project roller bender

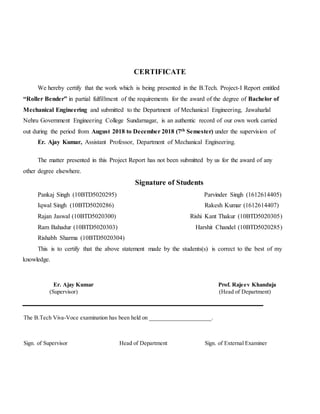

- 1. CERTIFICATE We hereby certify that the work which is being presented in the B.Tech. Project-I Report entitled “Roller Bender” in partial fulfillment of the requirements for the award of the degree of Bachelor of Mechanical Engineering and submitted to the Department of Mechanical Engineering, Jawaharlal Nehru Government Engineering College Sundarnagar, is an authentic record of our own work carried out during the period from August 2018 to December 2018 (7th Semester) under the supervision of Er. Ajay Kumar, Assistant Professor, Department of Mechanical Engineering. The matter presented in this Project Report has not been submitted by us for the award of any other degree elsewhere. Signature of Students Pankaj Singh (10BTD5020295) Parvinder Singh (1612614405) Iqwal Singh (10BTD5020286) Rakesh Kumar (1612614407) Rajan Jaswal (10BTD5020300) Rishi Kant Thakur (10BTD5020305) Ram Bahadur (10BTD5020303) Harshit Chandel (10BTD5020285) Rishabh Sharma (10BTD5020304) This is to certify that the above statement made by the students(s) is correct to the best of my knowledge. Er. Ajay Kumar Prof. Rajeev Khanduja (Supervisor) (Head of Department) The B.Tech Viva-Voce examination has been held on ____________________. Sign. of Supervisor Head of Department Sign. of External Examiner

- 2. CONTENTS CERTIFICATE ACKNOWLEDGEMENT ABSTRACT LIST OF FIGURES LIST OF TABLES Chapter-1 INTRODUCTION 1.1 Need and Significance of Proposed Project 1.2 Objective of The Project 1.3 Expected Outcomes Chapter-2 LITERATURE REVIEW Chapter-3 CONSTRUCTION AND SPECIFICATION Chapter-4 CONCLUSION AND SCOPE OF FUTURE WORK REFERENCES

- 4. ACKNOWLEDGEMENT This acknowledgement is a humble attempt to earnestly thank all those who were directly or indirectly involved in preparation of this synopsis report. In particular we are thankful to our guide Er.Ajay kumar who guided us in our project work. We are thankful to him for taking active part in the preparation of our synopsis report. It was impossible to present this report without his co-operation and suggestion. Last but not least we would like to express out deep sense of gratitude to all the faculty members of Mechanical Engineering

- 5. ABSTRACT Roller Bender is used to bend a metal sheet, plate and pipe. The aim of this project is to develop a portable metal bender. It is used to bend sheets into curve and the other curvature shapes. The size of bender is very small as compare to other machines. And it is convenient for portable work. It is fully made by MS. And it is the easy to be carry and use at any time and any place. It eases human effort and no required skill workers to operate the machine. We are developing manually operated metal roller bender with use of metal shaft, hydraulic bottle jack, pedestal bearing and support (frame). This machine works on simple kinematic system instead of complicated design. This machine can bend up-to 8 mm thick sheet and up-to 2cm diameter of pipe. Due to its light weight and it is portable so it can be used by small workshop, fabrication shop, small scale industry etc. Roller bender is a common machine in machine shop that is used to bend a metal. There is no proper small scale roller bender for bending a pipe. A Metal Roller bender uses roller to bend metal. There are 3 roller used in bending machine. The common product of metal roller bender are pipe (square and circular) bending if separate attachment of die is provided, sheet bending. During the roller bending process the sheet or plate or pipe is passed through consecutive rollers that gradually apply pressure on pipe. Because of this pressure the change in radius of pipe or sheet occurs.

