Furnace Improvements Sales Presentation

- 1. Furnace Improvements Mission: Low cost value added solutions for fired heaters 1600 Hyw 6, Sugar Land TX, 77478 Phone: (281) 980-0325 www.heatflux.com

- 6. Some of Our Clients

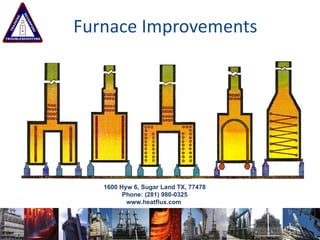

- 9. Typical Fired Heater Fluid--- Convection section Radiant section Conventional revamp Add 2 more passes

- 10. Split Flow Fired Heater FIS-183

- 11. Inclined Firing System www.heatflux.com

- 12. FIS-Split Flow

- 13. Capacity Increased FIS Client Capacity (MMBtu/hr) % FIS Client Capacity (MMBtu/hr) % Before After Before After 183 Citgo 181 194 10% 296 Alon USA 12.4 15 20% 187 Citgo 13.7 15.1 10% 12 13.2 303 Alon USA 9 11 20% 242 Valero 120 151 25% 314 CountryMark 12 20 70% 248 Valero 135 186 35% 333 HPCL 163 187 15% 53 61 255 Valero 54 57 5% 335 Conoco 74 83 10% 73 81 260 Alon USA 30 37 20% 339 HPCL 135 169 25% 283 Country Mark 8.1 8.35 3%

- 14. Efficiency Improvement FIS Client Efficiency % FIS Client Efficiency % Before After Before After 183 Citgo 67 86 19% 280 Valero 79 90 11% 187 Citgo 74 82 8% 283 Country-Mark 65 75 10% 188 Conoco 68 73 5% 296 Alon USA 74 86 12% 242 Valero 80 89 9% 303 Alon USA 83 88 5% 248 Valero 80 89 9% 333 HPCL 82 90 8% 266 Conoco 66 86 20%

- 15. NOx Reduction FIS Client Technology NOx Emissions (lb/MMBtu) FIS Client Technology NOx Emissions (lb/MMBtu) 208 Husky Oil LNB 0.05 287 Conoco SCR - 210 Conoco ULNB < 0.03 290 Lion Oil ULNB 0.025 242 Valero ULNB - 299 Conoco SCR - 254 Conoco SCR <0.01 329 Alon USA ULNB <0.03 263 Conoco ULNB + FGR + SI <0.02 335 Conoco ULNB <0.03 266 Conoco ULNB <0.04

- 16. New Fired Heaters FIS Client Service Duty 247 CITGO Combine Feed Heater 47 MMBtu/hr 269 Conoco Vacuum Heater 42 MMBtu/hr 279 Devon Hot Oil Heater 25 MMBtu/hr 286 Conoco BEU Heater 165 MMBtu/hr

- 17. Other Services Furnace Improvements

- 18. CFD Modeling for Heaters & Boilers Vertical Cylindrical Heater Riley Stoker CO Boiler

- 23. Heat pickup in convection section is high – Afterburning Suspected Air Flow reported appears erroneous. Check the meter calibration. Heater Performance Index Performance Monitors Description Flow (BPM) Inlet Pressure (PSIG) Crossover Temp (°F) Outlet Temp (°F) TMT (°F) Pass #1 709.5 278.92 585.1 686.78 960.7 / 969.4 Pass #2 676.52 295.97 589.75 678.62 965.1 / 994.5 Pass #3 670.8 275.85 592.02 680.15 895.8 / 927.1 Pass #4 729.08 285.95 597.14 678.49 907 / 1034.4 Pass #5 729.1 281.66 594.54 683.37 930.6 / 1041.67 Pass #6 695.13 283.84 590.9 670.14 887.6 / 845.62 Pass #7 737.39 298.2 594.39 682.95 959.9 / 863.41 Pass #8 653.35 275.73 583.27 679.04 964 / 1048.68 Individual pass flow above minimum acceptable Radiant coil metal temperature is OK Burners are OK Oxygen in firebox OK Draft in the firebox is OK Number of burners in operation is OK No. of burners in operation 24 Heater Performance Index 0.56 Thermal Efficiency 90.25 Fuel Saving Potential 3.08

- 25. We have an Agent near You AUSTRALIA, INDONESIA, MALAYSIA, NEW ZEALAND & SINGAPORE Kate Gimblett Tel: +61 (0) 7 5435 2205 Mobile: +61(0)417 087 129 www.energysystem.com.au INDIA Ajai Agarwal Tel: +9111-4214-3751 Mobile:+9198-1015-9901 aqology@gmail.com TAIWAN Douglas Chang Tel: +8862-2706-1544 Mobile: +8869-2106-9827 china.abc@msa.hinet.net LOUISIANA, USA Charles H. Thatcher Tel: 985-892-4224 Mobile: 985-966-5513 cht@bellsouth.net BRAZIL Jose Fleischmann Tel: (+55) 11-5641-4361 Fax: (+55) 11-5641-4361 jofleis@attglobal.net KUWAIT Alex Ambi Tel: +965-2482-9160 ext.126 Mobile: +965-3384-1712 alex@alzahemgroup.com U.A.E., OMAN, QATAR Sarwar Ali Tel: +971-6742-5035 Mobile: +9715-0631-7452 mists@emirates.net.ae SOUTHEAST, USA David Gangle Tel: +20-5437-1702 Mobile:+20-5542-7006 dgangle@gancoheat.com CANADA Paul Henry Tel: +450-676-3222 Fax: +450-676-5997 bjuren@bellnet.ca MEXICO Lorena Nieto G. Cel: (04455)43493284 lorenanietogarfias@gmail.com VENEZUELA, COLUMBIA, ARUBA & ARGENTINA Carlos Alarcon Tel: +58-441-6609-3444 Fax: +58-441-4366-8406 caav-ramasco@cantv.net TEXAS, USA Stan McHugh Tel: +713-839-8788 Mobile:+713-703-8907 sam.co@sbcglobal.net INDIA R. Rajamani Tel: + 91 94483 79108 Tel: +91 80 65971113 [email_address] SAUDI ARABIA Azfar Mahmood Tel: +966-3899-6333 Mobile: +9665-3451-2635 azfar@smartbde.com CALIFORNIA, USA David P. Diggins Tel: +94-9497-6551 Mobile:+94-9463-8591 digginsinc@cox.net UTAH, WYOMING, IDAHO, MONTANA & NEVADA Allan Woodbury Tel: +801-274-3333 Mobile: +801 918-4826 [email_address]

