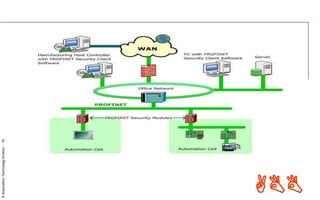

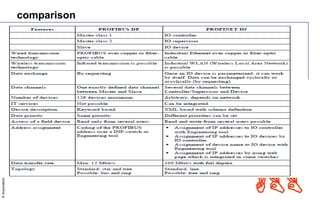

PROFIBUS and PROFINET are fieldbus communication protocols, with PROFIBUS being the older standard developed over 25 years ago for industrial automation applications. PROFIBUS is suited for high-speed synchronized applications like robotics, while PROFINET is an newer standardized Industrial Ethernet protocol that provides high-speed deterministic networking capabilities. Both support masters and slaves to control data exchange, with PROFIBUS having variants like DP, PA, and FMS and PROFINET using IO and CBA function classes to distribute devices and applications.