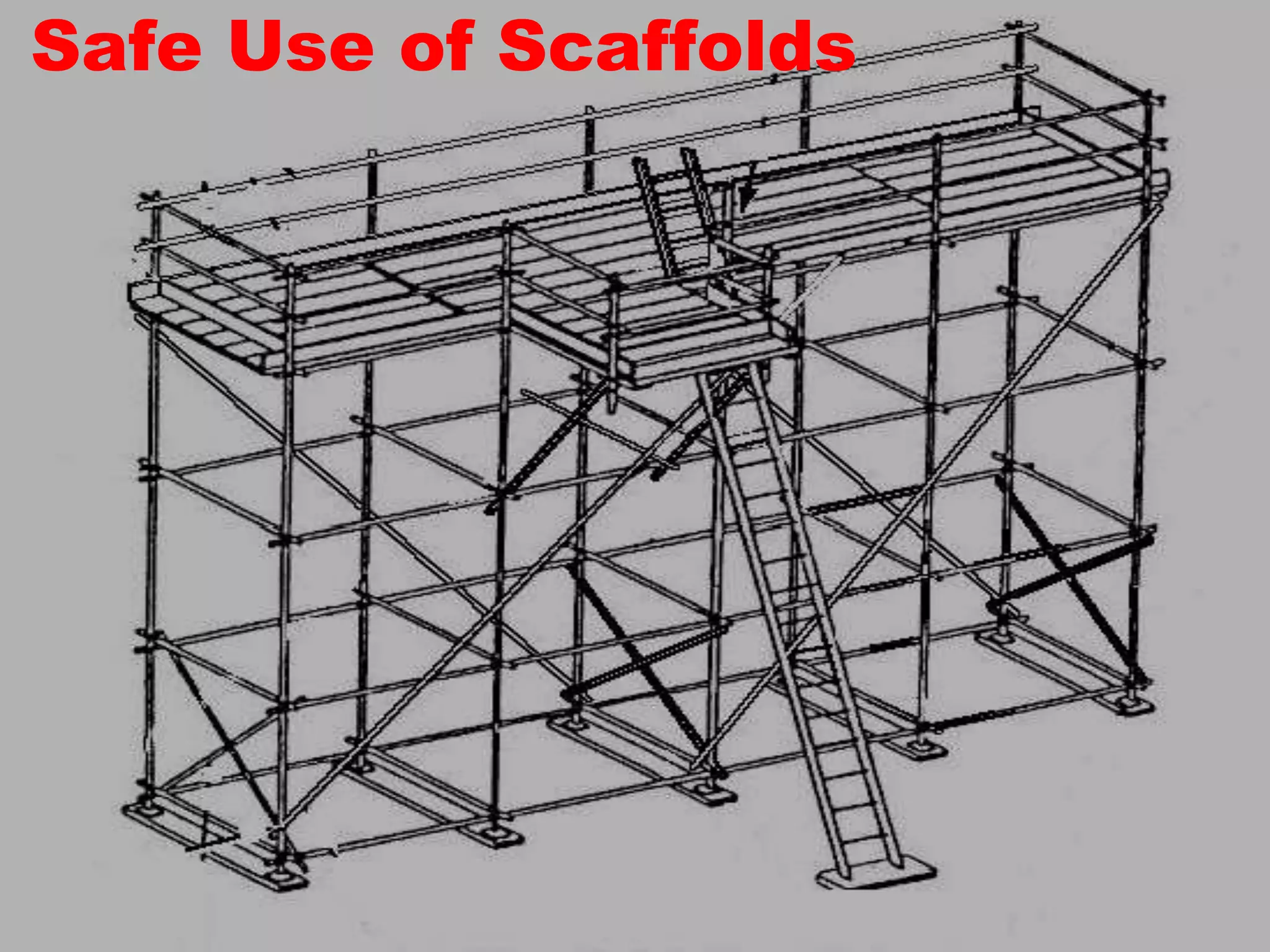

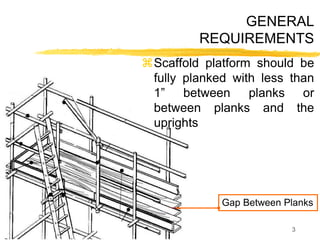

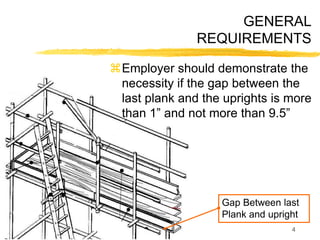

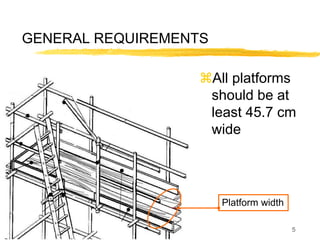

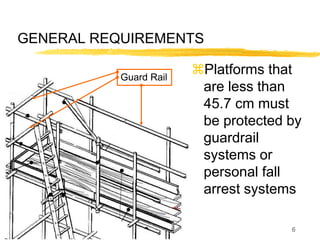

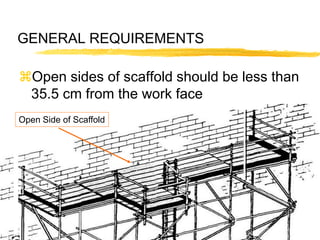

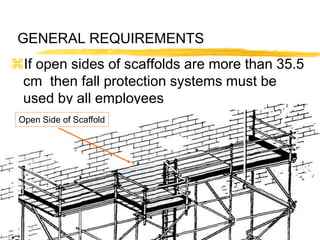

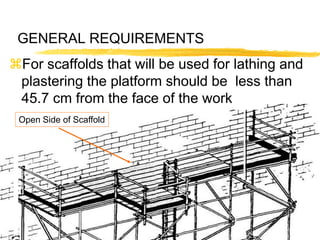

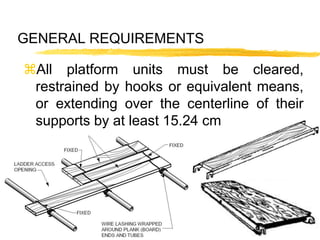

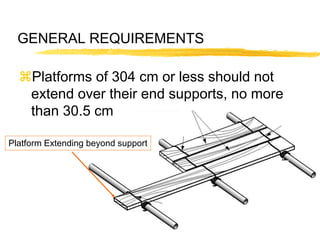

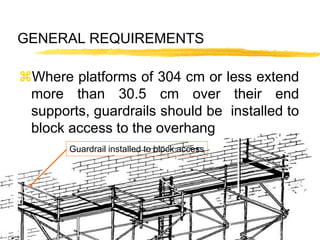

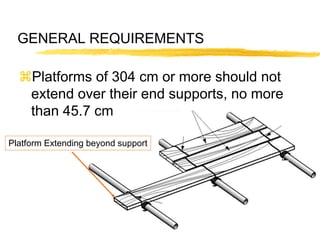

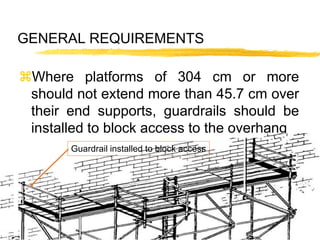

