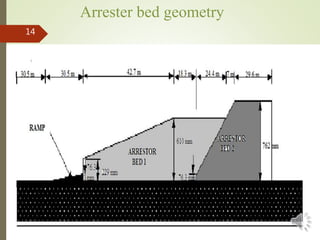

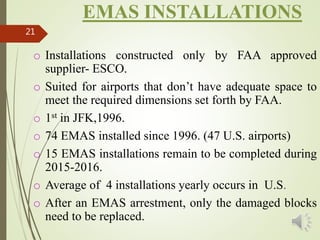

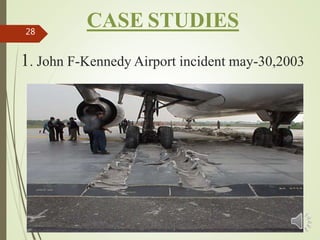

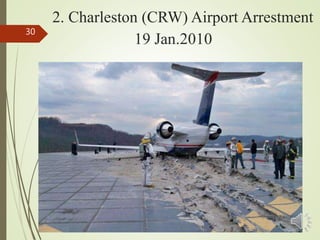

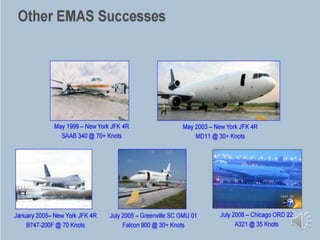

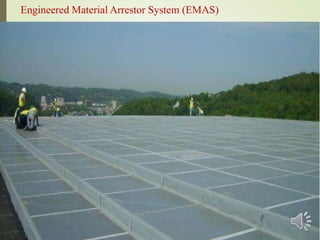

The document discusses the Engineered Material Arresting System (EMAS), designed to mitigate hazards associated with aircraft overruns during landing and takeoff. EMAS consists of crushable concrete that safely decelerates aircraft and has a successful track record of preventing injuries in numerous incidents worldwide. The document outlines design requirements, material composition, installation details, advantages and disadvantages, and case studies demonstrating EMAS effectiveness.

![MATERIAL COMPOSITION

Component Quantity

Cement type II A-LL 42,5 R [kg] 05

Limestone filler [kg] 10

Expanded polystyrene [L] 42

Water [L] 07.90

Air entraining agent [g] 81.75

w∕c ratio 01.58

9

Recommended by the FAA advisory circular (FAA 2005)](https://image.slidesharecdn.com/newseminarppt1-160131135549/85/EMAS-Engineered-Material-Arrestor-System-9-320.jpg)