542001127.pdf

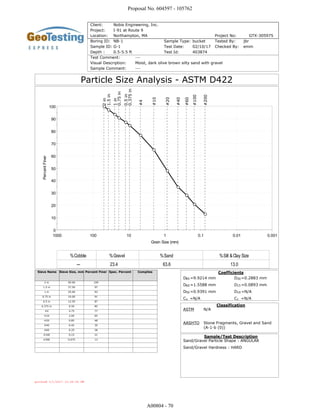

- 1. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-1 Sample ID: G-1 Depth : 0.5-5.5 ft Sample Type: bucket Test Date: 02/10/17 Test Id: 403874 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, dark olive brown silty sand with gravel Sample Comment: --- Particle Size Analysis - ASTM D422 printed 3/1/2017 12:05:05 PM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 23.4 %Sand 63.6 %Silt &Clay Size 13.0 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 50.00 37.50 25.00 19.00 12.50 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 97 93 91 87 85 77 65 48 35 28 21 13 Coefficients D =9.9214 mm 85 D =1.5588 mm 60 D =0.9391 mm 50 D =0.2883 mm 30 D =0.0893 mm 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Stone Fragments, Gravel and Sand (A-1-b (0)) Sample/Test Description Sand/Gravel Particle Shape : ANGULAR Sand/Gravel Hardness : HARD Proposal No. 604597 - 105762 A00804 - 70

- 2. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-2 Sample ID: G-1 Depth : 1.1-6 ft Sample Type: bucket Test Date: 02/13/17 Test Id: 403876 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, dark olive brown silty sand with gravel Sample Comment: --- Particle Size Analysis - ASTM D422 printed 3/1/2017 12:05:06 PM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 3 in 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 20.1 %Sand 47.1 %Silt &Clay Size 32.8 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 3 in 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 75.00 50.00 37.50 25.00 19.00 12.50 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 98 97 93 91 88 86 80 73 65 60 57 53 33 Coefficients D =8.6163 mm 85 D =0.4395 mm 60 D =0.1344 mm 50 D =N/A 30 D =N/A 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Silty Gravel and Sand (A-2-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : ANGULAR Sand/Gravel Hardness : HARD Proposal No. 604597 - 105762 A00804 - 71

- 3. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-2 Sample ID: S-1 Depth : 5.5-7.5 ft Sample Type: jar Test Date: 02/07/17 Test Id: 403879 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist,, olive gray sandy silt Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:49:06 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 0.0 %Sand 42.2 %Silt &Clay Size 57.8 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies #4 #10 #20 #40 #60 #100 #200 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 100 100 100 98 87 58 Coefficients D =0.1422 mm 85 D =0.0790 mm 60 D =N/A 50 D =N/A 30 D =N/A 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Silty Soils (A-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : --- Sand/Gravel Hardness : --- Proposal No. 604597 - 105762 A00804 - 72

- 4. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-3 Sample ID: G-1 Depth : 1.1-6 ft Sample Type: bucket Test Date: 02/10/17 Test Id: 403873 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, olive brown silty sand Sample Comment: Sample contains organics Particle Size Analysis - ASTM D422 printed 3/1/2017 12:05:07 PM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 3 in 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 7.9 %Sand 58.6 %Silt &Clay Size 33.5 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 3 in 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 75.00 50.00 37.50 25.00 19.00 12.50 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 98 97 96 95 94 94 92 90 86 79 73 58 33 Coefficients D =0.7530 mm 85 D =0.1591 mm 60 D =0.1190 mm 50 D =N/A 30 D =N/A 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Silty Gravel and Sand (A-2-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : ANGULAR Sand/Gravel Hardness : HARD Proposal No. 604597 - 105762 A00804 - 73

- 5. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-4 Sample ID: S-4 Depth : 6-8 ft Sample Type: jar Test Date: 02/07/17 Test Id: 403877 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, dark brown sand with silt and gravel Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:45:50 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 46.1 %Sand 47.3 %Silt &Clay Size 6.6 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 37.50 25.00 19.00 12.50 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 86 74 67 62 54 45 35 22 15 10 6.6 Coefficients D =24.1710 mm 85 D =7.9143 mm 60 D =3.2681 mm 50 D =0.6572 mm 30 D =0.2528 mm 15 D =0.1449 mm 10 C =54.619 u C =0.377 c Classification ASTM N/A AASHTO Stone Fragments, Gravel and Sand (A-1-a (1)) Sample/Test Description Sand/Gravel Particle Shape : ANGULAR Sand/Gravel Hardness : HARD Proposal No. 604597 - 105762 A00804 - 74

- 6. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-4 Sample ID: S-6 Depth : 15-17 ft Sample Type: jar Test Date: 02/07/17 Test Id: 403878 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, brown silty sand with gravel Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:45:51 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 19.1 %Sand 62.0 %Silt &Clay Size 18.9 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 25.00 19.00 12.50 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 90 87 85 81 76 67 53 39 29 19 Coefficients D =9.4480 mm 85 D =0.6098 mm 60 D =0.3815 mm 50 D =0.1603 mm 30 D =N/A 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Silty Gravel and Sand (A-2-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : ANGULAR Sand/Gravel Hardness : HARD Proposal No. 604597 - 105762 A00804 - 75