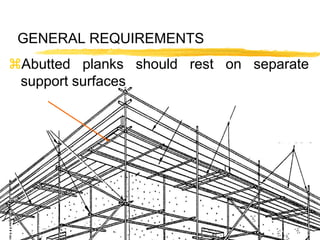

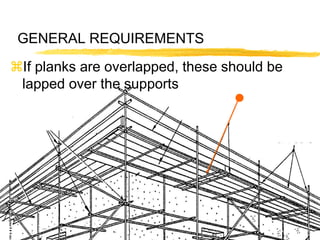

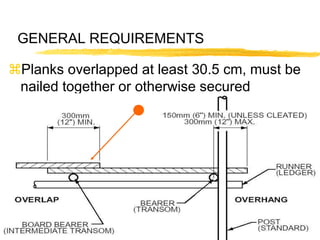

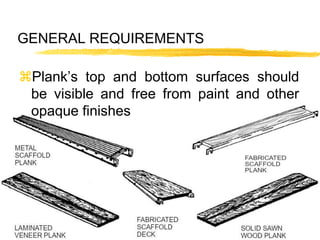

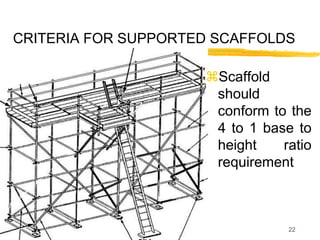

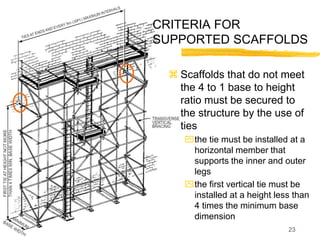

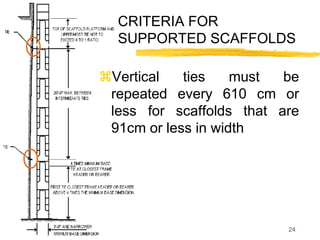

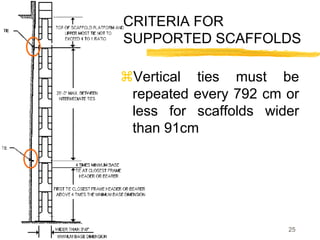

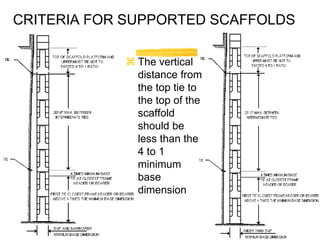

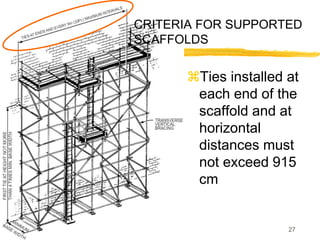

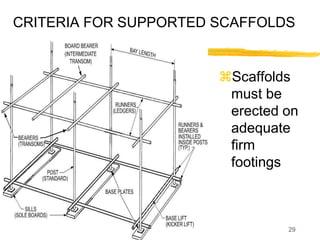

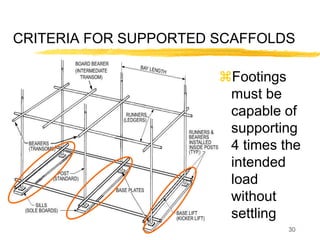

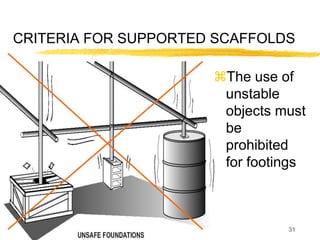

