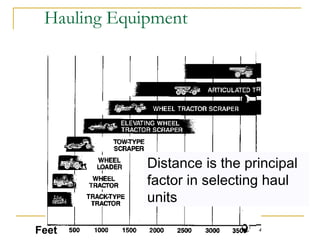

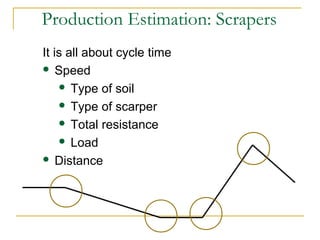

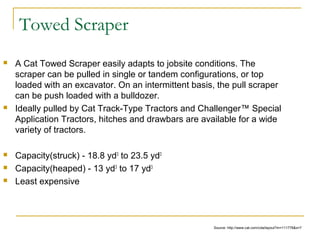

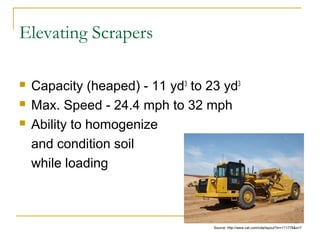

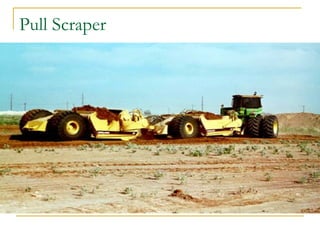

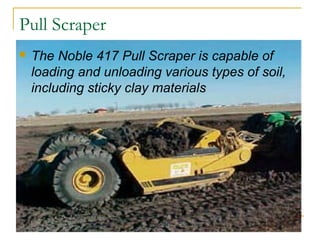

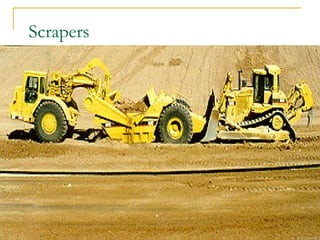

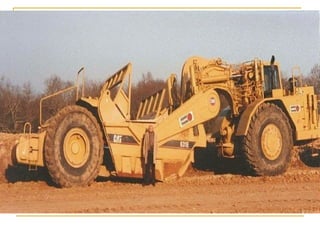

Scrapers are heavy earthmoving machinery used to collect, transport, and dump soil and other materials over short distances. They have a hopper at the rear that is lowered to collect dirt which can then be raised and dumped as needed. Self-propelled scrapers were invented in the 1930s and come in various types like towed, elevating, coal bowl, open bowl, and pull scrapers with capacities ranging from 14 to 44 cubic yards. Scrapers load soil through being pushed by bulldozers and transport it within a mile or two before dumping the collected materials.