- 6. LIST OF FIGURE Fig. No Title ofFigure. Page No. 1.1 Rollerbender 2 1.2 Blockdiagramof roller bender 4 3.1 Base frame 7 3.2 Horizontal frame 8 3.3 Roller 9 3.4 Pedestal bearing 10 3.5 Hydraulicjack 11 3.6 Nutand Bolt 12 3.7 Cut piecesof girder 14 3.8 Cuttingof square cross- section 14 3.9 Frames 15 3.10 Drilling 16

- 7. LIST OF TABLES CHAPTER-1 INTRODUCTION Table No. Title ofTable. Page No. 3.1 Frame 7 3.2 Horizontal frame 8 3.3 Roller 9 3.4 Pedestal Bearing 10 3.5 Hydraulicjack 11 3.6 Nutand Bolt 12

- 8. Due to increasing globalization, it is very much essential for the manufacturer to produce a goods having highest reliability. Metal Bending and Rolling is generally used in fabrication as an alternative method for casting or forging operations. Since it is related to human being hence it is necessary to design the joint with prior attention to safely of its user. Generally Bending is a process that produces U-shape, V-shape, or channel shapes in ductile materials, most commonly in sheet metal as per requirement on different types of bending machines. As we have studied bending is also called as flexure which characterises the behaviour of structural element when subjected to external load applied perpendicularly to a longitudinal axis of the element. A beam is an element whose length thickness and width is smaller than the length. A shell is a geometric structure in which width and length are of same magnitude and the thickness of this geometric structure is smaller. There are two different machines available in market for bending of sheet and bending of pipe. There is no single machine available which bends sheet as well as pipe in a single unit. Roller bending process can be used to deform a sheet or plate. Cylindrical shells are the basic components used for the various engineering applications like boiler chambers, cylindrical tanks, heat exchanger shells, pressure vessels, etc. The process can be performed using many materials such as carbon and alloy steels, aluminium alloys and titanium alloys. Rolling machines with both three rollers are used to produce of cylinders with various curvatures. The rolling process is generally performed by a three roll roller bender often called as pyramid type, because of these types of arrangement of the three rollers. The process mainly consist 3 steps: 1) Positioning of the sheet or pipe. 2) Lowering of central roller. 3) Repeating feed of sheet or pipe. In first step, a flat blank sheet is fed into the machine by two rotating side rollers until the sheet is properly positioned. In the 2nd step, centre roller is displaced downward causes bending of the sheet. In the final step, two side rollers rotate again, so that the sheet is bending continuously the rolling process always starts with the crucial operation of pre-bending both ends of sheet. The success of 3 roller bending process is depends on the experience and skill of the operator. Rollerfor Bending of pipe

- 9. To give the required shape and size, roller is used. Primary function of the roller is to achieve angular shape to the pipe. This is done through screw which apply pressure on roller and also this roller achieved rolling action by using Bearings. Fig no 1.1 Diagram of Roller Bender

- 10. 1.1 Needand Significance ofRoller bender The reason to design a roller bender for pipe bending is because there is no proper roller bender to bend a metal pipe for small scale. The bending machines found in the market come from variety of types. There are roller bender such as press brake bending machine, roll roller bender and a folding machine. Moreover, the design for the roller bender for pipe bending is to bend a metal pipe. It produces sheet metal bending with desire degree of bending except 90°. Other reason regarding to the roller bender design, the roller bender in the market come with big size and is expensive. The existing roller bender in the market is created for huge capacity for bending a metal pipe. With the capacity of roller bender that exists in the market, the existing roller bender is not fulfilling the requirement of the usage. The requirement of operation of roller bender is simple. Thus it is not suitable to purchase existing roller bender to be used for simple roller bending operation. Also, the machine is heavy and use up a lot of space. In addition, the problem will arise when to move and put the roller bender due to heavy and space. Functions 1. To bend a pipe having thickness up to 5 mm in required angular shape. 2. To provide curvature shape to pipe. 3. Machine is convenient for portable work. 4. The machine is power operated to achieve maximum accuracy in less time. Requirements 1. Roller should be very accurate and easy to handle. 2. The effort required to bend pipe should be minimal. 3. The rolling attachment should also provide directional stability. This implies that the pipe should have a tendency to move too & fro. 1.2 Objective ofRollerBender To bend metal sheet and pipe in one system. To operate the system hydraulically. To provide curvature shape to pipe. Machine is convenient for portable work. To ease the operation in small scale industries.

