Axial Flow Turbine.ppt

- 3. Axial and Radial Flow Turbines Differences between turbine and compressor: Long Short Blade 1 Last blade Compressor Turbine Work as nozzle ► Work as diffuser ► Direction of rotation is same as Life ► Direction of rotation is opposite to lift direction ► Number of stages is small <3 ► Number of stages are many ► Temperature is high, sometimes blade cooling is required ► Temperatures are relative low ►

- 4. Axial and Radial Flow Turbines Differences between Radial and Axial Types. Axial Radial (Centrifugal) Used for large engines ► Used for small engines ► Large mass flow rates ► Small mass flow rates ► Better efficiencies ► Lower efficiencies ► Expensive ► Cheap ► Difficult to manufacture ► Easy to manufacture ►

- 5. Axial Flow Turbines Most of the gas turbines employ the axial flow turbines. The chapter is concerned with axial flow turbines. The radial turbine can handle low mass flows more efficiently than the axial flow machines.

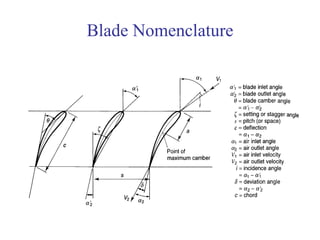

- 6. Axial Flow Turbine Elementary Theory of Axial Flow Turbine ► Velocity Triangles. ■ The velocity triangles for one axial flow turbine stage and the nomenclature employed are shown. The gas enters the row of nozzle blades with a static pressure and temperature P1, T1, and a velocity C1, is expanded to P2, T2, with an increased velocity C2 at an angle α2. ■ The rotor blade angle will be chosen to suit the direction β2 of the gas velocity V2 relative to the blade at inlet. ■ V2 and β2 are obtained from the velocity diagram of known C2, α2, and U.

- 7. Axial Flow Turbine • Elementary Theory The gas leaves the rotor at β3, T3, with relative velocity V3 at an angle β3. C3 and α3 can be obtained from the velocity diagram.

- 8. Axial Flow Turbine ► Single Stage Turbine ■ C1 is axial → α1 = 0, and C1 = Cα1. For similar stages (same black shapes) C1 = C3, and α1 = α3, called repeating stage. ■ Due to change of U with radius, velocity triangles vary from root to tip of the blade.

- 9. Axial Flow Turbine ► Assumptions ■ Consider conditions at the mean diameter of the annulus will represent the average picture of what happen to total mass flow. ■ This is valid for low ratio of tip radius to root radius. ■ For high radii ratio, 3-D effects have to be considered. ■ The change of tangential (whirl) mass is . This amount produces useful torque. ■ The change in axial component produces the axial thrust on the rotor. ■ Also there is an axial thrust due to P2 – P3. ■ These forces (net thrust on turbine rotor) are normally balanced by the thrust on the compressor rotor.

- 11. Axial Flow Turbine ► Calculation of Work Assume Ca= constant 2 3 Ca Ca Ca 2 2 3 3 tan tan tan tan U Ca 2 2 3 tan tan tan tan e 2 2 tan tan U Ca Ca (1)

- 12. Axial Flow Turbine Applying principle of angular momentum 2 3 2 3 ( ( )(tan tan ) s W U C C U Ca From Equation (1) 2 3 (tan tan ) s W U Ca Steady-state energy equation: s p o W C T Thus: 2 3 (tan tan )/ 1.148, 1.333 and 4 1 s o p p T U Ca C C

- 13. Axial Flow Turbine Elementary theory of axial flow turbine 1 3, 3, 1 1 1 1 3 1 1 1 1 / s isent isent isent o s o s o o o s o o s o o o T T T T T T T T P P

- 14. Axial Flow Turbine ηs is the isentropic stage efficiency based on stagnation (total) temperature. 1 3 1 3 o o s o o T T T T 1 3 1 3 ( ) o o s o T T total to static T T (used for land-based gas turbines). Defining ψ = blade loading coefficient (temperature drop coefficient) 2 2 s p o C T U

