TrainingMine Course Library

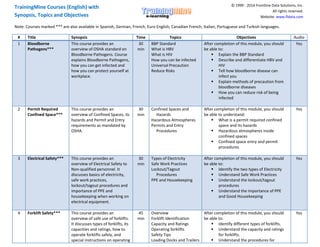

- 1. © 1999 - 2014 Frontline Data Solutions, Inc. All rights reserved. Website: www.fldata.com TrainingMine Courses (English) with Synopsis, Topics and Objectives Note: Courses marked *** are also available in Spanish, German, French, Euro English, Canadian French, Italian, Portuguese and Turkish languages. # 1 Title Bloodborne Pathogens*** Synopsis This course provides an overview of OSHA standard on Bloodborne Pathogens. Course explains Bloodborne Pathogens, how you can get infected and how you can protect yourself at workplace. Time 30 min Topics BBP Standard What is HBV What is HIV How you can be infected Universal Precaution Reduce Risks Objectives After completion of this module, you should be able to: Explain the BBP Standard Describe and differentiate HBV and HIV Tell how bloodborne disease can infect you Explain methods of precaution from bloodborne diseases How you can reduce risk of being infected Audio Yes 2 Permit Required Confined Space*** This course provides an overview of Confined Spaces, its hazards and Permit and Entry requirements as mandated by OSHA. 30 min Confined Spaces and Hazards Hazardous Atmospheres Permits and Entry Procedures After completion of this module, you should be able to understand: What is a permit required confined space and its hazards Hazardous atmospheres inside confined spaces Confined space entry and permit procedures Yes 3 Electrical Safety*** This course provides an overview of Electrical Safety to Non-qualified personnel. It discusses basics of electricity, safe work practices, lockout/tagout procedures and importance of PPE and housekeeping when working on electrical equipment. 30 min Types of Electricity Safe Work Practices Lockout/Tagout Procedures PPE and Housekeeping After completion of this module, you should be able to: Identify the two types of Electricity Understand Safe Work Practices Understand the lockout/tagout procedures Understand the importance of PPE and Good Housekeeping Yes 4 Forklift Safety*** This course provides an overview of safe use of forklifts. It discusses types of forklifts, its capacities and ratings, how to operate forklifts safely, and special instructions on operating 45 min Overview Forklift Identification Capacity and Ratings Operating forklifts Safety Tips Loading Docks and Trailers After completion of this module, you should be able to: Identify different types of forklifts. Understand the capacity and ratings for forklifts. Understand the procedures for Yes

- 2. forklifts on Loading Docks and Trailers. operating a forklift safely. Follow safety tips and avoid an accident. Safely operate a forklift on Loading Docks and in Trailers. 5 Personal Protective Equipment*** This course provides a basic overview of Personal Protective Equipment (PPE), selecting proper PPE for a job and proper use, care and handling of PPE. 30 min What is PPE Selecting PPE Use of PPE After completion of this module, you should be able to: Understand what PPE is Select proper PPE for a job Proper use of PPE and additional training on its use Yes 6 Hazard Communication Awareness This course provides a basic overview of OSHA's Hazard Communication Standard, how to meet its requirements, and how to conduct hazard assessment for this program. 30 min Purpose of HazCom HazCom Program Hazard Assessment After completion of this module, you should be able to: Describe the purpose of the Hazard Communication (HazCom) Standard Define components of the HazCom program Conduct a Hazard Assessment Yes 7 Hand and Power Tool Safety*** This course provides basic familiarity with OSHA Hand and Power Tool Standard. Common tool hazards, PPE, proper tool care, selecting right tool and common tool abuse are discussed. 45 min Overview Tool Hazards Tool Care Right Tool for the Job Special Tools Abusing tools After completion of this module, you should be able to understand: Hazards associated with Hand & Power Tools Proper tool care and the "right tool for the job" When to use "special tools" Correct use of tools Yes 8 Asbestos Awareness*** This course provides an overview of Asbestos, its history, its health hazards, OSHA regulations concerning work with Asbestos and safe practices to follow when handling Asbestos. 45 min Background OSHA Regulations Health Hazards Safe Handling of Asbestos Conclusion After completion of this module, you should be able to understand: History of Asbestos and its properties OSHA regulations regarding working with Asbestos Health hazards posed by Asbestos Safe handling of Asbestos including its disposal and recommended PPE Yes 9 Hazardous Waste Awareness This course provides an overview of Hazardous Wastes. It defines solid wastes, explains characteristics of solid wastes 30 min Introduction Hazardous Wastes Solid Wastes Characteristics of After completion of this module, you should be able to understand: What is Hazardous Wastes What is solid waste Yes

- 3. that make it hazardous and proper handling and storage of Hazardous Wastes. Hazardous Wastes Handling and Storage Conclusion What are characteristics of Hazardous Wastes Proper handling and storage of Hazardous Wastes 10 Ladders and Stairways*** This course provides an overview of ladders (both portable and fixed) and stairways. Ladder types, safe use, inspection/maintenance and housekeeping are discussed. 30 min Overview Portable Ladders Stepladder Extension Ladders Portable Ladder Safety Tips Fixed Ladders Inspection and Maintenance Stairways Conclusion After completion of this module, you should be able to understand: What are fixed and portable ladders Types of portable ladders Safe use of portable ladders Inspection/Maintenance and Housekeeping Yes 11 Respiratory Protection*** This course provides an overview of respiratory protection in hazardous environment. Types of respirators, selection guidelines, proper use, maintenance and inspection procedures are discussed. 30 min Overview Types of Respirators Negative type Respirators Positive type Respirators Use and Maintenance Inspection Conclusion After completion of this module, you should be able to understand: Situations where respiratory protection is necessary Types of respirators and guidelines for selecting proper type Commonly used respirators for different environments Use, maintenance and inspection procedures Yes 12 Haz-Com Material Safety Data Sheets This course provides an overview of Material Safety Data Sheets (MSDS) part of the Haz-Com program. The course covers various sections of MSDS and how you can use information contained therein for safe and responsible handling of material. 30 min Overview What does MSDS include? Conclusion After completion of this module, you should be able to understand: What is MSDS? What does it contain? How can the information provided by MSDS help in safe and responsible handling of material Other requirements of the MSDS program Yes 13 HAZWOPER Awareness This course provides awareness training that is necessary for OSHA’s HAZWOPER program. The training covers basic understanding of hazardous materials and how to 30 min Overview Hazardous materials Emergencies Conclusion After completion of this module, you should be able to understand: What is HAZWOPER Level 1 Awareness What are hazardous materials How to recognize emergencies resulting from these materials Yes

- 4. appropriately provide initial response to emergencies resulting from these materials. How to provide appropriate initial (or first responder) response to such emergencies 14 Hearing Protection*** This course emphasizes necessity of proper hearing protection in high noise areas. Types of hearing protection and when to use, how to recognize hearing loss, what are harmful noise levels and need for routine hearing test are explained. 30 min Overview Types of Hearing Protection When do you need Hearing Protection? Hearing Loss Ear sections Harmful Noise Level Hearing Test Conclusions After completion of this module, you should be able to understand: What is noise and its types Common hearing protection devices Situation when hearing protection should be used How to recognize hearing loss How ear functions and section which gets damaged by high noise Importance of regular hearing test Yes 15 Indoor Cranes*** This course provides an overview of safe use of Indoor Cranes. Topics covered are prelift preparation and inspection, proper rigging and lifting of load. 30 min Background Pre-Lift Preparation Rigging Lifting Conclusion After completion of this module, you should be able to understand: How to inspect a crane prior to lifting How to prepare for lifting Proper method to rig the load Proper method to lift the load Yes 16 Scaffolds*** This course provides an overview of Scaffolds. Topics covered are general Scaffold requirements, components of Scaffold and proper Scaffold inspection prior to use. 30 min Overview General Requirements Scaffold Components Scaffold Inspection Conclusion After completion of this module, you should be able to understand: General Scaffold requirements Components of Scaffold Proper Scaffold inspection Yes 17 Temporary Barricades*** This course provides an overview of Temporary Barricades and how through proper use of such barricades, exposure to hazardous situations can be reduced. Topics covered are types of barricades and when to use them, responsibility for barricades and procedure for entry into barricaded areas. 30 min Overview Tape Barricades Situations requiring Barricades Entry into Barricaded area Barricade Responsibility Conclusions After completion of this module, you should be able to understand: Red and Yellow tape barricades and their significance Typical situations requiring each barricade type Procedure for entry into barricaded areas Who is responsible for installing and removing barricades Yes 18 Voluntary Protection Program This course provides an overview of OSHA’s Voluntary 30 min What is VPP? OSHA Guidelines After completion of this module, you should be able to understand: Yes