- 11. 1.3 ExpectedOutcomes The Roller Bender will be able to bend different types of pipe cross-sections like rectangular, square, circular, angular etc. with the minimum efforts. It will be cost effective as compared to the bender available in the market. It is simple in design and hence require less floor space. Fig no 1.2 BLOCK DIAGRAM OF ROLLER BENDER CHAPTER-2

- 12. LITERATURE REVIEW 3.1 INTRODUCTION This literature is about the work of designing a roller bender to bend a pipe. A bending is a process of giving curvature to a metal. The metal can be a sheet metal, tubes, square hollow, rod, and iron angle. This type of metal has its own thickness. The roller bender designer will take into consideration a number of factors including type of metal, type of the roller bender, power driven or manual and the size of the bending machine. P. S. Thakare et al, (2012)Proposed a model that, The paper dealt with manufacturing of pipes which use power operated sheet roller bender and manually operated sheet bending machine. It also includes limitations of manually operated bending machine. From the results of the paper the productivity of power operated roller bender is higher paper deals. P.G. Mehar et al, (2012) In his M. Tech Thesis studied the manually operated and power operated sheet bending machine. Experimentations were conducted on sheet in order to measure actual no. of passes, time required to complete bending process etc. Also, productivity of sheet bending process is analyzed in depth. Design of various components of power operated sheet considering various theories of failure in elastic region and values for bending force, power required, spring back radius etc. for different diameters, thicknesses and width of sheet metal has been determined V. Senthil Raja etal, (2014)Author told in recent year’s pipe roller bender was used in both industry and domestic purpose for bending the pipe under the required angles and dimensions. Sometimes Heat treatment is used for pipe bending but the heat treatment technique is not safe and have problems are produced in the pipes, such as wrinkling, curve forming, reduced thickness, whole forming, reduced strength, easy breakable. In the hydraulic pipe roller bender having good advantage compared to heat treatment method. H. A. Hussainetal, (2014)Designed a machine which was a bicycle integrated pipe bending mechanism was designed and developed. The applications of bent pipes are in frames, barricades, handle of bicycle. Most of industries uses bent pipes as air conditioning, boiler, power generation, ship building, furniture, railroad, automotive, off-road and farm equipment, aircraft etc. Due to adequate human power in countries like India, the human powered machine will result in improvement of the economy and employment of nation. In Asian countries people are facing electricity cut-off during most of the days so such system plays an important role in rural areas.

- 13. Mohan Krishna S. A. et al, (2014) Proposed model that, Hydraulic equipment has wide use in various automobile fields. These hydraulic instruments are used for lowering and raising chair in Barber shops and in dental clinics. Hydraulic roller the suitable equipment to bend pipes, rods and bars. The pipe or rod to be bending is kept between the rollers. With use of hydraulic jack we implement force on the pipe and bend it to the required angle depending on the dies used. Hydraulic roller bender is less expensive, flexible and portable compared to those which are discussed earlier. Hence it is better to replace current standard machines by hydraulic pipe bending machine. MaheshGadekaretal, (2015)Proposed a report that , Metal forming is a process in which the desired shape and size are obtained through plastic deformation of a material without any loss of material. Bending is a metal forming process in which straight length is transformed into a curved length. Roller forming process is a continuous bending operation in which a long strip of metal is passed through typical roller adjustments, until the desired curvature shape is obtained. The bending changes according to material and according to the loading condition and thickness of sheet. Prashant P. Khandare et al, (2016) The main aim of this paper was to develop a pipe roller bender which was useful to bend a pipe in workshop. This project was to design and construct a portable pipe bending machine. This machine was used to bend steel pipes into curve and the other curvature shapes. The size of machine was very convenient for portable work. It was fully made by steel. Moreover it was easy to be carry and use at any time and any place. It decreased human effort and required low skill labours for operating the machine. In this paper they designed manually operated pipe roller bender with use of gears, motors, pulley, and frame.

