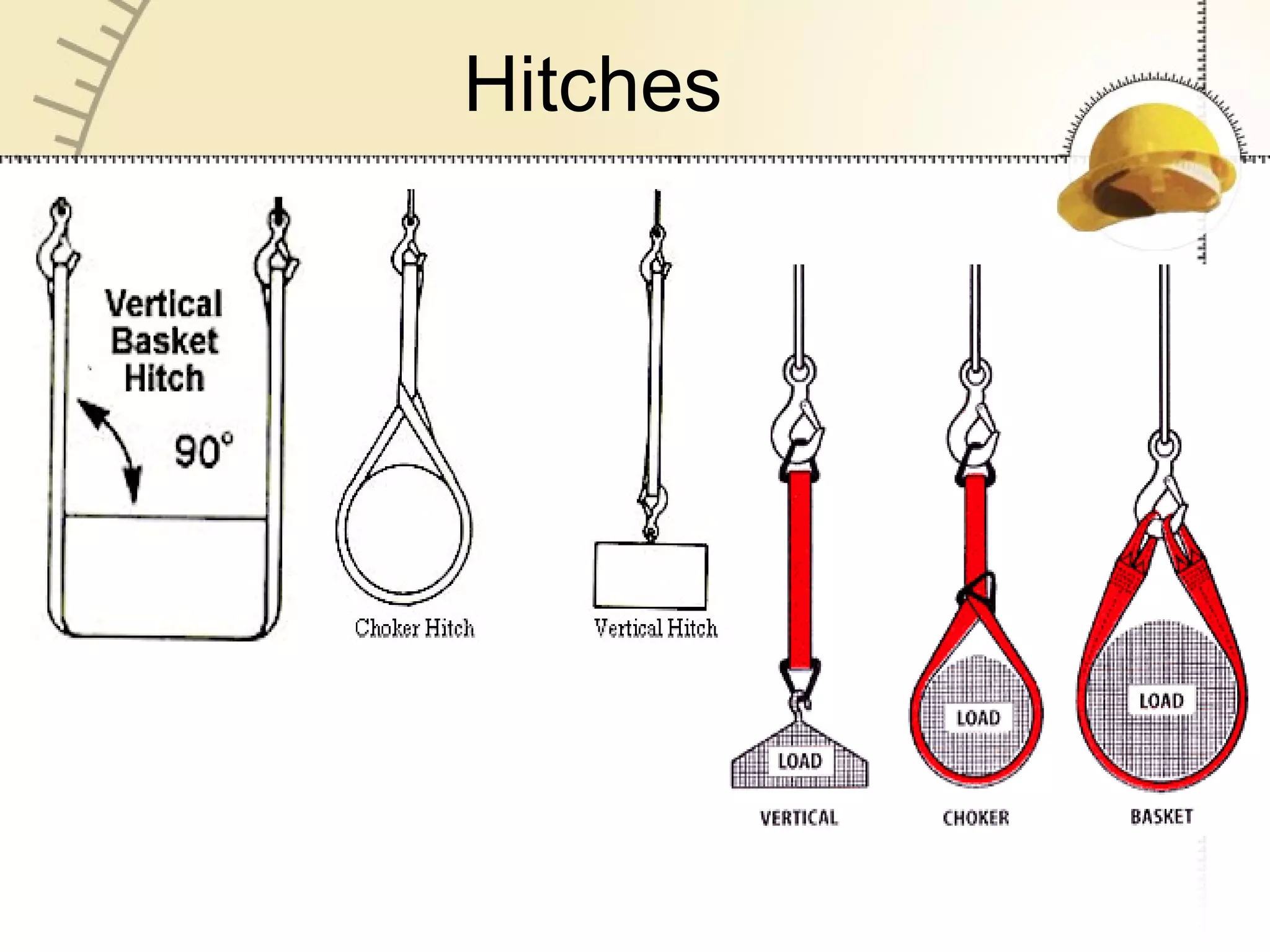

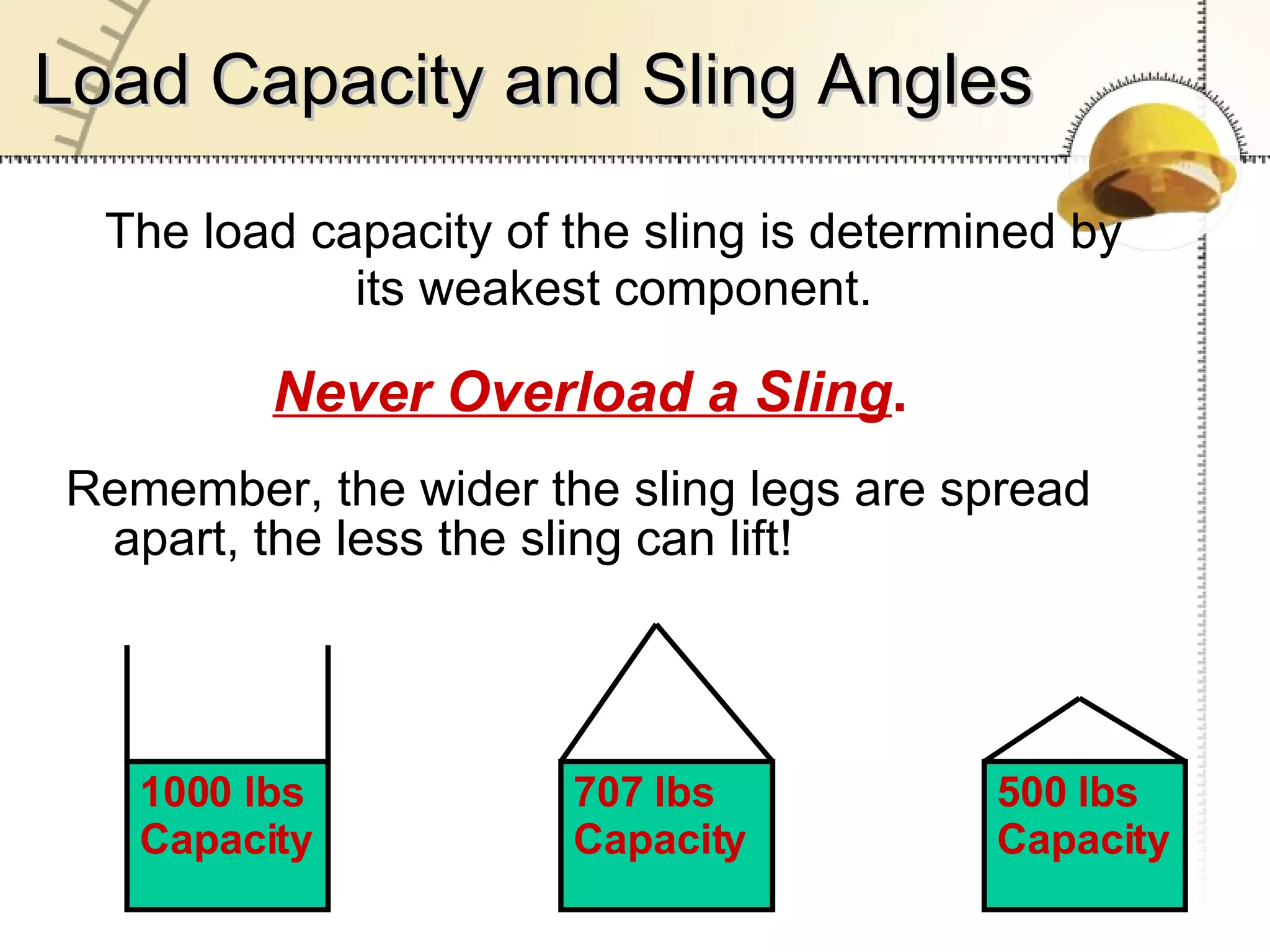

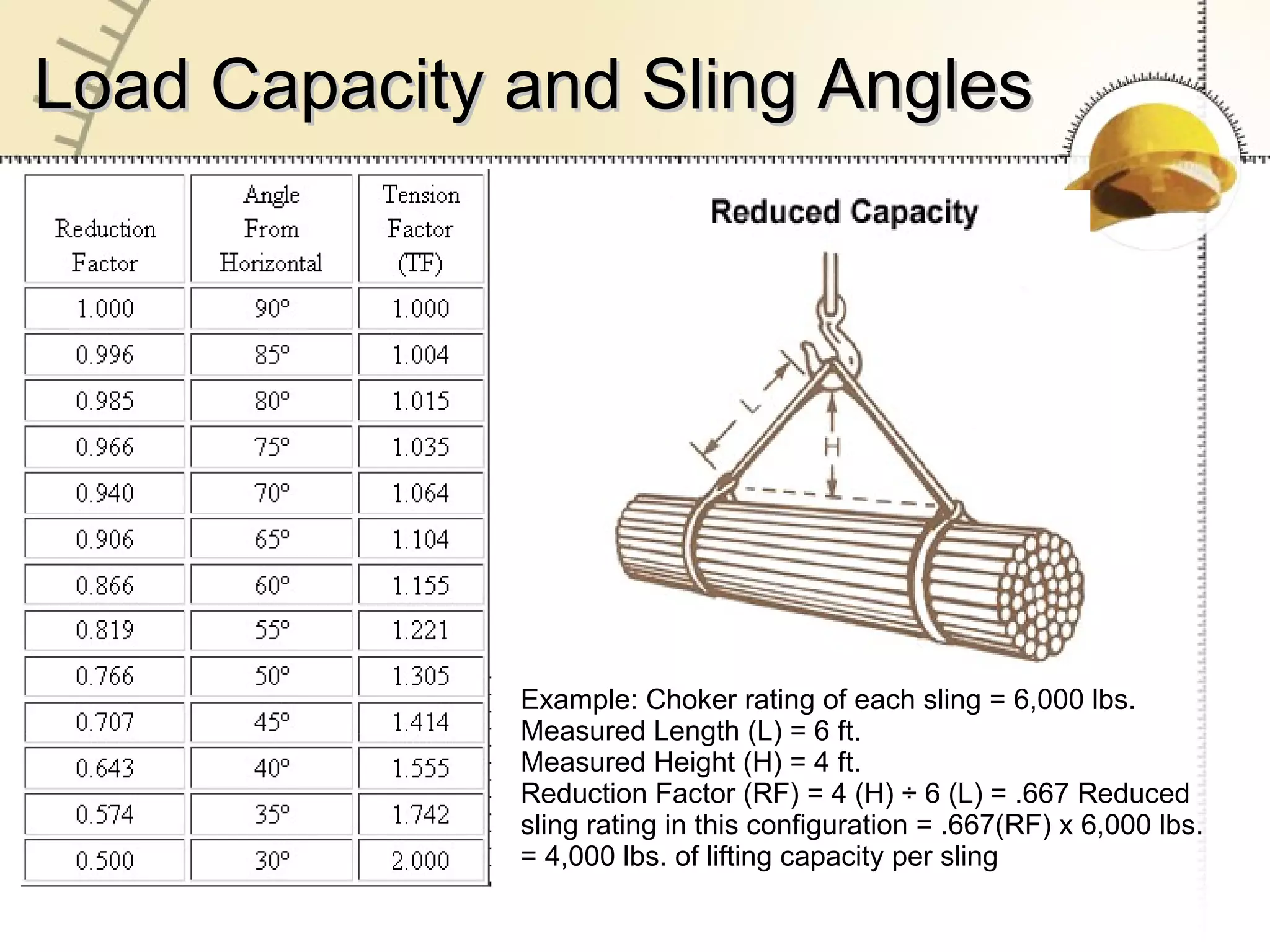