- 5. Protection Program, VPP. Guidelines for VPP qualification, its benefits to qualifying site and elements that must be addressed for qualification are discussed. VPP Benefits Key VPP Elements Conclusions Voluntary Protection Program (VPP) and its different levels OSHA guidelines to qualify for VPP Benefits to a site qualifying for VPP What elements must be addressed to qualify for VPP 19 Office Safety*** This course provides an overview of some of the hazards one may encounter in a typical office. Hazards and Risks of Electricity, Office Machinery, Manual Handling and Ergonomics, Chemicals, Environmental factors such as Air and Noise, Housekeeping, Slips, Trips and Falls, Occupational Aggression and Violence, and Fire are discussed. 30 min Overview Legislation What can go wrong in an Office? Hazards and Risks Conclusions After completion of this module, you should be able to understand: Factors contributing to injury in an office Learn to recognize hazards and risks of Electricity, Office Machinery, Manual Handling and Ergonomics, Chemicals, Environmental factors such as Air and Noise, Housekeeping, Slips, Trips and Falls, Occupational Aggression and Violence, and Fire Yes 20 Office Ergonomics*** This course provides an overview of the basic elements of Office Ergonomics and tasks that can potentially cause Workrelated Musculoskeletal Disorders (WMSD) and other injuries to the muscle and joints. 30 min Overview Definitions Risk Factors Office Equipment Ergo Check Tips for Avoiding Injury Injury Awareness Conclusions After completion of this module, you should be able to understand: What are Work-related Musculoskeletal Disorders (WMSD) Workstation ergonomics Types of Musculoskeletal injuries and how to avoid them Yes 21 Knife Safety*** This course provides an overview of safe use of knife. Topics covered are safety precautions, importance of First Aid, knife maintenance and selecting right knife for the job. 30 min Overview Safety Precautions First Aid Knife maintenance Right Tool in Right Condition Conclusions After completion of this module, you should be able to understand: Precautions to take when using knife Importance of First Aid if injured by knife Importance of maintaining a knife Selecting right knife in right condition for the job at hand Yes 22 Lockout/Tagout*** This course provides an overview of OSHA standard for lockout/tagout of equipment and machines. Topics covered are scope of the standard, use of energy isolating devices to 45 min Overview Energy Isolating Devices Scope of Lockout/Tagout Standard Definitions Lockout/Tagout/Tags After completion of this module, you should be able to understand: What are Energy Isolating Devices What is covered by the OSHA Lockout/Tagout Standard What is lockout/tagout and how to Yes

- 6. isolate equipment/machine, proper use of lockout/tagout devices on energy isolating devices per established procedures and specific roles and responsibilities of employers and employees for proper implementation of the lockout/tagout standard. Lockout/Tagout Devices Roles and Responsibilities Conclusions use them to secure energy isolating devices Situations under which tagout may be acceptable Types of lockout/tagout devices Employers and employees responsibilities for proper implementation of this program 23 Process Safety Management This course provides an overview of OSHA standard for Process Safety Management (PSM) of highly hazardous chemicals. Brief overview of all fourteen elements of this program - Process Safety Information, Process Hazard Analysis, Operating Procedures, Employee Participation, Training, Contractors, PreStartup Safety Review, Mechanical Integrity, Hot Work Permit, Management of Change (MOC), Incident Investigation, Emergency Response Plan, Compliance Audits and Trade Secrets is provided. 45 min Overview Process Safety Information Process Hazard Analysis Operating Procedures Employee Participation Training Contractors Pre-Startup Safety Review Mechanical Integrity Hot Work Permit Management of Change (MOC) Incident Investigation Emergency Response Plan Compliance Audits Trade Secrets Conclusions After completion of this module, you should be able to understand: Basis for OSHA’s standard for Process Safety Management (PSM) of highly hazardous chemicals Fourteen points addressed by this standard -- Process Safety Information, Process Hazard Analysis, Operating Procedures, Employee Participation, Training, Contractors, Pre-Startup Safety Review, Mechanical Integrity, Hot Work Permit, Management of Change (MOC), Incident Investigation, Emergency Response Plan, Compliance Audits and Trade Secrets Yes 24 Job Safety Analysis This course provides an overview of Job Safety Analysis (JSA), a systematic technique useful for identifying, evaluating and controlling health and safety hazards associated with a job or task. Benefits of JSA, when to use it, proper techniques to complete it and how to formulate corrective actions are discussed. 30 min Introduction Learning Objectives What is a Job Safety Analysis? Benefits of Job Safety Analysis Uses of Job Safety Analysis 8-step Method Conclusions After completion of this module, you should be able to understand: What is Job Safety Analysis (JSA) Benefits of JSA Situations when JSA is useful Step-by-step method of completing JSA How to formulate corrective actions on hazards identified Yes 25 Driver Safety This course provides an overview of driving safely and is useful whether you are driving 45 min Introduction Before You Drive Behavior and Actions After completion of this module, you should be able to understand: How to drive safely both on or off the Yes

- 7. to/from work or on/off company business. Topics discussed are road, traffic, vehicle, lighting, weather and driver conditions and why you must monitor these constantly in order to reach your destination safely. Vision Fatigue and Drowsiness Other Physical Conditions Basic Rules of the Road Stopping Distance Weight Transfer Skids Additional Defensive Driving Terms Blind Zones Searching Technique Making Turns Pulling Out From Stop Signs Passing Braking Cell Phone Use Conclusions job What to check and be aware of before you put your foot on the accelerator Be aware of your behavior and actions, as these factors cause 70% of all accidents Why and how you must constantly monitor changing vehicle, lighting, weather, road and traffic conditions 26 Incident Investigation*** This course provides an overview of an effective Incident Investigation methodology and its benefits. Systematic step-bystep investigation process starting with setting up of a team, collecting information, identifying all causes, determining root cause, devising correcting/preventive actions with communication and followup can avoid recurrence of the incident. 30 min Incident Investigation Policy Purpose and Benefits of Incident Investigation Training Objectives Definitions Incident Investigation Team Investigation Tools Investigation Process Collecting Information Identifying All Possible Causes Determining the Root Cause Corrective and Preventive Actions Communicating Findings Incident Reporting Follow-up After completion of this module, you should be able to understand: Why is it important to investigate an incident Kinds of incidents that must be investigated Investigation team and tools they can use Step-by-stem effective investigation process that results in determining root cause How to formulate corrective/preventive actions Importance of communicating findings and follow-up to close out all actions No 27 Resource Conservation and Recovery Act (RCRA) This course provides an overview of Resource Conservation and Recovery Act (RCRA) for regulation and 45 min Resource Conservation and Recovery Act (RCRA) Legal Implications After completion of this module, you should be able to understand: Why Congress passed Resource Conservation and Recovery Act (RCRA) No