- 14. CHAPTER-3 CONSTRUCTION AND SPECIFICATION 3.1 SELECTION AND SPECIFICATION OF MATERIAL 1 Frame: A) Base Frame: The home girder of material of mild steel are selected for the frame. The pieces are cut into required size by cutting machine. The end of the pipes cut into 45 degree (angle) to form rectangular frame. After cutting, the end of the girder is grinded so that it became smooth and convenient for welding. The girder are welded together to form a required basic frame. Fig no 3.1 BASE FRAME Parameters of frame Parameters Values Length 2ft Width 2ft Height 1.5ft Table no 3.1

- 15. b) Horizontal Frame: Horizontal frame is the second frame after the base frame. It is rest on base frame and girders are cut at 45 deg. on the ends in order to weld all the girders properly. It consist of four pedestal bearings along with two rollers. It will only rest on base frame and remains stationary during whole bending process. Fig no 3.2 HORIZONTAL FRAME Parameter of Horizontal Frame Parameters Values Length 2ft Width 9inch Height 9inch Table no 3.2

- 16. c) Vertical Frame: It is the third frame which is vertical. In this there is only one pedestal bearing holding the one roller. It will be allowed to move in the vertical direction and guided by the angles in the vertical direction. Motion is given to it with help of hydraulic jack. 2 Roller In this project the roller is used to bend a pipe in angular shape. There are 3 rollers are used to bend a pipe in curvature shape. Roller is a cylinder that rotates about a central axis and is used in various machines and devices to move, flatten or spread something. A roller always consist a bearing. Fig no. 3.3 Parameters of Rollers Parameters Values Diameter 30mm Material Mild Steel Table no 3.3

- 17. 3 Pedestal bearing: Pedestal bearing are used to give easy and convenient motion to roller by using shafts which is attach to roller. It is also known as pillow block bearing. Fig no 3.4 Pedestal bearing Parameters of Pedestal Bearing Parameters Values Internal dia. 30mm External dia. 84mm Table no 3.4

- 18. 4 Hydraulic jack: A jack, screw jack or jackscrew is a mechanical device used as a lifting device to lift heavy loads or to apply great forces. A mechanical jack employs a screw thread for lifting heavy equipment. The jack used in this project is Hydraulic Jack which lift the loads with help of the hydraulic fluid. It reduces efforts required to lift the load. Fig no 3.5 HYDRAULIC JACK Parameters of Hydraulic Jack Parameters Values Load Capacity 3tonn Table no 3.5 5 Hand wheel:

- 19. It is nothing but a rotary wheel of round pipe to give rolling action to rollers manually. When we rotate the wheel, a torque is applied on it to pass the sheet and pipes under it. This hand wheel is attached with one the 3 rollers and used to rotate roller manually. It is larger in size in order to reduce the efforts to rotate it. 6 Angles: Angles are used to guide the outermost vertical frame in the vertical direction for the motion. It will avoid any kind of deviation of vertical frame from its path. Angles are welded and bolted with the horizontal frame. 7 Nut and Bolt: Nut and Bolt are mainly used to attach pedestal bearing with the frames. Angles are also bolted with frames which guide the vertical frame. Fig no 3.6 NUT AND BOLT Parameters of nut and bolt Parameters Values Diameter of bolt 12mm Table no 3.6 FABRICATION

- 20. Fabrication of Roller Bender is carried out in the different steps which are mentioned below: I. Cutting of basic frame (girder) according to required dimension with the help of cutter or gas welding. II. Grinding of the edges of the girder. III. Drilling of holes in the basic frame for the movement of bearing. IV. Welding of the girders according to design (arc welding). V. Then fixing bearing in the frame with help of nut & bolt. VI. Then passing silver steel rods from bearing to check the alignment of the bearing. VII. Making arrangement for jack in base of girder on moveable side to lift the edge for bending purpose. VIII. Coloring of the project. OPERATIONSPERFORMED IN THE PROJECT: TO GATHER REQUIRED MATERIAL GIRDER/BEAM BEARINGS HYDRAULIC JACK FRAMES ASSEMBLY OF PARTS BY WELDING AND NUT BOLT OPERATING THE ROLLER BENDER RESULT/CONCLUSION

- 21. CUTTING In this project we have performed cutting operation on the girders. First of all the girders are cut with help of abrasive cutter and dimensions varies for every frame. For the base frame dimensions of girder is CUT PECICES OF GIRDER Fig no. 3.7 Fig no. 3.8 ARC WELDING After cutting all girders next operation is welding operation.