- 15. Axial Flow Turbine Thus, 2 3 2 (tan tan )/ a C U Degree of reaction: 0 ≤ Λ ≤ 1 2,3 2,3 2 3 1,3 1 3 1,3 rotor total h T T T T T T h For, Ca = const. and C3 = C1 1 3 1 3 2 3 ( ) (tan tan ) p p o o a C T T C T T U C and relative to rotor blades no work, thus (a)

- 16. Axial Flow Turbine 2 2 2 3 3 2 2 2 2 3 2 2 2 2 3 2 1 ( ) 2 1 sec sec 2 1 tan tan 2 p a a C T T V V C C 2 2 1 3 2 2 2 3 1 3 2 3 tan tan (tan tan a a C T T T T U C 1 3 2 (tan tan ) 2 C U Substitute in (a):

- 17. Axial Flow Turbine 3 2 3 2 2 2 2 2 2 2 3 2 2 2 2 2 2 2 3 2 tan tan a w a w w w a a V V C C u C C u C u C u C C 2 3 3 2 and 3 2 3 2 and V V 3 2 3 2 , C C a C U Λ = 0.5 → Symm. velocity triangles ● Λ = 0 : Impulse turbine ● Λ = 1 : Defining flow coefficient:

- 18. Axial Flow Turbine 2 1 3 2 2 (tan tan ) (tan tan ) 2 Adding: 3 1 1 tan 2 2 2 2 1 1 tan 2 2 2 From: 2 2 3 3 3 3 2 2 (tan tan ) (tan tan ) 1 tan tan 1 tan tan a a U C U C

- 19. Axial Flow Turbine If , Λ, and are assumed, blade angles can be determined. ● For aircraft applications: 3 < ψ < s, 0.8 < < 1 ● For industrial applications: is less (more stages) is less (larger engine size) α3 < 20 (to min. losses in nozzle) ● Loss coefficient: 1 2 1 2 2 2 ( ) 2 2 / 2 n nozzle stator p o o N o T T C C P P Y P P Λ and Y: The proportion of the leaving energy which is degraded by friction.

- 20. Axial Flow Turbine Example (Mean diameter design) Given: 1 1 3 1 3 1 Single-stage turbine = 20 kg/s = 0.9 = 1100 K Temperature drop, = 145 K Pressure ratio, / = 1.873 Inlet pressure, = 4 bar t o o o o o o m T T T P P P Assumptions: Rotational speed fixed by compressor: N = 250 rps Mean blade speed: 340 m/s Nozzle loss coefficient: 2 2 2 2 / 2 N p T T C C

- 21. Axial Flow Turbine / t r r r 2 3 1 3 1 , 0 a a C C C C Calculation: a)Λ degree of reaction at mean radius b)Plot velocity diagrams c)Blade height h, tip/root radius, Assume: 3 2 2 2 2 1.148 145 10 2.88 340 s p o C T U flow coefficient 0.8 a C U The temperature drop coefficient: Assume (try):

- 22. Axial Flow Turbine 3 3 1 tan tan 3 tan 1.25 3 1 1 tan 2 2 2 0.28 ■ To get Λ use This is low as a mean radius value because Λ will be low or negative at the root. This introduce a value for α3. Take α3 = 10° * To calculate degree of reaction Λ: ■ Get β3: α3 = 0

- 23. Axial Flow Turbine 3 3 3 3 1 tan tan tan 1.426 1 1 tan 2 2 2 0.421 (Acceptable) Reaction at root should be checked. Thus α3 = 10°, β3 = tan-1 1.426 = 54.96 2 2 1 1 tan 2 0.374 2 2 0.421 2.88 0.8 20.49

- 24. Axial Flow Turbine 2 2 2 1 tan tan 1.624 58.38 3 3 2 2 , , , , U / t r r r 1 1 :axial a C C With knowledge of plot velocity diagrams. * Determine blade height h and tip/root radius ratio, . Assumption: Calculation of area at Section 2 (exit of nozzle)

