Switchgear and protection - lab

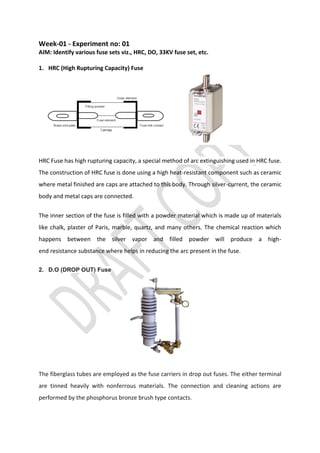

- 1. Week-01 - Experiment no: 01 AIM: Identify various fuse sets viz., HRC, DO, 33KV fuse set, etc. 1. HRC (High Rupturing Capacity) Fuse HRC Fuse has high rupturing capacity, a special method of arc extinguishing used in HRC fuse. The construction of HRC fuse is done using a high heat-resistant component such as ceramic where metal finished are caps are attached to this body. Through silver-current, the ceramic body and metal caps are connected. The inner section of the fuse is filled with a powder material which is made up of materials like chalk, plaster of Paris, marble, quartz, and many others. The chemical reaction which happens between the silver vapor and filled powder will produce a high- end resistance substance where helps in reducing the arc present in the fuse. 2. D.O (DROP OUT) Fuse The fiberglass tubes are employed as the fuse carriers in drop out fuses. The either terminal are tinned heavily with nonferrous materials. The connection and cleaning actions are performed by the phosphorus bronze brush type contacts.

- 2. The material used in drop out fuses should possess lower resistance as well as lower melting points, drop-out High voltage fuse (33KV) mounting plate is fixed in the middle of the support insulator. Support insulator has the upper and lower terminals for the connection wire. 3. Horn Gap Fuses Horn-Gap Fuse sets are of 11KV,22KV & 33KV voltage class, outdoor, vertically mounted are required for protection of transformers and tapping points. Rated current of Horn- Gap fuse sets shall be 50A/100A/200A/400A. Insulator of H.G Fuse shall be Porcelain (Pin/Post type)/ Solidcore /Polymeric type 4. Kit Kat Fuse Porcelain type kit kat Fuse Flush type kit kat Fuse Kit Kat Fuse is a semi-enclosed fuse also considered as rewireable fuse designed mainly for the domestic wiring and small-scale usage. 5. Automotive Fuse Automotive Fuse (Blade fuse type) used to protect the electrical components and devices of vehicle. They act as a safety measure to protect from overcurrent of an electrical circuit. Its basic purpose is to break the circuit when the current becomes more than the desired value, thereby preventing possible damage from equipment failures and short circuits.

- 3. Week-01 - Experiment no: 02 (a) AIM: Measure and select the appropriate size of fuse wire. Standard fuse SWG table for the fuse elements used in this type are tinned copper wire, lead and tin alloy or aluminium wire.

- 4. PROCEDURE: 1. Measure the gauge of given fuse wire/element using SWG. 2. Observer the Standard fuse SWG Table & Write down the Current rating in Observation Table. 3. Repeat the above procedure for the different fuse wire/elements. OBSERVATION TABLE: SL. No Fuse wire gauge in S.W.G Current rating as per the Standard table in Amps CONCLUSION:

- 5. Week-01 - EXPERIMENT NO: 2(b) AIM: Test the HRC fuse by performing a Load test. APPARATUS REQUIRED: Sl. No Apparatus Range Quantity 1. HRC Fuse 2A 01 2. Voltmeter (A.C) 0-500V 01 3. Ammeter (A.C) 0-10A 01 4. S.P.S.T Switch ----------- 01 5. Lamp Load 0-2KW / 10 Amps 01 6. Patch Chords 1 Sq.mm As Required CIRCUIT DIAGRAM: OBSERVATION TABLE: Sl.No Load Current in Amps Current through HRC Fuse element in Amps Time of Operation in Seconds