- 30. #4 Platformer Heater Data Comparison Item Units Before Revamp After Revamp Capacity BPD 18,500 24,000 Heat Duty MM Btu/hr 158.0 194.5 Heat Release MM Btu/hr 234 225 Efficiency % 67.50 86.60 Stack Temp. °F 1,092 478 Fuel MSCFH 244 242.8 Fuel Savings $/annum 5.8 Million* *Based on $6.0 / MM Btu

- 31. #4 Platformer Heater Before and After Revamp Before After Capacity Increased Efficiency Improvement Split Flow Low NOx Reduction New Heater

- 32. CITGO Corpus Christy Reboiler Trim Heaters Capacity Increased Efficiency Improvement Split Flow Low NOx Reduction New Heater Trim Heaters Parameters (Stripper / Stabilizer) Parameter Units Before Revamp After Revamp Parameter Units Before Revamp After Revamp Heat Duty MMBtu/hr 13.78 15.14 Heat Duty MMBtu/hr 12.0 13.20 Heat Release MMBtu/hr 18.06 18.29 Heat Release MMBtu/hr 16.13 16.10 Efficiency % 76.4 83.2 Efficiency % 74.4 82.0 Stack Temp. °F 813 572 Stack Temp. °F 832 575

- 38. Platformer Heaters (H-20/21/22) Parameter Units Original Design Total Heater Duty MMBtu/hr 155.98 Radiant Heat Duty MMBtu/hr 74.09 Convection Heat Duty MMBtu/hr 81.89

- 43. Valero Proposed Revamp – Split Flow Scheme

- 69. Revamp Results Capacity Increased Efficiency Improvement Split Flow Low NOx Reduction New Heater H-102 H-205 Design Operating After Revamp Design Operating After Revamp Efficiency % 85 83 86 84 81 86 Capacity MMBtu/hr 46 30.1 51.15 33.7 20.1 37.07 NOx Emission Lb/MM btu - - < 0.03 - - < 0.03 No. of Burners - 8 8 8 6 6 6 Heat release / Burner MMBtu/hr 8.51 - 8.65 8.35 - 8.36

- 75. Split Flow H-5 Heater

- 77. Revamp Results Capacity Increased Efficiency Improvement Split Flow Low NOx Reduction New Heater Parameter H4 H-5 Before After Before After Total Heat Duty (MMBtu/hr) 110 103 103 98 Process Heat Duty (MMBtu/hr) 74 83 73 81 Efficiency ND/FD (%) 82 / - 88 / 95 79 / 88 90 / 92 # Burners 12 12 12 12 Heat Release per Burner 10.95 10.12 10.95 9.8 NOx Emissions (lb/MMBtu) - < 0.03 - < 0.03

Editor's Notes

- 06/22/11 Furnace Improvements. Low Cost Solutions for Fired Heaters and Boilers. FIS appreciates your interest in watching our company Presentation. During this video, we will give brief information about our company history, our technologies and review a few, very interest, case studies. FIS was started in 1996, with a mission to improve the performance of existing fired heaters and boilers in refineries and petrochemical plants. Our goal is to provide low cost value added solutions for increasing capacity, improving efficiency and reducing NOx emissions.

- 06/22/11 In our 14 years of experience, FIS have successfully completed over 200 projects. Our dedicated team consists of more than 40 professionals with over 300 years of combined high quality technical experience. We are located in USA and India which give our clients a high quality 24 hr service. FIS offers advanced, economical and practical approaches to solve and improve heaters and boilers performances. We take pride in doing excellent technical work. For us, the most economical way to do a project is to do it right the first time.

- 06/22/11 FIS have the experience working and designing all type of fired heaters and Boilers. We specializes in revamping projects for increasing capacity, improving efficiency, and reducing NOx emissions. We have worked Crude heaters, Vacuum heaters, Hydrotreater heaters, Reformer charge heaters CO boilers, Coker heaters, Waste heat boilers and many more.

- 06/22/11 FIS offer: Revamping services, New Heater Design, Training for engineers and operators, and computer softwares. All our services are aim to improve the performance of your Fired Heater. Revamping focuses on working with existing components. It is an efficient and cost effective way to get more capacity and reliability from existing equipment. Our new designs never compromise any key parameters and work at full load since day one. The heaters shown in the picture are at a refinery in Port Arthur. These heaters were supplied by other company. The heaters were having performance issues. They could not go more than 60% in load. The project manager contractor approach FIS to resolve the problem. FIS took the challenge, analyzed the design and operation parameters of the heaters and gave the necessary recommendations to bring the capacity to 100%.