- 7. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-5 Sample ID: G-1 Depth : 0.5-6 ft Sample Type: bucket Test Date: 02/12/17 Test Id: 403875 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, very dark grayish brown silty sand with gravel Sample Comment: Sample contains asphalt Particle Size Analysis - ASTM D422 printed 3/1/2017 12:05:08 PM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 3 in 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 40.7 %Sand 46.0 %Silt &Clay Size 13.3 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 3 in 2 in 1.5 in 1 in 0.75 in 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 75.00 50.00 37.50 25.00 19.00 12.50 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 93 89 81 77 73 69 59 50 39 30 24 19 13 Coefficients D =30.2836 mm 85 D =5.0041 mm 60 D =1.9889 mm 50 D =0.4317 mm 30 D =0.0917 mm 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Stone Fragments, Gravel and Sand (A-1-b (0)) Sample/Test Description Sand/Gravel Particle Shape : ANGULAR Sand/Gravel Hardness : HARD Proposal No. 604597 - 105762 A00804 - 76

- 8. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-5 Sample ID: S-3 Depth : 14-16 ft Sample Type: jar Test Date: 02/07/17 Test Id: 403880 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, dark olive brown silty sand Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:45:52 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 1.1 %Sand 80.2 %Silt &Clay Size 18.7 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 0.5 in 0.375 in #4 #10 #20 #40 #60 #100 #200 12.50 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 100 99 99 99 99 98 87 50 19 Coefficients D =0.2422 mm 85 D =0.1718 mm 60 D =0.1495 mm 50 D =0.0962 mm 30 D =N/A 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Silty Gravel and Sand (A-2-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : --- Sand/Gravel Hardness : --- Proposal No. 604597 - 105762 A00804 - 77

- 9. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: TP-1 Sample ID: G-1 Depth : 0.3-6 ft Sample Type: jar Test Date: 02/08/17 Test Id: 403869 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, olive gray silty sand Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:45:53 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 0.0 %Sand 73.2 %Silt &Clay Size 26.8 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies #4 #10 #20 #40 #60 #100 #200 --- --- --- --- --- --- --- --- --- 4.75 2.00 0.85 0.42 0.25 0.15 0.075 Particle Size (mm) 0.0361 0.0234 0.0137 0.0096 0.0067 0.0048 0.0034 0.0014 100 100 100 100 99 85 27 Percent Finer 6 3 2 2 2 2 2 1 Spec. Percent Complies Coefficients D =0.1520 mm 85 D =0.1117 mm 60 D =0.0991 mm 50 D =0.0779 mm 30 D =0.0493 mm 15 D =0.0412 mm 10 C =2.711 u C =1.319 c Classification ASTM N/A AASHTO Silty Gravel and Sand (A-2-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : --- Sand/Gravel Hardness : --- Dispersion Device : Apparatus A - Mech Mixer Dispersion Period : 1 minute Specific Gravity : 2.65 Separation of Sample: #200 Sieve Proposal No. 604597 - 105762 A00804 - 78

- 10. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: TP-2 Sample ID: G-3 Depth : 5.5-8.5 ft Sample Type: jar Test Date: 02/08/17 Test Id: 403870 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, dark olive gray clay Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:45:54 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 0.0 %Sand 2.1 %Silt &Clay Size 97.9 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies #4 #10 #20 #40 #60 #100 #200 --- --- --- --- --- --- --- --- --- 4.75 2.00 0.85 0.42 0.25 0.15 0.075 Particle Size (mm) 0.0276 0.0186 0.0119 0.0087 0.0063 0.0045 0.0033 0.0014 100 100 100 100 100 100 98 Percent Finer 87 71 51 41 31 24 20 12 Spec. Percent Complies Coefficients D =0.0265 mm 85 D =0.0144 mm 60 D =0.0114 mm 50 D =0.0061 mm 30 D =0.0019 mm 15 D =N/A 10 C =N/A u C =N/A c Classification ASTM N/A AASHTO Silty Soils (A-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : --- Sand/Gravel Hardness : --- Dispersion Device : Apparatus A - Mech Mixer Dispersion Period : 1 minute Specific Gravity : 2.65 Separation of Sample: #200 Sieve Proposal No. 604597 - 105762 A00804 - 79

- 11. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: TP-3 Sample ID: G-2 Depth : 7.3-8 ft Sample Type: jar Test Date: 02/08/17 Test Id: 403871 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, very dark gray sandy clay Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:45:54 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 0.0 %Sand 32.7 %Silt &Clay Size 67.3 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies #4 #10 #20 #40 #60 #100 #200 --- --- --- --- --- --- --- --- --- 4.75 2.00 0.85 0.42 0.25 0.15 0.075 Particle Size (mm) 0.0321 0.0208 0.0129 0.0092 0.0066 0.0047 0.0033 0.0014 100 100 98 93 88 82 67 Percent Finer 41 31 20 15 11 10 8 6 Spec. Percent Complies Coefficients D =0.1921 mm 85 D =0.0591 mm 60 D =0.0427 mm 50 D =0.0203 mm 30 D =0.0090 mm 15 D =0.0048 mm 10 C =12.313 u C =1.453 c Classification ASTM N/A AASHTO Silty Soils (A-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : --- Sand/Gravel Hardness : --- Dispersion Device : Apparatus A - Mech Mixer Dispersion Period : 1 minute Specific Gravity : 2.65 Separation of Sample: #200 Sieve Proposal No. 604597 - 105762 A00804 - 80