- 6. PROCEDURE: 1. Connections are made as per the circuit diagram. 2. Keep all the Load Switches in OFF position & Keep the SPST switch in Close Position. 3. Now Switch ON the Main supply, Observe the Voltmeter reading & confirm for rated voltage (1Ø- 230V). 4. Now switch ON the Loads in Stepwise, Observe the Load Current & Increase the load current up to more than 2 times of HRC Fuse current rating. 5. Now Open the SPST switch as well as start the STOP WATCH (Timmer). 6. Note down the Load current & HRC fuse Blows time. 7. Switch OFF the main Supply & Disconnect the circuit. CONCLUSION:

- 7. Week- 02 - EXPERIMENT NO: 1(a) AIM: Identify the various types of CB- MCB, ELCB, RCCB, MPCB and MCCB. Trace and locate MCBs used in your institution and note down their specifications. I. Identify the various types of CB- MCB, ELCB, RCCB, MPCB and MCCB. MCB - Miniature Circuit Breakers. ELCB - Earth-leakage circuit breaker RCCB - Residual Current Circuit Breaker MPCB- Motor Protection Circuit Breaker MCCB - Moulded Case Circuit Breaker

- 8. II. Trace and locate MCBs used in your institution and note down their specifications. MCB Place2: Place2: Place3: Specification Parameters Ranges Ranges Ranges Standard Conformity Standard Rated Current (In) Type of Curve Poles Rated Short Circuit Breaking Capacity (Icn) Rated Voltage (Ue) Rated Frequency(f) Rated Insulation Voltage (Ui) Ambient Temperature Contact indication mounting mode & mounting support

- 9. Week- 02 - EXPERIMENT NO: 01(b) AIM: Dismantle MCCB or ELCB and identify various parts.

- 10. Week- 02 - EXPERIMENT NO: 01(c) AIM: Test the MCB and plot its inverse time characteristic curve. APPARATUS REQUIRED: Sl.No Apparatus Range Quantity 1. M.C.B Fuse (Single Pole) 2A 01 2. Voltmeter (A.C) 0-500V 01 3. Ammeter (A.C) 0-10A 01 4. S.P.S.T Switch ----------- 01 5. Lamp Load 0-2KW / 10 Amps 01 6. Patch Chords 1 Sq.mm As Required CIRCUIT DIAGRAM: OBSERVATION TABLE: Sl.No Load Current in Amps Time of Operation in Seconds 1. 2. 3. 4. 5.

- 11. PROCEDURE: 1. Connections are made as per the circuit diagram. 2. Keep all the Load Switches in OFF position & Keep the SPST switch in Close Position. 3. Now Switch ON the Main supply, Observe the Voltmeter reading & confirm for rated voltage (1Ø- 230V). 4. Now switch ON the Loads in Stepwise, Observe the Load Current & Increase the load current up to more than 2 times of MCB current rating. 5. Now Open the SPST switch as well as start the STOP WATCH (Timmer). 6. Note down the Load current & MCB Trip time. 7. Repeat the Steps No. 4, 5 & 6 for different load currents. 8. Switch OFF the main Supply & Disconnect the circuit. NATURE OF GRAPH: CONCLUSION:

- 12. Week- 02 - EXPERIMENT NO: 02(a) AIM: Troubleshooting and servicing of LT circuit breaker. Troubleshooting of LT circuit breaker: Causes & Remedies 1. Identify Tripped Circuit Breaker Circuit breaker emits a humming sound when it is overloaded but has not switched off yet. Inside electric access panel, the tripped breaker lever can usually be found between the “on” and “off” position 2. Test Circuit Breaker Check the lever by moving it from ‘on’ to ‘off’ a couple of times to check how loose it is. If breaker has no ‘give’ and moves easily then it is faulty and you need to have it replaced as soon as possible. 3. Switch Off All of Appliances Again Switch off all appliances that are connected to circuit breaker but make sure to do it all at once to prevent a surge of electrical power when you reset it. If circuit breaker keeps on tripping then hire a professional to come and have a look at it. 4. Check Wiring If home has faulty wiring, then circuit breaker will be tripping continuously and you may find yourself receiving electrical shocks when powering certain appliances. This requires a trained professional so don’t try this on own. Simply identify the problem and hire a professional to take care of it. 5. Have Circuit Breaker Tested for the Necessary Voltage Touch one probe of the 120–240-volt tester to the tip of the “hot” wire, while touching the other tip to a bare copper grounding wire within the main electrical box. Use a neutral grounding terminal which is secured with ground wires and neutral wires for the probe. You will need to replace circuit breaker if you find the right amount of voltage present.