- 06/22/11 Our scope of services consists of process design services, followed by detail engineering, project services, erection and start up assistance. We have in-house CFD modeling capabilities. Our working methodology typically starts with an engineering study with +/- 30% cost estimates for revamp. It is followed by a project design basis report with +/- 10% cost estimates. The final phase consists of detailed engineering and project services.

- 06/22/11 This slide shows a partial list of our clients we’ve had the pleasure to work with. We have worked with most of the refining companies in U.S.A. and a few more around the world. A detailed reference list can be made available on request.

- FIS not only works on proposing solutions to the heater/boiler operational problems but is spearheaded by a technology developer. We have three patented technologies for fired heater applications: Split Flow Flue Gas injection Inclined Firing System Our split flow technology has successfully been implemented in many refineries. We shall describe our technologies briefly in the following slides. 06/22/11

- The Split Flow Technology is a new approach to revamp fired heaters. Fired heaters can be revamped for increasing the process heat duty and also for achieving higher efficiencies. One of the main benefits of split flow technology is lower pressure drop even at higher charge rates. Split Flow Technology revamps are at least half the cost of typical conventional revamps. 06/22/11

- February 24, 2007 A typical fired heater consists of convection section and radiant section. Feed gets preheated in the convection section and then goes to the radiant section for final heating. In this sketch we are showing a 4 pass heater. In most of the revamps, extra capacity needed is only 25 – 30%. The conventional revamp approach is to increase the number of passes from 4 to 6 or 8. This approach is expensive and heater performance goes down.

- February 24, 2007 With FIS’ patented technology, the process fluid is split into two streams: one to the convection - radiant section and the other only to the convection section. About 70% of the feed heats in the main flow and the rest goes to the split flow and it is heated in the convection section. These streams mix at the radiant outlet. We shall learn more about the split flow technology in few of the revamp case studies where we have implemented this technology.

- 06/22/11 Most of the tube failures in fired heaters are due to high tube skin temperatures and flame impingement. Over firing of heaters is also a frequent reason for flame impingement. Furnace Improvements has developed the Inclined Firing System technology in order to avoid flame impingement on tubes. The burners are installed inclined at 5-15° from the vertical. This technology is very useful for installing Ultra Low NOx Burners in very tight heater boxes.

- The following table shows some of the Split flow projects we have worked on. The split flow have been used as a better approach for increasing capacity. In All the cases, conventional revamp had a high price and in most of the cases, convectional revamp was not possible because of high pressure drop or plat space. FIS provided design, detail engineering, supply and project management services for these revamp projects. Except for 335 and 329 , all other projects have been successfully commissioned. 335 and 329 are schedule to be commissioned by beginning of next year.

- In the following table we are showing some of the capacity increase projects we have work on. In all these projects FIS have provided design, detail engineering supply and project management services. These projects have been successfully commissioned.

- In the following table we are showing some of the efficiency improvement projects we have work on. In all these projects FIS have provided design, detail engineering supply and project management services. These projects have been successfully commissioned.

- In the following table we are showing some of the NOx reduction projects we have work on. Some of them are in fired heaters and others are in boilers. In all these projects FIS have provided design, detail engineering, supply and project management services. These projects have been successfully commissioned.

- The following table shows FIS new heater projects. We provided design, detail engineering, supply and project management services. All other projects have been successfully commissioned and our clients are extremely happy with the performance of their heaters.

- FIS knows that a revamp or a new heater design is not always the best option. Because of that we offer many other services to give you the most economical and practical solution to increase the performance of your equipment. Some of these services are CFD modeling, Field Survey, Fired heater or boiler tuning, heater performance index and trainings. We will briefly explain a few of this services. 06/22/11

- Computational Flow Dynamics is a sophisticated computationally-based design and analysis technique. CFD gives you the power to simulate flows of gases and liquids, heat and mass transfer, moving bodies, multiphase physics, chemical reaction, fluid-structure interaction and acoustics through computer modeling. Using CFD software, you can build a 'virtual prototype' of a heater or boiler that you wish to analyze and then apply real-world physics and chemistry to the model, and the software will provide you with images and data, which predict the performance of that design. FIS has the knowledge and the tools to perform in house CFD. 06/22/11

- Fired Heaters and boilers tuning. Improper fired heater settings can lead to reduced equipment service life, shorter cycle times, reduced efficiency, increased maintenance cost and increased stack emissions. A Furnace Improvements’ engineer will observe your fired heater performance and evaluate operating parameters. FIS will measure and evaluate fuel gas flow, pressure, fired heater draft, etc. With this information and a visual inspection of the fired heater, the engineer will make the necessary adjustments to improved performance.

- FIS offers on-site training programs to train and guide your engineers and operators. These trainings are designed to give solid basis and tools to understand how a furnace works. As a result the attendees will make educated decisions to improve the heater performance. We can customized our trainings for your technical personnel. It can be developed for engineers, operators, senior engineers, etc. Get your technical personnel trained and start getting the benefit of having excellent heater performance.

- Fired heaters are major consumers of energy and even the smallest improvement in efficiency can save thousands of dollars. A recent survey indicated that average draft in the furnaces is maintained at almost 3-4 times the value recommended. This causes considerable energy loss! FIS Draft Control System is very reliable as it takes into account a number of parameters before making any adjustments. It is programmed using heater modeling. FIS draft control system will monitor the Heater O 2 / CO Content, Fuel Firing Rate, ΔP across Damper, Damper Position Switch, Arch Draft. Benefits of the draft control system are Improved Heater Efficiency, Decreased NO x Emissions, Optimized Combustion and Reduced Fuel Consumption. It is calculate to have a payback time of less than a year.