- 12. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: TP-4 Sample ID: G-2 Depth : 2.5-5.8 ft Sample Type: jar Test Date: 02/08/17 Test Id: 403872 Tested By: jbr Checked By: emm Test Comment: --- Visual Description: Moist, reddish brown silty sand Sample Comment: --- Particle Size Analysis - ASTM D422 printed 2/16/2017 11:50:58 AM 0 10 20 30 40 50 60 70 80 90 100 0.001 0.01 0.1 1 10 100 1000 Percent Finer Grain Size (mm) 0.375 in #4 #10 #20 #40 #60 #100 #200 %Cobble --- %Gravel 2.9 %Sand 73.1 %Silt &Clay Size 24.0 Sieve Name Sieve Size, mm Percent Finer Spec. Percent Complies 0.375 in #4 #10 #20 #40 #60 #100 #200 --- --- --- --- --- --- --- --- --- 9.50 4.75 2.00 0.85 0.42 0.25 0.15 0.075 Particle Size (mm) 0.0365 0.0223 0.0129 0.0091 0.0065 0.0047 0.0033 0.0014 100 97 94 86 70 51 35 24 Percent Finer 20 17 14 13 12 11 9 6 Spec. Percent Complies Coefficients D =0.8286 mm 85 D =0.3229 mm 60 D =0.2418 mm 50 D =0.1096 mm 30 D =0.0160 mm 15 D =0.0039 mm 10 C =82.795 u C =9.539 c Classification ASTM N/A AASHTO Silty Gravel and Sand (A-2-4 (0)) Sample/Test Description Sand/Gravel Particle Shape : ANGULAR Sand/Gravel Hardness : HARD Dispersion Device : Apparatus A - Mech Mixer Dispersion Period : 1 minute Specific Gravity : 2.65 Separation of Sample: #200 Sieve Proposal No. 604597 - 105762 A00804 - 81

- 13. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-2 Sample ID: S-8 Depth : 39-41 ft Sample Type: jar Test Date: 02/10/17 Test Id: 403889 Tested By: cam Checked By: emm Test Comment: --- Visual Description: Wet, olive clay Sample Comment: --- Atterberg Limits - ASTM D4318 printed 2/16/2017 11:35:18 AM 0 10 20 30 40 50 60 0 10 20 30 40 50 60 70 80 90 100 Plasticity Index Liquid Limit Plasticity Chart ML or OL CL-ML CL or OL MH or OH CH or OH "A" Line "U" Line Symbol Sample ID Boring Depth Natural Moisture Content,% Liquid Limit Plastic Limit Plasticity Index Liquidity Index Soil Classification S-8 NB-2 39-41 ft 58 53 27 26 1.2 Sample Prepared using the WET method Dry Strength: VERY HIGH Dilatancy: SLOW Toughness: MEDIUM Proposal No. 604597 - 105762 A00804 - 82

- 14. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-3 Sample ID: S-9B Depth : 41.7-43 ft Sample Type: jar Test Date: 02/10/17 Test Id: 403890 Tested By: cam Checked By: emm Test Comment: --- Visual Description: Moist, olive clay Sample Comment: --- Atterberg Limits - ASTM D4318 printed 2/16/2017 11:35:18 AM 0 10 20 30 40 50 60 0 10 20 30 40 50 60 70 80 90 100 Plasticity Index Liquid Limit Plasticity Chart ML or OL CL-ML CL or OL MH or OH CH or OH "A" Line "U" Line Symbol Sample ID Boring Depth Natural Moisture Content,% Liquid Limit Plastic Limit Plasticity Index Liquidity Index Soil Classification S-9B NB-3 41.7-43 ft 61 59 29 30 1.1 Sample Prepared using the WET method Dry Strength: VERY HIGH Dilatancy: SLOW Toughness: LOW Proposal No. 604597 - 105762 A00804 - 83

- 15. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-1 Sample ID: G-1 Depth : 0.5-5.5 ft Sample Type: bucket Test Date: 02/10/17 Test Id: 403882 Tested By: cwd Checked By: emm Test Comment: --- Visual Description: Moist, dark olive brown silty sand with gravel Sample Comment: --- Compaction Report - ASTM D1557 printed 3/1/2017 12:12:37 PM 115 120 125 130 135 140 0 5 10 15 20 Dry Density, pcf Water Content, % zero air voids line uncorrected corrected Data Points Point 1 Point 2 Point 3 Point 4 Dry density, pcf Moisture Content, % 129.0 4.9 130.5 7.0 128.8 9.1 124.9 11.2 Method : C Preparation : WET As received Moisture :5 % Rammer : Mechanical Zero voids line based on assumed specific gravity of 2.75 Maximum Dry Density= 130.5 pcf Optimum Moisture= 7.1 % Oversize Correction (9.1% > 3/4 inch Sieve) Corrected Maximum Dry Density= 132.7 pcf Corrected Optimum Moisture= 6.4 % Assumed Average Bulk Specific Gravity = 2.55 Proposal No. 604597 - 105762 A00804 - 84

- 16. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-2 Sample ID: G-1 Depth : 1.1-6 ft Sample Type: bucket Test Date: 02/14/17 Test Id: 403884 Tested By: cwd Checked By: emm Test Comment: --- Visual Description: Moist, dark olive brown silty sand with gravel Sample Comment: --- Compaction Report - ASTM D1557 printed 3/1/2017 12:13:07 PM 105 110 115 120 125 130 0 5 10 15 20 Dry Density, pcf Water Content, % zero air voids line uncorrected corrected Data Points Point 1 Point 2 Point 3 Point 4 Dry density, pcf Moisture Content, % 118.7 7.4 120.2 9.1 119.1 11.2 115.3 13.0 Method : C Preparation : WET As received Moisture :10 % Rammer : Mechanical Zero voids line based on assumed specific gravity of 2.65 Maximum Dry Density= 120.3 pcf Optimum Moisture= 9.6 % Oversize Correction (8.7% > 3/4 inch Sieve) Corrected Maximum Dry Density= 122.9 pcf Corrected Optimum Moisture= 8.8 % Assumed Average Bulk Specific Gravity = 2.55 Proposal No. 604597 - 105762 A00804 - 85