- 25. Axial Flow Turbine 2 2 2 1 2 2 2 2 2 2 2 2 340 0.8 272 m/s cos 519 m/s 1100 K 5.9 K 2 a a o o o p C U C C C T T C T T T C 2 2 2 2 2 0.05 117.3 5.9 K 2 976.8 K N p C T T C T 1 1 1 2 / 1 4 2 2 2.49 bar o P o o o P T P P T

- 26. Axial Flow Turbine For the nozzle: 1 1 2 1 2 1 1 1 1 /(2 ) 1 1 1 2 2 1 4 2.16 2 1.853 o p o c c M T T C C M T T P P P P2 > Pc, the nozzle is not choked. 2 , 2.49 throat Thus P P 3 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 0.833 / , , m , 0.0833 throat area of nozzles; A , m 0.0437 , also A cos a a P kg m RT m A or C A A m C m N C or C A N A N m A N

- 27. Axial Flow Turbine Calculate areas at section (1) inlet nozzle and (3) exit rotor. 3 1 1 1 1 1 1 1 1 3 3 3 2 1 1 1 1 1 1 1 3 1 1 1 1 2 1 1 1 , but C C , 276.4 / cos 1067 2 3.54 1.155 / 0.626 a a a o p o o a C C C C and C m s C T T T K c P T P bar P T P kg m RT m C A A m

- 28. Axial Flow Turbine 3 1 5 3 3 3 o 2 3 3 3 1 3 3 3 3 3 3 5 5 Similarly at outlet of stage ( rotor) T 1100 145 955 , 922 2 1.856 0.702 / o o o p o o T T K given C T T T K c P T P bar P T P kg m RT 3 2 3 5 5 2 3 3 3 3/ 0.702 / 0.1047 Blade height and annulus radius ratio a P RT kg m m C A A m

- 29. Axial Flow Turbine Mean radius m 340 2 0.216 2 (250) for known (A); A 2 r m m m u Nr r m also h t r , 2 2 2 m r m m A h h h then r r r r using areas at stations 1,2,3 thus 2 1m A m h1 / t r r r 3 2 1 Location 0.1047 0.0833 0.0626 0.077 0.0612 0.04 1.43 1.33 1.24

- 30. Axial Flow Turbine Blade with width W Normally taken as W=h/3 Spacing s between axial blades t r a t space 0.25, should not be less than 0.2 W width r * should be 1.2 1.4 r unsatisfactory values such as 0.43 can be reduced by changing axial velocity through . increasing C reduce r check has to s w will v be made for mach number M .

- 31. Axial Flow Turbine Vortex Theory The blade speed ( u=r) changes from root to tip, thus velocity triangles must vary from root to tip. Free Vortex design axial velocity is constant over the annulus. Whirl velocity is inversely proportional to annulus. , C , tan tan C , tan 3 3 2 2 const r t cons C t cons r t cons C a a Along the radius. 2 3 2 3 ( ) tan s W u C C C r C r cons t

- 32. Axial Flow Turbine For variable density, m is given by t r r r a a rdr C m C r r m 2 2 2 2 2 ) 2 ( 2 2 2 2 a 2 2 2 2 3 3 3 tan tan C cosntant, thus changes as tan tan (a) tan tan (b) a m m m m C r cons t r C but is r r similarly r r

- 33. Axial Flow Turbine 2 2 2 2 s 3 3 2 2 2 2 m 2 2 a 3 3 3 3 3 3 tan tan , , tan tan r tan (c) r for exit of rotor u C tan tan tan tan (d) a a a m m a a m m m a u u C C thus C u r m r C C r r u thus r r C Ex: Free vortex Results from mean diameter calculations 2 2m 3 3 2 3 58.38, 20.49, 10 , 54.96, 0.0612, 0.216, 0.077, 2 o m m m m r m h r h h r r

- 34. Axial Flow Turbine 58.33 8.52 0 54.93 Tip 51.13 12.12 39.32 62.15 Root 54.96 10 20.49 58.38 mean 3 3 2 3 2 3 2 3 m a 1.164,( ) 0.877, 1.217, 0.849 u 1 also 1.25, Results are C m m m m t t r t m a r r r r r r r r u C 2 2