- 8. management of hazardous wastes. Topics covered are definition of hazardous wastes and their characteristics, proper labeling, storage and transportation of such wastes. Cradle-to-grave manifest system for shipping hazardous wastes and legal implications (civil and criminal penalties) of violating the Act are also discussed. Hazardous Waste Hazardous Waste Characteristics Hazardous Waste Labeling Hazardous Waste Storage Hazardous Waste Transportation Conclusion for regulation and management of hazardous wastes What are civil and criminal penalties if you violate this law What is hazardous waste and what are its characteristics Importance of proper labeling of hazardous wastes Types of hazardous wastes storage facilities and criteria they must meet How to transport hazardous wastes from your facility to "Permitted Hazardous Waste Treatment, Storage or Disposal (TSD) facility" using manifest system Importance of filling out proper manifest forms 28 Fire Extinguishers*** This course provides an overview of proper selection and use of Fire Extinguishers. Topics covered are an understanding of what causes fire, classes of fire, types of Fire Extinguishers, proper use and inspection of Fire Extinguishers and basic fire prevention practices. 30 min Overview Fire Triangle Classes of Fire Types of Fire Extinguishers Fire Prevention Using Fire Extinguishers Conclusion After completion of this module, you should be able to: Understand what Fire Triangle is Understand the different classes of fires Identify the different types of Fire Extinguishers Understand fire prevention and how to use Fire Extinguishers effectively Yes 29 Fall Protection*** This course provides an overview of OSHA requirements for Fall Protection. The course explains situations when Fall Protection should be used, correct Fall Protection equipment for a situation, and proper use and inspection of the equipment. 30 min Overview Fall Protection Equipment Tie-off and Anchor Points Equipment Inspection and Rescue Conclusion After completion of this module, you should be able to understand: Basics of Fall Protection Fall Protection equipment components How to tie off and anchor correctly Equipment Inspection and rescue Yes 30 Toxic Substance Control Act Section I This course provides an overview of requirements of Toxic Substance Control Act, TSCA. The basic purpose of this regulation is to prevent the 30 min Overview Enforcement and Penalties Inspections Inventory, After completion of this module, you should be able to understand: What is TSCA Why did Congress believe a regulation was necessary No

- 9. introduction into the US of chemicals which present an unreasonable risk of injury to health or the environment. Basic understanding of this complex regulation is provided in three course sections. This section covers an overview of TSCA, key TSCA topics covered in this three section course, the reason behind this Act, enforcement and penalties provided in this Act, EPA inspections to check compliance with the Act, and TSCA Inventory and Premanufacture Notification. Premanufacture Notifications Conclusions What would you learn from this training How does EPA enforce TSCA What constitutes a TSCA violation What penalties are provided in the Act for violations Inspections conducted by EPA to check compliance What is TSCA inventory and how you can check status of any material What is Premanufacture Notification and how you can get one US and International Chemical Inventory laws 31 Toxic Substance Control Act Section II This course provides an overview of requirements of Toxic Substance Control Act, TSCA. The basic purpose of this regulation is to prevent the introduction into the US of chemicals which present an unreasonable risk of injury to health or the environment. Basic understanding of this complex regulation is provided in three course sections. This section covers TSCA Export and Import requirements for chemical materials. Procedures to follow for R&D synthesis of new materials or importation of test quantities of materials not on TSCA inventory are also discussed. 30 min Introduction Export Requirements Import Requirements R&D Exemption Requirements Conclusions After completion of this module, you should be able to understand: Procedures for exporting and importing chemical material What is TSCA Export Notification listing Mechanics of Import Compliance How to handle unsolicited samples Procedures for R&D synthesis and handling of new chemical material Procedures for importation of test quantities of material not on TSCA inventory No 32 Toxic Substance Control Act Section III This course provides an overview of requirements of Toxic Substance Control Act, TSCA. The basic purpose of this regulation is to prevent the introduction into the US of 30 min Introduction Adverse Reactions to Health and Environment Compliance Checks Conclusions After completion of this module, you should be able to understand: What are unusual health and environmental effects Documentation of adverse health and environmental effects No

- 10. chemicals which present an unreasonable risk of injury to health or the environment. Basic understanding of this complex regulation is provided in three course sections. This section addresses TSCA requirement that chemical companies maintain records of unusual health and environmental reactions caused by materials they handle. It also addresses procedures a company can implement to ensure TSCA compliance. Notification of significant adverse reactions to EPA Company and Employee reporting responsibilities Internal company procedures to ensure compliance with TSCA 33 Workplace Violence - This course provides employees Employees with an overview of workplace violence, the sources of workplace violence, warning signs and possible triggering incidents for workplace violence, what employees can do and how to protect themselves and their fellow employees and how to deal with threats and violence. 45 min Background What is Workplace Violence? Company’s Commitment Company’s Policy Sources of Workplace Violence Warning Signs and Indications What Employees can do Reporting Dealing with Threats and Violence Summary After completion of this module, you should be able to understand: What Workplace Violence is Company’s Commitment and Policy How to recognize warning signs How to deal with Workplace Violence When to report possible Workplace Violence No 34 Workplace Violence - This course provides managers Managers with an overview of workplace violence, possible liability of the Company for workplace violence, the sources of workplace violence, warning signs and possible triggering incidents for workplace violence, what employees can do and how to protect themselves and their fellow employees, training employees, and how to deal with threats 60 min Background Company Liability for Workplace Violence What is Workplace Violence? Company’s Commitment Company’s Policy Sources of Workplace Violence Warning Signs and Indications What Employees can do Reporting After completion of this module, you should be able to understand: What Workplace Violence is Company’s Commitment and Policy How to recognize warning signs How to Train Employees on Workplace Violence How to deal with Workplace Violence When to report possible Workplace Violence No

- 11. and violence. Dealing with Threats and Violence Summary 35 Harassment and Discrimination Employees This course provides an overview of Harassment & Discrimination, classes legally protected from harassment & discrimination, Equal Employment Opportunity Commission regulations and federal statutes concerning harassment & discrimination in the workplace, and how to protect yourselves, your fellow employees and your employer from prohibited harassment & discrimination. 45 min Background Company Expectations and Requirements Legally Protected Status What Harassment is Company’s Commitment Company’s Policy After completion of this module, you should be able to understand: Who is Legally Protected What improper Harassment and Discrimination is Company’s Commitment and Policy Company’s Expectations and Requirements No 36 Harassment and Discrimination Managers This course provides managers with an overview of Harassment & Discrimination, classes legally protected from harassment & discrimination, Equal Employment Opportunity Commission regulations, important court cases, and federal statutes concerning harassment & discrimination in the workplace, and how to protect themselves, their fellow employees and their employer from prohibited harassment & discrimination. 60 min Background Company Expectations and Requirements Legally Protected Status Major Federal Laws Other Laws Prohibited Actions What Harassment is Company Liability for Supervisors’ Actions Company’s Commitment Company’s Policy Important Court Cases After completion of this module, you should be able to understand: What improper Harassment and Discrimination is Harassment & Discrimination Laws, Cases and Regulations Company’s Commitment and Policy Company’s Expectations and Requirements Proper handling of Employee issues to prevent exposure No 37 Workplace Hazardous Materials Information System (WHMIS) This course provides an overview of Canada’s hazard communication standard, Workplace Hazardous Materials Information System (WHMIS). Key elements of the standard, Labeling, Material Safety Data Sheets (MSDS) and Worker Education are discussed. 30 min Overview WHMIS Key Elements Hazard Symbols, Classes and Divisions Material Safety Data Sheets (MSDS) WHMIS Glossary Conclusion After completion of this module, you should be able to understand: Canada’s hazard communication standard, Workplace Hazardous Materials Information System (WHMIS) Key Elements of WHMIS -- Labeling, MSDS and Worker Education WHMIS Hazard Symbols, Classes and Yes