- 17. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-3 Sample ID: G-1 Depth : 1.1-6 ft Sample Type: bucket Test Date: 02/08/17 Test Id: 403881 Tested By: cwd Checked By: emm Test Comment: --- Visual Description: Moist, olive brown silty sand Sample Comment: Sample contains organics Compaction Report - ASTM D1557 printed 3/1/2017 12:13:30 PM 105 110 115 120 125 130 0 5 10 15 20 Dry Density, pcf Water Content, % zero air voids line uncorrected corrected Data Points Point 1 Point 2 Point 3 Point 4 Dry density, pcf Moisture Content, % 116.6 7.2 118.1 9.2 119.6 11.2 115.6 13.0 Method : C Preparation : WET As received Moisture :10 % Rammer : Mechanical Zero voids line based on assumed specific gravity of 2.65 Maximum Dry Density= 119.8 pcf Optimum Moisture= 10.9 % Oversize Correction (5% > 3/4 inch Sieve) Corrected Maximum Dry Density= 121.3 pcf Corrected Optimum Moisture= 10.3 % Assumed Average Bulk Specific Gravity = 2.55 Proposal No. 604597 - 105762 A00804 - 86

- 18. Client: Nobis Engineering, Inc. Project: I-91 at Route 9 Location: Northampton, MA Project No: GTX-305975 Boring ID: NB-5 Sample ID: G-1 Depth : 0.5-6 ft Sample Type: bucket Test Date: 02/14/17 Test Id: 403883 Tested By: cwd Checked By: emm Test Comment: --- Visual Description: Moist, very dark grayish brown silty sand with gravel Sample Comment: Sample contains asphalt Compaction Report - ASTM D1557 printed 3/1/2017 12:14:00 PM 115 120 125 130 135 140 0 5 10 15 20 Dry Density, pcf Water Content, % zero air voids line uncorrected corrected Data Points Point 1 Point 2 Point 3 Point 4 Dry density, pcf Moisture Content, % 125.8 3.1 130.0 5.0 130.6 6.9 128.4 8.7 Method : C Preparation : WET As received Moisture :6 % Rammer : Mechanical Zero voids line based on assumed specific gravity of 2.65 Maximum Dry Density= 130.8 pcf Optimum Moisture= 6.2 % Oversize Correction (22.8% > 3/4 inch Sieve) Corrected Maximum Dry Density= 136.4 pcf Corrected Optimum Moisture= 4.8 % Assumed Average Bulk Specific Gravity = 2.55 Proposal No. 604597 - 105762 A00804 - 87

- 19. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 88

- 20. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 89

- 21. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 90

- 22. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 91

- 23. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 92

- 24. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 93

- 25. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 94

- 26. by ASTM D1883 Proposal No. 604597 - 105762 A00804 - 95

- 27. APPENDIX F – Calculations Proposal No. 604597 - 105762 A00804 - 96

- 28. APPENDIX F.1 – Bearing Resistance and Settlement for Proposed Modular Block Wall Proposal No. 604597 - 105762 A00804 - 97

- 29. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 1 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Objective: References: 1) AASHTO LRFD Bridge Design Specifications 7th Edition with 2016 Interim Revisions. Assumptions: Solution: Bearing Soil Properties/Subsurface Information 125 pcf Estimated 130 pcf Estimated 0 psf Estimated 33 degrees Estimated Footing Elevation: 138.25 ft, NAVD88 Reference 3 Min. Ground Surface (GS) Elevation: 138.75 ft, NAVD88 Reference 3 Groundwater Elevation: 114.8 ft, NAVD88 Footing Geometry 0.5 ft Groundwater Height Below GS: 23.95 ft 3.42 ft Reference No. 3 176 ft Reference No. 3 Width Eccentricity (eB): 1 ft See Note 2 Length Eccentricity (eL): 0 ft Assumed 2.3 ft 176 ft Notes: Reference No. 4 (B-17) 2) Width eccentricity (eB) assumes maximum allowable eccentricity (i.e. B/6). 3) AutoCAD file titled "604597_SV" and PDF drawing entitled "ACAD-604597_HD(Corr) Model" prepared by TranSystems. 4) Record I-91 bridge over Bridge Street construction drawings, dated 1966 and 1992. 1) Soil and groundwater conditions encountered in the Nobis borings are representative of existing soil conditions at the locations of the proposed temporary abutments. 2) Calculation considers minimum embedment of four (4) feet below grade. Effective Width (B'): 3) Refer to pages 2 and 3 for example bearing resistance and settlement calculations, respectively. Refer to page 4 for graph created using a range of effective footing dimensions. Bearing Resistance and Settlement Calculations for Proposed Modular Block Retaining Wall Develop a graph for a range of effective footing sizes that can be used to evaluate bearing resistance and settlement based on effective footing width for the proposed modular block retaining wall. Width ( B ): 2) Test borings observed by Nobis in January and February, 2017. Cohesion of Bearing Soil ( c ): Friction Angle of Bearing Soil ( φ' ): Minimum Footing Depth ( Df ): 3) Engineering properties for gravel borrow for bridge foundations. 1) Calculations for bearing resistance and settlement assume footing subgrade is prepared in accordance with Geotechnical Report. Unit Weight of Bearing Soil ( γ ): Unit Weight of Soil Above Footing ( γ ): Length ( L ): Effective Length (L'): Soil Description: Minimum of 12 inches of compacted Gravel Borrow overlying proof-compacted fill soils. See Note 1. Proposal No. 604597 - 105762 A00804 - 98

- 30. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 2 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.3.1.1-1 0.45 26.1 1.01 i q = [1-H/(V+cB'L'cotφf )]n 1.0 Assumed n =[(2+L'/B')/(1+L'/B')]cos2 θ 1.99 Eq. 10.6.3.1.2a-9 + [(2+B'/L')/(1+B'/L')]sin2 θ Load Angle (θ) 90 degrees Assumed 1.0 Nqm= 26.32 Bearing Capacity Factor ( Nc ) = 38.6 Tb. 10.6.3.1.2a-1 Shape Correction Factor ( sc ) = 1.01 Tb. 10.6.3.1.2a-3 Load Inclination Factor ( i c ) = i c = i q -[(1-i q)/Nq-1)] = 1.0 Assumed Ncm = 38.94 35.2 Tb. 10.6.3.1.2a-1 0.99 i γ = [1-H/(V+cB'L'cotφf )]n+1 1.0 Assumed Nγm= 35.02 ( Cwq ) 1.00 ( Cwγ ) 1.00 qn= 6.7 ksf qR= 3.0 ksf Groundwater Coefficients Tb. 10.6.3.1.2a-2 Shape Correction Factor ( sγ ) Tb. 10.6.3.1.2a-3 Load Inclination Factor ( i γ ) Bearing Capacity Factor ( Nγ or Nγq ) Depth Correction Factor ( dq ) Tb. 10.6.3.1.2a-4 Ncm = Nc*sc*i c Eq. 10.6.3.1.2a-2 Nγm = Nγ*sγ*i γ Eq. 10.6.3.1.2a-4 Shape Correction Factor ( sq ) Tb. 10.6.3.1.2a-3 Load Inclination Factor ( i q ) q n = c*Ncm + γ*Df *Nq m*Cwq + 0.5*γ*B'*Nγm*Cwγ Eq. 10.6.3.1.2a-1 Nqm = Nq*sq *dq *i q Eq. 10.6.3.1.2a-3 Bearing Capacity Factor ( Nq ) Tb. 10.6.3.1.2a-1 Factored Bearing Resistance: qR = qn * φb Resistance Factor ( φb ) = Tb. 10.5.5.2.2-1 Nominal Resistance (q n) = Example Bearing Resistance Calculation Proposal No. 604597 - 105762 A00804 - 99

- 31. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 3 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.2.4.2-1 Poisson's Ratio (v) 0.3 Tb. C10.4.6.3-1 Young's modulus of elasticity (Es) 7 ksi Tb. C10.4.6.3-1 Flexible or Rigid Flexible Shape Factor (βz) 1.41 Tb. 10.6.2.4.2-1 Effective Footing Width (B') 2 Effective Area of Footing (A') 401 ft2 B' * L' Example Settlement (Elastic) Calculation Se = (q o(1-v 2 )√A') 144*Es*βz 1.0 6.5 Assumed Settlement, Se (in) Applied Vertical Stress, q o (ksf) 0.5 3.2 Proposal No. 604597 - 105762 A00804 - 100

- 32. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 4 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 1) AASHTO LRFD Bridge Design Specifications 7th Edition with 2016 Interim Revisions. 2) BB-4, performed by New Hampshire Boring, Inc. dba New England Boring Contractors. 2) Calculation considers minimum embedment of four (4) feet below grade. Notes: qR = Factored Bearing Resistance - Strength Limit State (enter graph with B' and read qR) q0 = Maximum Bearing Pressure - Service Limit State (enter graph with q0 and read settlement at B') 1. q R vs B' line and settlement curves developed using test boring information. 2. Bearing capacity and settlements are based on foundations bearing conditions provided on page 1. 3. A bearing resistance factor of 0.45 was used to calculate the bearing resistance at the strength limit state. North and South Abutment 2 3 4 5 6 7 8 0 2 4 6 8 10 q R or q o (ksf) B' - Effective Footing Width (ft) qR vs B' S = .5 inch S = 1 inch Proposal No. 604597 - 105762 A00804 - 101

- 33. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 5 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 2) Calculation considers minimum embedment of four (4) feet below grade. Proposal No. 604597 - 105762 A00804 - 102

- 34. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 6 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 103

- 35. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 7 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 104

- 36. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 8 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 105

- 37. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 9 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 106

- 38. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 10 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 107

- 39. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 11 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 108

- 40. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 12 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 109

- 41. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 13 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 110

- 42. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 14 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 111

- 43. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 15 of 15 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 112

- 44. APPENDIX F.2 – Lateral Earth Pressures Proposal No. 604597 - 105762 A00804 - 113

- 45. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 1 of 1 Calculated by: PC Date: 2/20/17 Checked by: AJ Date: 2/20/17 Objective: Approach: References: 1. MassDOT LRFD Bridge Manual, Section 3.1.6, 2013. 2. Principles of Foundation Engineering, Second Edition, Das. 3. AASHTO Bridge Design Specifications, 2014. Assumptions: 1. Retained soil is crushed stone with a friction angle of 37°. At‐Rest Earth Pressure using Rankine's Method (Principles of Foundation Engineering, Second Edition, Das) Ko = 1 ‐ sin(φ) Ko = 0.40 Effective friction angle of soil: φ = 37° Active Earth Pressure using Coulomb's Method (Principles of Foundation Engineering, Second Edition, Das) = backslope angle = wall batter angle = soil friction angle = soil/wall friction angle ( = φ(2/3) ) Proposed Wall 30 90 φ = 37° 25 Ka = 0.37 (Use for proposed walls) Calculate lateral earth pressure coefficients for the proposed modular block retaining wall. Use Coulomb's method to determine active earth pressure and Rankine's method to determine the at‐rest earth pressure coefficient in accordance with MassDOT LRFD Bridge Manual. (and active earth pressure) will vary with height and wall type selected. 4. PDF drawing entitled "ACAD‐604597_HD(Corr) Model" Proposal No. 604597 - 105762 A00804 - 114

