Laser Cutting: Advanced Joinery

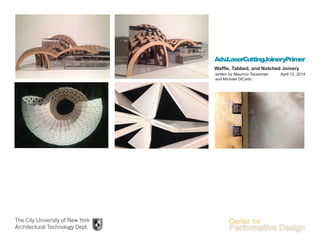

- 1. Adv.LaserCuttingJoineryPrimer The City University of New York Architectural Technology Dept. written by Mauricio Tacaoman and Michael DiCarlo Waffle, Tabbed, and Notched Joinery April 12, 2014

- 2. 2 This material is based upon work supported by the National Science Foundation under Grant Numbers 1141234. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

- 3. Adv.LaserCuttingJoineryPrimer Fig. 1 -Surface Based in Rhino Waffle Structure Joinery Step One: The first step in creating a waffle structure is to create a base surface. Ideally it is better to have a surface that does not have exaggerated peaks and valleys as this will result pieces that are too thin. The surface itself can be any size, but eventually it will need to moved into a laser cutter. The laser cutters in Architectural Technology Department are limited to 32” x 18”, so it is best to accommodate your model to those dimensions. Step Two: At this point the initial contours in both the X and Y axes can be created. To begin, create a layer for the X-contours, and Y-Contours. Step Three: Now to create the sections use Rhino command: Contour. It will prompt you to select object for contour, so pick the surface you created. Then it will ask you for the contour plane base point, pick either the X or Y direction. After you have chosen a direction type in the distance between contours. (The larger the distance the lower the amount of pieces and the lower accuracy of the final model.) Step Four: Repeat the same process to create the contours along the other axis. 2 Fig. 2 -Contours along the Y-AxisFig. 3 -Contours along the X-Axis Fig. 4 -Contours along the Y-AxisFig. 5 -Contours along the X-Axis

- 4. Adv.LaserCuttingJoineryPrimer 3 Waffle Structure Joinery Step Five: You may need to join the curves making up each contour cut. Select them individually and us Rhino command: Join (Ctrl + J). Step Six: Use Extrude Curve>Straight command (ExtrudeCrv) to create surfaces from the contour curves. Step Seven: Move the Y-Axis surfaces vertically half the depth of the extrusion made on the previous step. Step Eight: Use the Surface> Offset Surface command (OffsetSrf) to give the surfaces thickness, this thickness is determined by the thickness of the material being used. (i.e. .0625” chipboard). Step Nine: Use the Boolean Split command on both the X and Y axes extruded contours. This will result in a slots that allow you to join the parts. Fig. 6 -Y-Axis Member with notchesFig. 7 -Sectional Members Fig. 8 -Sectional Curves on a Cartesian Grid Fig. 9 -Extruded Sectional Curves Fig. 10 -Detail of extruded sectional curves Fig. 11 -Shifted sectional planes

- 5. Adv.LaserCuttingJoineryPrimer 4 Waffle Structure Joinery Step 10: Use the contours of the sectional mebers as your laser cutting profile, assemble. Fig. 12 -Separated Sectional Members Fig. 13 -Sectional Members After Make2D

- 6. Adv.LaserCuttingJoineryPrimer 5 Unrolled- Tabbed surface Joinery Step 1- Once you have a 3dimentional shape or object you want to reproduce, it’s important to make sure it is “closed” meaning all the edges are touching with no gaps, think “water tight”. You can check or openings using the “SelOpenSrf” command, if no surfaces are high- lighted that means you’re good to go, if surfaces do become highlighted, that means they are not closed and you should check your geometry. If the object is a type of panel or part of a system, there may be open edges at its extents, that is fine too. Step 2- Select the polysurface and run the “UnRollSrf” command, make sure that the sub-command “ex- plode” is set to “No”, this will keep adjecent edges aligned, as shown in the image to the left. Step 3- After successfully completing the unroll and ad- justing any overlaping geometry you should create 4 layers,; Surfaces, Score lines, Cut lines, and an “construction line” layer. Then, select the polysurface and run the “DupBor- der” command, this will give you a curve outline of the geometry, this curve should be exploded and entered into the construction line layer. Step 4- Take the unrolled polysurface and explode it into it’s subsurfaces. Then run the “DupBorder” com- mand again on all the subsurfaces, the resulting curves will make up the score lines for each face. Fig. 14 -Tetrahedrom, sold geometry Fig. 15 -Unrolled Surfaces Fig. 16 -DupBorder Fig. 17 -Explode Surfaces