- 22. Arc welding is a process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals when cool result in a binding of the metals. It is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. We can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding region is usually protected by some type of shielding gas, vapour or slag. In this we have welded together all the cut pieces of girder with arc welding. This process leads to the formation of 3 frames i.e. 1) base frame 2) horizontal frame 3) vertical frame. BASE FRAME HORIZONTAL FRAME Fig no 3.9 DRILLING

- 23. Drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece, cutting off chips from the hole as it is drilled. A drill is a tool fitted with cutting tool attachment or driving tool attachment, usually a drill bit or driver bit, used for boring holes in various materials or fastening various materials together. Drilling operation is used to drill holes in the girders of horizontal and vertical frame. Holes are drilled to fasten nut and bolt in order to attach pedestal bearing with both the frames. Drilling is performed on the vertical column machine. Drilling Fig no 3.10 CHAPTER-4

- 24. CONCLUSION AND SCOPE OF FUTURE WORK 4.1 Conclusion Such type of roller bender more important for small scale work as well as industrial work in less cost and more precision and accuracy of different type of pipe bending. The machine capacity can be increased according to the need. Manual bending tends to minimize wrinkles and can reduce springbuck. By its design the defects can be easily overcome. Simpler design not only reduces the defects but also contributes to fluid pressure test during bending. It should be noted the tendency to wrinkle and the cross section of tube deformation are reduced. Thus, this approach can be used for bending a thin walled tube over a small radius of the die, which can be achieved with a conventional method of bending the tube. In this paper, the problem of bending and axial stretching the internal pressure is investigated using the machine coordinate system (CMM) measurement. The objective of the study is to develop a tool that accurately predicts the change of the wall thickness and the cross-section of the tube distortion under different loading conditions. 4.2 SCOPE FOR FUTURE WORK The scopes of the study are encompasses investigation of the difficulties in portable metal pipe bending machine. The investigation is starting with stating with the problem statements. The idea of designing a bending machine can be seen clearly through the problem statements, which is a solution of designing a bending machine can be generated to encounter those problems. From this investigation, a literature review can be conducted. In the literature review, it will discuss about the reason to design a bending machine for pipe bending, the comparison of existing bending machine, classification of bending machine, working principle of bending machine, etc. REFRENCES

- 25. [1] P. S. Thakare, P. G. Mehar, Dr. A. V. Vanalkar and Dr. C. C. Handa, “Productivity Analysis of Manually Operated And Power Operated Sheet Bending Machine: A Comparative Study”, International Journal of Engineering Research and Applications (IJERA), ISSN: 2248-9622, Vol. 2, Issue 2, Mar-Apr 2012, PP.111-114 [2] P. G. Mehar, P. S. Thakare, Dr. A, V, Vanalkar, Dr. C. C. Handa, “Productivity Analysis of Manually Operated and Power Operated Sheet Bending Machine: A Comparative Study”, International Journal of Engineering Research and Applications, Vol. 2, Issue 2, Mar-Apr 2012, pp.111-114. [3] V. Senthil Raja, R.Maguteeswaran, C. Karthik, S.Rajarajan and D. Shanmuga Vadivel, “A New Model in Design and Manufacturing of Mobile Hydraulic Pipe Roller benderin Industry”, International Journal of Engineering Research & Technology (IJERT), ISSN: 2278-0181, Vol. 3 Issue 1, January – 2014 PP 2706-2713 [4] H. A. Hussain, M. Sohail Pervez, Md. Naushad Alam and Atul. P. Ganorkar, “Design and Development of Bicycle Integrated Pipe Bending Machine”, IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE), e-ISSN: 2278-1684, p-ISSN: 2320-334X, 2014, PP 24-28. [5] Mohan Krishna S. A., “Experimental Design and Fabrication of a Portable Hydraulic Pipe Bending Machine”, International Journal of Development Research, ISSN: 2230-9926, Vol. 4, Issue, 12, pp. 2681-2684, December, 2014, PP 2681-2684 [6] Mahesh Gadekar and Mr. Amol, “Design & Development of Three Roller Sheet Bending Machine”, International Journal on Recent and Innovation Trends in Computing and Communication, ISSN: 2321-8169, Volume: 3, Issue: 8, August 2015, PP 5132 – 5135. [7] Prashant P. Khandare, Dhiral N. Patel, Mayur K. Aher, Ravi S. Parbat and Prof. Swapnil S. Patil, “Study of Portable 3 Roller Pipe Bending Machine”, International Conference on Emerging Trends in Engineering and Management Research, ISBN 978-81- 932074-7-5, 23 March 2016, 624-630.