ICAMS -2021.pptx

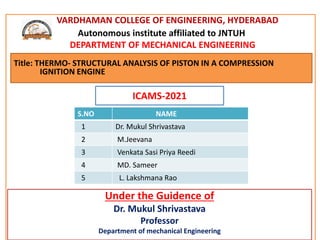

- 1. VARDHAMAN COLLEGE OF ENGINEERING, HYDERABAD Autonomous institute affiliated to JNTUH DEPARTMENT OF MECHANICAL ENGINEERING Under the Guidence of Dr. Mukul Shrivastava Professor Department of mechanical Engineering ICAMS-2021 Title: THERMO- STRUCTURAL ANALYSIS OF PISTON IN A COMPRESSION IGNITION ENGINE S.NO NAME 1 Dr. Mukul Shrivastava 2 M.Jeevana 3 Venkata Sasi Priya Reedi 4 MD. Sameer 5 L. Lakshmana Rao

- 2. OUTLINE 2 • Abstract • Introduction • Objective of the project work • Literature review • Research gap • Proposed methodology • Types of piston models • Thermal analysis of pistons • Expected outcomes • References

- 3. Abstract 3 DEPARTMENT OF MECHANICAL ENGINEERING The piston is a component of the internal combustion engine. The main function of the piston is to transform the pressure generated by the burning air-fuel mixture into force, acting on the crankshaft In IC engine, Piston is one of the most important and complex part. With increasing power and performance of engine, higher thermal load and the thermal stresses are acting on piston, thereby, decreasing its life time. So It is necessary to maintain Piston in good condition in order to maintain the proper functioning of the engine. Piston mainly fails due to thermal Conditions. So Its is essential to evaluate the piston with different crown shapes and find the thermal and structural performance. In this paper 4 different types of piston is developed using CATIA – V5 a powerful 3D Modelling tool and structural and thermal analysis will be done by ANSYS using different materials to find out the temperature and thermal stress distribution.

- 4. INTRODUCTION 4 DEPARTMENT OF MECHANICAL ENGINEERING • Piston is one of the mechanical component which was invented by German scientist Nicholas August Otto in year 1866. • A piston is a component of reciprocating IC-engines. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. The purpose of the piston is to provide a means of conveying the expansion of gases to the crankshaft via connecting rod, The piston acts as a movable end of the combustion chamber Piston is essentially a cylindrical plug that moves up & down in the cylinder It is equipped with piston rings to provide a good seal between the cylinder wall. Functions of Piston • To reciprocate in the cylinder as a gas tight plug causing suction, Compression, expansion, and exhaust strokes.

- 5. 5 DEPARTMENT OF MECHANICAL ENGINEERING • To receive the thrust generated by the explosion of the gas in the cylinder • And transmit it to the connecting rod. • To form a guide and bearing to the small end of the connecting rod and to take the side thrust due to obliquity of the rod. Factors Considered For Proper Functioning Of Piston : • The piston should have enormous strength and heat resistance properties to withstand gas pressure and inertia forces. They should have minimum weight to minimize the inertia forces. • The material of the piston should have good and quick dissipation of heat from the crown to the rings and bearing area to the cylinder walls. It should form an effective gas and oil seal.

- 6. 6 DEPARTMENT OF MECHANICAL ENGINEERING • Material of the piston must possess good wearing qualities, so that the piston is able to maintain sufficient surface-hardness unto the operating temperatures. • Piston should have rigid construction to withstand thermal, mechanical distortion and sufficient area to prevent undue wear. It has even expansion under thermal loads so should be free as possible from discontinuities.

- 7. 7 DEPARTMENT OF MECHANICAL ENGINEERING PISTON PARTS:

- 8. 8 DEPARTMENT OF MECHANICAL ENGINEERING Piston Head or Crown : • The piston head or crown is designed keeping in view the following two main considerations, i.e. • It should have adequate strength to withstand the straining action due to pressure of explosion inside the engine cylinder, and It should dissipate the heat of combustion to the cylinder walls as quickly as possible. On the basis of first consideration of straining action, the thickness of the piston head is determined by treating it as a flat circular plate of uniform thickness, fixed at the outer edges and subjected to a uniformly distributed load due to the gas pressure over the entire Cross-section. Piston Rings :The piston rings are used to impart the necessary radial pressure to maintain the seal between the piston and the cylinder bore. These are usually made of grey cast iron or alloy cast iron because of their good wearing properties and also they retain spring characteristics even at high temperatures.

- 9. 9 DEPARTMENT OF MECHANICAL ENGINEERING The piston rings are of the following two types: • Compression rings or pressure rings, and • Oil control rings or oil scraper. • The compression rings or pressure rings are inserted in the grooves at the top portion of the piston and may be three to seven in number. These rings also transfer heat from the piston to the cylinder liner and absorb some part of the piston fluctuation due to the side thrust. The oil control rings or oil scrapers are provided below the compression rings. These rings provide proper lubrication to the liner by allowing sufficient oil to move up during upward stroke and at the same time scrap the lubricating oil from the surface of the liner in order to minimize the flow of the oil to the combustion chamber.

