Winch Test Certs

- 1. Certificate Of Test & Thorough Examination ASME B30.7 Description AIR WINCH INGERSOLL RAND Serial Number A014716 Date Inspected: 12 May 2015Certificate No:TSI/KMN/TR/0515/018 PORT FWD BOP DECK KEY MANHATTAN 12 May 20152841 KG Is this the first examination after installation or assembly at a new site/location? Yes No If the answer to the above question is YES, has it been installed correctly? Yes No After the occurrence of exceptional circumstances? Yes No Was the examination carried out within an interval of 6 months? Yes No Yes NoWas the examination carried out within an interval of 12 months? In accordance with an examination scheme Yes No Identification of any part found to have a defect which is or could become a danger to persons and a description of the defect. (If none state NONE) NONE Particulars of any test carried out as part of the examination : (If none state NONE) LOAD TESTED WINCH TO 25% OVER SWL PRE & POST NDT/ MPI WAS CARRIED OUT NO INDICATION FOUND Is this equipment safe to use? Yes No Colour code: GREEN Client Address: P.O.Box # 51852, Plot # MB-34, Phase 2, Hamriyah Free Zone, Sharjah, U.A.E Test DateQty 1 Proof Load Platform/Rig: Item Location Manufacturer Examined in accordance with Name of person who carried out the inspection Position & Qualifications of person who carried out the test & examination Signed: DAVID BARRETT IRATA LEV I LEEA 1 & 2 Next Exam Due: 11/05/2016 SWL 2273 KG

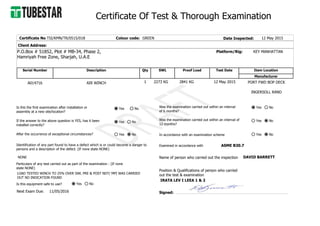

- 2. Certificate Of Test & Thorough Examination ASME B30.7 Description AIR WINCH INGERSOLL RAND Serial Number A027058 Date Inspected: 12 May 2015Certificate No:TSI/KMN/TR/0515/019 STBD AFT BOP DECK KEY MANHATTAN 12 May 20152841 KG Is this the first examination after installation or assembly at a new site/location? Yes No If the answer to the above question is YES, has it been installed correctly? Yes No After the occurrence of exceptional circumstances? Yes No Was the examination carried out within an interval of 6 months? Yes No Yes NoWas the examination carried out within an interval of 12 months? In accordance with an examination scheme Yes No Identification of any part found to have a defect which is or could become a danger to persons and a description of the defect. (If none state NONE) NONE Particulars of any test carried out as part of the examination : (If none state NONE) LOAD TESTED WINCH TO 25% OVER SWL PRE & POST NDT/ MPI WAS CARRIED OUT NO INDICATION FOUND Is this equipment safe to use? Yes No Colour code: GREEN Client Address: P.O.Box # 51852, Plot # MB-34, Phase 2, Hamriyah Free Zone, Sharjah, U.A.E Test DateQty 1 Proof Load Platform/Rig: Item Location Manufacturer Examined in accordance with Name of person who carried out the inspection Position & Qualifications of person who carried out the test & examination Signed: DAVID BARRETT IRATA LEV I LEEA 1 & 2 Next Exam Due: 11/05/2016 SWL 2273 KG