- The Heater Performance Index software can be used for all fired heaters to monitor the performance 24 hours per day. It is an online tool for continuous monitoring of heaters. HPI is custom built for each heater based on analysis of heater operating data and modeling. With the use of HPI software, the current performance of the heater is thoroughly analyzed by taking live data from the DCS and performs calculations. HPI will check: High tube metal temperatures, Coking inside tubes, plugging & excess fuel gas pressure at burners, Draft and Excess Oxygen, Flow Mal distribution , High stack temperature and lower efficiency, Convection Section Performance, Fuel Saving Potential, etc.

- HPI helps increase the run length of heaters and take corrective action. Any significant deviations of the key process parameters from the desired values are highlighted and can be corrected. It will generate various messages to provided guidelines for the operator in safe and efficient operation. HPI will ensure your heater always performs the best possible.

- 06/22/11 Thank you very much for your time and interest. We look forward to working with you on your fired heater projects. Please contact us with any question, training requirements or clarification you might need.

- FIS knows that a revamp or a new heater design is not always the best option. Because of that we offer many other services to give you the most economical and practical solution to increase the performance of your equipment. Some of these services are CFD modeling, Field Survey, Fired heater or boiler tuning, heater performance index and trainings. We will briefly explain a few of this services. 06/22/11

- The basic objective in the Platformer heater #4 revamp, located in CITGO, Corpus Christi, was to improve the thermal efficiency and to reduce NOx emissions. The client did not want to generate steam or preheat combustion air to improve efficiency. The stack temperatures were over 1100 o F. Thermal efficiency of the heater was only 66%. FIS studied the design and operating parameter and proposed to revamp the heater using split flow technology. Our approach was half of the price of the conventional revamp.

- The conventional series flow design was to preheat the fluid in the convection section and then heat it in the radiant section. The pressure drop in all four cells increased. Since 100% of the flow has to go through the convection sections, this design required large convection sections, new grade mounted stack and large process piping. Cost of the conventional revamp was estimated at $6 million.

- FIS patented Split flow technique divides the process fluid into two streams. The convection section heats approximately 25 – 30% of the total flow and the rest is heated by the radiant section to the same temperature. The exiting fluids from both the sections are then combined into one stream. This requires smaller process piping and narrow convection section. The existing stacks could be re-used which eliminated the need for additional duct work and grade mounted stack. Our cost was 3 million dollars

- This table shows the comparison of major parameters before and after revamp. The heater capacity went up from 18,500 to 24,000 Barrels per day. Stack temperature was reduced from 1100 to 478 ° F . The thermal efficiency improved from 67 to 86%. 44 low NOx burners were installed. The NOx emissions were reduced to 0.06 lb/MMBtu. The pressure drop is lower and the firing rate also went down. The installation costs were half compared to that of the conventional series flow design. The estimated fuel savings were approximately 6 million dollars per year.

- These pictures show the heater before and after revamp. The job was completed in October 2002 and has been running since without any problems. The client was extremely happy.

- The two trim heaters, stripper and stabilizer reboiler were originally designed for a heat duty of 12 and 13.8 MM Btu/hr respectively. The convection sections in these heaters were in poor condition. They were operating at very low efficiency. Client contacted FIS looking to improve the performance of these trim heaters. FIS studied the design and operating conditions of the heaters. FIS solution was to replace the existing convection sections and provide new stacks to increase the capacity of the heaters by 10% and improve their thermal efficiency by 7 to 8%. FIS carried out process design, detailed engineering, fabrication drawings, engineering specifications, material requisitions, and supervised field activities. The heaters are running with the enhanced capacity and efficiency since October 2002.

- ConocoPhillips has a C.O. boiler in their Fluid Catalytic Cracking Unit. The CO boiler was more than 40 years old. The boiler had three problems: (1) low economizer tube metal temperatures were reaching dew point levels. (2) high super heated steam temperature. (3) problems with tube supports in the hottest zones. The refinery approached Furnace Improvements to provide thermal design for replacing the convection section of the CO boiler. Furnace Improvements carried out the engineering study, we conducted a detailed operation analysis of the existing CO boiler and built a model of the existing design. We developed a better design overcoming the drawbacks in the existing CO heaters. The convection section was redesigned to: Increase FCC feed flow. Improve CO Boiler efficiency. Prevent cold end corrosion of economizer. And Eliminate flow distribution problems. The new design was developed retaining the existing soot blower locations, same platform elevations, and without any additional firing requirement. It was estimated to save the client almost $550,000 per year on fuel consumption. The boiler was successfully commissioned in March 2003 and is running continuously now.

- The existing heater was originally designed as gas fired natural draft in 1968. An air preheating system was added in April 1983. The heat duty of this balanced draft crude heater is 420 MMBtu/hr. The radiant section is divided into 4 cells and the heater has 84 burners. Premcor contacted FIS to revamp the heater to reduce the NOx emissions to less than 0.05 lb/MMBtu. FIS performed the study and it was found that the convection section had high flue gas temperatures leading to high air preheat temperatures The radiant section bridge wall temperature was high. The burners flames were touching the roof tubes. The heater efficiency was low and the air preheater was reaching the limit on flue gas temperature.

- FIS modified the radiant section tubes, and retubed the convection section with new arrangement. After the radiant and convection section modifications were executed, the heater capacity was increased from 420 to 460 MMBtu/hr. The c oking rate was reduced by 1/3 in the convection. The air preheat temperature was lowered by 300 F. FIS replaced the existing burners with low NOx burners. Flame impingement was eliminated. The flue gas temperature leaving convection section was reduced by more than a 250 deg F. FIS scope of services included Basic Design, Process Engineering, Detailed Engineering. Project Services, Erection/Start up and Supervision. This crude heater has been running successfully since Jan 2004 and client is extremely satisfied.

