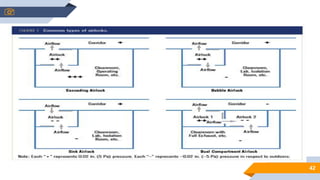

The document provides an overview of heating, ventilation and air conditioning (HVAC) systems. It begins with definitions of HVAC and its components. It then discusses the history of HVAC, with Willis Carrier inventing modern air conditioning in 1902. Applications of HVAC include shopping malls, hotels, hospitals and pharmaceutical industries. The document also covers clean rooms, airlocks, HVAC qualification processes including design, installation, operation and performance qualification tests.