- 3. Certificate Of Test & Thorough Examination ASME B30.7 Description AIR WINCH INGERSOLL RAND Serial Number A027461 Date Inspected: 12 May 2015Certificate No:TSI/KMN/TR/0515/020 PORT FWD DRILLFLOOR KEY MANHATTAN 12 May 20152841 KG Is this the first examination after installation or assembly at a new site/location? Yes No If the answer to the above question is YES, has it been installed correctly? Yes No After the occurrence of exceptional circumstances? Yes No Was the examination carried out within an interval of 6 months? Yes No Yes NoWas the examination carried out within an interval of 12 months? In accordance with an examination scheme Yes No Identification of any part found to have a defect which is or could become a danger to persons and a description of the defect. (If none state NONE) NONE Particulars of any test carried out as part of the examination : (If none state NONE) LOAD TESTED WINCH TO 25% OVER SWL PRE & POST NDT/ MPI WAS CARRIED OUT NO INDICATION FOUND Is this equipment safe to use? Yes No Colour code: GREEN Client Address: P.O.Box # 51852, Plot # MB-34, Phase 2, Hamriyah Free Zone, Sharjah, U.A.E Test DateQty 1 Proof Load Platform/Rig: Item Location Manufacturer Examined in accordance with Name of person who carried out the inspection Position & Qualifications of person who carried out the test & examination Signed: DAVID BARRETT IRATA LEV I LEEA 1 & 2 Next Exam Due: 11/05/2016 SWL 2273 KG

- 4. Certificate Of Test & Thorough Examination ASME B30.7 Description AIR WINCH INGERSOLL RAND Serial Number A021729 Date Inspected: 12 May 2015Certificate No:TSI/KMN/TR/0515/021 STBD FWD DRILLFLOOR KEY MANHATTAN 12 May 20156250 KG Is this the first examination after installation or assembly at a new site/location? Yes No If the answer to the above question is YES, has it been installed correctly? Yes No After the occurrence of exceptional circumstances? Yes No Was the examination carried out within an interval of 6 months? Yes No Yes NoWas the examination carried out within an interval of 12 months? In accordance with an examination scheme Yes No Identification of any part found to have a defect which is or could become a danger to persons and a description of the defect. (If none state NONE) NONE Particulars of any test carried out as part of the examination : (If none state NONE) LOAD TESTED WINCH TO 25% OVER SWL PRE & POST NDT/ MPI WAS CARRIED OUT NO INDICATION FOUND Is this equipment safe to use? Yes No Colour code: GREEN Client Address: P.O.Box # 51852, Plot # MB-34, Phase 2, Hamriyah Free Zone, Sharjah, U.A.E Test DateQty 1 Proof Load Platform/Rig: Item Location Manufacturer Examined in accordance with Name of person who carried out the inspection Position & Qualifications of person who carried out the test & examination Signed: DAVID BARRETT IRATA LEV I LEEA 1 & 2 Next Exam Due: 11/05/2016 SWL 5000 KG

- 5. Certificate Of Test & Thorough Examination ASME B30.7 Description AIR WINCH (MANRIDER) INGERSOLL RAND Serial Number KG025584 Date Inspected: 12 May 2015Certificate No:TSI/KMN/TR/0515/023 DRILL FLOOR MEZZ LEVEL KEY MANHATTAN 12 May 2015187 KG Is this the first examination after installation or assembly at a new site/location? Yes No If the answer to the above question is YES, has it been installed correctly? Yes No After the occurrence of exceptional circumstances? Yes No Was the examination carried out within an interval of 6 months? Yes No Yes NoWas the examination carried out within an interval of 12 months? In accordance with an examination scheme Yes No Identification of any part found to have a defect which is or could become a danger to persons and a description of the defect. (If none state NONE) NONE Particulars of any test carried out as part of the examination : (If none state NONE) LOAD TESTED WINCH TO 25% OVER SWL PRE & POST NDT/ MPI WAS CARRIED OUT NO INDICATION FOUND Is this equipment safe to use? Yes No Colour code: GREEN Client Address: P.O.Box # 51852, Plot # MB-34, Phase 2, Hamriyah Free Zone, Sharjah, U.A.E Test DateQty 1 Proof Load Platform/Rig: Item Location Manufacturer Examined in accordance with Name of person who carried out the inspection Position & Qualifications of person who carried out the test & examination Signed: DAVID BARRETT IRATA LEV I LEEA 1 & 2 Next Exam Due: 11/05/2016 SWL 150 kg