Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (19)

Design and Performance Evaluation of an Indirect Evaporative Air Cooler

Design and Performance Evaluation of an Indirect Evaporative Air Cooler

State of matter 3: Latent heat, Vapor pressure, Critical point, Eutectic mixt...

State of matter 3: Latent heat, Vapor pressure, Critical point, Eutectic mixt...

Refrigeration and air conditioning - psychrometry and air conditioning load e...

Refrigeration and air conditioning - psychrometry and air conditioning load e...

Similar to J.Christiansen Batelle Poster

Similar to J.Christiansen Batelle Poster (20)

Agc wp-dissolved gases in transformer insulation fluids

Agc wp-dissolved gases in transformer insulation fluids

Distillation MSG.ppt for B.Pharmacy SEM-III Pharmaceutical EngineeringStudy m...

Distillation MSG.ppt for B.Pharmacy SEM-III Pharmaceutical EngineeringStudy m...

A Systemic Optimization Approach for the Design of Natural Gas Dehydration Plant

A Systemic Optimization Approach for the Design of Natural Gas Dehydration Plant

J.Christiansen Batelle Poster

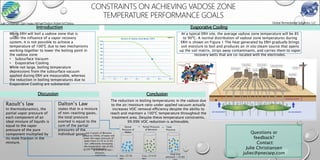

- 1. Discussion Julie Christiansen, Gary Healea, Michael Dodson,Robert MD'anjou While ERH will boil a vadose zone that is under the influence of a vapor recovery system, it is not possible to achieve a temperature of 100ºC due to two mechanisms working together to lower the boiling point in the vadose zone: • Subsurface Vacuum • Evaporative Cooling While not large, boiling temperature depressions from the subsurface vacuum applied during ERH are measurable, whereas the reduction in boiling temperatures due to Evaporative Cooling are substantial. Evaporative Cooling CONSTRAINTS ON ACHIEVING VADOSE ZONE TEMPERATURE PERFORMANCE GOALS Introduction Global Remediation Solutions, LLC Raoult’s law In thermodynamics, the partial vapor pressure of each component of an ideal mixture of liquids is equal to the vapor pressure of the pure component multiplied by its mole fraction in the mixture. At a typical ERH site, the average vadose zone temperature will be 85 to 90ºC. A normal distribution of vadose zone temperatures during ERH is shown on Figure 1 The heat generated by ERH gradually brings soil moisture to boil and produces an in situ steam source that opens up the soil matrix, strips away contaminants, and carries them to vapor recovery wells that are co-located with the electrodes. Conclusion Dalton’s Law states that in a mixture of non-reacting gases, the total pressure exerted is equal to the sum of the partial pressures of the individual gases. The reduction in boiling temperatures in the vadose due to the air/moisture ratio under applied vacuum actually increases VOC removal efficiency despite the ability to reach and maintain a 100ºC temperature throughout the treatment area. Despite these temperature constraints, 99.99% VOC reduction is achievable. Partial Pressure of Water Partial Pressure of Benzene Total Pressure + = H₂O = 23.76 torr C₆H₆ = 214.52 torr Final H₂O pressure = 22.83 Just 4 grams of Benzene added to 200mL of water will lower the vapor pressure of water from 23.76 to 22.83 torr, effectively increasing the evaporation rate of the mixed liquids. STP 200 mL of H₂O = 200 grams, respectively Questions or feedback? Contact: Julie Christiansen juliec@pnecorp.com 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 100 ᵒC90 ᵒC85 ᵒC75 ᵒC 95 ᵒC80 ᵒC70 ᵒC Percent of Vadose Zone Below 100°C Figure 1