- 36. EES Design Calculations of Axial Flow Turbine Known Information To1 = 1100 [K] Pratio = 1.873 DelTs = 145 Ettaturbine = 0.9 Assumptions U = 340 [m/s] Nrps = 250 = 0.8 3 = 10 Loss nozzle = 0.05

- 37. EES Design Calculations of Axial Flow Turbine cp = 1148 R = 0.287 = 1.333 DelTs = To1 – To3 Pratio = Po1 Po3 Ca = C2 · cos ( 2 ) = Ca U Gamr = – 1 Epsi = 2 · cp · DelTs U 2 Epsi = 2 · · ( tan ( 2 ) + tan ( 3 ) ) Reaction = 2 · ( tan ( 3 ) – tan ( 2 ) ) U = Ca · ( tan ( 2 ) – tan ( 2 ) ) U = Ca · ( tan ( 3 ) – tan ( 3 ) )

- 38. EES Design Calculations of Axial Flow Turbine Calculate A2 Loss nozzle = T2 – T2dash C2 2 2 · cp To2 = To1 To2 – T2 = C2 2 2 · cp Po1 P2 = To1 T2dash Gamr Po1 Pc = + 1 2 Gamr Pth = P2 Rho2 = Pth R · T2 A2 = m Rho2 · Ca A2 · cos ( 2 ) = A2N

- 39. EES Design Calculations of Axial Flow Turbine Calculate A1 To1 – T1 = C1 2 2 · cp Po1 P1 = To1 T1 Gamr Rho1 = P1 R · T1 C1 = Ca A1 = m Rho1 · Ca Calculate A3 To3 – T3 = C3 2 2 · cp Po3 P3 = To3 T3 Gamr Rho3 = P3 R · T3 C3 = Ca A3 = m Rho3 · Ca

- 40. EES Design Calculations of Axial Flow Turbine Blade height U = 2 · · Nrps · rm Blade height at section 1 A1 = 2 · · rm · h1 rt1 = rm + h1 2 rr1 = rm – h1 2 rratio1 = rt1 rr1 Blade height at section 2 A2 = 2 · · rm · h2 rt2 = rm + h2 2 rr2 = rm – h2 2 rratio2 = rt2 rr2 Blade height at section 3 A3 = 2 · · rm · h3 rt3 = rm + h3 2 rr3 = rm – h3 2 rratio3 = rt3 rr3

- 41. EES Design Calculations of Axial Flow Turbine A1 = 0.06345 A2 = 0.08336 A2N = 0.04372 A3 = 0.1046 2 = 58.37 3 = 10 2 = 20.49 3 = 54.97 C1 = 272 C2 = 518.7 C3 = 272 Ca = 272 cp = 1148 [J/kgK] DelTs = 145 Epsi = 2.88 Ettaturbine = 0.9 = 1.333 Gamr = 4.003 h1 = 0.04666 h2 = 0.06129 h3 = 0.07692 Lossnozzle = 0.05 m = 20 [kg/s] Nrps = 250 [rev per sec] P1 = 355.1 P2 = 248.8 P3 = 186.1 Pc = 215.9 = 0.8 Po1 = 400 [kPa] Po3 = 213.6 Pth = 248.8 Pratio = 1.873 R = 0.287 [kJ/kgK] Reaction = 0.4211 Rho1 = 1.159 Rho2 = 0.8821 Rho3 = 0.7029 rratio1 = 1.242 rratio2 = 1.33 rratio3 = 1.432 rm = 0.2165 rr1 = 0.1931 rr2 = 0.1858 rr3 = 0.178 rt1 = 0.2398 rt2 = 0.2471 rt3 = 0.2549 T1 = 1068 T2 = 982.8 T2dash = 977 T3 = 922.8 To1 = 1100 [K] To2 = 1100 [K] To3 = 955 U = 340 [m/s]