- 12. Divisions Various sections of MSDS How to safely handle hazardous materials 38 TrackMobile Switching Safety This course provides an overview of safe use of a TrackMobile to switch railcars. Topics covered are pre-startup checks, responsibilities of switch crews, proper coupling, switching and communication techniques and general safety measures. 30 min Overview Pre-Startup Checks Switch Crews Coupling, Switching and Communication Safety Measures Conclusion After completion of this module, you should be able to understand: Items to check prior to using a TrackMobile Switch crews and their responsibilities Proper coupling, switching and communication techniques Safety techniques to follow Yes 39 Self Contained Breathing Apparatus (SCBA) This course provides an overview of Self Contained Breathing Apparatus (SCBA) and its importance during emergencies and hazardous atmospheres. Two types of SCBA are discussed with safety precautions and recommended method for donning SCBA. 30 min Overview Hazardous Atmospheres Types of SCBA Systems Open Circuit Demand Unit Closed Circuit Breathing Unit Safety Precautions Recommended Method for Donning Conclusions After completion of this module, you should be able to understand: Importance of Self Contained Breathing Apparatus (SCBA) during emergencies and hazardous atmospheres Open and Closed Circuit SCBAs and their components Safety precautions to follow when using SCBA Recommended method for donning SCBA Yes 40 DOT - Regulatory Overview This course provides an overview of the Department of Transportation requirements for personnel managing hazardous materials. The applicable sections of the regulations and important definitions are provided. The nine steps necessary for compliance with the hazardous materials regulations are discussed, including an overview of the Hazardous Materials Table, how to properly classify a material, and how to assign a proper shipping name. In addition, the 90 min Introduction Definitions Nine Transportation Steps Hazardous Materials Table Classification Proper Shipping Names Training Other Requirements After completion of this module, you should be able to understand: Regulations applicable to managing hazardous materials How to use the Hazardous Materials Table How to properly classify a hazardous material How to assign a proper shipping name Training requirements for hazardous materials management No

- 13. training requirements and special requirements such as security are discussed. 41 DOT - Marking and Labeling This course provides an overview of the Department of Transportation marking and labeling requirements for personnel managing hazardous materials. The general marking requirements are identified, as well as specific requirements for non-bulk and bulk packages. The special requirements identified for non-bulk and bulk packages are discussed, as well as the additional requirements for tanks and tank cars and identification numbers. The general labeling requirements are identified, including additional labeling requirements specified in certain situations. 60 min Introduction General Requirements Non-Bulk Packages Bulk Packages Special Requirements Tanks and Tank Cars Identification Numbers General Labeling Requirements Additional Labeling Requirements After completion of this module, you should be able to understand: Properly identify the marking and labeling requirements for a package Properly mark a package Properly label a package No 42 DOT - Packaging This course provides an overview of the Department of Transportation packaging requirements for personnel managing hazardous materials. The procedures for selecting a package for a particular hazardous material are presented, as well as the general requirements applicable to all packages. The requirements applicable to nonbulk and bulk packages are discussed, and additional packaging issues such as overpacks are identified. 60 min Introduction Selecting a Package General Requirements Non-Bulk Packages Bulk Packages Additional Packaging Issues After completion of this module, you should be able to understand: How to properly select a package for a particular hazardous material General requirements applicable to all packages Requirements for non-bulk and bulk packages No 43 DOT - Placarding This course provides an overview of the Department of Transportation placarding 60 min Introduction Placard Selection and Exceptions After completion of this module, you should be able to understand: How to properly select a placard for No

- 14. requirements for personnel managing hazardous materials. The steps necessary to properly select a placard, including placarding exceptions are identified. In addition, how a placard must be designed and displayed is discussed, as well as the placarding responsibilities for both shippers and carriers. Additional Exceptions Design, Display, and Visibility Shipper Responsibilities Carrier Responsibilities any shipment of hazardous materials Specific design and display requirements for placards Responsibilities of shippers related to placards Responsibilities of carriers related to placards 44 DOT - Shipments This course provides an overview of the Department of Transportation shipping requirements for personnel managing hazardous materials. The requirements for shipping hazardous materials by highway, air, rail, and vessel are discussed. 60 min Introduction Highway Shipments Air Shipments Rail Shipments Vessel Shipments After completion of this module, you should be able to understand: Requirements for shipping hazardous materials by highway Requirements for shipping hazardous materials by air Requirements for shipping hazardous materials by rail Requirements for shipping hazardous materials by vessel No 45 DOT - Shipping Papers This course provides an overview of the Department of Transportation shipping paper requirements for personnel managing hazardous materials. The general requirements for shipping papers and the requirements for assigning basic shipping descriptions are provided. Additional descriptions applicable to proper shipping names are also discussed. The emergency response information required on a shipping paper is provided and the different types of certifications on a shipping paper are discussed. Finally, the use of hazardous waste manifests as shipping papers is reviewed when shipping hazardous wastes. 60 min Introduction General Requirements Basic Descriptions Additional Descriptions Emergency Response Information Certifications Hazardous Waste Manifests After completion of this module, you should be able to understand: General requirements for shipping papers for hazardous materials How to enter a basic shipping description When additional descriptions are needed in the shipping description How to enter the required emergency response information on a shipping paper When to use the appropriate certification When to use a hazardous waste manifest No

- 15. 46 EPA - RCRA Overview This course provides an overview of the hazardous waste regulations, how to classify solid and hazardous wastes, and reviews the general requirements for generators, transporters, and treatment, storage and disposal facilities (TSDFs). It also discusses the land disposal restriction requirements applicable to hazardous wastes. 90 min Introduction Solid Wastes Hazardous Wastes Generator Requirements Transporter Requirements TSDF Requirements Land Disposal Restrictions After completion of this module, you should be able to understand: History of RCRA How to properly identify and classify solid and hazardous wastes Basic RCRA requirements applicable to generators of hazardous wastes Basic RCRA requirements applicable to persons who transport hazardous wastes Basic RCRA requirements applicable to persons who treat, store, and dispose or hazardous wastes Basic RCRA Land Disposal Restrictions No 47 EPA – Generator Container Management This course provides an overview of the requirements for generators who manage hazardous wastes in containers. The general regulatory requirements are discussed, as well as the identification and definition of incompatible materials, and the individual requirements for marking, labeling, and inspecting containers. Finally the requirements for the closure of an area used to manage containers are identified. 60 min Introduction General Requirements Incompatible Materials Subpart CC Inspections 90-Day Generator Requirements Closure Conclusion After completion of this module, you should be able to understand: How to identify containers that can be used to manage hazardous wastes Proper management of containers How to properly inspect containers How to identify incompatible materials Marking and labeling requirements for containers How to properly close an area used to manage containers No 48 EPA – Generator Contingency Plan This course provides an overview of the preparedness and prevention requirements for generators who manage hazardous wastes. The required emergency equipment is identified as well as the operating procedures applicable to emergencies. In addition, the Contingency Plan and the appropriate emergency procedures are discussed. 60 min Introduction Preparedness and Prevention Contingency Plan Emergency Procedures Conclusion After completion of this module, you should be able to understand: Regulatory requirements for preparedness and prevention for emergencies such as spills, fires, and releases Emergency equipment that must be present at the facility, including alarms Specific operational requirements for emergencies when managing hazardous wastes Facility Contingency Plan and its No

