15t LF ladle refining furnace solution.docx

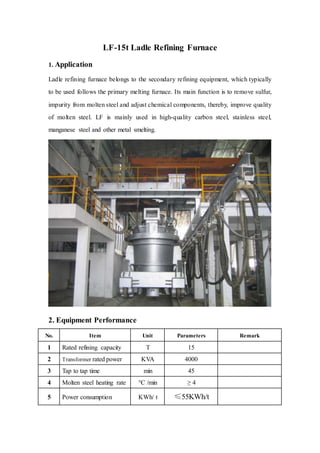

- 1. LF-15t Ladle Refining Furnace 1. Application Ladle refining furnace belongs to the secondary refining equipment, which typically to be used follows the primary melting furnace. Its main function is to remove sulfur, impurity from molten steel and adjust chemical components, thereby, improve quality of molten steel. LF is mainly used in high-quality carbon steel, stainless steel, manganese steel and other metal smelting. 2. Equipment Performance No. Item Unit Parameters Remark 1 Rated refining capacity T 15 2 Transformer rated power KVA 4000 3 Tap to tap time min 45 4 Molten steel heating rate °C /min ≥ 4 5 Power consumption KWh/ t ≤55KWh/t

- 2. 6 Electrode consumption /KWh ≤ 0.6-0.7kg 3. Component Parameters No. Item unit parameters Remark 1 Transformer Rated power KVA 4000 Overload 20% Primary voltage KV 20 Secondary voltage V 200-185-135V Level 5 Secondary current A 12483 Voltage regulating OFF Load cooling type OFWF 2 ladle Max diameter of ladle mm Φ2300 Spare height mm 500 3 lager current Impedance unbalance factor % ≤5 Theoretical value resistance 0.65+J2.5mΩ 4 Electrode system Electrode diameter mm Φ350 Graphite electrode Electrode distribution circle mm Φ600 Lifting speed m/min up/ down:4/3 Electrode lifting height mm 2000 Drive mode of lifting Hydraulic control Electrode arm structural Single arm copper clad 5 Gantry and roof Lifting mechanism Roof lifting type Hydraulic cylinder-Chain type Roof lifting height mm 400 6 Roof Roof type Tube type water cooling roof 7 Ladle car Weight of load T 50 Drive mode Motor Frequency control Speed m 2-20 Positioning accuracy mm ±10 8 Circulating water cooling system

- 3. Flow rate m3/h 140 Inlet pressure MPa 0.4~0.6 Inlet temperature ℃ <35 Outlet temperature ℃ <55 9 Hydraulic station Rated pressure MPa 17.5 Working pressure MPa 10 Motor Kw 22 2 stands(one for use and one for standby) Accumulator 100Lx2 Hydraulic medium Hydraulic oil Electrode lift proportioner valve Inlet proportional valve 10 Centralized lubrication Tank volume L 30 Max working pressure MPa 21 Lubricating medium High temperature resistant dry grease 11 Argon system Inlet pressure MPa 1.2-1.6 Working pressure MPa 0.3-0.8 Purity 99% 12 HV system Disconnecting switch GN2 Voltage transformer JDZ High voltage vacuum circuit breaker VS1 Current transformer LZJ Zinc oxide arrester SDB Main loop metering and protect system 13 L.V control system GGD type L.V switch cabinet GGD type Rettale L.V electrical components DELIXI PLC Simens inverter Simens 4. Strengths of ZL Ladle Refining Furnace

- 4. 4.1 Low power consumption ZL’s large current system made of pure copper as conductive medium, the whole circuit with less resistance. Electrode arm shaped as copper-clad box type, resistance and heat can be reduced efficiently. Reasonable arrange of all conductive systems to minimize the resistance of every circuit. 4.2 Optimized structure, Low failure rate, limited investment Clamping mechanism of the three electrodes is mounted in three separated small box, which installed on one electrode arm and supported by one column, thereby, compared to the traditional three electrodes and three columns, ZL’s electrode system is easier, limited investment, lower fault rate. 4.3 Safety & Stability Full set of hydraulic driving system equipped with accumulator to ensure stability of facilities in the operation process. Whist, equipments can go on the motion when there any emergency accidents happen. 4.4 High flexibility & Maximum simplicity of operation HMI used in electrical automation control, interface simulates the real form of furnace, which make the operation more convenient. Mixing feedstock, charging feedstock, melting, tapping all the commands can be implemented by computer. 4.5 Coordinated with ZL’s patented multi-pouring systems, per batch liquid steel pouring out more times is available, which benefits foundries requirements of different size castings. ZL’s patented technology <Multi-pouring Mechanism>, is a kind of rod utilized to block the hole on ladle bottom, which can realize pouring through the bottom of ladle, make the pouring process easier, safer. Advantages of this kind mechanism: 1.Make one batch liquid steel with multiple pouring come true, which casting times is far more than sliding nozzle does. 2. The

