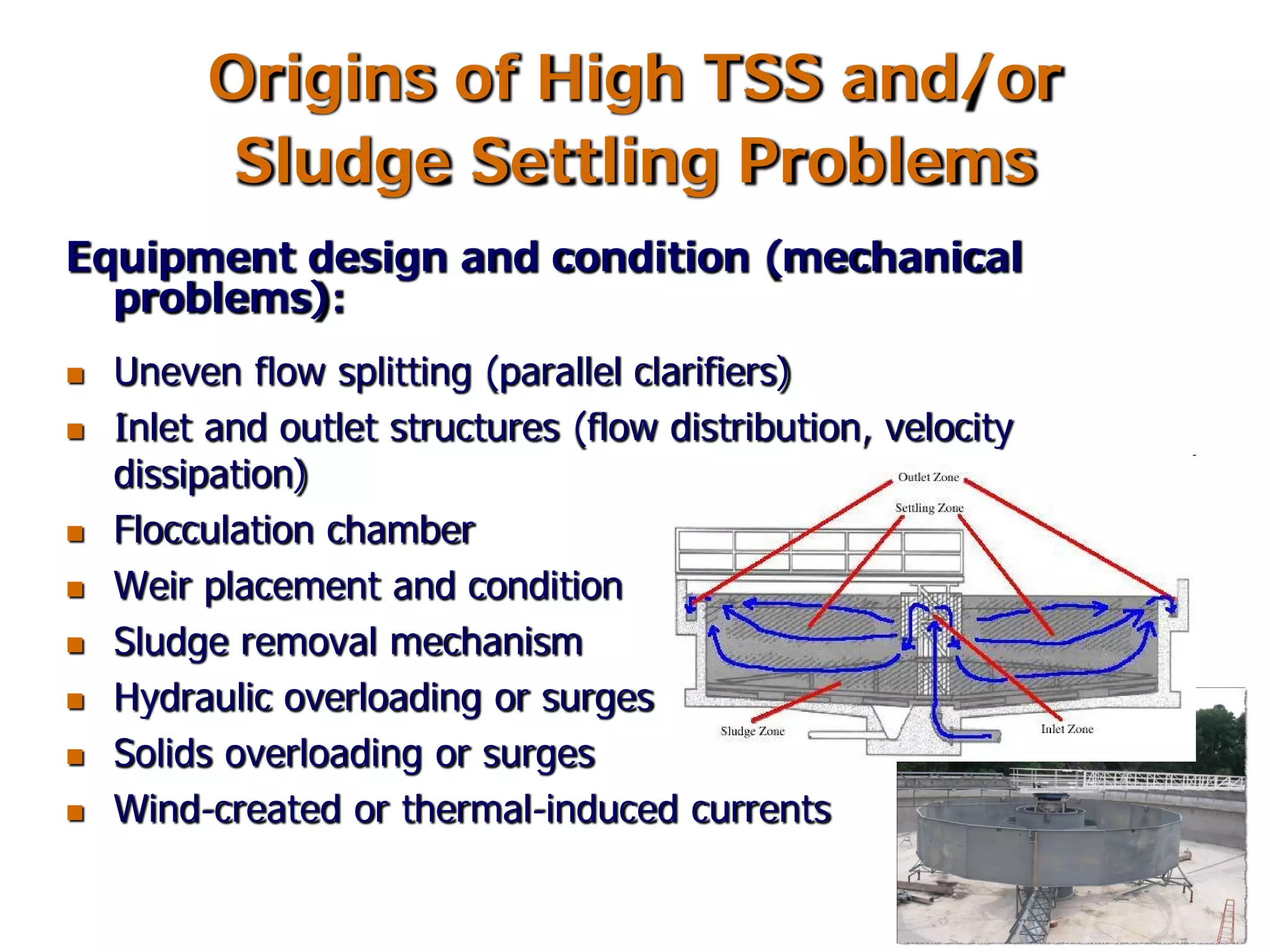

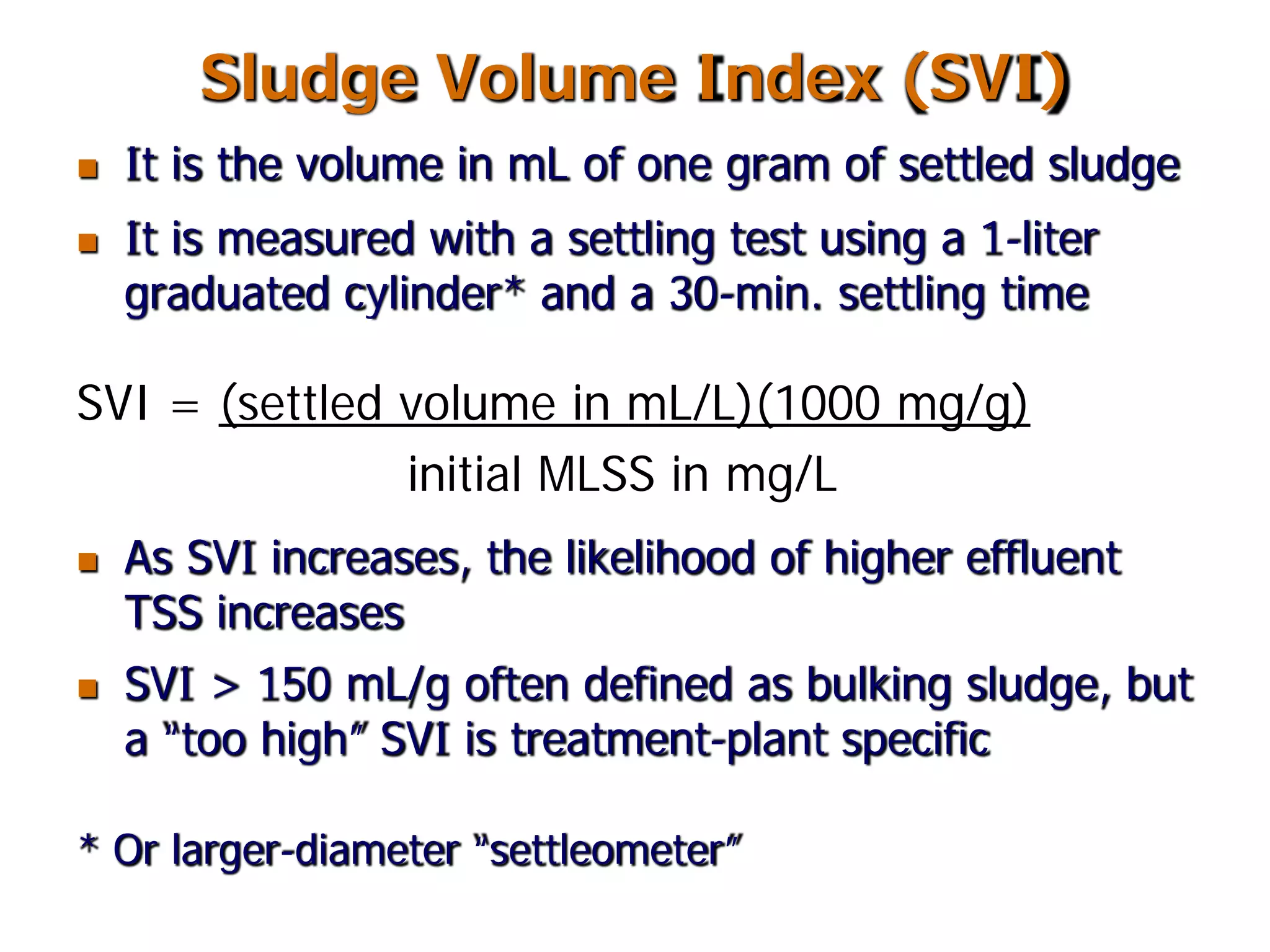

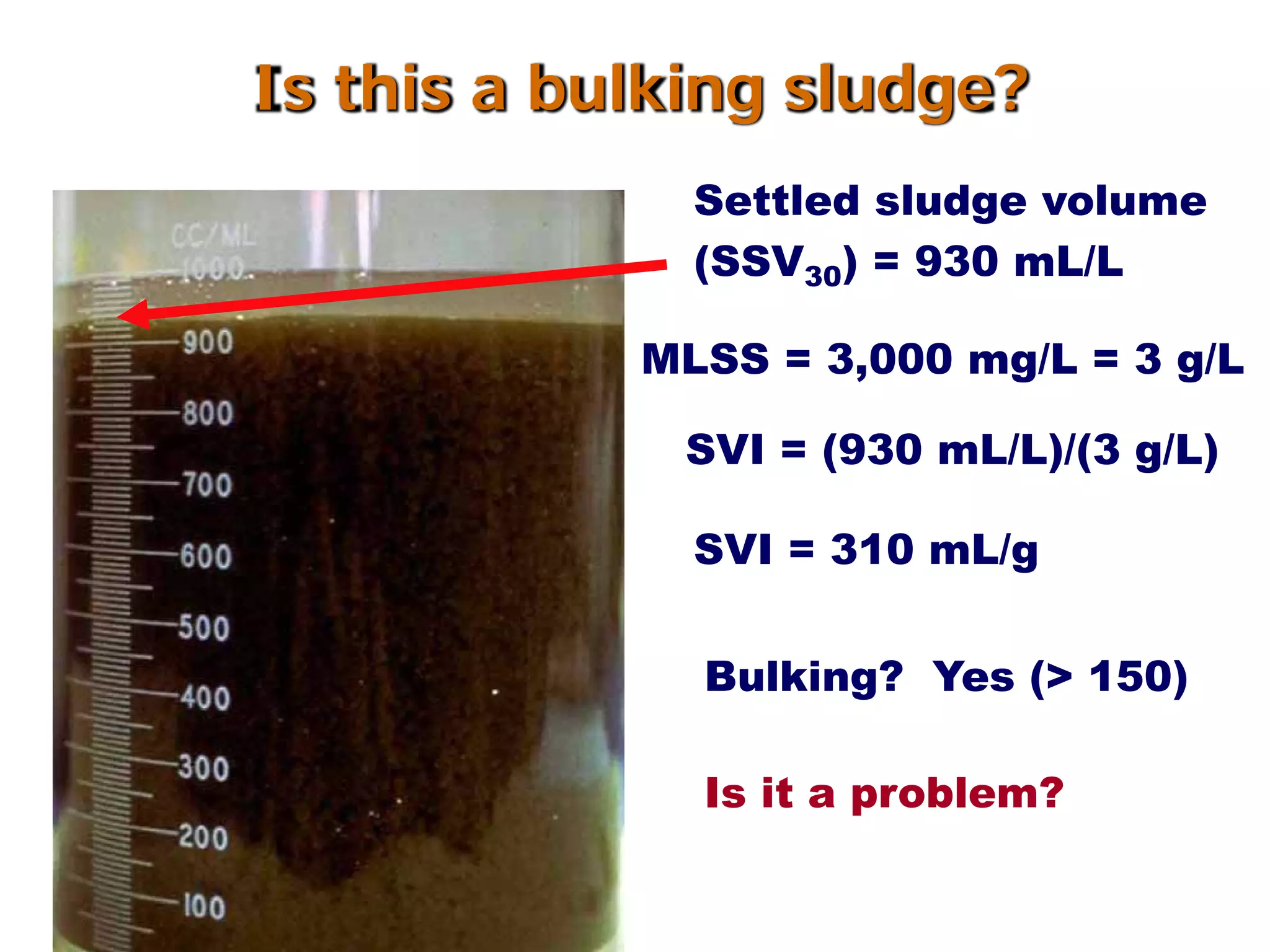

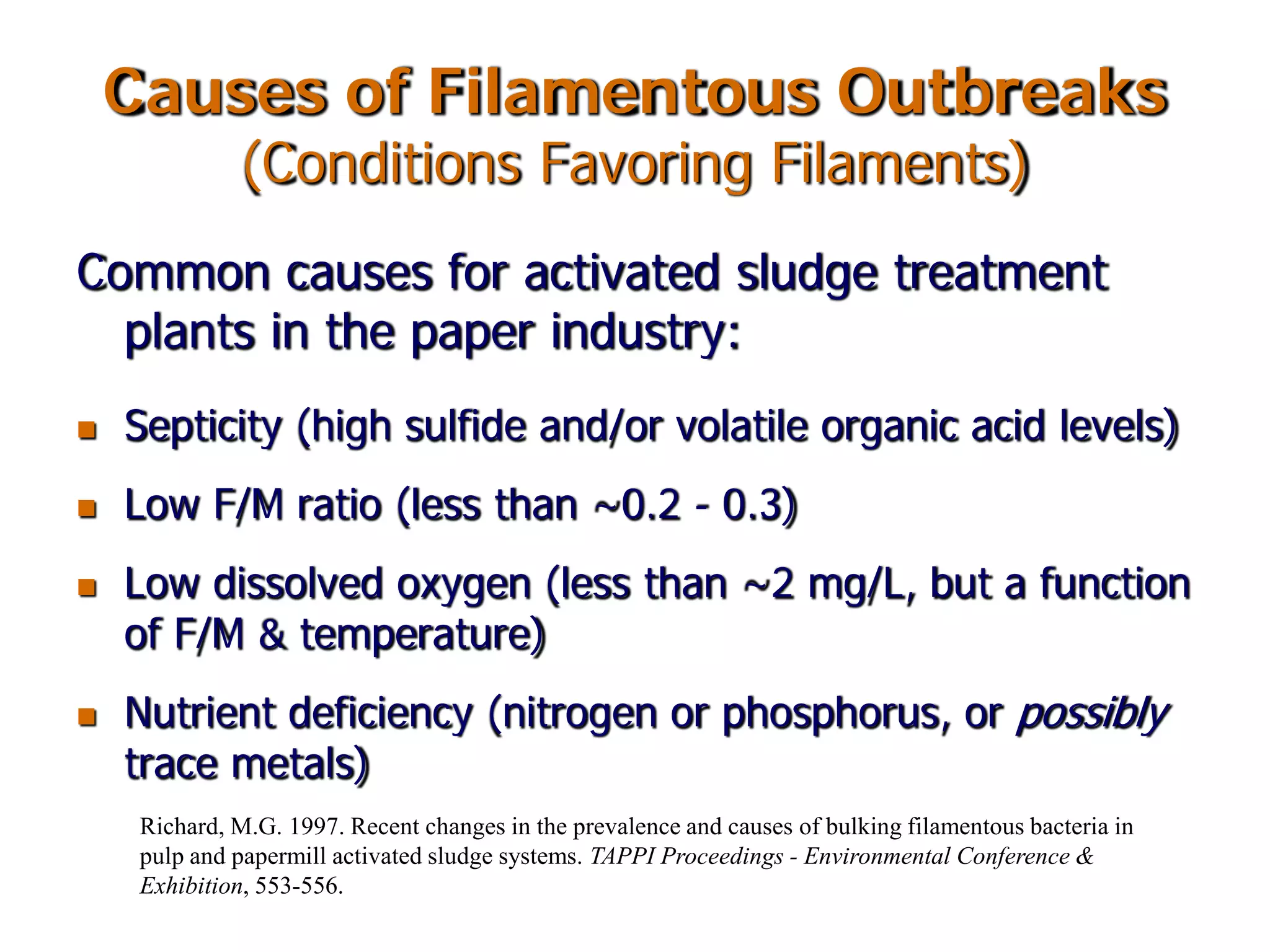

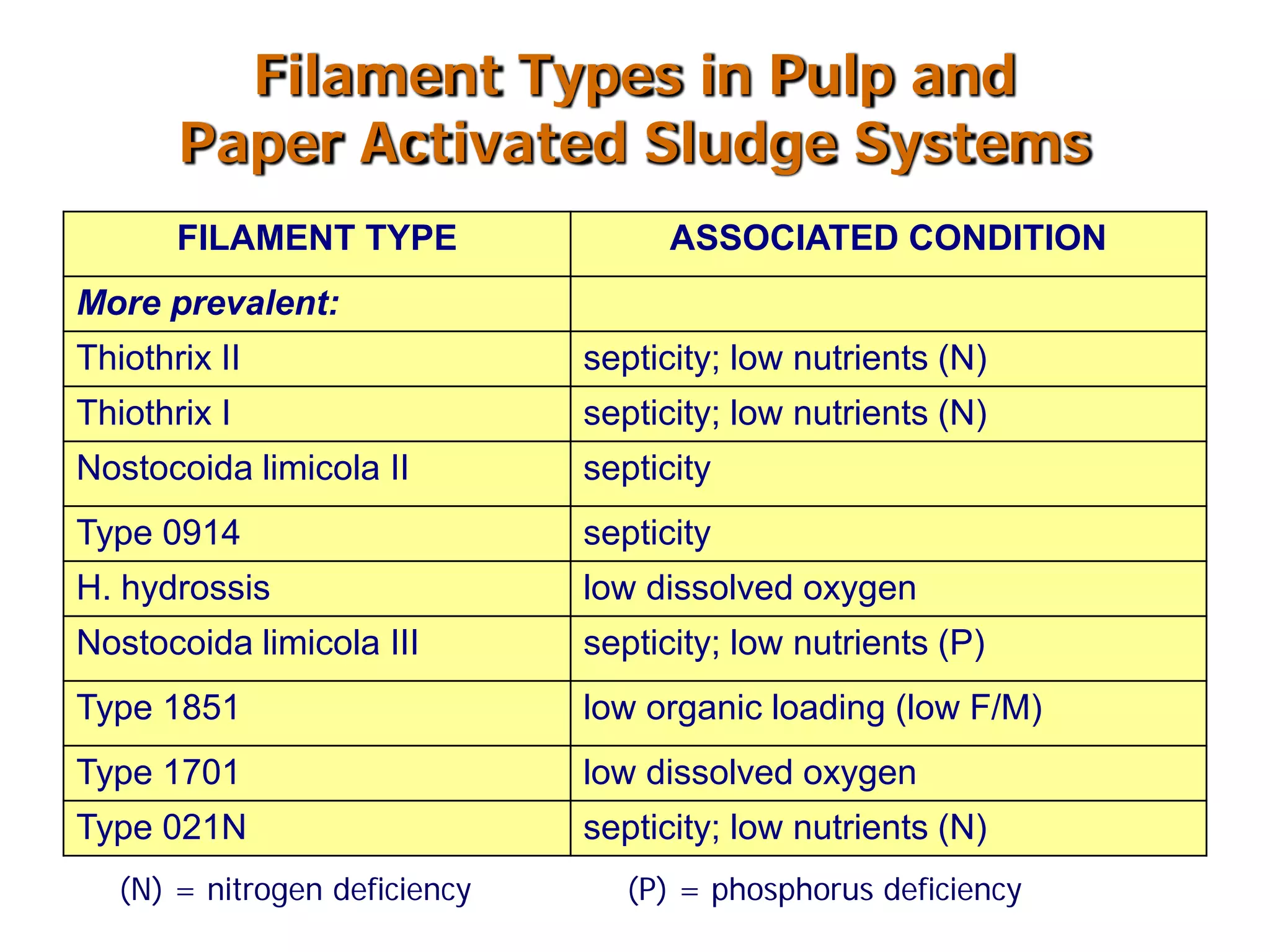

This document discusses sludge bulking, which occurs when sludge has poor settling and compaction characteristics in secondary treatment. Sludge bulking can be caused by mechanical issues, solids characteristics like filaments, or nutrient deficiencies. Filamentous bulking is the most common type and is caused by high levels of filamentous bacteria that interfere with sludge settling. Remedies include adding chemicals to improve settling or identifying and addressing the root causes, such as low dissolved oxygen, nutrients, or organic loading. Selectors may help by providing initial high organic loading to control filament growth.