- 16. contents, including evacuation routes Implementation of the Contingency Plan Emergency procedures that must be employed if there is a fire, explosion, or release 49 EPA - Generator Tank Management This course provides an overview of the requirements for generators who manage hazardous wastes in tanks. The general regulatory requirements are discussed, as well as an overview of the operating requirements for tank systems. The identification and definition of incompatible materials is reviewed, and the individual requirements for marking, monitoring, inspecting, and closure of a tank system are identified. 60 min Introduction General Requirements Operating Requirements Incompatible Materials Subparts BB and CC Inspections 90-Day Generator Requirements Closure Conclusion After completion of this module, you should be able to understand: Applicable equipment associated with a tank system Proper installation and management of a tank system Secondary containment requirements for a tank system How to properly operate, inspect, and monitor a tank system How to identify incompatible materials Marking requirements for tank systems How to properly close a tank system No 50 EPA - Generator Inspections This course provides an overview of the inspection requirements for facilities that manage hazardous wastes. The general inspection program requirements are identified, as well as the specific inspection requirements for emergency equipment, tanks, and containers. The appropriate remedial actions are discussed and the recordkeeping requirements associated with inspections are identified. 60 min Introduction Facility Inspection Program Emergency Equipment Inspections Generator Requirements Container Inspections Tank Inspections Remedial Actions Recordkeeping After completion of this module, you should be able to understand: Why inspections are required How to develop a written inspection program Inspection requirements for emergency equipment, tanks, and containers How to implement corrective actions in response to issues identified during inspections Recordkeeping requirements associated with inspections No 51 EPA - Generator Subpart BB This course provides an overview of the Subpart BB regulations (which regulates organic emissions from specific equipment at hazardous waste management facilities) and 60 min Introduction General Requirements Inspections and Monitoring Specific Equipment Requirements After completion of this module, you should be able to understand: What equipment is regulated under Subpart BB How to properly identify wastes regulated by Subpart BB No

- 17. discusses how to properly identify materials subject to the regulations. The specific requirements for different types of equipment are identified as well as the inspection and monitoring requirements for this equipment. The recordkeeping requirements for all Subpart BB regulated activities are also discussed. Delay of Repair Recordkeeping Regulatory requirements applicable to specific equipment types Inspections and monitoring required for Subpart BB regulated equipment Recordkeeping associated with Subpart BB 52 EPA - Generator Subpart CC This course provides an overview of the Subpart CC regulations (which regulates organic emissions from specific equipment at hazardous waste management facilities) and discusses how to properly identify materials subject to the regulations. The specific requirements for containers, tanks, and control devices are identified as well as the inspection and monitoring requirements for this equipment. The recordkeeping requirements for all Subpart CC regulated activities are also discussed. 60 min Introduction General Requirements Containers Tanks Control Devices Inspections and Monitoring Recordkeeping After completion of this module, you should be able to understand: What equipment is regulated under Subpart CC How to properly identify wastes regulated by Subpart CC Regulatory requirements applicable to containers, tanks, and control devices Inspections and monitoring required for Subpart CC regulated equipment Recordkeeping associated with Subpart CC No 53 HAZWOPER Awareness Level 1 This course provides an overview of OSHA and EPA joint standard on Hazardous Waste Operations and Emergency Response (HAZWOPER) with emphasis on training requirements for Awareness (Level 1) of this standard. The module also provides basic understanding of hazardous materials, how to recognize them and how to respond to emergencies arising out of their 30 min Overview Training Hazardous Materials Emergency Response Plan MSDS Conclusion After completion of this module, you should be able to understand: Purpose of HAZWOPER Standard and its Levels Training requirements of HAZWOPER Awareness Level 1 What are hazardous materials and how to recognize them Emergency Response Plan and how to use it Material Safety Data Sheets (MSDS) and its benefits No

- 18. use. 54 Job Site Safety This course provides an overview of Safety Hazards at typical industrial Job Site. The module outlines method to analyze Job Site Safety and how to protect from hazards. Common Job Site hazards such as Slips/Trips/Falls, Lifting, Burns, Conveying Systems, Lockout/Tagout, Hot/Cold Weather hazards, Unprotected Hoses and Perimeters, Power Tools, Falling Objects, Exposure to Chemicals, Confined Spaces, Ladders, Scaffolds, and Platforms are discussed. Proven methods to protect from these hazards is also discussed. 30 min Overview Protecting Yourself Analyze Job Site Safety Common Job Site Hazards Summary After completion of this module, you should be able to understand: How to identify and avoid common Job Site Hazards How to analyze Job Site prior to beginning work How to protect yourself from common Job Site Hazards Specific analysis of hazardous situations involving Slips/Trips/Falls, Lifting, Burns, Conveying Systems, Lockout/Tagout, Hot/Cold Weather hazards, Unprotected Hoses and Perimeters, Power Tools, Falling Objects, Exposure to Chemicals, Confined Spaces, Ladders, Scaffolds, and Platforms Yes 55 Centrifugal Pumps This course provides an overview of Centrifugal Pumps, one of the most commonly used pumps in industry to move liquids. The module concentrates on single-stage electrically driven centrifugal pumps. It covers basic design and operation, key components and five main centrifugal pump functions -- Driving, Pumping, Lubricating, Cooling and Seal Flushing. 30 min Overview Installation Driving and Pumping Lubricating and Cooling Conclusion After completion of this module, you should be able to understand: Basic Design and Operation of Centrifugal Pump Components of Centrifugal Pump Five Functions of Centrifugal Pump Driving, Pumping, Lubricating, Cooling and Seal Flushing Details and Equipment involved in each function Yes 56 Field Hazard Recognition Module 1 This course provides an overview of field hazards at industrial work locations that workers can be exposed to. This two module course covers hazard recognition, protection from hazards and good safety practices that help avoid accidents. This first module 30 min Overview After completion of this module, you should Good Housekeeping be able to understand: Hazard Recognition Importance of Good Housekeeping in Protection against Hazards reducing work area Hazards Slips, Trips and Falls How to recognize Hazards Good Safety Practices Protection against Hazards Conclusion Slips, Trips and Falls Good Safety Practices No

- 19. emphasizes on good housekeeping practices and protection from slips, trips and falls. 57 Field Hazard Recognition Module 2 This course provides an overview of field hazards at industrial work locations that workers can be exposed to. This two module course covers hazard recognition, protection from hazards and good safety practices that help avoid accidents. This second module emphasizes on accident prevention signs and tags, material handling hazards and work area checklists to help identify and eliminate hazards. 30 min Overview Signs & Tags Material Handling Hazards Work Area Checklist Conclusion After completion of this module, you should be able to understand: Field hazards and the common causes of serious accidents Colors, shapes, wording, and meaning of accident prevention signs and tags required by OSHA Material handling hazards How to identify hazards Work Area Checklists to help you identify and eliminate hazards No 58 Drawings: P&ID and PFD This course provides an overview of drawings used in process industries, Piping and Instrument Diagrams (P&IDs) and Process Flow Diagrams (PFD). The course covers drawing conventions, symbols used and significant differences between these drawings. The course provides enough information for employees in these industries to be able to read and understand these drawings. 30 min Overview P&IDs Valve Symbols Piping Symbols Miscellaneous Symbols Process Flow Diagrams Title Block Conclusion After completion of this module, you should be able to understand: Piping & Instrumentation Diagrams (P&IDs) and Process Flow Diagrams (PFD) Differences between two types of drawings Typical Drawing conventions Symbols used for illustrating Piping, Valves, Equipment and Instruments Importance of reading and understanding each drawing Yes 59 Employee Rights of Access to Exposure and Medical Records This course provides an overview of OSHA standard on Employees Rights of Access to Exposure and Medical Records. The module covers the scope of the standard, key definitions such as types of records that constitute medical and exposure records, records retention 30 min Overview Scope and Definitions Records Retention Rights of Access Conclusion After completion of this module, you should be able to understand: Requirements of the OSHA standard on Employees Rights of Access to Exposure and Medical Records Definitions of key terms: Type of access, Employee and Designated Representative, Written consent, Exposure Records, and Medical Yes