- 46. APPENDIX F.3 – Bearing Resistance and Settlement for Existing Bridge Proposal No. 604597 - 105762 A00804 - 115

- 47. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 1 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Objective: References: 1) AASHTO LRFD Bridge Design Specifications 7th Edition with 2016 Interim Revisions. Assumptions: Solution: Bearing Soil Properties/Subsurface Information 130 pcf Estimated 130 pcf Estimated 0 psf Estimated 37 degrees Estimated Footing Elevation: 146.3 ft, NAVD88 Reference 4 (North Abutment, I‐91 SB) Min. Ground Surface (GS) Elevation: 150.3 ft, NAVD88 Assumption 2 Groundwater Elevation: 114.8 ft, NAVD88 Footing Geometry 4 ft Groundwater Height Below GS: 35.5 ft 6 ft Reference No. 4 49.2 ft Reference 4 (North Abutment, I‐91 SB) Width Eccentricity (eB): 1 ft See Note 2 Length Eccentricity (eL): 0 ft Assumed 5 ft 49.2 ft Notes: 2) Loads on abutments not available, effective abutment footing width (B') reduced by 20 percent to account for unknown loading eccentricities. 2) Calculation considers minimum embedment of four (4) feet below grade. 3) AutoCAD file titled "604597_SV" and PDF drawing entitled "ACAD‐604597_HD(Corr) Model" prepared by TranSystems. 4) Record I‐91 bridge over Bridge Street construction drawings, dated 1966 and 1992. Estimate bearing resistance and settlement for existing abutments bearing on concrete spread footings. 1) Soil and groundwater conditions encountered in the Nobis borings are representative of existing soil conditions at the locations of the proposed temporary abutments. Effective Width (B'): Effective Length (L'): Soil Description: Reference No. 4 (B‐17) Compacted Gravel Borrow for bridge foundations (M1.03.0). Bearing Resistance and Settlement Calculations ‐ Existing Concrete North Abutments Width ( B ): 2) Test borings observed by Nobis in January and February, 2017. Cohesion of Bearing Soil ( c ): Friction Angle of Bearing Soil ( ' ): Minimum Footing Depth ( Df ): 3) Engineering properties for gravel borrow for bridge foundations. 1) Example bearing resistance and settlement calculations can be found on pages 2 and 3, respectively. Unit Weight of Bearing Soil ( γ ): Unit Weight of Soil Above Footing ( γ ): Length ( L ): Proposal No. 604597 - 105762 A00804 - 116

- 48. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 2 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.3.1.1‐1 0.45 0 Footings bearing on or near slope 1.07 i q = [1‐H/(V+cB'L'cotf )]n 1.0 Assumed n =[(2+L'/B')/(1+L'/B')]cos 2 θ 1.91 Eq. 10.6.3.1.2a‐9 + [(2+B'/L')/(1+B'/L')]sin 2 θ Load Angle (θ) 90 degrees Assumed 1.0 Nqm= 0.00 Bearing Capacity Factor ( Nc ) = 55.6 Tb. 10.6.3.1.2a‐1 Shape Correction Factor ( sc ) = 1.00 Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i c ) = i c = i q ‐[(1‐i q)/Nq‐1)] = 1.0 Assumed Ncm = 55.60 65 Figure 10.6.3.1.2c‐2 0.96 i γ = [1‐H/(V+cB'L'cotf )]n+1 1.0 Assumed Nγm= 62.46 ( Cwq ) 1.00 ( Cwγ ) 1.00 qn= 19.5 ksf qR= 8.8 ksf Groundwater Coefficients Tb. 10.6.3.1.2a‐2 Shape Correction Factor ( sγ ) Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i γ ) Bearing Capacity Factor ( Nγ or Nγq ) Depth Correction Factor ( dq ) Tb. 10.6.3.1.2a‐4 Ncm = Nc*sc*i c Eq. 10.6.3.1.2a‐2 Nγm = Nγ*sγ*i γ Eq. 10.6.3.1.2a‐4 Shape Correction Factor ( sq ) Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i q ) q n = c*Ncm + γ*Df *Nq m*Cwq + 0.5*γ*B'*Nγm*Cwγ Eq. 10.6.3.1.2a‐1 Nqm = Nq*sq *dq *i q Eq. 10.6.3.1.2a‐3 Bearing Capacity Factor ( Nq ) Factored Bearing Resistance: qR = qn * b Resistance Factor ( b ) = Tb. 10.5.5.2.2‐1 Nominal Resistance (q n) = Example Bearing Resistance Calculation Proposal No. 604597 - 105762 A00804 - 117

- 49. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 3 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.2.4.2‐1 Poisson's Ratio (v) 0.3 Tb. C10.4.6.3‐1 Young's modulus of elasticity (Es) 7 ksi Tb. C10.4.6.3‐1 Flexible or Rigid Rigid Shape Factor (βz) 1.41 Tb. 10.6.2.4.2‐1 Effective Footing Width (B') 5 Effective Area of Footing (A') 236 ft2 B' * L' Example Settlement (Elastic) Calculation Se = (q o(1‐v 2 )√A') 144*Es*βz 1.0 8.5 Assumed Settlement, Se (in) Applied Vertical Stress, q o (ksf) 0.5 4.2 Proposal No. 604597 - 105762 A00804 - 118

- 50. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 4 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 119

- 51. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 5 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 120

- 52. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 6 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 121

- 53. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 7 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 122

- 54. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 8 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 123

- 55. Shared Use Bridge over MBTA/CSX Franklin, MA 85891.00 Page: 7 of 7 Calculated by: RAC Date: 4/14/2015 Checked by: PCC Date: 4/20/2015 Revision: 1 b/B = 0.2 N(gamma)q = 65 Page 9 of 9 Proposal No. 604597 - 105762 A00804 - 124