- 10. 10 DEPARTMENT OF MECHANICAL ENGINEERING The compression rings are usually made of rectangular cross-section and the diameter of the ring is slightly larger than the cylinder bore. A part of the ring is cut- off in order to permit it to go into the cylinder against the liner wall. The gap between the ends should be sufficiently large when the ring is put cold so that even at the highest temperature, the ends do not touch each other when the ring expands, otherwise there might be buckling of the ring. Major Force Acting over Piston : • Due to explosion of fuel gases • Due to compression of fuel gases • Side wall friction and forces • Thermal load • Inertia force due to high frequency of reciprocation of piston • Friction and forces at crank pin hole

- 11. 11 DEPARTMENT OF MECHANICAL ENGINEERING Piston Application or uses: The main application of the Piston is: • Reduced inertia also improves the mechanical efficiency of the engine. • It compresses the fluid inside the cylinder hence increases the pressure and temperature of the fluid inside the cylinder. • It also provides the direction. Piston Advantages: The main advantages of the Piston are: • Mechanical simplicity • Flexibility and reliability • Power to weight ratio • Multi-fuel capability • Low turbine operating temperature • Less vibration and noise • Less maintenance

- 12. Objective of the project • There three objectives for this dissertation which is focus on the piston for IC engine based on the finite element analysis. The objectives are: • To design 4 Different 3D models of piston for IC engine using Catia V5. • To investigate the maximum temperature distribution during combustion using Steady state thermal analysis in Ansys. • To investigate the maximum Thermal stress developed due to rise in temperature and pressure using structural linear analysis using Ansys. 12 DEPARTMENT OF MECHANICAL ENGINEERING

- 13. Literature review 13 DEPARTMENT OF MECHANICAL ENGINEERING 1. S.Srikanth Reddy, Dr. B. Sudheer Prem Kumar Did Thermal Analysis and Optimization of I.C.Engine Piston Using Finite Element Method In this study, firstly, thermal analyses are investigated on a conventional (uncoated) diesel piston, made of aluminum silicon alloy for design 1 and design 2 parameters. Secondly, thermal analyses are performed on piston, coated with Zirconium material by means of using a commercial code, namely ANSYS. The effects of coating on the thermal behaviors of the pistons are investigated. The finite element analysis is performed by using computer aided design software. The main objective is to investigate and analyze the thermal stress distribution of piston at the real engine condition during combustion process.

- 14. Finally they concluded that Piston skirt may appear deformation at work, which usually causes crack on the upper end of piston head. Due to the deformation, the greatest stress concentration is caused on the upper end of piston, the situation becomes more serious when the stiffness of the piston is not enough, and the crack generally appeared at the point A which may gradually extend and even cause splitting along the piston vertical •G.V.N. Kaushik did “Thermal and Static Structural Analysis on Piston” In this paper 3D model of piston is developed, structural and thermal analysis is done by ANSYS using 5 different materials to find out the temperature and thermal stress distribution, theoretically finding the total heat flux and compare with the practical values of different Piston Materials used. 14

- 15. Finally they conclude that 42CrMo, Al-Si-C-12 undergo least deformation under thermal loads and under mechanical loads Al-Si, Al-Si-C-12 undergo least deformation. In case of Both Mechanical and Thermal loads Al-Si-C-12 undergoes the least deformation. This is mainly because while 42CrMo can withstand high temperatures but cannot withstand high mechanical loads and in case of Al-Si, it can withstand mechanical loads but cannot withstand high temperatures like 42CrMo. In case of Al-Si-C-12, it can withstand both mechanical and thermal loads. Hence Al-SI-C-12 undergoes least deformation when both mechanical and thermal loads are applied. In conclusion while designing a piston 42CrMo must be used to make the piston top land because it is the surface of piston that directly comes in contact with combustion of fuel and high temperatures and Al-Si-C-12 must be used for piston skirt and rest of the piston. 15

- 16. • A.R. Bhagat, Y. M. Jibhakate & Kedar Chimote did “Thermal Analysis and Optimization of I.C. Engine Piston Using Finite Element Method” This paper describes the stress distribution of the seizure on piston four stroke engine by using FEA. The main objectives is to investigate and analyze the thermal stress distribution of piston at the real engine condition during combustion process. The optimization is carried out to reduce the stress concentration on the upper end of the piston. With using computer aided design (CAD), Pro/ENGINEER software the structural model of a piston will be developed. Furthermore, the finite element analysis performed with using software ANSYS. Finally they concluded that the stress distribution on the pistonmainly depends on the deformation of piston. Therefore, in order to reduce the stress concentration, the piston crown should have enough stiffness to reduce the deformation. 16