- 5. hot rod is mounted before pouring. Compared to cold rod, which will not be melted with liquid steel, and protect the plug rod from meltdown process, thereby, steel leakage can be avoided. 3. Implementation of hot rod is convenient, pressing down hand shank the pouring starts, otherwise, the pouring ends. 4.6 Automatic temperature sampling system is available, so that the operation is more safe and convenient. 4.7 ZL’s furnaces are equipped with a variety of dust removal systems, can be based on environmental requirements of different countries support different forms of dust removal equipments. 5. Equipment Components 5.1 Furnace body Furnace shell, Furnace door mechanism, Tapping spout mechanism 5.2 Furnace Roof Water-cooling ring, Refractory center cover (To be made by buyer according to drawings of seller) 5.3 Lifting furnace roof Lifting mechanism (hydraulic cylinder, transmission chain, chain wheel, etc.) (support of Γ form) 5.4 Swiveling mechanism Arc frame, foundation base, hydraulic cylinder 5.5 Electrode cross arm & lifting mechanism Bracket of electrode, Clamping device of electrode, Lifting mechanism. 5.6 Large-current system Compensator, Water-cooled cables, Stainless steel support, Water-cooled conductive copper tube 5.7 Water-cooling system Water inlet distributor, water return tank, pressure gauge, thermometer, valve 5.8 Hydraulic system Motor, pump, Oil filter, Oil tank, Control valve,Accumulator

- 6. 5.9 HV. Power supply system Disconnecting switch, Voltage transformer, Vacuum breaker, Current transformer, Zinc-oxide arrester, etc. 5.10 Furnace transformer 5.11 L.V system L.V. power distribution cabinet, PLC cabinet, Main operation desk, Operation desk in front of furnace, Hydraulic operation box, Detect instrument and transducer, limited switch, 5.12 Automation control system PLC SIMENS PLC 6. Self-preparation Components by User 6.1 Refractory 6.2 Graphite electrode 6.3 The foundation construction, basic pre-embedded parts 6.4 Rail(Track) and fasteners 6.5 Hydraulic oil 6.6 Thermometer of liquid steel, Sampling device 6.7 HV. Cable used from H.V. cabinet to transformer 7. Quality guarantee One year since equipment debugging was done Looking for LF ladle refining furnace, please mail at marketing2@hanrm.com, we will make a perfect solution for you. More Articles You May Be Interested in: Hot Rolling VS Cold Rolling Electric Arc Furnace Processing Cost of Cold Rolling Strip Introduction of EAF(Electric Arc Furnace) Hot rolling On the Distance between the Rolling Mills

- 7. How to Determine the Steel Temperature by Naked Eye Second Hand Wire Rod Mill for Sale Roller FAQs An Effective Way to Reduce Roll Consumption On the Application of Cardan Shaft in Hot Strip Steel Rolling High-Speed Wire Rod Steel Production Process Roughing Rolling Mill Machine On the Advantage and Disadvantage of Electric Arc Furnace and Induction Furnace The Advantage of Induction Furnace Indian and Sri Lankan Customers Pay A Visit To Hani Steel and Discuss Finishing Rolling Mill Line Solution The Difference Between Hot Rolled Steel and Cold Rolled Steel The Advantages and Disadvantages of Hot Rolling Introduction of Our Factory Analysis of Five Common Failures in Steel Rolling Bar Rolling Process and Equipment Selection The Export Delivery of High-Speed Wire Rod Production Line to Iran What are the Main Ancillary Equipment for Rolling Mills? The Production Process of the Wire Rod What are the Categories of Steel Products? 50,000-300,000 tons of Rebar and Wire Rod Production Line Advantages of Multi-roll Rolling Mill VibSCAN Online Monitoring System Solution for Han Steel Technical Requirements of Rolls and Reasons for Broken Rolls

- 8. DC Electric Arc furnace vs DC Submerged Arc Furnace How to Choose Cardan Shaft? "Turn-key" TMT Rolling Mill Production Project under Construction Presentation on Continuous Casting Machine Electric Arc Furnace VS Submerged Arc Furnace