- 7. Adv.LaserCuttingJoineryPrimer 6 Unrolled- Tabbed surface Joinery Step 6- The lines should be exploded and the “SelDup” command run, all duplicates should then be deleted and the left over curves moved into the “score lines” layer. Step 7- For now hide the score lines and bring up the construction lines. Here you will begin creating the cutting profile that includes the tabs. Indi- vidually select the curve segments and run the “OffsetCurve” command, you can choose to “Cap” the offset which will create a connection to the endpoints of each line. Step 8- Also, you can choose not to “Cap” the offset then manually chamfer the ends and trim the excess, as you can see in some areas the offsets may over lap. Step 9- After the tabs are created and tailored to your needs in the “constrction line” layer, you should run the “BooleanCurve” command. In Top view, highlight the whole object, press enter, then click outside of the object, this will creat a single polyline around the perimeter of all the curves, this line is your “Cut” line, and should be positioned in that layer. Step 10- The score layer should be set to green, and the cut layer set to blue, hide or delete the construc- tion lines, scale appropriately for your piece and you should be set to sent your item(s) to be cut. Fig. 18 -DupBorder of exploded surfaces Fig. 19 -Offset border Curves Fig. 20 -Clean up over laps Fig. 21 -Establish Cut lines Fig. 22 -Establish Score lines

- 8. Adv.LaserCuttingJoineryPrimer 7 Unrolled- Tabbed surface Joinery Step 11- Create a bounding box the size of the machine’s printable area, in this case 24”x48” and a sec- ond box the size the the material, in this case 14”x17”. Position your material in either the upper right or left hand corner of the printable area. Set your layers to their appropriate colors, at citytech green=score, blue=cut and red=etch. Step 12- Select print, set your scale and position the “print window” over your printable area box. Send to plotter. Step 13- Remove material, fold along score lines and glue along tabs. Fig. 23 -Organize the print layout Fig. 24 -Send to cutter Fig. 25 -Cut Pieces Fig. 26 -Cut single piece Fig. 27 -Fold Tabs Fig. 28 -Glue

- 9. Adv.LaserCuttingJoineryPrimer 8 Notched Joinery Step1- Starting with a simple geometry, like this box, de- cide which edges need to be joined to create the desired object, forthis example we’ll go throught joining this single edge. Step 2 - Next you will need to divide the edge curve, us- ing the “Divide” command we divide the edge to be joined into 7 equal length segments, this will give us all the division points, then the points on the edge should be offset along the surface the distance of what ever material the you are working wth wil be. For this example we are asuming the use of 1/4” acrylic or craft plywood. Step 3 - After Offseting the points accordingly, draw a ploy- line accros each set of points to create this sort of “tooth” pattern Step 4 - Once the lines defining the notches is drawn over ech surface you can use them to “Trim” the negative spaces. The left over surfaces should be the profiles necessary to cut with. You can us the “unrollsurface” command to project each to the C-plane. Step 5 - Once projected to the C-plane use the “DupBor- der” command to extract the perimeter curves, color them blue, and for more complex geometries labeling which surface is which may be helpful., use the text tool to type any identifying informa- tion, the text will be filled in and not “cuttable”, to create vector out-lines, select the text and “ex- plode”. Fig. 29 -Solid base geometry Fig. 30 -Divide Edges Fig. 31 -Outline the notch pattern Fig. 32 -Trim the excess Fig. 33 -Flatten/ Unroll the faces to cut Fig. 34 -Prepare for cutting and label if needed

- 10. Adv.LaserCuttingJoineryPrimer 9 Notched Joinery Also, for pressure fits you will need to take into ac- count the kerf width. The “kerf” is the width of the material removed by a cutting device, like a saw or laser. The kerf of the lasers at Citytech are around 1/64”, though there is some variance between the machines, material choice and power settings. The offset of the “tooth” curves should move in the direction of the opening and the distance somewhere in the nighborhood of 0.002”, to get a perfect fit will require a little testing, It’s wise to conduct a material/ power test with a small piece of or selected material. Fig. 35 -Fit together