- 17. • Preeti Kumari, Anamika & Dr.H.C.Thakur did “Thermal Analysis ofPiston of IC engine” In this paper thermal stress distribution is shown for the simple piston and reduced skirt length piston by changing the geometry of the piston and it is suggested that which piston is better for same thermal load. Steady state thermal analysis of the Piston have been done in ANSYS 14.5. Finally they concluded,it can be demonstrated from the above graphical data and figures that reduced skirt length piston temperature reduced by 10-20’ as compared to simple piston while boundary conditions are same .Similarly total heat flux variation also reduced in case of reduced skirt length piston as compare to simple piston. Piston failure occurs because of thermo-mechanical overload by insufficient intercooling thermo-mechanical overload by over fuelling 17

- 18. Research gap • Most of the papers discussed about piston materials and their thermal performance only . They didn’t consider the structural performance. Temperature differences between the Engine Head and the piston cylinder have been a major role in inducing thermal stresses and hence play a vital role in predicting the life of an IC Engine. • In this paper we focussed on thermal and structural evaluation of different piston heads. 18

- 19. Proposed methodology 19 Create a 3D CAD model of the Piston for the specifications available. Export the solid model into ANSYS Workbench and edit the model in Design modeler environment if it is necessary Create FEA Model and Apply the loads and BCs of the Piston model and run the thermal analysis. Convert the thermal model to structural model and apply the structural/thermal loads and BCs. Carryout the structural analysis for this model and tabulate the results.

- 20. 20 Do the Same procedure for remaining models Compare the stresses between 4 models and observe the differences.

- 21. Types of piston design • CATIA is a mechanical design software. It is a feature-based, parametric solid modeling design tool that takes advantage of the easy-to-learn Windows graphical user interface. You can create fully associative 3D solid models, with or without constraints, while using automatic or user-defined relations to capture the design intent. The four types of piston are designed using CATIA V5. PISTON TYPES : FLAT TYPE PISTON . DOME TYPE PISTON. CUP TYPE PISTON. BOWL TYPE PISTON. 21

- 22. Catia Introduction • CATIA is a mechanical design software. It is a feature-based, parametric solid modeling design tool that takes advantage of the easy-to-learn Windows graphical user interface. You can create fully associative 3D solid models, with or without constraints, while using automatic or user-defined relations to capture the design intent. 22

- 23. • FLAT PISTON TYPE: 23

- 24. • DOME PISTON TYPE: 24

- 25. • CUP PISTON TYPE: 25

- 26. • BOWL PISTON TYPE: 26

- 27. THERMAL ANALYSYS • Flat Type piston Geometry : 27

- 28. Expected outcomes • Material properties for AL4032 : 28

- 29. Meshed model • Type of element : Hexahedral: 29

- 31. 31

- 32. Temperature distribution along path 32

- 33. 33

- 34. Cup Type piston Geometry 34

- 36. Temperature distribution along path 36

- 37. 37

- 38. Dome type piston Geometry 38

- 41. Temperature distribution along path 41

- 42. Temperature distribution along path 42

- 43. Bowl type piston Geometry 43

- 46. Temperature distribution along path 46

- 47. Temperature distribution along path 47

- 48. Structural analysis of flat type piston 48

- 49. Structural analysis of flat type piston 49

- 51. Equivalent stress along path 51

- 52. Equivalent stress along path 52

- 53. Cup type piston geometry 53

- 54. Boundary condition for cup type 54

- 56. Equivalent stress along path 56

- 58. Dome type piston geometry 58

- 59. Boundary condition for Dome type piston 59

- 61. Equivalent stress along path 61

- 63. Bowl type piston geometry 63

- 64. Boundary condition for Bowl type piston 64

- 66. Equivalent stress along path 66

- 68. Conclusion 68

- 69. • After Performing Thermal Analysis and structural Analysis, it is found that while using Aluminum Material among four pistons, flat type and the Dome piston is obtained with lowest stress valves. So those two types are considered as best type where their values in both Thermal stress analysis and deflection in geometrical structural analysis were optimal than compared to the other two types of the pistons which are noted. • From the above table it was clear that the flat type and dome type pistons values in thermal stresses are 80.11 and 80.24 Mpa respectively, , which are very efficient than other two types of pistons. 69

- 70. • Likewise in structural analysis the deflection was found to be very optimal in flat and dome type piston which was noted as 0.02 and 0.01 mm respectively hence it is clear from the above study that using aluminium alloy AL4032 the flat and dome type pistons are efficient in both thermal and structural analysis. 70

- 71. References 1. S. Srikanth Reddy, Dr. B. Sudheer Prem Kumar Did Thermal Analysis and Optimization of I.C.Engine Piston Using Finite Element Method. 2. G.V.N. Kaushik did “Thermal and Static Structural Analysis on Piston”. 3. K.S.Mahajan and S.H.Deshmukh did “Structural and Thermal Analysis of Piston”. 4. A.R. Bhagat, Y. M. Jibhakate & Kedar Chimote did “Thermal Analysis and Optimization of I.C. Engine Piston Using Finite Element Method”. 5. Preeti Kumari, Anamika & Dr.H.C.Thakur did “Thermal Analysis ofPiston of IC engine”. 71

- 72. Thank You 72