Report

Share

Download to read offline

Recommended

More Related Content

What's hot

What's hot (20)

Power Plant Simulator, Unloading and shutting the Turbogenerator

Power Plant Simulator, Unloading and shutting the Turbogenerator

Thermal Power Plant Simulator, Cold, warm and Hot rolling of Steam Turbine

Thermal Power Plant Simulator, Cold, warm and Hot rolling of Steam Turbine

EB-321DFS API607 Fire Safe Certified Screw Ends Ball Valve

EB-321DFS API607 Fire Safe Certified Screw Ends Ball Valve

Thermal Power Plant Simulator Hands-on Malfunctions

Thermal Power Plant Simulator Hands-on Malfunctions

Similar to Biscuit Cooler 2010-Layout1 (7)

280 Series One & Two Stage Turbines/Multi-Stage Vertical In-Line Boiler Feed ...

280 Series One & Two Stage Turbines/Multi-Stage Vertical In-Line Boiler Feed ...Callaghan Pump and Controls, Inc.

Philippe Anglaret the VP Business Development for Alstom Nuclear (Atoms for t...

Philippe Anglaret the VP Business Development for Alstom Nuclear (Atoms for t...Société Française d'Energie Nucléaire

Similar to Biscuit Cooler 2010-Layout1 (7) (20)

Furnace Improvements patented - Split Flow technology

Furnace Improvements patented - Split Flow technology

280 Series One & Two Stage Turbines/Multi-Stage Vertical In-Line Boiler Feed ...

280 Series One & Two Stage Turbines/Multi-Stage Vertical In-Line Boiler Feed ...

Philippe Anglaret the VP Business Development for Alstom Nuclear (Atoms for t...

Philippe Anglaret the VP Business Development for Alstom Nuclear (Atoms for t...

Energy study Fan Coil Units versus active chilled beams

Energy study Fan Coil Units versus active chilled beams

Biscuit Cooler 2010-Layout1 (7)

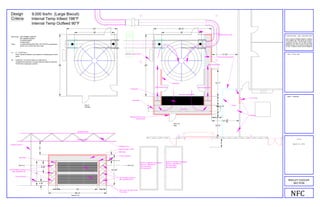

- 1. Product Outfeed Existing Girt 26'-4" 6' 2'-8" 13'-10" 1'-9" Existing Roof Existing Column Each Evap: 216" FINNED LENGTH 66" FINNED HEIGHT 12 ROWS DEEP 4 FINS/ INCH Total: 115,000 CFM @ 583 FPM 1.25" STATIC at spiral face 85 TR 15°F ΔT 30° SST 45°F AIR Design Criteria 9,000 lbs/hr. (Large Biscuit) Internal Temp Infeed 198°F Internal Temp Outfeed 90°F Product Infeed Existing Truss 4' 10" 216" long x 66" high Evaps 4 Fins/Inch 3'Ø fans @7.5 hp each 460 volts/3Ø 60 HZ 3'Ø fans @7.5 hp each 460 volts/3Ø 60 HZ 5'-6" 18' (1) 6 - 7.5 HP Fans Note: Electrical Starters to be placed in existing spiral control panel. (2) Install two 110 volt #14 wires in conduit fan to Condenser/Compressor to liquid solenoid valves in spiral for R-507 freon evaporator controls. Blank off with 4" IMP 11' Plan A-APlan A-A Plan A-A New 3' 28' 18' Plan A Existing 23' 28' 18' 26'-4" Evaporator Existing Access Door Relocated Door From Existing Wall 583 CFM New Access Door New Access Door 4' 4' 12'-1" New Access Door Existing Control Panel 4'-6" 10'-5" 11'-9" Remove Existing Wall 12'-37 8" Remove Existing Wall 60 HP Condenser/ Compressor 3225 lbs., 460/3/60 hz 122 Amps MCA 150 Amps MOP 60 HP Condenser/ Compressor 3225 lbs., 460/3/60 hz 122 Amps MCA 150 Amps MOP Demo Fill in Wall Bollards New Wall A Section A-A IMP Wall Section A-A New Wall IMP Wall NFC BISCUIT COOLER SECTION