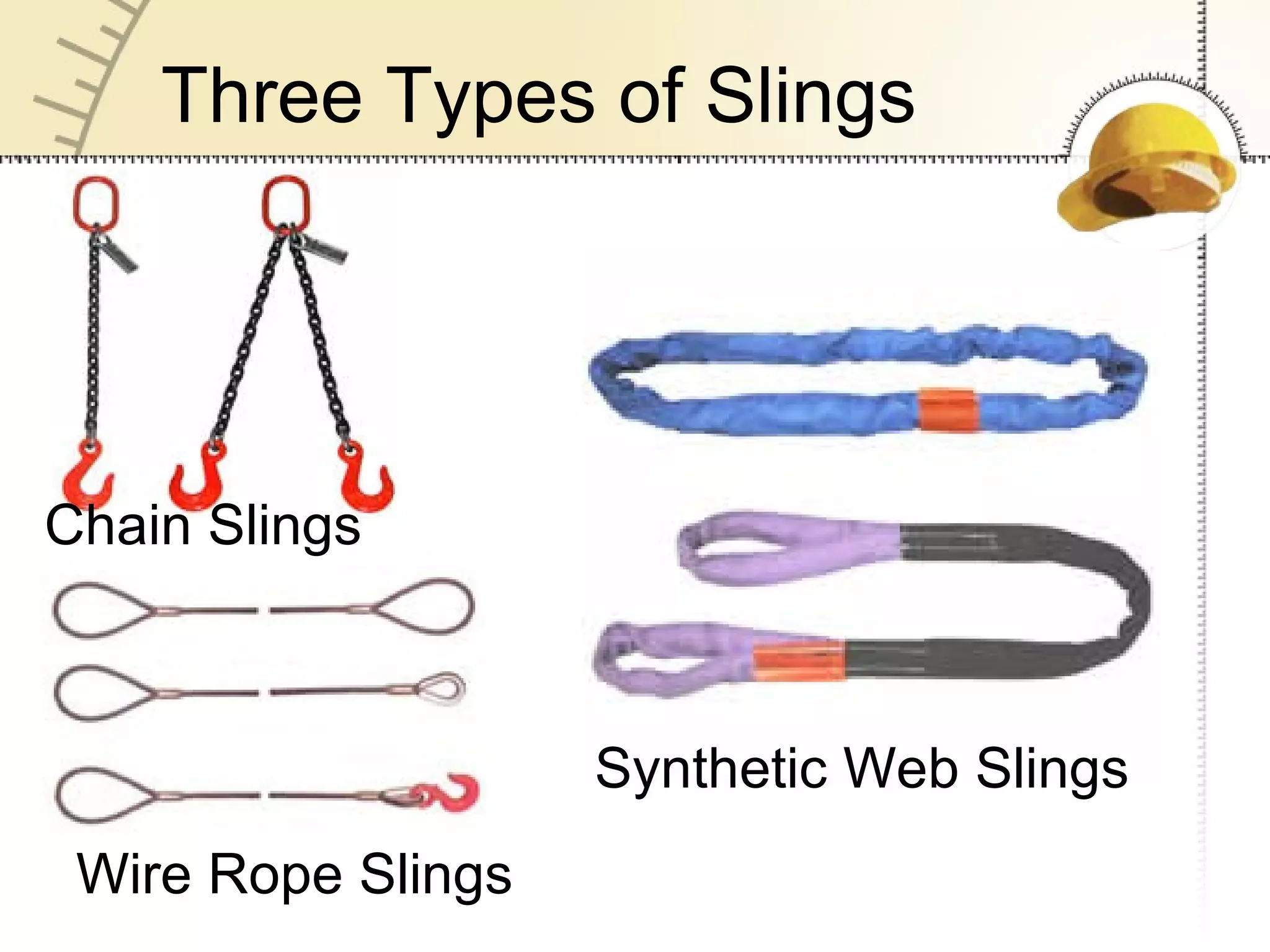

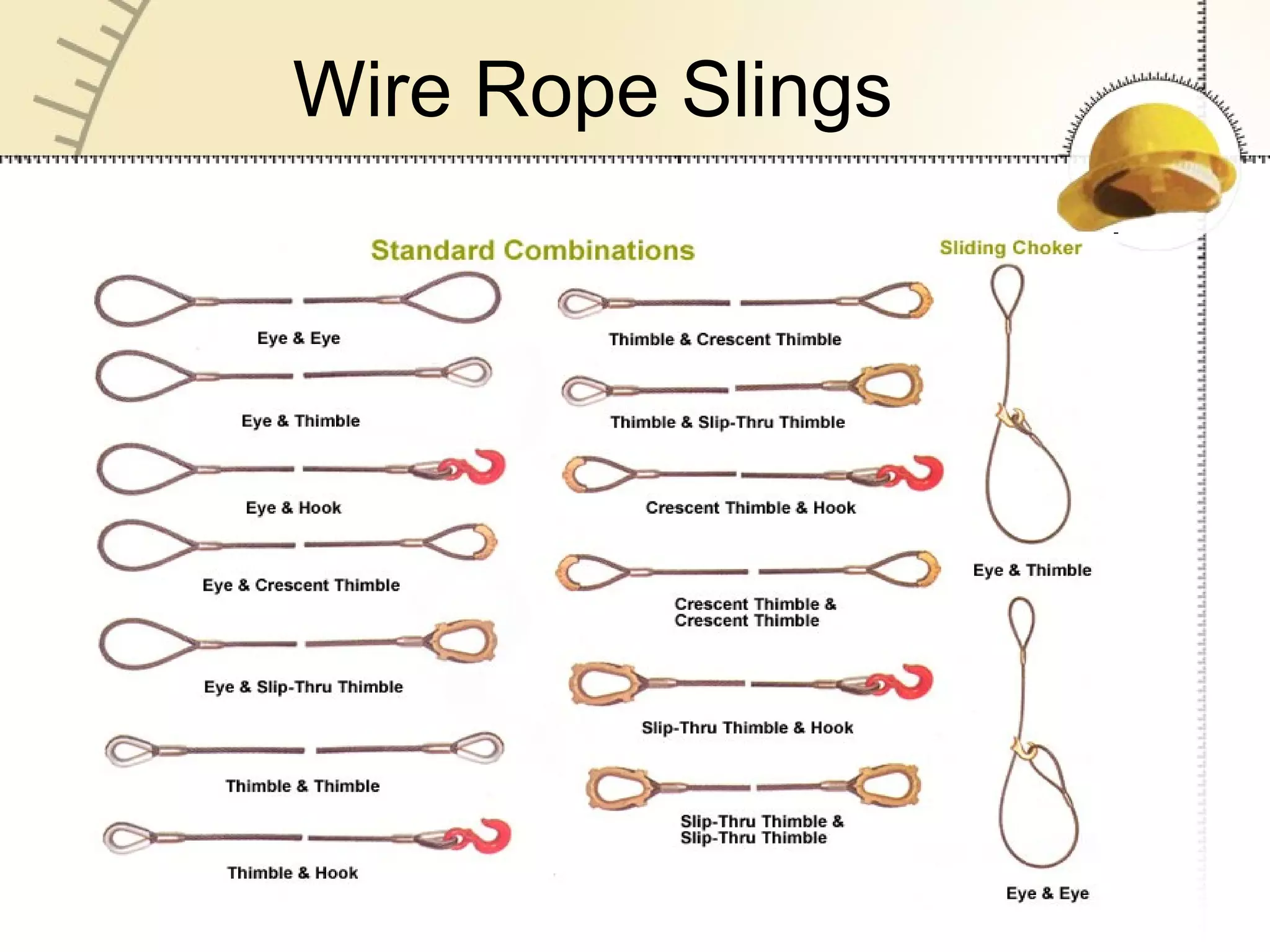

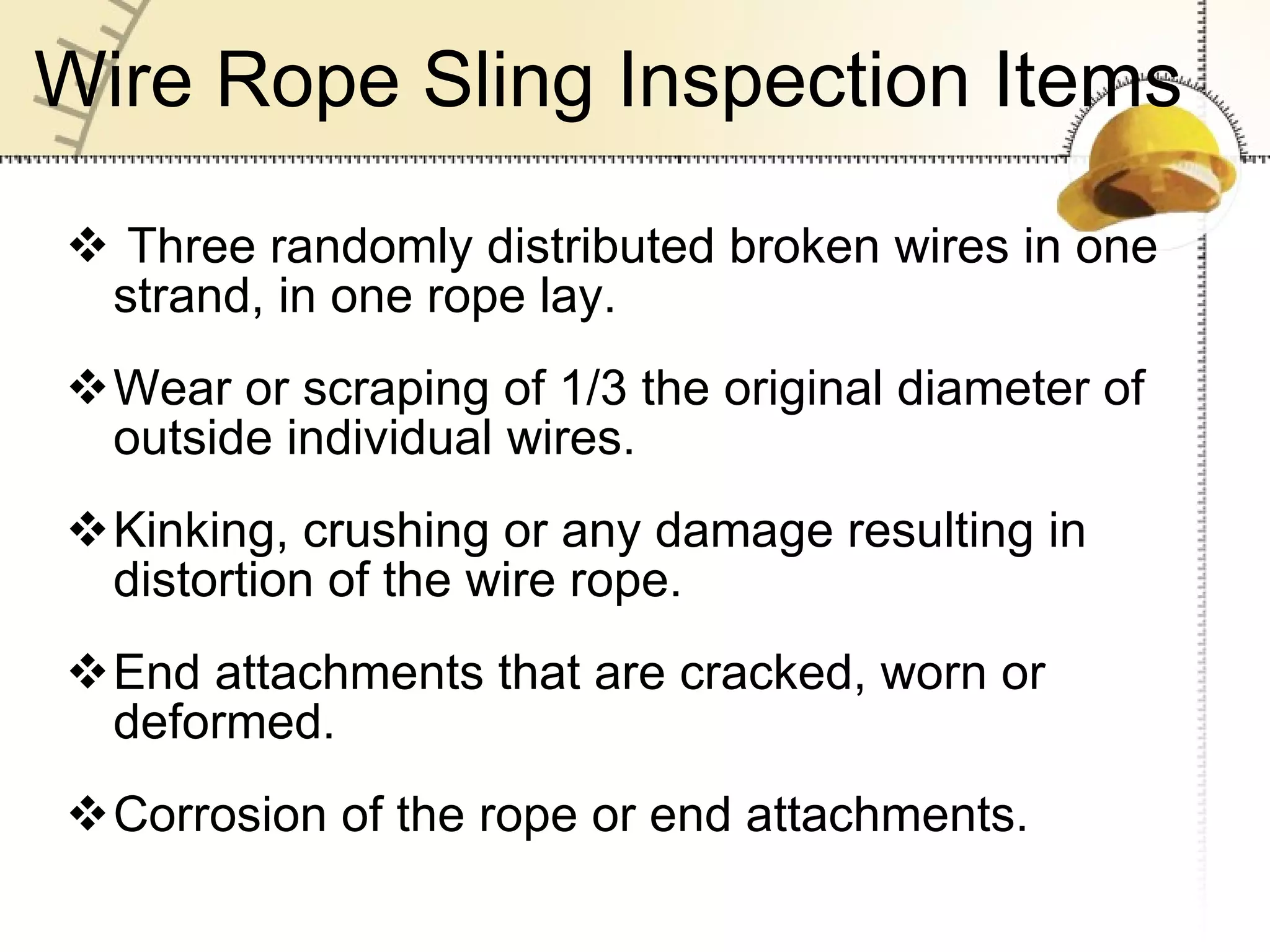