- A Reformer Heater was designed as a multi-cell heater consisting of five radiant cells, a common convection section and five stacks. The existing heater is rated to process 24,000 BPD of feed (Naphtha) at an absorbed heat duty of 160.6 MM Btu/hr, an efficiency of 86.9% with a total of 62 burners. FIS was approached to do the study and developed options to reduce NOx emissions. FIS reviewed the design and operating data and recommended replacing the existing burners with Next Generation Ultra Low NOx Burners. Two of the cells have staged fuel burners and other three-cells have premix burners. FIS installed 15 burners in cells in 4 cells. The burners were installed on a staggered pattern to allow maximum flue gas recirculation. The last Cell have 6 burners which were replaced with ULNBs. FIS carried out the entire scope of activities from conceptualization to commissioning of this heater revamp. The heater was successfully commissioned in October 2004. The NOx emission was reduced to less than 0.03 lbs Btu.

- Another example of the advantages of using the split flow technology are highlight in this case. Valero Texas City had a platformer and naphtha hydrotreating unit at its Texas City Refinery. The three heaters you see on the side are in naphtha hydrotreating service. The big heater consisted on three cells housing charge heater, #1 interhater and #2 interheater. The heater has a common convection section and a tall stack. Convection section had a steam generation coil, steam superheater and a BFW preheater coil. All the process coils were in the radiant section. The heater had a very tall stack about 130 ft. www.heatflux.com September 2010

- The heater duty was about 155 MMBtu/hr . Process heat duty was about 74 MMBtu/hr. The convection waste heat recovery duty was 81 MMBtu/hr. The heater was running very hard. Overfiring. www.heatflux.com September 2010

- The convection consisted of waste heat recovery unit. The lower most bank consisted of 4 rows of tubes in steam generator service. It was followed by a row of steam superheater tubes. The upper steam generation coil consisted of 7 rows of tubes. The economizer coil had 6 rows of tubes. There was a provision to install 2 future rows. www.heatflux.com September 2010

- The naphtha hydrotreater section consisted of 3 heaters. The heaters were vertical cylindrical all radiant heaters. The duty was between 12-19 Million Btu/hr. The thermal efficiency of the heaters was only 52 to 55%. www.heatflux.com September 2010

- The client was finding that heater was a bottleneck. The radiant section tubes were getting overheated and some of them were bowed. There had been a few tube failures. The convection section was in a bad state and flue gas temperature was almost 400 F higher than the design. The steam superheater coil was not working well and SSH outlet temperature was 40 F lower. In addition, the three all radiant heaters were in bad shape. They were getting over fired and were firing limited. www.heatflux.com September 2010

- The conventional way of efficiency improvement was to provide a new convection section or install new tubes. That would take care of the high stack temperature. This would not have solved any problems with the heaters over firing and capacity bottlenecks. After the experience of first unit, several options were examined for taking care of the problems. We recommended that in the platformer heater, we limit the duty to 15000 Btu/hr ft2 radiant flux and shift the duty to the convection section. Similarly in the three VC heaters, We decided to limit the firing rate to the design, reduce the heat flux and shift the balance duty to the big convection section. www.heatflux.com September 2010

- The split flow scheme proposed is shown here. We implemented split flow in two cells only for platform heater and for the 3 naphtha hydrotreater heaters. About 15 to 30% of the heat duty from naphtha hydrotreater heaters was shifted to the convection section. September 2010

- This is the sketch of the revamped convection section. The bottom part of the convection section was used to preheat the process feeds and upper part of the convection section was used for generating steam. We were able to reduce the flue gas temperature leaving the stack to 300 F and thus improve the efficiency by almost 10%. www.heatflux.com September 2010

- Furnace Improvements was employed by Valero to develop the best capacity improvement scheme for #2 Platformer Heater and NHT Heaters. The heater was revamped not only for increased capacity but also for improved thermal efficiency and improved reliability. The capacity was to be increased from 12,000 BPD to 18000 BPD. The process heat duty was increased from 120 MMBtu/hr to 151.51 MMBtu/hr. FIS’ “ Split Flow Technology ” increased the capacity and had a design heat duty of 150.4 MMBtu/hr. The revamp cost was one fourth of the alternate design. The thermal efficiency of the heaters was increased from 80% to 89%. The Platformer Heater burners were replaced with new Ultra Low NO x flat flame burners. FIS scope included from process design to commissioning of this heater. Revamp scope included replacements of coils, radiant floor, burners, new convection section and stack damper. The heater was commissioned in Nov 2005 and has been running successfully ever since. September 2010

- The first new heater job by Furnace Improvements was for CITGO Corpus Christi. The new vertical cylindrical heater is a combined feed heater with a natural draft. It is used to heat a mixture of hydrocarbon and hydrogen. The heater is designed for a heat duty of 47 MMBtu/hr and has an efficiency of 82%. FIS scope of services included design, engineering, fabrication and supply of this heater. The heater was successfully commissioned in 2005. 06/22/11

- Furnace Improvements was employed by Valero Wilmington Refinery, CA to perform a capacity improvement (12,000 BPD to 18,000 BPD) on their platformer Heater. FIS used the patented split flow technology which lowered the heat flux and firing rates for increased capacity. The costs were also lowered by 70% as no radiant section modification was required. The overall heater efficiency was improved by 10%. We not only designed, engineered, fabricated and supplied the heater but were also involved with the erection and commissioning activities. The commissioning was completed in January 2008. 06/22/11