- 20. requirements and employees’ rights of access. Records Employer’s responsibility for Records Retention Employee's Rights of Access 60 Sexual Harassment Prevention This module provides an overview of Sexual Harassment prevention at your workplace. It explains what is and is not Sexual Harassment, how law defines Sexual Harassment, how you can deal with it and how to prevent it from happening at your workplace. 30 min Overview Law Awareness Scenarios Conclusion After completion of this module, you should be able to understand: What constitutes Sexual Harassment What is Sexual Harassment in the eyes of the law How you can help prevent sexual harassment from occurring at your workplace Procedure for dealing with sexual harassment at your workplace No 61 Basic Corrosion This course provides an overview of corrosion that causes failure of industrial equipment. It explains basic corrosion concepts such as corrosion cell and how it causes corrosion, types of corrosion such as Galvanic Corrosion and Oxygen Corrosion, and how to detect and prevent corrosion. 30 min Basic Corrosion Concepts Galvanic Corrosion Oxygen Corrosion Hydrogen Sulfide Corrosion Erosion Corrosion Conclusion After completion of this module, you should be able to understand: What causes corrosion Corrosion cell components – Anode, Cathode, Electrolyte and Conductor Types of corrosion such as Galvanic Corrosion, Oxygen Corrosion, Hydrogen Sulfide Corrosion and Erosion Corrosion What causes different types of Corrosion, how to detect and prevent these from occurring No 62 Welding, Cutting and Brazing Safety This module provides an overview of hazards associated with commonly used industrial task of welding, cutting and brazing and protection from these hazards. Personal protective equipment and other miscellaneous safety precautions are discussed. 30 min Introduction Definitions Welding Hazards Personal Protective Equipment Miscellaneous Precautions Conclusion After completion of this module, you should be able to understand: What is Welding, Cutting and Brazing Common types of welding processes Common welding hazards such as Radiant Energy, Temperature Extremes, Fumes and Gases, Noise, Sparks and Slag, Electrical Shock, Chemicals, Fires, Explosions, Housekeeping and Musculoskeletal Injuries Proper Personal Protective Equipment Other miscellaneous safety precautions such as exposure monitoring, medical monitoring, No

- 21. training and ventilation 63 Industrial Hygiene*** This module provides an overview of Industrial hygiene as it relates to workplace hazards. Basic elements of an effective Industrial hygiene program such as health hazard evaluation, recognition, control, and employee education are covered. Emphasis is placed on recognition, evaluation, and control of factors that reduce or eliminate potentially harmful workplace exposures. 45 min Introduction Management commitment Basic Elements Health hazard recognition Health hazard evaluation Chemical hazards Physical hazards Biological hazards Health hazard control Employee education and training Program audit and review Conclusion After completion of this module, you should be able to understand: Industrial hygiene (IH) as it relates to workplace health hazards Primary focus of industrial hygiene Basic Elements of Industrial hygiene – Health hazard recognition, evaluation, control, employee education and audits How sound industrial hygiene program can help anticipate, recognize, evaluate, and control of factors in an occupational environment that can lead to illness, impaired health or discomfort No 64 JLG Lifts This module provides an overview of proper procedures for operation of JLG Lifts with emphasis on safety. Responsibilities of manufacturer, dealer, owner, and operators with regards to safe operation of JLG Lifts, hazards encountered during operation and how to avoid them, and pre-operation inspection items are discussed. 30 min Overview Manufacturer Responsibility Dealer Responsibility Owner Responsibility Operator Responsibility Electrocution Hazards Tip Over Hazards Miscellaneous Hazards Pre-Operation Inspection Conclusion After completion of this module, you should be able to understand: Proper procedures for safe operation of JLG Lifts Responsibilities of the manufacturer, dealer, owner and operators with regards to safe operation of JLG Lifts Hazards involved in the operation of JLG Lifts and how to avoid them Pre-operations inspections that must be performed for safe operation No 65 Zero Energy Program This course provides an overview of OSHA regulation on Control of Hazardous Energy during servicing and maintenance of equipment in an industrial environment. The course explains how a properly established Zero Energy program using locks, tags, procedures and defined responsibilities can help control all forms of potentially hazardous energy during 30 min Introduction Scope of Zero Energy Program Locks Tags Zero Energy Survey Servicing and Maintenance When work is complete Conclusion After completion of this module, you should be able to understand: What is hazardous energy How Zero Energy program can help control all forms of hazardous energy Use of standardized color-coded locks to control energy Use of tags and their limitations How to create job or equipment specific energy control procedure using Zero Energy survey Proper steps to follow prior to, during and after servicing and maintenance Yes

- 22. servicing and maintenance activities. of equipment under this program 66 Trucks and Towing This module provides general information and tips that can help you make safe decisions when purchasing and driving a tow vehicle. Topics such as selecting a tow vehicle, connecting trailer to your tow vehicle, loading and weight distribution, maintenance, predeparture check list and driving safety tips are covered. The module also provides an overview of safe driving of a Light Duty Truck or Sports Utility Vehicle (SUV). 45 min Part I : Light Duty Truck Safety Mirrors and Visibility Tires Winter Driving Part II : Trailers and Towing Selecting a Tow Vehicle Hitching Systems Wiring Systems Braking Systems Loading and Weight Distribution Choosing the proper hitch Measuring the Weight of a Trailer Maintenance Pre-Departure Safety Checklist Safety Tips for Driving with a Trailer Conclusions After completion of this module, you should be able to understand: Safe driving of a Light Duty Truck or Sports Utility Vehicle (SUV) Different handling characteristics of Light Duty Truck such as visibility, tires and winter driving General information and tips that can help you make safe decisions when purchasing and driving a tow vehicle Trailer hitching, wiring and braking Loading and weight distribution Maintenance, pre-departure check list and driving safety tips Yes 67 Properties and Hazards of Hydrogen Sulfide (H2S) This module provides an overview of working safely with Hydrogen Sulfide (H2S). Topics covered are H2S formation chemistry and physical properties, personal protective equipment for H2S, precautions to take when working with H2S, and rescue and first aid including artificial respiration and CPR. 30 min Formation of H2S Properties of hydrogen sulfide (H2S) H2S Protective Measures Precautions to follow when working with H2S Rescue and First Aid Conclusion After completion of this module, you should be able to understand: How to work safely with hydrogen sulfide (H2S) How hydrogen sulfide forms and some important properties such as: flammability, toxicity, odor thresholds and vapor density Personal protective equipment such as respirators, rescue packs and gas monitors Precautions to take to ensure your safety when entering an area which may contain H2S vapors Rescue and first aid as it applies to H2S exposure How to revive victims of H2S inhalation using artificial respiration No

- 23. and CPR 68 ISO 9001: 2000 Standards This module provides an overview of new ISO 9000 quality standard, ISO 9001:2000. The module provides a background on ISO 9000 standards, their importance, their popularity, application in various organizations, and how they have evolved into the newer, more efficient standard. The module discusses five primary sections of the standard and how you can structure your organization, procedures and quality management system to meet its requirements. 45 min Introduction ISO 9001:2000 Structure New Emphasis Quality Management System Management Responsibility Resource Management Product Realization Measurement Analysis & Improvement Closing tips Conclusion After completion of this module, you should be able to understand: What are ISO 9000 quality standards, their purpose, importance and application How is new standard different from original ISO standards ISO 9001:2000 standard’s key requirements that your quality management system must meet New standard’s process approach to quality management using methodology “Plan-Do-Check-Act” (PDCA) Five primary sections of the new ISO 9001:2000 standard (Quality Management System, Management Responsibility, Resource Management, Product Realization, Measurement, Analysis and Improvement) and their individual requirements How must you structure your organization, resources, policies, procedures and documentation to meet requirements of each primary section No 69 NORM (Naturally Occurring Radioactive Materials) Awareness This module provides an overview of Naturally Occurring Radioactive Material (NORM) and their hazards. The module covers NORM in industrial environment, types of radiation, their hazards and measurements, health effects of radiation, risks involved and ways to minimize these risks, and safe practices to follow when working with NORM. 30 min Introduction Radiation Radiation Measurement Contamination vs. Radiation Health Effects Radiation Risks The "ALARA" Concept Working with NORM After completion of this module, you should be able to understand: What is NORM or Naturally Occurring Radioactive Material What is Radiation Types of Radiation, their properties and hazards How Radiation is measured Amount of Radiation that is safe and hence not regulated Health effects of Radiation and other risks How to keep Radiation as low as reasonable possible No