- 13. Servicing steps of LT circuit breaker. 1. Evaluate, Clean, Service and Test 2. Insulating parts which include bushings should be wiped down and cleaned 3. Check fault operations. 4. Trip Testing to ensure manufacturer standards 5. Inspection of alignment conditions and stationary contacts 6. Remove damaged parts 7. Reset breaker operation mechanism to manufacturer’s instruction book 8. Primary and Secondary Testing 9. On Site Evaluation of breakers, bus ducts, and fuses

- 14. Week- 02 - EXPERIMENT NO: 02(b) AIM: Test commercially available ACCL. APPARATUS REQUIRED: Sl.No Apparatus Range Quantity 1. A.C.C.L 32A 01 2. Voltmeter (A.C) 0-500V 01 5. Lamp Load 0-2KW / 10 Amps 01 6. Patch Chords 1 Sq.mm As Required CIRCUIT DIAGRAM: OBSERVATION TABLE: CURRENT LIMIT setting: _________Amps Sl. No E.B D.P switch D.G D.P switch Load Switch’s A.C.C.L Actions 1 ON OFF ON 2 OFF ON ON 3 ON ON ON 4 OFF ON TRIP

- 15. PROCEDURE: 1. Connections are made as per the circuit diagram. 2. Keep all the Load Switches in OFF position. 3. Now Switch ON the Main supply, Switch ON the EB Side DP switch & observe the lamp Load by Switch ON the loads in Steps. 4. Now switch OFF the EB side DP switch & Switch ON the DG side DP. 5. Switch ON the Loads in Stepwise, Observe the Load Current & Increase the load current up to more than CURRENT LIMIT setting. 6. Observe the Results as per the Observation Table & write down the Actions by the ACCL. 7. Switch OFF the main Supply & Disconnect the circuit. CONCLUSION:

- 16. Week-03 - EXPERIMENT NO: 1 AIM: Visit to Substation. a. Identify the parts of circuit breaker and check its operation. b. Demonstrate test tripping characteristic of circuit breaker for over current and short circuit current. Parts of Circuit Breaker

- 17. Week-03 - EXPERIMENT NO: 2 AIM: a. Demonstrate Installation operation and maintenance of SF6 circuit breaker, Vacuum circuit breaker. b. Carry out timer test on circuit breakers. c. Demo on RMU

- 18. Week-04 - EXPERIMENT NO: 1 AIM: a. Demonstrate various parts of the relay and ascertain the operation. b. Demonstrate setting of pick-up current/ time setting multiplier for relay operation Pick Up Current of Relay: In all electrical relays, the moving contacts are not free to move. All the contacts remain in their respective normal position by some force applied to them continuously. This force is called the controlling force of the relay. This controlling force may be the gravitational force, may be a spring force, or may be a magnetic force. The force applied to the relay’s moving parts for changing the normal position of the contacts is called deflecting force. This deflecting force is always in opposition of controlling force and is present always in the relay. The current for which the relay initiates its operation is called pick up current of relay. Current Setting of Relay: The minimum pick up value of the deflecting force of an electrical relay is constant. Again, the deflecting force of the coil is proportional to its number of turns and current flowing through the coil. Now, if we can change the number of active turns of any coil, the required current to reach at minimum pick value of the deflecting force, in the coil also changes. The current setting of relay is expressed in percentage ratio of relay pick up current to rated secondary current of CT.