- This crude heater in Conoco Phillips alliance refinery is the biggest heater within the Conoco Phillips system, with a heat duty of 750 MMBtu/hr. The scope was to install a selective catalytic reduction unit, to reduce NOx emissions to less than 0.01lb/MMBtu. The convection section was split to get the correct flue gas temperature window for the SCR. A novel scheme was implemented by FIS that saved 5 million dollars to the client. FIS option didn’t require installing new ID fans or duct work. The ID/FD fans were upgraded. FIS performed the CFD analysis to ensure there is proper mixing of Ammonia with the flue gases in the SCR unit and there is uniform distribution of flue gases over the catalyst bed. FIS reduced the flue gas temperature leaving stack from 420 deg F to 300 deg F, thus improving the efficiency by 3.5%. The annual fuel savings are approximately 1.5 million dollars. 06/22/11

- As you can see, drawing shows the conventional scheme versus FIS scheme. The alternative is to route the cold and hot flue gas ducting into convection section instead of the stack. The convection section is split into two parts by installing a blanking plate. This eliminates the need to install new ID fans and stack and saves on duct work. This heater was commissioned in February 2009 and is running successfully ever since.

- 9/11/2007 06/22/11 Premcor Port Arthur Refinery contracted Furnace Improvements to carry out the revamping of the Reactor Charge Heater in their refinery. The revamping was required because of the need to process higher charge rates through the heater and maintaining the same pressure drop. The heater was provided with an 8 pass 4 inch coil in convection and radiant section. It has been installed with an air preheating system. It has 4 fuel gas burners in the heater floor. FIS modeled the heater and simulated for original and operating conditions. FIS recommended to convert the 8 pass heater to 4 pass. The 4” radiant and convection coil was changed to 8” size. The coil material was upgraded from SS 321 to SS 347H. The burners were relocated to increase the burner and tube clearance. A new tight shut off stack damper was installed. The heater is running successfully since 2007. The other option was to convert the 4” coil to 6” coil which would have had a very low pressure drop for this service.

- Furnace Improvements carried out a Hydrogen Heater revamp project for AlonUSA, Big Spring Refinery, Texas. Client wanted a higher charge rate and a lower pressure drop across the coil. The conventional revamp scheme, would have been to convert the heater to two passes that would require radiant coil modification. This would have resulted in a very low fluid pressure drop, which was not desirable. Operating data analysis indicated that: Convection section fins were burned out. We redesigned the convection section with FIS patented Split Flow Technology . The pressure drop across the heater was optimized due to the parallel processing. The thermal efficiency of this heater increased from 78% to 86% after revamp. FIS scope includes design, engineering, supply and commissioning of this heater revamp. The heater was successfully commissioned in May 2009. 06/22/11

- Client approached FIS to convert a CO boiler to a stand alone refinery fuel gas fired boiler. COP wanted to reduce NOx emissions to 0.02lb/MMBtu. FIS solution was to install ultra Low NOx burners, flue gas recirculation system and dilution steam injection system. A new economizer section was installed which increased the efficiency by 4%. The Steam Super heater coil was revamped. This boiler had a number of operating problems which were taken care of during the revamp. Our client saved $600,000/yr in fuel gas consumption. FIS modeled the existing and new burners to predict the combustion improvements using CFD. This job was successfully completed in March 2008. 06/22/11

- ConocoPhillips contracted Furnace Improvements to perform a NO x Reduction revamp for Alky Unit Heater. The target NO x emission rate was 0.035 lb/MMBtu. FIS perform the heater analysis and found out that the efficiency was very low during operating data analysis. FIS carried out heater floor modifications, installation of 8 new ultra low NOx burners, installation of stack Oxygen and temperature indicators, stack damper for draft control and new upgraded convection module. FIS did the design, engineering, fabrication and erection for this job. The excess air was reduced by 50%. Thermal efficiency of the heater increased from 66 to 86%, the NOx emissions were at target and the fuel savings are almost $800,000 per year. The project payout in less than 2 years. This heater was successfully commissioned in March 2008. 06/22/11

- This is the 2 nd new heater job that we have executed for ConocoPhillips Wood River Refinery. COP was facing coking problems in their Vacuum Heater and they also wanted to revamp the heater to handle Canadian Crude and reduce NOx emissions. FIS did the process study and as a result of the study, ConocoPhillips decided to build a new vacuum heater with an existing heater foundation. The new heater is 4 ft wider and FIS designed a superficial frame to make the heater sit on the existing foundation. This vacuum heater is a horizontal tube box with a convection section. It is designed for a heat duty of 42.82 MMBtu/hr. FIS’ scope involves design, engineering and supply of this heater to the site. This heater was erected in March 2009. 06/22/11

- FIS was employed by Devon Energy to supply a new hot oil heater at Beaver Creek Gas plant. This Hot Oil Heater is designed for a heat duty of 25.0 MMBtu/hr. FIS executed the heater process, mechanical design, structural analysis, material procurement, fabrication and installation of the hot oil heater within an eight month schedule. FIS also supplied the burner management system and procured all the instrumentation controls of the heater. The heater was designed for thermal efficiency of 85% and was successfully commissioned in August 2007. 06/22/11

- Valero approach furnace improvements to develop an efficiency improvement scheme for their CDHDS reboiler. The heater was design to process a heat duty of 72 MMBtu/hr with an efficiency of 81%. However, the heater was operating at 79% efficiency. FIS analyze the heater and revamped for a heat duty of 82 MMBtu/hr with an efficiency of 90%. The scope included adding Steam generation coils in the convection section, adding a new transition cone and 25 more feet of stack. The fuel savings are calculated around $600,000 per year. The payback period of this project was only 1.2 years. The project was successfully commissioned on October 2007.