- 24. Practices to follow when working with NORM 70 Product Stewardship Overview This module provides an overview of Product Stewardship, a key code of management practice of the Responsible Care® program. The module explains how a sound Product Stewardship program can ensure that health, safety, and environmental protection are integral parts of product design, manufacture, sale, distribution, use, recycling, and disposal. 30 min Overview What is Product Stewardship? Responsible Care Scope of Product Stewardship Elements of Product Stewardship Product Life Cycle Conclusion After completion of this module, you should be able to understand: What is Product Stewardship What is Responsible Care, its guiding principles and codes Requirements of a Product Stewardship program Key areas to be addressed in a Product Stewardship program - Management Leadership and Commitment, Product Information and Characterization, and Risk Management Typical product life cycle and Product Stewardship issues No 71 Back Safety This course provides an overview of back safety and proper lifting procedures. It is useful whether you are at work or home. Topics discussed are why back injuries occur, the spine, types of injuries that occur, the forces involved, contributing factors, common causes of back injuries, how to prevent back injuries, using proper lifting procedures, how to lift safely and body management. 30 min Introduction Why Back Injuries Occur Spine Types of Injuries that Occur Forces Involved Contributing Factors Common Causes of Back Injuries How to Prevent Back Injuries Using Proper Lifting Procedures How to Lift Safely Body Management Conclusion After completion of this module, you should be able to understand: Anatomy of a Back Injury Identifying common risk factors of your own work place Recognize your own posture & position and correct as needed Problem-solving how to reduce risk factors for specific job tasks Performing appropriate exercises that are job specific No 72 Machine Guarding This course provides an overview of the safety role of machine guards with descriptions of machine parts that can cause injury, the hazards presented by these parts and the OSHA requirements for guarding to prevent these injuries. Some 30 min Introduction Machine Components General Requirements Hazards Cutting, Punching, Shearing, Bending Requirements for Safeguards Training At the end of this Machinery and Machine Guarding module, you should be able to: Identify hazards associated in working with and around machinery and the guards used to protect the operator Identify hazards and machine guards for various types of specialized machinery. Understand good maintenance and No

- 25. other areas covered are: ideas for hands-on training for workers, details on guard construction, and recommendations for machinery maintenance and repair. Miscellaneous Aids Guard Construction Types of Feeding and Ejection Methods Machinery Maintenance and Repair Guards Conclusion repair procedures that contribute significantly to the safety of the maintenance crew as well as that of machine operators. 73 Safety Orientation This course provides an overview of the various elements of safety orientation, stressing the importance of simply “knowing your area”. Other areas covered are: what to do in case of a fire or chemical spill, fire extinguisher operation, safety around radiation sources, personal protective equipment and good work practices. 30 min Know Your Area Chemicals Radiation Safety Fire Safety Personal Protective Equipment Good Work Practices After completion of this module, you should be able to: Describe good housekeeping practices that promote workplace safety. Describe safety concerns associated with the proper use of tools, ladders, and energy sources. Describe the types of information that can be obtained from Material Safety Data Sheets. Describe warning signs and labels that may be used to communicate information about hazards in a workplace. Yes 74 Lead Awareness This course provides an overview of lead awareness. Some topics discussed are: a description of lead, where you find it, the health hazards associated with lead, how to protect yourself from these hazards, and what to do if you are exposed to lead in the workplace. 30 min Overview Health Hazards Protecting Yourself More Information Conclusion After reading this module, you will be able to: Identify health problems associated with overexposure to lead Indicate how lead is typically absorbed into the body Select controls used to prevent absorbing lead into the body Indicate that you should contact Health Services if you believe you have been overexposed to lead Identify that there is an OSHA regulation and appendices that specifically address lead in the workplace No 75 Eye and Face Protection This module provides an overview of eye hazards in the workplace and how to prevent them. OSHA requirements, personal protective equipment 30 min Introduction OSHA Requirements Hazards Requiring Eye and Face Protection Conclusion After completion of this course, you should be able to understand: Common causes of Eye Injury Proper Eye Protection for the Job Hazard No

- 26. and other miscellaneous safety precautions are discussed. Proper selection of Eye Protection How to prevent eye injuries on the job 76 Steel Erection Standards Steel erection presents many hazards to the employees on the worksite, a number of which are unique to steel erection. Because of the inherent hazards, steel erection is heavily regulated by OSHA. These hazards, their prevention and related OSHA standards are discussed in this module. 45 min Overview Causes of Steel Erection Accidents Precautions General Requirements Hazards New Standard Key Provisions of the Standard Conclusion After completion of this course, you should be able to understand: Hoisting and rigging Structural steel assembly Falling object protection Steel erection safety No 77 Trenching and Excavation The purpose of this module is to provide the learner with an overview of the key safety issues related to trenching and excavation. 30 min Overview Structural Implementations Precautions Protection Equipment Inspections Conclusion After completion of this course, you should be able to understand: Structural Implementation Safety precautions when Trenching or Excavating Necessary protection needed for Trenching and Excavating Types of equipment used How and when inspections are needed No 78 Cyber Security Awareness After completing this module the learner will understand that cyber security is about protecting their company’s computers and other digital information assets from security threats such as viruses, hackers, etc. 30 min Introduction Protecting You from Cyber Threats Reduce Your Exposure to Cyber Threats Conclusion After completion of this course, you will understand how to: Identify and report potential cyber threats Protect yourself from cyber threats Reduce your exposure to cyber threats Choose strong passwords Encrypt email No 79 Chemical Plant Evacuation Emergencies, both inside and outside your facility, may require evacuations to protect your personnel. This course will emphasize to the worker the importance of good evacuation plans that address issues of alarms, exits, assembly areas, and accounting for all persons at the plant. 30 min Introduction Communications Outside Assembly Areas Training Conclusion Upon completion of this course, you will understand: What to do in the event of an emergency Events that may require evacuation How to develop good communication within your facility Where to assemble during an evacuation No

- 27. 80 Homeland Security This module provides an overview of the Homeland Security Threat Conditions and the precautions that need to be taken during each level. Also discussed are specific potential terrorist threats, including what to do before, during and after attacks. 30 min Introduction Threat Conditions and Protective Measures Specific Terrorist Threats Evacuation Plans Conclusion Upon completing this course you will know: Threat conditions and protective measures How to identify specific terrorist threats What to do if there is a nuclear blast Definition of a radiation threat or "dirty bomb" What items are needed for supply checklists Evacuation plans for your area No 81 Below Grade Safety There are some specific measures that can help reduce the risks associated with below grade construction. This module provides an overview of conditions, risks, and safety measures to consider in construction excavations. 30 min Objectives Definitions and Conditions Hazards Safety Measures Conclusion After completion of this module, you should understand Types of below grade construction, hazards faced in such a workplace, and safety measures to use when working below grade. Definitions and conditions Hazards Safety measures No 82 Methylene Chloride Methylene chloride is a dangerous chemical that exposes workers to the risk of cancer and other health problems. This module provides workers with information on the properties, health hazards, OSHA regulations, and suggestions for safety measures to use with this chemical. 30 min Objectives Background Health Hazards OSHA Regulations Safe Handling Conclusion After completion of this module, you should understand: Methylene Chloride and its properties Health hazards posed by Methylene Chloride OSHA regulations regarding working with Methylene Chloride Safe handling of Methylene Chloride No 83 Laser Safety Laser use is increasing, and lasers can be found in every industry. This module will provide workers with an overview of laser use and classification. Since there is little regulation of laser products, it is also important for the worker to be aware of potential hazards and safety measures to use. 30 min Objectives Background Regulation Classification Hazards Safety Measures Conclusion After completion of this module, you should be able to understand: Lasers - definition and use Regulation of lasers Classification of lasers Hazards of the laser beam Safety measures for the use of lasers No

