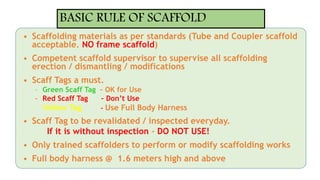

1. Scaffolding materials must meet standards, and a competent supervisor must oversee all scaffolding work including erection, dismantling, and modifications.

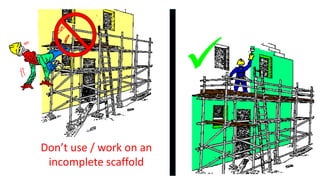

2. Scaffold tags must be used to indicate if a scaffold is safe to use, unsafe to use, or requires a full body harness. Tags must be inspected daily.

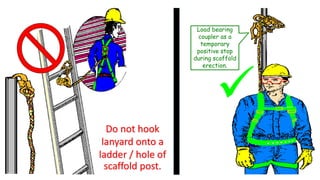

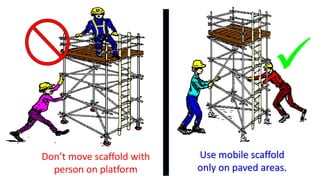

3. Only trained scaffolders can perform or modify scaffolding work. A full body harness is required for work over 1.6 meters high.