- 56. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 1 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Objective: References: 1) AASHTO LRFD Bridge Design Specifications 7th Edition with 2016 Interim Revisions. Assumptions: Solution: Bearing Soil Properties/Subsurface Information 130 pcf Estimated 130 pcf Estimated 0 psf Estimated 37 degrees Estimated Footing Elevation: 146.3 ft, NAVD88 Reference 4 (North Abutment, I‐91 SB) Min. Ground Surface (GS) Elevation: 150 ft, NAVD88 Reference 3 Groundwater Elevation: 114.8 ft, NAVD88 Footing Geometry 3.7 ft Assumption No. 2 Groundwater Height Below GS: 35.2 ft 6 ft Reference No. 4 49.2 ft Reference 4 (North Abutment, I‐91 SB) Width Eccentricity (eB): 1 ft See Note 2 Length Eccentricity (eL): 0 ft Assumed 5 ft 49.2 ft Notes: 2) Loads on abutments not available, effective abutment footing width (B') reduced by 20 percent to account for unknown loading eccentricities. 2) Calculation considers minimum embedment of 3.7 feet below grade. 3) AutoCAD file titled "604597_SV" and PDF drawing entitled "ACAD‐604597_HD(Corr) Model" prepared by TranSystems. 4) Record I‐91 bridge over Bridge Street construction drawings, dated 1966 and 1992. Estimate bearing resistance and settlement for existing abutments bearing on concrete spread footings during modular block retaining wall construction. 1) Soil and groundwater conditions encountered in the Nobis borings are representative of existing soil conditions at the locations of the proposed temporary abutments. Effective Width (B'): Effective Length (L'): Soil Description: Reference No. 4 (B‐17) Compacted Gravel Borrow for bridge foundations (M1.03.0). Bearing Resistance and Settlement Calculations ‐ Existing Concrete North Abutments During Construction Width ( B ): 2) Test borings observed by Nobis in January and February, 2017. Cohesion of Bearing Soil ( c ): Friction Angle of Bearing Soil ( ' ): Minimum Footing Depth ( Df ): 3) Engineering properties for gravel borrow for bridge foundations. 1) Example bearing resistance and settlement calculations can be found on pages 2 and 3, respectively. Unit Weight of Bearing Soil ( γ ): Unit Weight of Soil Above Footing ( γ ): Length ( L ): Proposal No. 604597 - 105762 A00804 - 125

- 57. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 2 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.3.1.1‐1 0.45 0 Footings bearing on or near slope 1.07 i q = [1‐H/(V+cB'L'cotf )]n 1.0 Assumed n =[(2+L'/B')/(1+L'/B')]cos 2 θ 1.91 Eq. 10.6.3.1.2a‐9 + [(2+B'/L')/(1+B'/L')]sin 2 θ Load Angle (θ) 90 degrees Assumed 1.0 Nqm= 0.00 Bearing Capacity Factor ( Nc ) = 55.6 Tb. 10.6.3.1.2a‐1 Shape Correction Factor ( sc ) = 1.00 Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i c ) = i c = i q ‐[(1‐i q)/Nq‐1)] = 1.0 Assumed Ncm = 55.60 15 Figure 10.6.3.1.2c‐2 0.96 i γ = [1‐H/(V+cB'L'cotf )]n+1 1.0 Assumed Nγm= 14.41 ( Cwq ) 1.00 ( Cwγ ) 1.00 qn= 4.5 ksf qR= 2.0 ksf Groundwater Coefficients Tb. 10.6.3.1.2a‐2 Shape Correction Factor ( sγ ) Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i γ ) Bearing Capacity Factor ( Nγ or Nγq ) Depth Correction Factor ( dq ) Tb. 10.6.3.1.2a‐4 Ncm = Nc*sc*i c Eq. 10.6.3.1.2a‐2 Nγm = Nγ*sγ*i γ Eq. 10.6.3.1.2a‐4 Shape Correction Factor ( sq ) Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i q ) q n = c*Ncm + γ*Df *Nq m*Cwq + 0.5*γ*B'*Nγm*Cwγ Eq. 10.6.3.1.2a‐1 Nqm = Nq*sq *dq *i q Eq. 10.6.3.1.2a‐3 Bearing Capacity Factor ( Nq ) Factored Bearing Resistance: qR = qn * b Resistance Factor ( b ) = Tb. 10.5.5.2.2‐1 Nominal Resistance (q n) = Example Bearing Resistance Calculation Proposal No. 604597 - 105762 A00804 - 126

- 58. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 3 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.2.4.2‐1 Poisson's Ratio (v) 0.3 Tb. C10.4.6.3‐1 Young's modulus of elasticity (Es) 8 ksi Tb. C10.4.6.3‐1 Flexible or Rigid Rigid Shape Factor (βz) 1.41 Tb. 10.6.2.4.2‐1 Effective Footing Width (B') 5 Effective Area of Footing (A') 236 ft2 B' * L' Example Settlement (Elastic) Calculation Se = (q o(1‐v 2 )√A') 144*Es*βz 1.0 9.7 Assumed Settlement, Se (in) Applied Vertical Stress, q o (ksf) 0.5 4.8 Proposal No. 604597 - 105762 A00804 - 127

- 59. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 4 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 128

- 60. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 5 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 129

- 61. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 6 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 130

- 62. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 7 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 131

- 63. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 8 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 132

- 64. Shared Use Bridge over MBTA/CSX Franklin, MA 85891.00 Page: 7 of 7 Calculated by: RAC Date: 4/14/2015 Checked by: PCC Date: 4/20/2015 Revision: 1 b/B = 0.2 N(gamma)q = 15 Page 9 of 9 Proposal No. 604597 - 105762 A00804 - 133