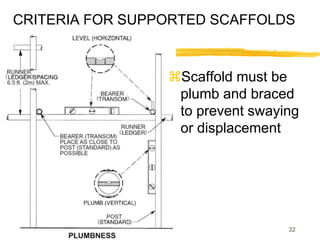

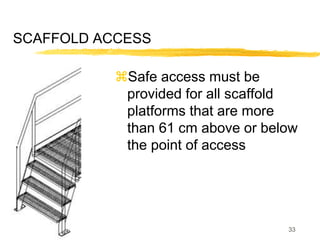

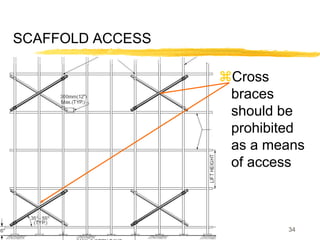

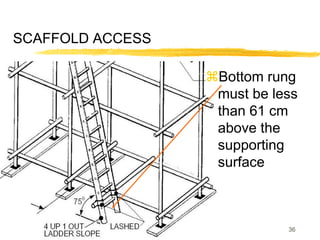

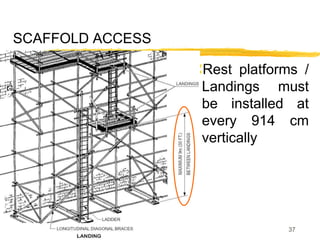

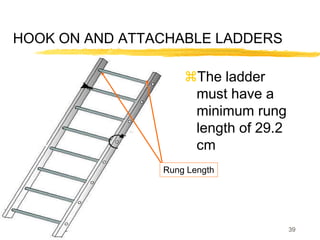

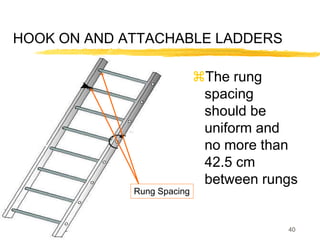

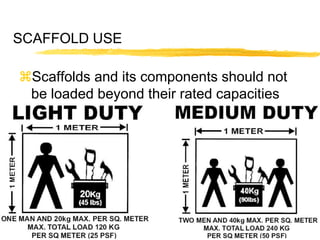

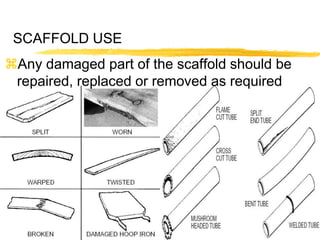

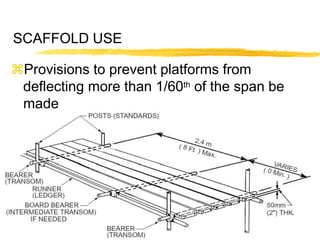

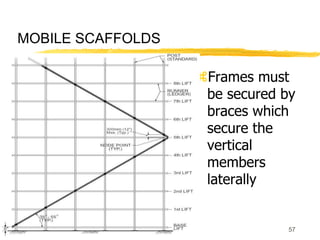

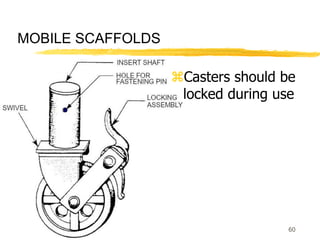

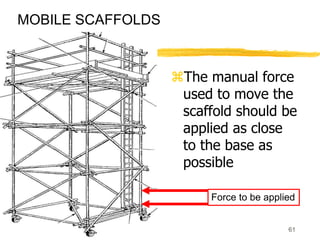

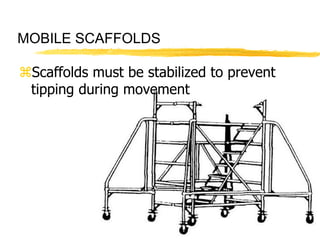

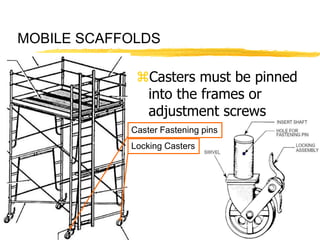

The document outlines general safety requirements for using scaffolds, including requirements for scaffold construction, platforms, guardrails, access, bracing, stability, inspection and use. Key requirements include platforms fully planked with less than 1 inch gaps, guardrails for platforms under 45.7 cm wide, fall protection when open sides over 35.5 cm wide, and inspection by a competent person as required. Mobile scaffolds must be stabilized, braced and have locked casters during use.