- 19. Plug Setting Multiplier of Relay: Plug setting multiplier of relay is referred as ratio of fault current in the relay to its pick up current. Suppose we have connected on protection CT of ratio 200/1 A and current setting is 150%. Hence, pick up current of the relay is, 1 × 150 % = 1.5 A Now, suppose fault current in the CT primary is 1000 A. Hence, fault current in the CT secondary, i.e., in the relay coil is, 1000 × 1/200 = 5A Therefore PSM of the relay is, 5 / 1.5 =3.33 Time Setting Multiplier of Relay: The operating time of an electrical relay mainly depends upon two factors : • How long distance to be travelled by the moving parts of the relay for closing relay contacts and • How fast the moving parts of the relay cover this distance. So far by adjusting relay operating time, both of the factors to be adjusted. The adjustment of traveling distance of an electromechanical relay is commonly known as time setting. This adjustment is commonly known as time setting multiplier of relay. The time setting dial is calibrated from 0 to 1 in steps of 0.05 sec. Hence, actual operating time of the relay is 3 × 0.1 = 0.3 sec. i.e. 10% of 3 sec.

- 20. Week-04 - EXPERIMENT NO: 2(a) AIM: Test the Earth Leakage Relay. APPARATUS REQUIRED: Sl.No Apparatus Range Quantity 1. Earth Leakage Relay kit Digital type 01 2. C.B.C.T with Lamp load --- 01 3. Patch Chords 1 Sq.mm As Required CIRCUIT DIAGRAM:

- 21. OBSERVATION TABLE: Leakage Current Setting: _________Amps Sl. No Lamp load Circuit Conditions Leakage Current In Amps Trip Circuit 1 Normal 2 Earth Leakage fault PROCEDURE: 1. Connections are made as per the circuit diagram. 2. Keep all the Load Switches in OFF position. 3. Now Switch ON the Main supply, Switch ON the lamps under normal condition. 4. Now switch OFF Lamp load, main supply & alter the circuit as the current leakage to earth. 5. Switch ON the main supply, Lamp load & Observe the Load leakage current & Trip condition. 6. Observe the Results & Note down in the Observation table. 7. Switch OFF the main Supply & Disconnect the circuit CONCLUSION:

- 22. Week-04 - EXPERIMENT NO: 2(b) AIM: Test the Electromechanical over voltage relay. APPARATUS REQUIRED: Sl.No Apparatus Range Quantity 1. Electromechanical over voltage relay kit Electromechanical type 01 2. Patch Chords 1 Sq.mm As Required CIRCUIT DIAGRAM:

- 23. OBSERVATION TABLE: Plug Setting (PS) : _________ Volts, Sl. No Plug Setting Multiplier (PSM) Applied Voltage = PS × PSM in Volts TSM: TSM: Operating Time in Seconds Operating Time in Seconds 1 2 3 4 5 6 PROCEDURE: 1. Connections are made as per the circuit diagram. 2. Make the Settings of PS as per the decide value & keep all the Load Switches in OFF position. 3. Now Switch ON the Main supply & Apply the Calculated Applied voltage. 4. Now reset the relay, if it is operated then Confirm the Disc Halt on Position. 5. Switch to Set Position, Observe Timmer & Trip condition. 6. Note down the Operating Time in the Observation table. 7. Repeat the Steps 4 , 5 & 6 for different PMS, Applied Voltage & TSM. 8. Switch OFF the main Supply & Disconnect the circuit NATURE GRAPH: CONCLUSION:

- 24. Week-05 - EXPERIMENT NO: 1 AIM: Test the Static Over Voltage and Under Voltage Relay and Plot its inverse time – Voltage Characteristics. APPARATUS REQUIRED: Sl.No Apparatus Range Quantity 1. Static / Microprocessor Over Voltage and Under Voltage Relay kit Microprocessor type 01 2. Patch Chords 1 Sq.mm As Required CIRCUIT DIAGRAM:

- 25. OBSERVATION TABLE: For Over Voltage (OV) % age of over Voltage = _______ % Pick up Voltage (Vs) = 1 + (0.05 + Σ a) Vn Volts = ________________________ Volts, Where Vn=110V Voltage Set switch Value (Σa) = Sl. No Applied Voltage in Volts Operating Time in Seconds 1 2 3 4 5 For Under Voltage (UV) % age of over Voltage = _______ % Pick up Voltage (Vs) = 1 - (0.05 + Σa) Vn Volts = ________________________ Volts, Where Vn=110V Voltage Set switch Value (Σa) = Sl. No Applied Voltage in Volts Operating Time in Seconds 1 2 3 4 5