- FIS was employed to conduct an engineering study as part of their expansion project. The refinery needed to increase the capacity of a cabin vacuum heater. This heater was originally installed in 1949. FIS developed revamping options to increase the capacity of the vacuum heater. The client opted for revamping the radiant section coil, new burners and a new stack. With these modifications, the capacity of the heater was increased from 8,200 to 9,500 BPD. The absorbed heat duty is 8.35 and the efficiency improved from 65 to 75%. The Heater was successfully commissioned and is working with increased capacity since May 2008.

- We have recently finished working on 2 new heater projects for ConocoPhillips. The BEU Heater is a natural draft, vertical cylindrical heater. The heater is use to heat hot oil. The heater is designed for a total heat duty of 165 MMBtu/hr. FIS executed the heater process, mechanical design, structural analysis, material procurement and fabrication of this hot oil heater. COP requested an expedited delivery for this heater to meet their turnaround schedule. We took this challenge and delivered the heater to the site within 9 months of receipt of the order. The fabrication was done to such an extent that there were no structural welds at the site. All the connections were designed to be bolted connections. This is a 6 pass heater and radiant panels were designed for each pass to fit in each radiant panel. It was successfully commissioned on December 2009. 06/22/11

- Conoco Phillips Wood River Refinery was installing new selective catalytic reduction (SCR) units to reduce NOx emissions from 2 CO Boilers in their FCC unit. FIS modeled the convection section for the correct SCR temperature window. The boiler was also facing CO slippage problems. FIS developed a CFD model for the existing combustion chamber. FIS devised a practical and inexpensive solution of installing a baffle wall. FIS also analyzed the heater structure to withstand the higher internal pressures. This project has been successfully commissioned in March 2008. 06/22/11

- Lion Oil El Dorado Refinery contracted Furnace improvements to reduce NOx emissions to 0.025 lb/MMBtu in six heaters. Some of the heaters needed to be rerated for new service duties due to change in process conditions. FIS is installing ultra low NOx burners on all 6 heaters. The Vacuum heater is a horizontal tube cabin heater built in 1995. This heater has 6 natural draft burners installed on the floor. The existing burners will be replaced with 10 ultra low NOx burners. The Cat Cracker is a vertical cylindrical heater built in 1978. It has 6 burners and they will be replaced with 6 ultra low NOx burners. The charge heater was built as a vertical cylindrical heater. Existing 6 burners will be replaced. Floor plate modifications will be done on all the three heaters owing to burner replacement. 06/22/11

- The preflash boiler was built in 1979 as a vertical cylindrical heater. The existing 4 burners will be replaced with ULNB’s. The charge stripper reboiler was built in 1958. It was revamped in 1979. It has 15 burners on the charge side and 13 burners on the Stripper reboiler side. FIS will replace the 28 floor fired burners to 12 wall fired burners. FIS is doing radiant end wall modifications. EPA nozzles are being added to the stack. FIS also designed and supplied the ladders and platforms required for the burner platforms nozzle access. The Platformer heater was built in 1979. This Platformer Heater is a vertical arbor tube heater with 3 radiant sections and a common convection section and a stack . The heater has 30 burners. They are being replaced with 52 ULNB’s. Radiant panel modifications along with ladder and platform work is being done on this heater. The detail engineering is completed and the erection is due in August, 2009. 06/22/11

- The Hydrogen Heater is a vertical cylindrical heater. The heater was revamped in 2003, for a heat duty of 12.48 MMBtu/hr but it was operating at an efficiency of 78% and an absorbed duty of 11.6 MMBtu/hr. FIS analyzed the heater and found that the convection section fins were burned out/ fouled, resulting in higher flue gas temperature leaving the convection section. The conventional revamp scheme (to preheat the feed in the convection section) resulted in very high fluid pressure drop and high fluid pressure drop was not feasible. FIS redesigned the convection section with FIS patented “Split Flow Technology”. The pressure drop across the heater reduced even at higher capacity, due to this parallel processing. After the revamp the heat duty increased from 11.6 to 14.8 MMBtu/hr and the efficiency improved by 10%. This project was successfully commissioned on May 2009.

- After the success of CCU-1 CO Boiler, ConocoPhillips gave FIS the project to re-rate the CCU-2 CO Boiler. The objective of the revamp was to project operating cases and reconfigure the heat transfer area in the existing convection section to control the oil outlet temperature and achieve the required flue gas temperatures for SCR installation. FIS reviewed and analyzed the existing design and current operation and re-rated the same for projected conditions. At the end of the study, FIS recommended modifications which provided flexibility in controlling the oil outlet temperature and flue gas temperature for SCR between the lower and higher range. This project was successfully commissioned on October 2009.

- AlonUSA requested FIS to rerate the NSR for new process conditions. FIS observed that the firebox was small and volumetric heat release was high. The proposed process conditions weren’t feasible with the existing radiant section. FIS is extending the radiant section and installing a new radiant coil with 50% more radiant area. Convection section temperatures were high and the stack height was limiting with the new firing conditions. FIS is working on the design, detail engineering, fabrication and supply of the new convection section, stack and radiant coils. This project will be completed in 5 months. 06/22/11

- FIS was employed by a Refinery in Indiana to carry out a heat duty increase project for the Naphtha Splitter Reboiler service. Operating heat duty was around 11.74 MMBtu/hr. This was being supplied by Naphtha Splitter Reboiler Heater and by Platformer Heater Convection Coil. Naphtha Splitter Reboiler service heat duty needs to be increased by 5 MMBtu/hr. FIS reviewed the design and operating data for the Naphtha Splitter Reboiler heater and for Platformer Heater. It was not feasible to increase the capacity in neither of them. Client has an Old Platformer Charge Heater. The heater was abandoned several years ago. FIS proposes using this heater for providing the required heat duty for Naphtha Splitter Reboiler service. FIS revamped the old Platformer Charge Heater adding a new radiant section with tubes and hangers and a small convection section. The stack was reused. The capacity was increase from 8.38 MMBtu/hr (Naphtha Splitter Reboiler) to 20.12 MMBtu/hr (old Platform Charge Heater). The heater was successfully commissioned in November 2009.

