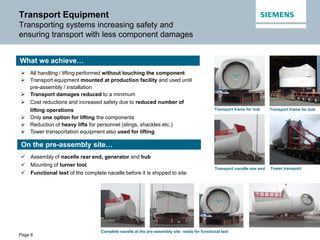

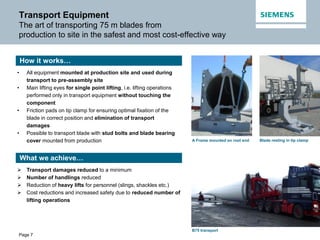

The document outlines optimized concepts for loading and installing offshore wind turbines, focusing on transport and installation equipment to enhance safety and efficiency. It includes details on transport systems, logistics for load-out, and techniques to secure components while minimizing crane time and manual handling. The presentation highlights innovations in equipment design that reduce costs and improve working conditions for technicians during turbine assembly and installation.