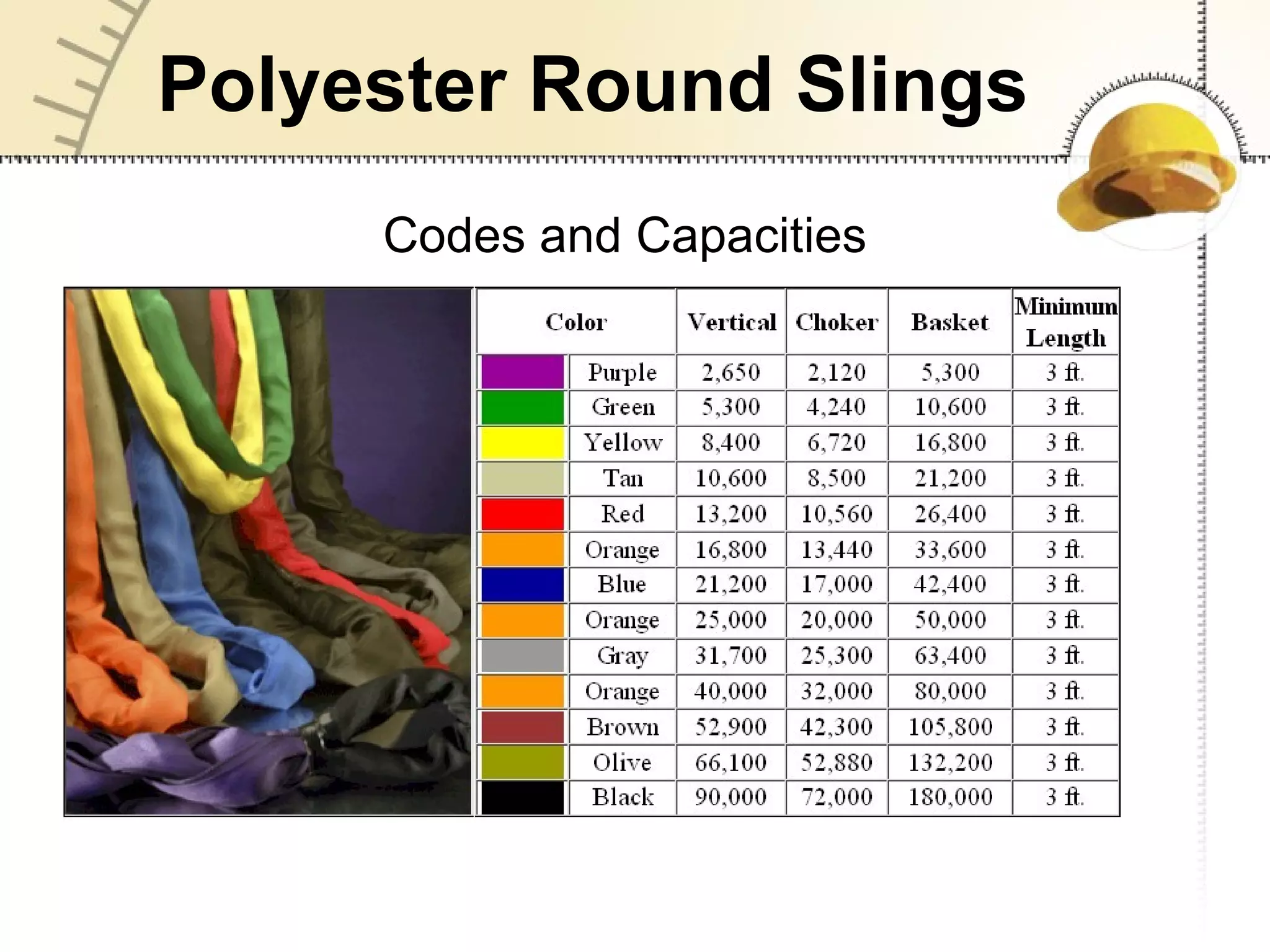

This presentation covers OSHA regulations and safe practices for using slings when lifting loads. Key points include inspecting slings prior to each use and at least annually, understanding how sling angles affect load capacity, identifying signs of wear that require sling replacement, and following safe handling practices such as avoiding shock loading or pinching slings. Common types of slings are discussed including wire rope, chain, and synthetic web slings along with their inspection criteria and safe operation.