- 26. PROCEDURE: 1. Connections are made as per the circuit diagram. 2. Make the Switch Settings as per Requirement like OV/UV. 3. Decide the %age of OV/UV, accordingly calculate the Vs. 4. Now make the Switch Settings of Vs as per the Value of Σa. 5. Switch ON the Main supply & apply the different voltages (OV/UV). 6. Observe the Timmer, Trip condition, note down the Operating Time & Voltage in the Observation table. 7. Reset the relay & repeat the step No. 6 for different Voltages (UV/OV). 8. Switch OFF the main Supply & Disconnect the circuit. NATURE GRAPH: CONCLUSION:

- 27. Week-05 - EXPERIMENT NO: 2(a) AIM: Program and test the Numerical Over Current for definite Time operations. APPARATUS REQUIRED: Sl.No Apparatus Range Quantity 1. Numerical / Digital Over Current Relay Kit Digital Over Current type 01 2. Patch Chords 1 Sq.mm As Required CIRCUIT DIAGRAM: OBSERVATION TABLE: Sl. No Set Current in Amps Set definite Time in Seconds Operating Current in Amps Operating Time in Seconds 1 2 3

- 28. PROCEDURE: 1. Connections are made as per the circuit diagram. 2. Switch ON the Main supply. 3. Set the Current & Time as per the operation procedure of relay. 4. Switch OFF & Switch ON the Main supply then apply the Current more than the Set Value using current source. 5. Now Switch to Starts operation & Observe the Timmer, Trip condition, note down the Operating Time & Current in the Observation table. 6. Set the relay for different Current & Time. 7. Repeat the steps No. 4 & 5. 8. Switch OFF the main Supply & Disconnect the circuit. NATURE GRAPH: CONCLUSION:

- 29. Week-06 - EXPERIMENT NO: 01 AIM: Test the operation of Buchholz Relay. APPARATUS REQUIRED: Sl.No Apparatus Range Quantity 1. Buchholz Relay Kit -- 01 2. Transformer oil -- 5 Litters 3. Patch Chords 1 Sq.mm As Required EXPERIMENTAL DIAGRAM:

- 30. OBSERVATION TABLE: Sl. No Air Pump Trip Circuit 1 OFF 2 ON PROCEDURE: 1. Make sure the transformer tank and relay are filled with oil and there is some oil in conservator tank, the air valve of the Buchholz relay must be closed. 2. Now turn ON the air Pump and the air bubbles starts blowing into the Buchholz relay. The Air Pump is fitted with a non-return valve to protect the compressor by reverse flow of oil. 3. Notice the relays trips after some time of air flow & simultaneously to the air pump is cut OFF. 4. Turn OFF the Air Pump switch and then release the air valve on the Buchholz relay. CONCLUSION:

- 31. Week - 06 - EXPERIMENT NO: 02 AIM: Conduct BDVT on Transformer oil. Sl.No Apparatus Range Quantity 1. BDVT on Transformer oil Kit 0-60KV / 1KVA 01 2. Transformer oil -- 1 Litters 3. Patch Chords 1 Sq.mm As Required EXPERIMENTAL DIAGRAM: OBSERVATION TABLE: Sl. No Distance of Electrodes in mm Breakdown Voltage in KV 1 2.5 2 4 3

- 32. PROCEDURE: 1. Adjust the gap between electrodes to 2.5mm/4mm by the guage. 2. Fill the cup with oil and place it on the H.T electrodes. Close the hood properly, so as to operate the interlock microswitch which acts as a safety precaution for the operator. 3. Switch ON the main supply, the corresponding lamp will glow. 4. Press the H.T ON push Button the contactor will operate and H.T ON lamp will glow. If the contactor does not operate, it means that the Variac brush arm is not at zero position OR the Hood interlock microswitch is not closed as mentioned in ‘step 2’. The zero interlocking od the variac is another safety feature against switching on the unit directly at a higher voltage. This will be indicated by the Voltmeter reading also. 5. Raise the voltage by turning the variac knob in clockwise direction. In case the oil sample fails the unit will trip to lower down the voltage turn the variac knob anti-clock and bring it to zero position before start of further tests. CONCLUSION: