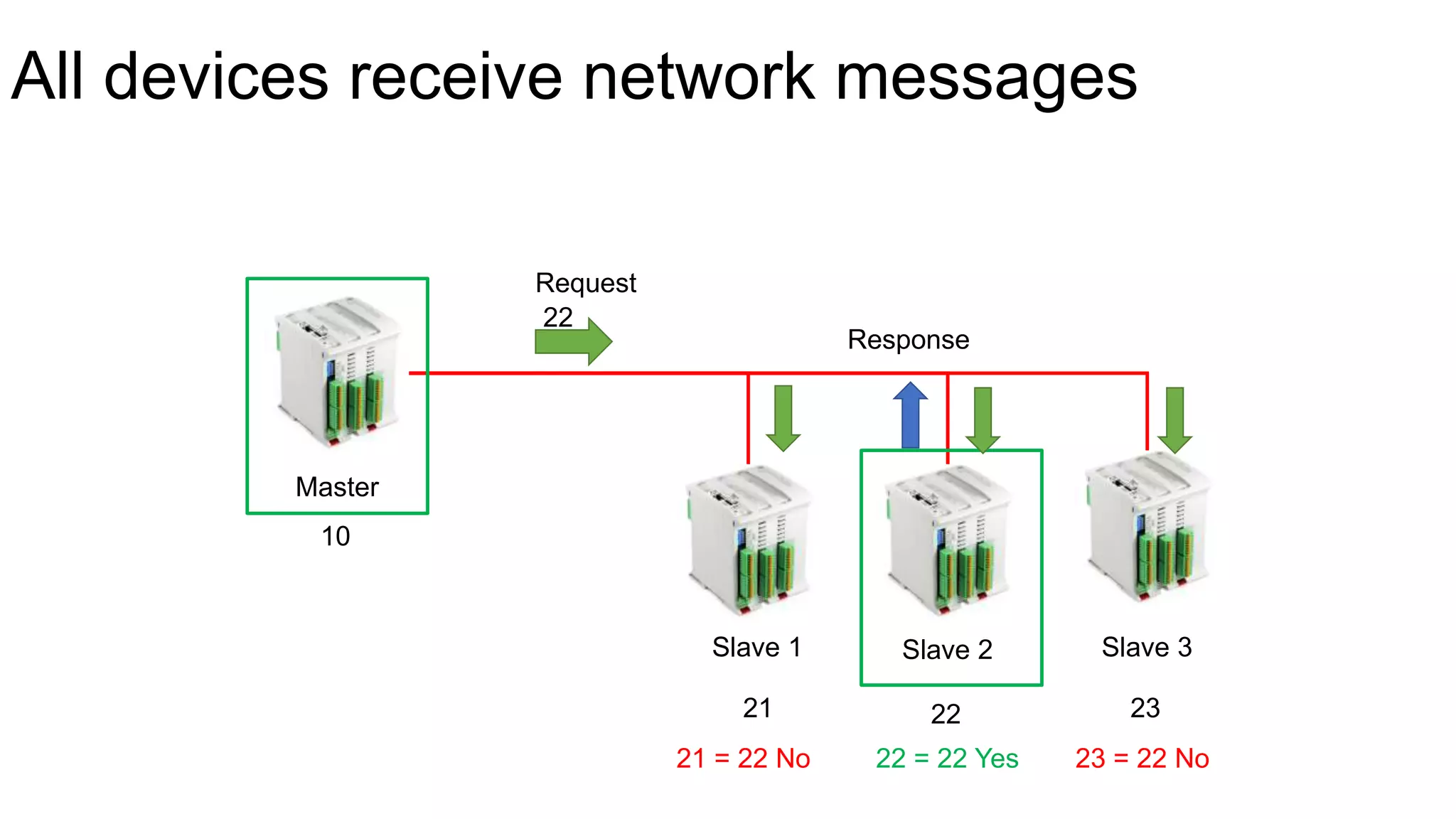

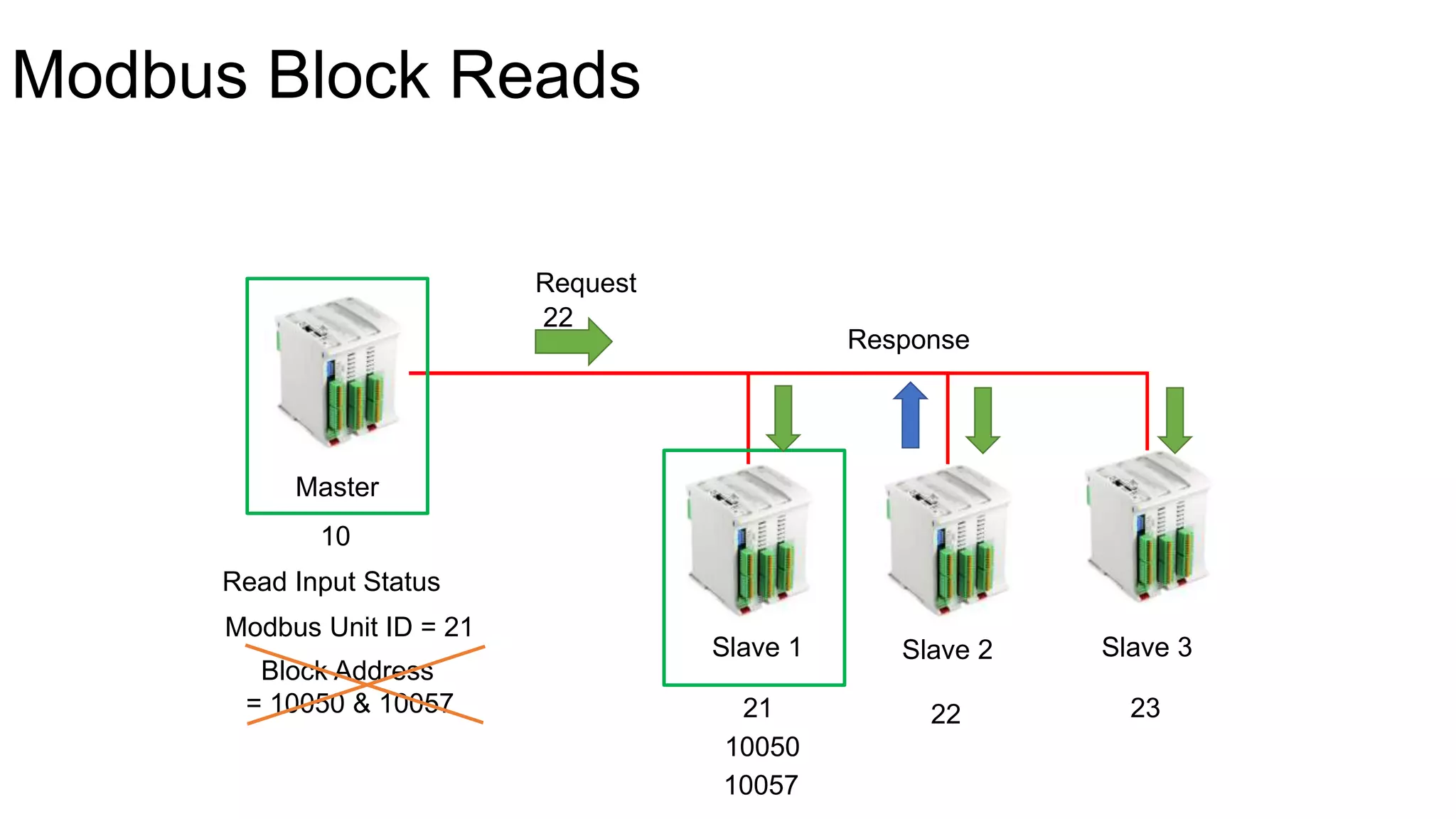

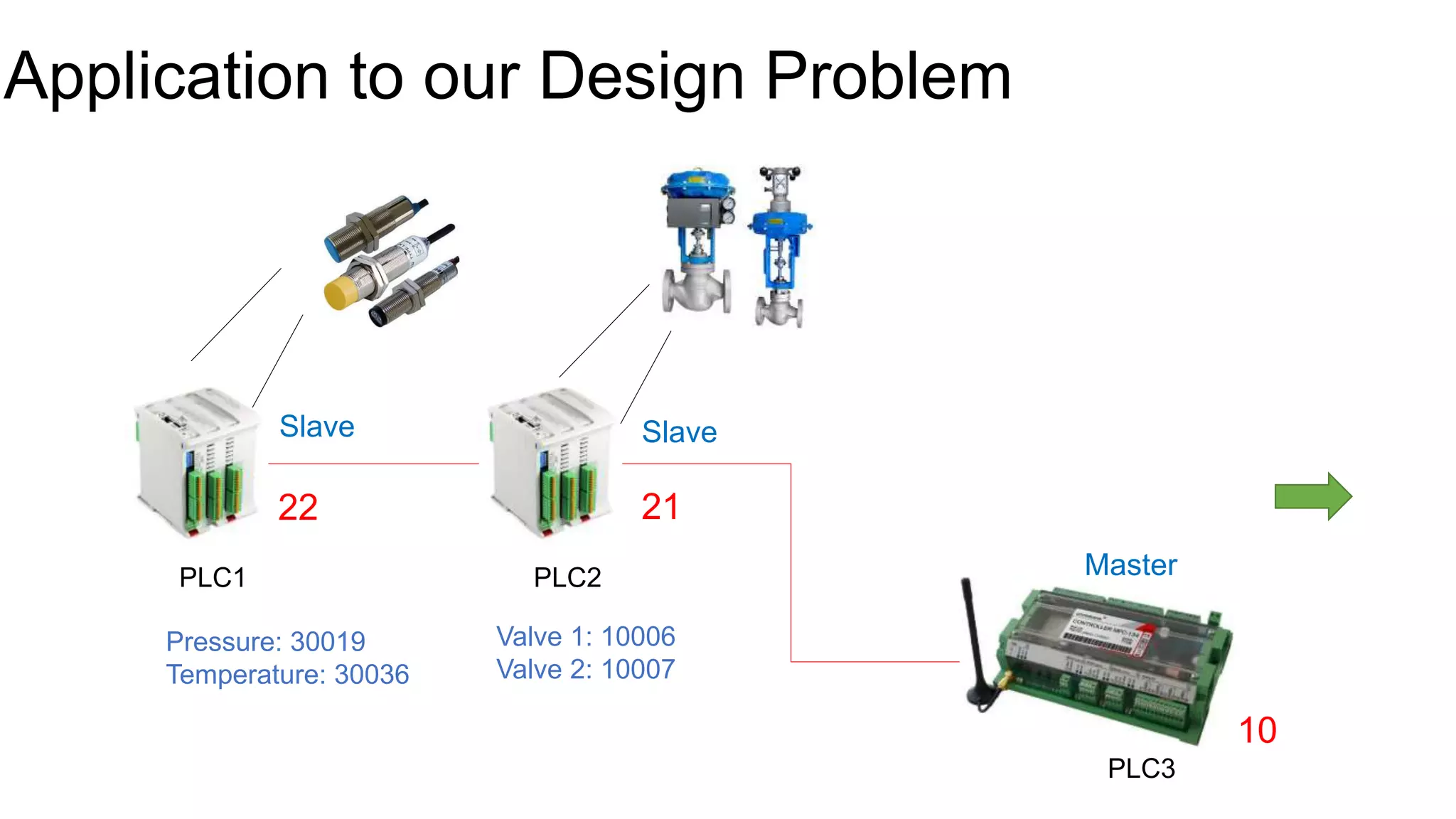

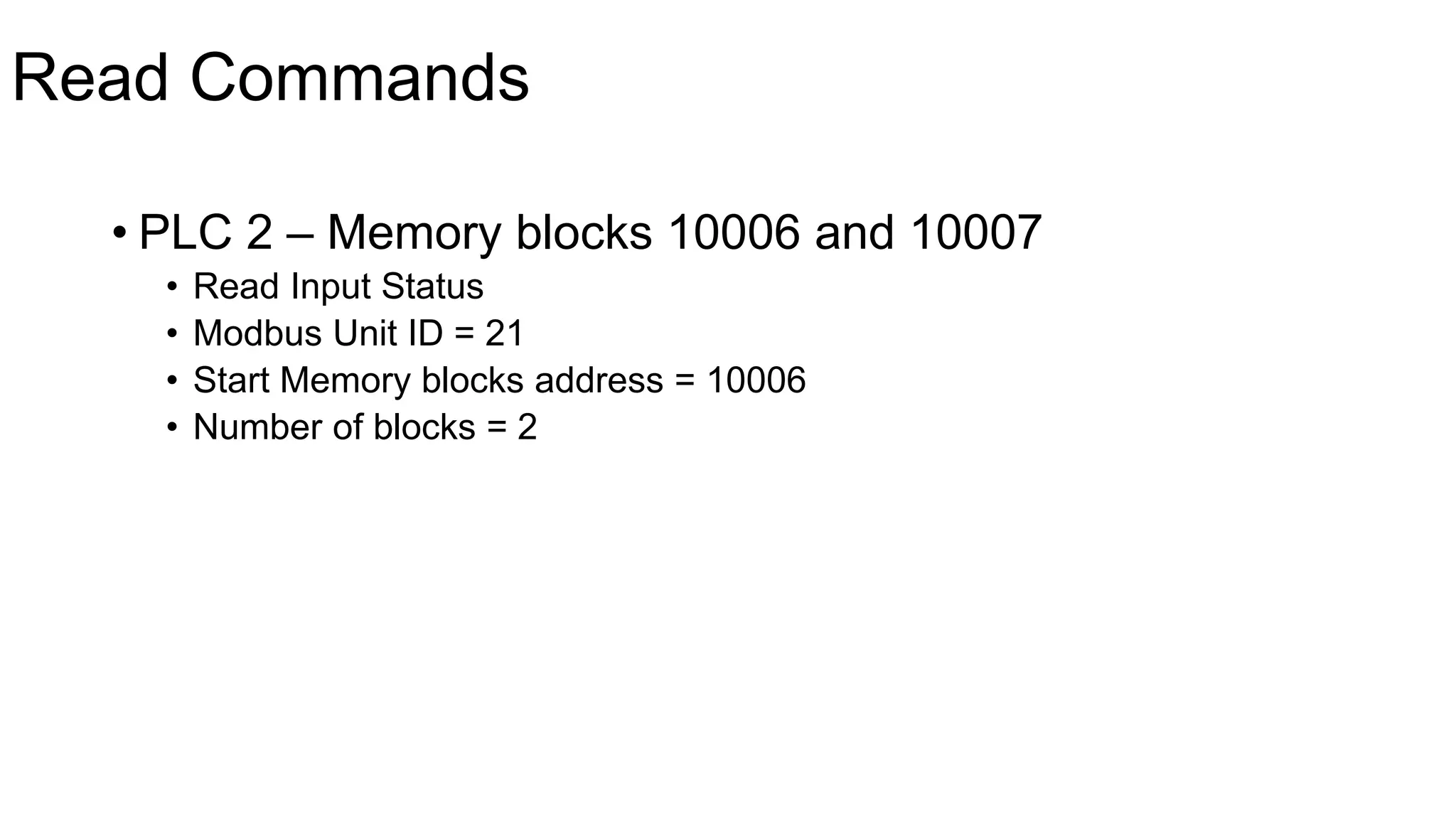

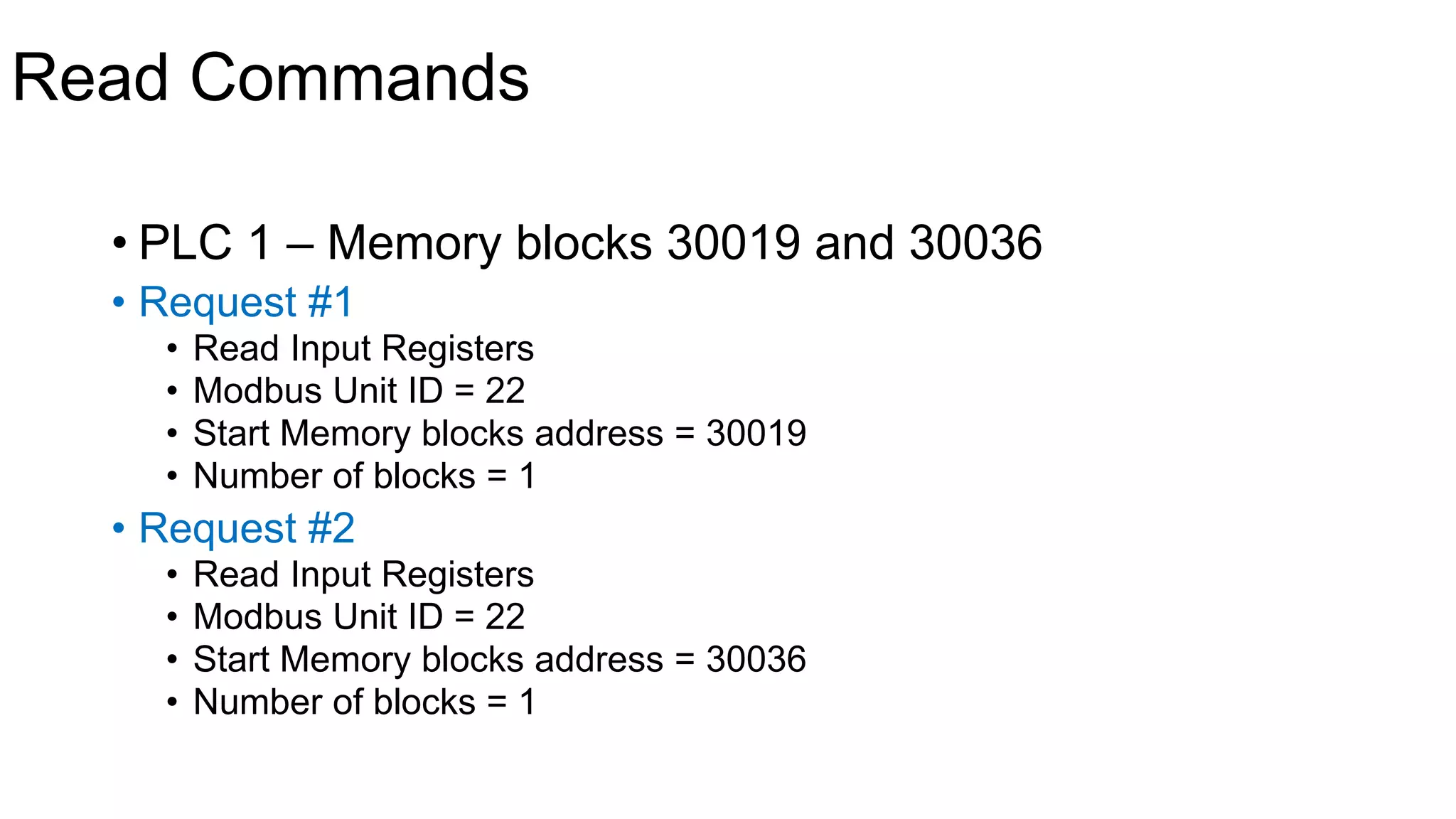

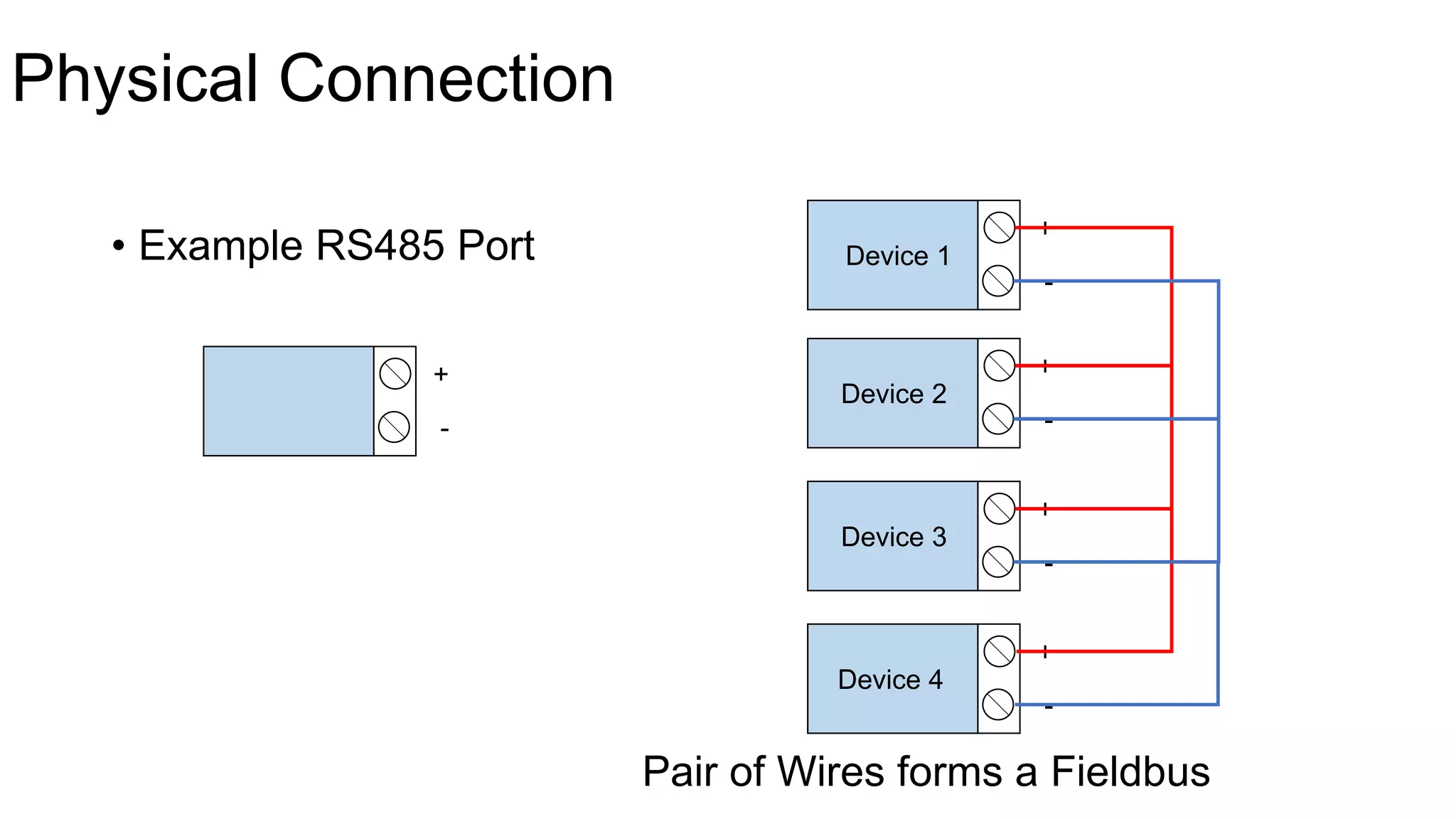

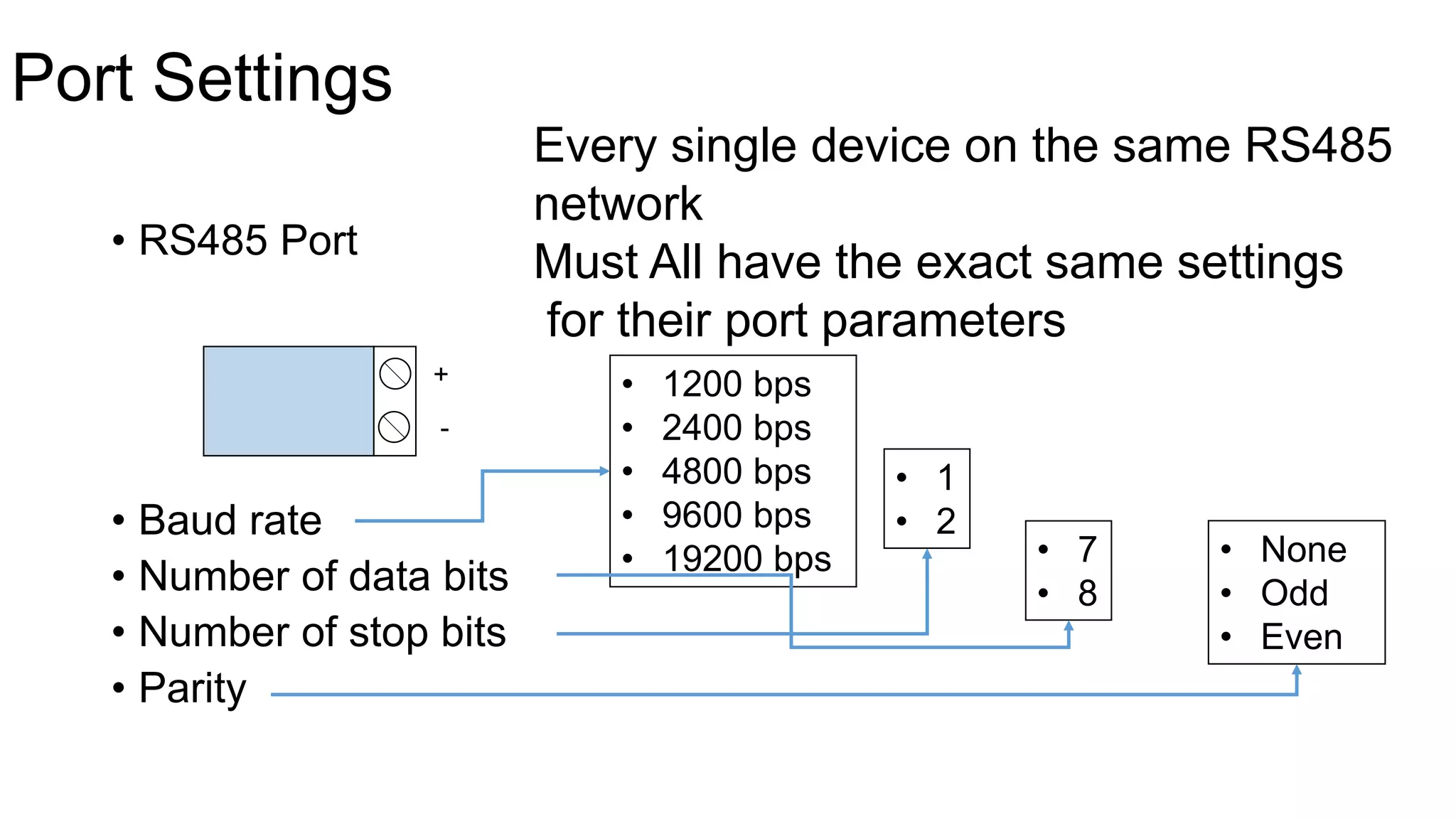

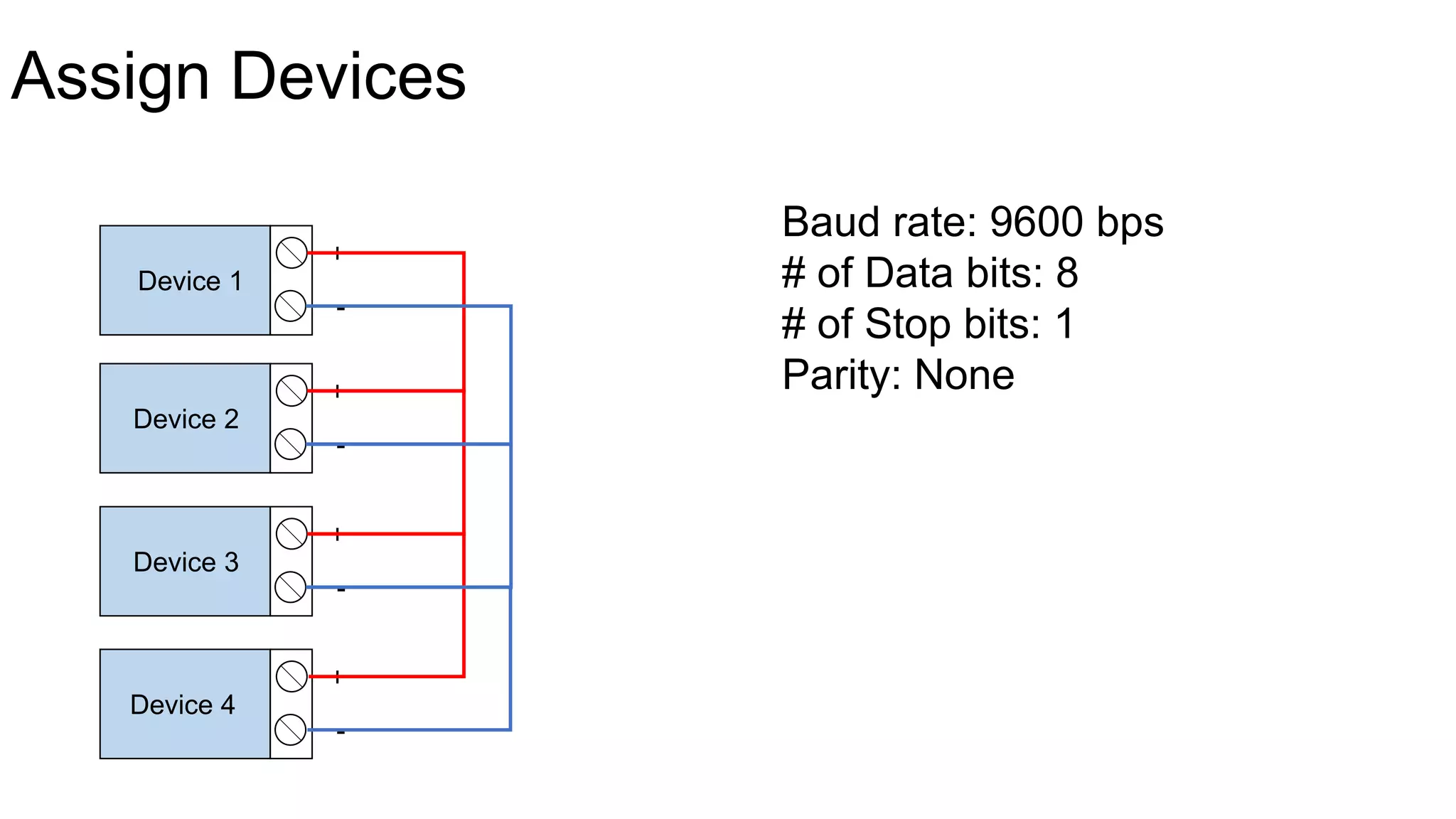

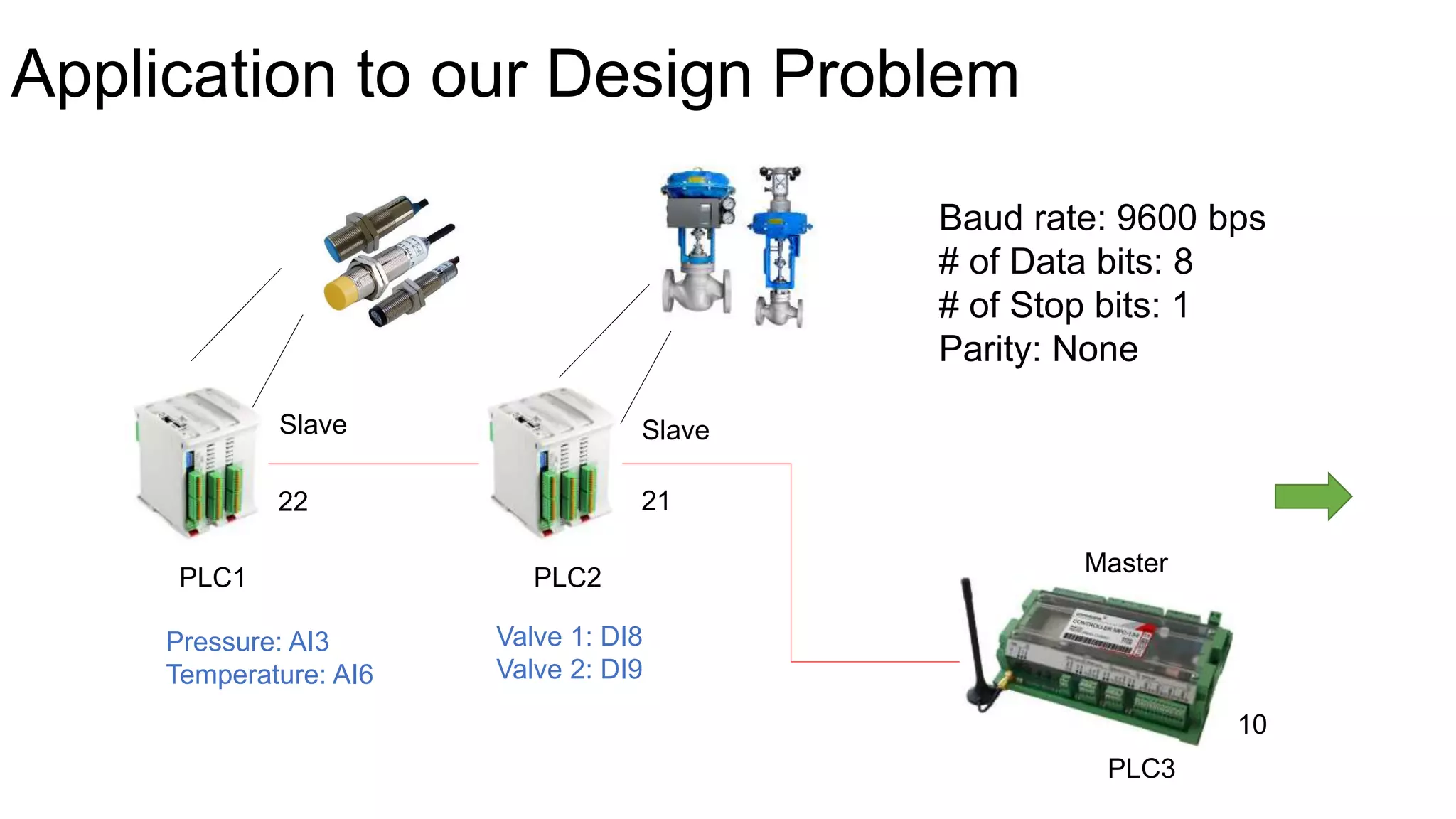

The document provides a comprehensive overview of the Modbus RS485 protocol, detailing its history, features, and application in various industrial devices such as PLCs and RTUs. It explains the differences between Modbus RTU and ASCII, the structure of Modbus memory, and the messaging methods used in Modbus networks. Additionally, it covers the setup and configuration considerations necessary for implementing an RS485 network, emphasizing the importance of consistent port settings across devices.