- 28. 84 Heat Stress Awareness The best defense against heatrelated illness is prevention. This module will explain some of the health problems arising from exposure to extreme heat and provide some guidance on preventing heat stress. 30 min Objectives Background Heat Stress Disorders Preventing Heat Stress Conclusion After completion of this training module, you should be familiar with: Background and general conditions of heat stress Heat stress disorders Tactics for preventing heat stress No 85 Carbon Monoxide Carbon monoxide poisoning is a silent risk that can be present in the workplace and in the home. This module will make workers more aware of the risks of carbon monoxide, describe symptoms of exposure, and give suggestions for safety measures to use to prevent carbon monoxide poisoning. 30 min Objectives What is carbon monoxide? How does carbon monoxide affect you? Prevention and care Conclusion Upon completion of this module, you will understand: Characteristics of carbon monoxide Identify the health consequences of exposure to CO Identify the symptoms of exposure to CO Ways to prevent your exposure to CO No 86 Cold Stress Awareness Working in very cold conditions may pose special hazards to safety and health. This module will explain some of the health problems arising from exposure to a cold environment and provide some guidance on preventing cold stress. 30 min Objectives Background Cold Stress Disorders Preventive Measures Conclusion Working in very cold conditions may pose special hazards to safety and health. After completion of this training module, you should be familiar with: Background and general conditions of cold stress Symptoms and treatment of cold stress disorders Preventive measures for reducing cold stress No 87 Ethylene Oxide Ethylene oxide is a dangerous chemical that exposes workers to the risk of cancer and other health problems. This module provides workers with information on the properties, health hazards, OSHA regulations, and suggestions for safety measures to use with this chemical. 30 min Objectives Background Health Hazards OSHA Regulations Safe Handling Conclusion After completion of this module, you should understand: Ethylene oxide and its properties Health hazards posed by ethylene oxide OSHA regulations regarding working with ethylene oxide Safe handling of ethylene oxide No 88 Benzene Benzene is a dangerous chemical that exposes workers to the risk of cancer and other 30 min Objectives Background Health Hazards After completion of this module, you should understand: Benzene and its properties No

- 29. health problems. This module provides workers with information on the properties, health hazards, OSHA regulations, and suggestions for safety measures to use with this chemical. OSHA Regulations Safe Handling Conclusion Health hazards posed by benzene OSHA regulations regarding working with benzene Safe handling of benzene 89 Latex Allergy Even though it is generally not life threatening, latex allergy is a growing problem for health care workers and others. This module provides workers with information on the causes and symptoms of latex allergy along with preventive measures to pursue when using latex products. 30 min Objectives Background Reaction and Treatment Prevention Conclusion After completion of this module, you should be more aware of: Growing incidence of latex allergy Symptoms and treatment for latex allergy Prevention of latex allergy No 90 Styrene Styrene is a dangerous chemical that exposes workers to health problems, especially relating to the central nervous system. Some agencies believe that styrene is potentially carcinogenic. This module provides workers with information on the properties, health hazards, and suggestions for safety measures to use with this chemical. 30 min Objectives Background Health Hazards Safe Handling Conclusion Although styrene is not classified as definitely carcinogenic at this time, this chemical can be hazardous to your health. After completing this training module, you should understand: Styrene and its properties Health hazards posed by styrene Safe handling of styrene No 91 Computer Workstations The factors and advice presented in this module apply not only to computer workstations on the job, but also are relevant for computers in the home. An appropriate workstation set-up will help workers avoid fatigue, stress, and potential medical problems. 30 min Objectives Introduction Body Position Station Components Other Important Factors Conclusion After completion of this module, you should be able to: Recognize and practice good body position at a computer workstation Understand the basic components of a computer workstation and their effects on your productivity and health Recognize other workplace factors that can affect your productivity and health at a computer workstation No

- 30. 92 Chemical Reactivity Hazards All chemicals react. Workers must separate safe reactions that produce useful products from reactive material hazards. This module describes some information sources, causes, and hazards relating to chemical reactions. 30 min Objectives Introduction Safety Resources Hazards Conclusion After completion of this module, you should know more about: Nature and importance of chemical reactivity hazards Safety information resources relating to chemical reactivity Hazards that result from chemical reactions Some causes of undesirable chemical reactions No 93 Diesel Exhaust Diesel exhaust is an enormous problem with dangerous health consequences for workers and the general public. This module emphasizes the need for management and workers to develop safe practices to help reduce these hazardous emissions. 30 min Objectives Background Emissions Effects Controls Conclusion After completion of this module, you should know more about: Emission of chemicals and gases from diesel exhaust Health problems resulting from diesel exhaust Workplace practices to control diesel exhaust No 94 Indoor Air Quality The quality of the air in the workplace will affect the worker’s production and health. It is often difficult to assess the causes of poor indoor air quality, and management is often slow to recognize the effects of problem air on the workers. This module should increase the worker’s awareness of the issues surrounding indoor air quality. 30 min Objectives Background Hazards and Effects Responses Conclusion After completion of this module, you should: Be more concerned with the quality of the air in your workplace Know some of the causes of poor indoor air quality Recognize ways that poor indoor air quality can affect the workers Learn some ways to improve the quality of the air in the workplace No 95 Ammonia Refrigeration Hazards The hazards associated with the operation and maintenance of ammonia refrigeration systems can be reduced if workers are trained and follow strict safety procedures. This module emphasizes the need for good work practices when handling ammonia. 30 min Objectives Background Exposure Safety Measures Receiving Safety Measures - Storage Safety Measures - Hoses Safety Measures - Other Conclusion After completion of this module, you should know more about: Nature of anhydrous ammonia Safety standards regulated by OSHA that relate to ammonia Hazards of exposure to ammonia Some specific safety measures to use for loading, unloading, and storing ammonia No

- 31. 96 Silica - Hazards of Silica dust can be a health problem for many workers, especially in the construction trades. In this module, the worker will learn how the major hazard of silicosis can be prevented with appropriate work practices and regular medical examinations. 30 min Objectives Background Health Effects Controls Conclusion After completion of this module, you should know more about: Nature of silica Health hazards from silica dust Controls to use to prevent workers from developing silicosis No 97 Sprains and Strains Sprains and strains are the number one cause of lost work time due to illness or injury in the U.S. Sprains and strains can be reduced through the use of ergonomics and good work practices. 30 min Objectives Introduction Statistics Sprains and Strains Prevention Conclusion After completion of this module, you should know more about: Relationship between ergonomics and musculoskeletal disorders (MSDs) Incidence of sprains and strains in national workplace injury statistics Causes, symptoms, and treatment of sprains and strains Methods of preventing sprains and strains in the workplace No 98 Fire Safety All businesses should have fire safety as a top priority. Good planning for fire emergencies includes fire prevention programs, fire-fighting training for employees, and specific evacuation plans. This module reinforces these ideas. 30 min Objectives Introduction Planning for Fires Flight or Fight Fire Extinguishers Fire Exits Conclusion After completing the Fire Safety training module, workers should have a basic understanding of: OSHA regulations regarding fire safety in the workplace Need for fire prevention and emergency action plans Use of fire extinguishers Construction of fire exits Decision making process in determining whether to fight a fire or to flee a fire No 99 Security Threats: An Overview No place can be considered completely safe when considering the potential threats posed by disgruntled or senseless individuals or the more organized and systematic threats posed by fanatical political and extremist groups. This module outlines some basic precautions regarding the most 30 min Objectives Preparing for Terrorism Preparing for Cyber attacks Suspicious Parcels or Letters Bomb Threats Explosions Chemical and Biological Weapons The purpose of this training module is to give you an overview of potential security threats and possible responses to those dangers. After completing this module, you should know more about: Preparing for terrorism Protection against cyber attacks Preparing for a building explosion Bomb threats Suspicious parcels and letters No