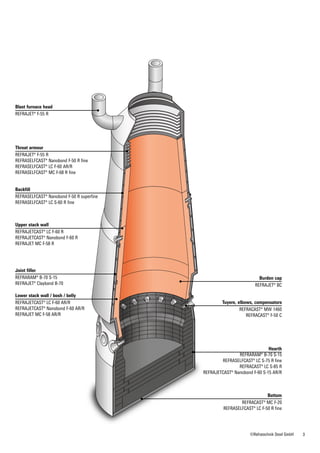

Refratechnik Steel GmbH specializes in high-performance lining solutions for blast furnace stacks, focusing on installation time and material selection. The company offers a variety of products, including cement-bonded and cement-free jetcasting materials, to meet the modern demands of blast furnace operations with minimal costs and maximum quality. With over 60 years of experience, Refratechnik is committed to providing optimal customer service worldwide.