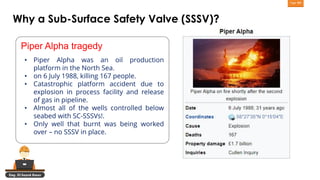

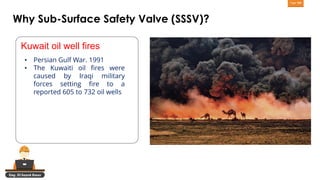

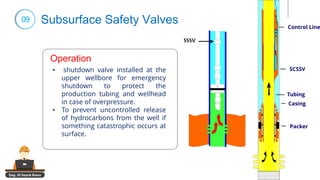

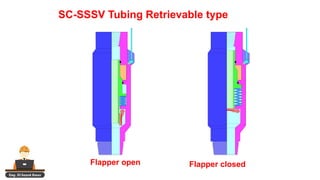

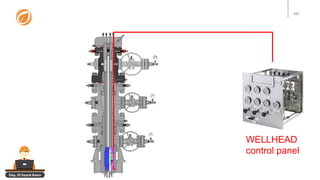

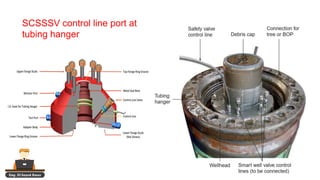

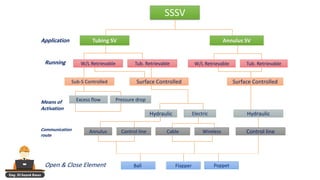

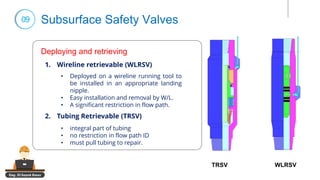

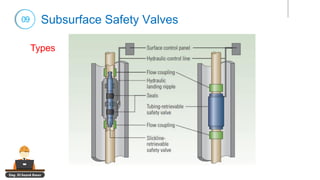

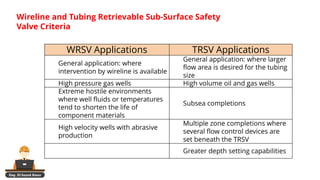

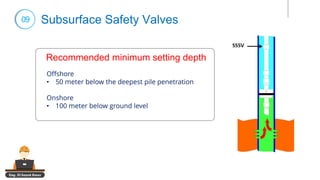

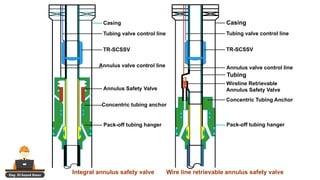

The document discusses subsurface safety valves (SSSVs), which are installed downhole to allow emergency shutdown and prevent uncontrolled hydrocarbon release from a well. SSSVs were not in place during the Piper Alpha platform disaster, exacerbating the accident. SSSVs come in two types: wireline-retrievable, which can be easily installed/removed via wireline but restrict flow; and tubing-retrievable, which are integral to the tubing and avoid flow restrictions but require pulling tubing for repair. Recommended minimum setting depths are 50m below the deepest pile for offshore and 100m below ground level for onshore. [/SUMMARY]