- 65. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 1 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Objective: References: 1) AASHTO LRFD Bridge Design Specifications 7th Edition with 2016 Interim Revisions. Assumptions: Solution: Bearing Soil Properties/Subsurface Information 130 pcf Estimated 130 pcf Estimated 0 psf Estimated 37 degrees Estimated Footing Elevation: 146.3 ft, NAVD88 Reference 4 (North Abutment, I‐91 SB) Min. Ground Surface (GS) Elevation: 150.3 ft, NAVD88 Assumption 2 Groundwater Elevation: 114.8 ft, NAVD88 Footing Geometry 4 ft Groundwater Height Below GS: 35.5 ft 6 ft Reference No. 4 49.2 ft Reference 4 (North Abutment, I‐91 SB) Width Eccentricity (eB): 1 ft See Note 2 Length Eccentricity (eL): 0 ft Assumed 5 ft 49.2 ft Notes: 3) AutoCAD file titled "604597_SV" and PDF drawing entitled "ACAD‐604597_HD(Corr) Model" prepared by TranSystems. 4) Record I‐91 bridge over Bridge Street construction drawings, dated 1966 and 1992. Estimate bearing resistance and settlement for existing abutments bearing on concrete spread footings post‐construction. 1) Soil and groundwater conditions encountered in the Nobis borings are representative of existing soil conditions at the locations of the proposed temporary abutments. Effective Width (B'): Effective Length (L'): Soil Description: Reference No. 4 (B‐17) Compacted Gravel Borrow for bridge foundations (M1.03.0). Bearing Resistance and Settlement Calculations ‐ Existing Concrete North Abutments Post‐Construction Width ( B ): 2) Test borings observed by Nobis in January and February, 2017. Cohesion of Bearing Soil ( c ): Friction Angle of Bearing Soil ( ' ): Minimum Footing Depth ( Df ): 3) Engineering properties for gravel borrow for bridge foundations. 1) Example bearing resistance and settlement calculations can be found on pages 2 and 3, respectively. Unit Weight of Bearing Soil ( γ ): Unit Weight of Soil Above Footing ( γ ): Length ( L ): 2) Loads on abutments not available, effective abutment footing width (B') reduced by 20 percent to account for unknown loading eccentricities. 2) Calculation considers minimum embedment of four (4) feet below grade. Proposal No. 604597 - 105762 A00804 - 134

- 66. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 2 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.3.1.1‐1 0.45 0 Footings bearing on or near slope 1.07 i q = [1‐H/(V+cB'L'cotf )]n 1.0 Assumed n =[(2+L'/B')/(1+L'/B')]cos 2 θ 1.91 Eq. 10.6.3.1.2a‐9 + [(2+B'/L')/(1+B'/L')]sin 2 θ Load Angle (θ) 90 degrees Assumed 1.0 Nqm= 0.00 Bearing Capacity Factor ( Nc ) = 55.6 Tb. 10.6.3.1.2a‐1 Shape Correction Factor ( sc ) = 1.00 Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i c ) = i c = i q ‐[(1‐i q)/Nq‐1)] = 1.0 Assumed Ncm = 55.60 50 Figure 10.6.3.1.2c‐2 0.96 i γ = [1‐H/(V+cB'L'cotf )]n+1 1.0 Assumed Nγm= 48.05 ( Cwq ) 1.00 ( Cwγ ) 1.00 qn= 15.0 ksf qR= 6.7 ksf Factored Bearing Resistance: qR = qn * b Resistance Factor ( b ) = Tb. 10.5.5.2.2‐1 Nominal Resistance (q n) = Example Bearing Resistance Calculation Shape Correction Factor ( sq ) Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i q ) q n = c*Ncm + γ*Df *Nq m*Cwq + 0.5*γ*B'*Nγm*Cwγ Eq. 10.6.3.1.2a‐1 Nqm = Nq*sq *dq *i q Eq. 10.6.3.1.2a‐3 Bearing Capacity Factor ( Nq ) Bearing Capacity Factor ( Nγ or Nγq ) Depth Correction Factor ( dq ) Tb. 10.6.3.1.2a‐4 Ncm = Nc*sc*i c Eq. 10.6.3.1.2a‐2 Nγm = Nγ*sγ*i γ Eq. 10.6.3.1.2a‐4 Groundwater Coefficients Tb. 10.6.3.1.2a‐2 Shape Correction Factor ( sγ ) Tb. 10.6.3.1.2a‐3 Load Inclination Factor ( i γ ) Proposal No. 604597 - 105762 A00804 - 135

- 67. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 3 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Eq. 10.6.2.4.2‐1 Poisson's Ratio (v) 0.3 Tb. C10.4.6.3‐1 Young's modulus of elasticity (Es) 7 ksi Tb. C10.4.6.3‐1 Flexible or Rigid Rigid Shape Factor (βz) 1.41 Tb. 10.6.2.4.2‐1 Effective Footing Width (B') 5 Effective Area of Footing (A') 236 ft2 B' * L' Example Settlement (Elastic) Calculation Se = (q o(1‐v 2 )√A') 144*Es*βz 1.0 8.5 Assumed Settlement, Se (in) Applied Vertical Stress, q o (ksf) 0.5 4.2 Proposal No. 604597 - 105762 A00804 - 136

- 68. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 4 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 137

- 69. Interstate 91 and Route 9 Intersection Reconstruction Northampton, Massachusetts Project No. 92470.00 Page: 5 of 9 Calculated by: PCC Date: 2/20/2017 Checked by: RAC Date: 2/23/17 Revision: 0 Proposal No. 604597 - 105762 A00804 - 138