- FIS was employed by Alon USA Refinery to develop a NOx reduction study for Depantanizer Reboilers (H-102 and H-205). Alon USA has two VC Heaters with convection section and stack. The operating heat duty for heaters H-205 and H-102 was 20.1 MMBtu/hr and 30.1 respectively. FIS performed the study and found out that the convection sections were fouled. FIS suggest to revamp the heaters with patented technology Split Flow to increase capacity by 10%. FIS also suggest to install the ULNB with patented “inclined firing system” to eliminate fouling problems and decrease the NOx emissions to less than 0.03 lb/mmbtu.

- The exiting heater had 4 passes. The convection sections had 15 rows with 4 tubes per row where the 1 st two rows were bare tubes and the rest 13 rows were finned tubes. FIS revamped the convection section using split flow technology. For this process the feed will split before entering the convection section. About 30% of the feed will only go to the convection section and the rest 70% will go to convection section followed by the radiant section. The revamp arrangement has 13 rows with 8 tubes per row. The first 3 rows are bare tubes follow by 2 more rows of finned tubes. This bottom 5 rows are for the main flow (70%) and the feed flow in 4 passes. The upper part of the convection section has 8 finned rows with one pass only which is use by the split flow (30%) With this arrangement the heater is able to process more feed without increasing the pressure drop or the firing rate.

- The burners were replaced by ULNB. The installation was done using inclined firing system which reduce the coke formation and flame impingement in the tubes. The burners were installed with 7.5° of inclination from the vertical. H-102 – 8 burners. The heat release increased from 8.51 (before revamp) to 8.65 (after revamp) H-205 – 6 burners. The heat release stay the same, from 8.35 to 8.36 (after revamp).

- The overall performance of the heaters are summarize in this table. The revamp increased the Efficiency and capacity of both heaters. It also reduced the NOx emissions to the target value of less than 0.03 MMBtu/hr. The Project started on 2010 and will be commissioned at beginning of 2011. FIS scope of work included design, engineering, procurement, erection and project management services.

- Hindustan Petroleum Corporation Limited, India, was already planning to install a new in-kind convection section, new stack, and a new tight shut-off damper during their forthcoming shutdown. A few weeks before that, HPCL approached FIS asking for recommendations to increase the capacity of the Crude Heater by 15%, improve the efficiency, and reduce the stack temperature during the same forthcoming shutdown. FIS analyzed the design of the Crude Heater and proposed the followings: Increase the number of burners and replace them for Low NOx Burners. Add a new convection section below the new-in kind convection. The proposed convection increases the absorbed duty in this section and help in reducing the stack temperature. The results of the revamp were a 15% increase in the capacity, 15% increase of heat duty and a 4% efficiency improvement. The recommendations were implemented in the 2010 Shut-down of the refinery.

- For the same HPCL forthcoming shutdown, FIS also provided recommendations to increase the capacity of the Vacuum Heater by 15%, improve the efficiency, and reduce the stack temperature. HPCL was already planning to install a new in-kind convection section, a new stack and new tight shut-off damper during the forthcoming shutdown. FIS analyzed the design of the Vacuum Heater and developed a scheme to increase the capacity and improve the efficiency of the same as requested. FIS proposed: Increase the number of burners and replace them for Low NOx Burners Add a new convection section below the new-in kind convection. The proposed convection increases the absorbed duty in this section and helped in reducing the stack temperature. The results of the revamp were an 15% capacity increase, 15% heat duty increase, plus the efficiency improved by 5%. The recommendations were successfully implemented in the 2010 Shut-down of the refinery.

- ConocoPhillips was looking to reduce the NOx emission of their H4 and H5 heaters with the replacement of the burners for Low NOx burners. FIS performed a study on the heaters and found the heaters in poor conditions. The radiant tubes were heavily scaled and convection section fin surface was only about 41 - 45 % effective. The flue gas temperature leaving the heaters was about 150 - 200 °F higher than the design which also leaded to higher airpreheat temperature. FIS concluded from the study the current processing capacity will be limited to 32,000 BPD when the heaters were replaced with Ultra Low NOx Burners. Moreover, the NOx emissions will be difficult to meet with higher air preheat temperature. FIS suggested the revamp of these 2 heaters with the installation of new convection sections using FIS patented “Split Flow Technology” and replacement of burners with Ultra low NOx Burners. The revamp increases the capacity from 32,000 to 40,000 BPD. It also improves the efficiency from 82 to 93% in H-4 and from 79 to 89% in H-5. The NOx emissions are calculated in less than 0.04 lb/MMBtu. In 2009 ConocoPhillips award FIS with the execution of the project.

- FIS carried out a Crude Heater Capacity Improvement project for HPCL Mumbai, India. HPCL wanted to increase the heater capacity by 15% with a thermal efficiency of 90%. FIS proposed addition of a small convection section on top of the existing heater convection section and addition of burners to the heater. The convection section had a coil for vacuum heater as well and the capacity of vacuum heater was also increased by 15%. The study was carried out in 2 weeks and the detail engineering was carried out in 8 weeks. The revamp work was completed on 2010 and the heaters have been put back into service. FIS carried out design of Pressure Parts, Tube Supports, Structural Analysis, Foundation Load Check and modifications on Process Piping, Burner Piping (including flexibility analysis) and APH ducting. FIS provided complete site supervision during the erection work.