machine tools Semi- automatic lathes U 2 part_2

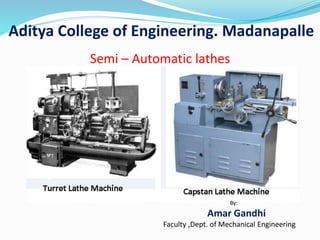

- 1. Semi – Automatic lathes Aditya College of Engineering. Madanapalle By: Amar Gandhi Faculty ,Dept. of Mechanical Engineering

- 2. Capstan lathe Capstan lathe is one of the types of semi-automatic lathe. In semi-automatic lathes machining operations are done automatically. Turret head is mounted on a slide called ram which is mounted on the saddle. The saddle is locked at a particular point and the ram is moved to provide feed to the tool. Lightweight machine and Suitable for bar work. Functions other than machining like loading and unloading of job, positioning of tools coolant operations are done manually.

- 5. . WORKING PRINCIPLE Work piece is held in collet or chucks which is actuated hydraulically or pneumatically. All the needed tools are held in the respective holes on the turret head. According to the sequence of operation the tool is moved with the help of turret head. · Drilling, boring, turning, reaming, threading tools are mounted on the turret head. · Forming, chamfering, knurling tools are mounted on the front end of the turret. · Parting tool is mounted in inverted position on the rear end of the turret. After completing each operation the turret head is moved back to its initial position which indexes the tools automatically

- 6. ADVANTAGES · Rate of production is higher. · Different ranges of speeds are obtained. · More number of tools can be accommodated. · Chucking of larger work pieces can be done. · Operators of less skill is required hence lowers the labour cost. · Higher rigidity so can withstand heavy loads.

- 7. The Turret or Saddle Type Lathe The turret lathe is another type of lathe machine. It is used for repetitive production of same duplicate parts, which by the nature of their cutting process are usually replaceable. The hexagonal turret as shown in the figure. It is mounted directly on a saddle and the whole unit moves back and forth on the bed-ways to apply feed. This type of turret lathe machine is heavier in construction. It is particularly adapted for larger diameter bar work and chucking work. The machine can take in longer work pieces than that in a capstan lathe.

- 8. TURRET LATHE

- 9. Turret Lathe

- 10. The main parts of a capstan and turret lathe: 1. Bed. 2. Headstock. 3. Cross slide and saddle. 4. The turret saddle and auxiliary slide.

- 11. 1. Bed The bed is a long box like casting provided with accurate guide ways upon which are mounted the carriage and turret saddle. The bed is designed to ensure strength, rigidity and permanency of alignment under heavy duty services. 2. Headstock The headstock is a made up of large casting. It is located at the left-hand end of the bed. The different types of headstocks in capstan and turret lathe are as follows: Step cone pulley driven headstock. Direct electric motor driven headstock. All geared headstock. Pre-optive or pre-selective headstock.

- 12. 3. Cross-Slide and Saddle In small capstan lathes, hand-operated cross slide is used which are clamped on the lathe bed at the required position. The larger lathes and heavy-duty turret lathes are equipped with usually two designs of the carriage. 1. Conventional type carriage 2. Side hung type carriage

- 13. 4. The Turret Saddle and Auxiliary Slide In a capstan lathe, the turret saddle bridges the gap between two bed-ways. And the top face is accurately machined to provide a bearing surface for the auxiliary slide. The saddle is adjusted on lathe bed-ways and clamped at the desired position. The hexagonal turret is mounted on the auxiliary slide. In a turret is directly mounted on the top of the saddle and any movement of the turret is affected by the movement of the saddle. The movement of the turret may be effected by hand or power. The turret is a hexagonally shaped tool holder intended for holding six or more tools.

- 14. Hexagonal Turret

- 15. Differences between Capstan & Turret lathes Capstan lathe 1. It is a light duty semi automatic lathe 2 . The turret lathe head is mounted on a ram . The ram slides on a saddle . The saddle is clamped at the required position on the bed ways 3 . It has non rigid construction . Hence only light cuts can be taken 4 . The ram with the head can be moved to small distance .(It is limited by the lathe travel of the ram of saddle ) Turret lathe 1 . It is heavy duty automatic lathe 2 . The turret head is mounted on a saddle .The saddle slides directly on the bed-ways , while on machining. 3 . The construction provides rigidity to the tool while cutting. Hence heavier cuts can be taken. 4 .The saddle with turret can be moved over the entire length of the bed , while machining

- 16. - 5 . Only shorter pieces can be machined . 6 . This is suitable for machining small components for a bar stock . collects are used for holding 7 . The turret head fitting on a ram can be easily moved over saddle . 8 . It is used for machining and small jobs up to 60 mm dia. 5 . Longer pieces can be machined . 6 . This is suitable for heavy work , which are held in chucks. 7 . It is difficult to move the turret head with saddle manually on the bed. 8 . It is used for machining large and heavier work pieces up to 200 mm.

- 17. Differences Between semi-automatic And Engine Lathe CAPSTAN AND TURRET LATHE 1 . The head stock is similar to that of engine lathe but posses wider range of speeds and heavier in construction 2 . Power consumption will be up to 15 H.P 3 . Rate of production is high 4 . The tool post mounted on cross slide is a four way tool post ,which holds 4 tools and may be indexed at 900. ENGINE LATHE / CENTRE LATHE 1 . The head stock is light in construction , posses smaller range of speeds. 2 .Engine lathe requires 3 H.P. 3 . Rate of production is low. 4. In engine lathe , it is usual practice to hold only one tool on the tool post .

- 18. - 5 . In turret lathe , tail stock is replaced by a hexagonal turret , which carrys 6 more tools . 6 . In turret lathe , combination of cuts can be taken .Two or more tools can be mounted on the same face of turret . 7 . Labour cost to operate capstan and turret lathe is less . 8 . A semi skilled operator can operate 9. capstan and Turret lathes are fundamentally production machine , capable of machining large number of identical pieces. 5. In engine lathe no such turret head to fix extra tools. 6. This facility is quite un common. 7. Labour cost is more 8. A skilled operator may be required 9. It is suitable for odd jobs having shapes and sizes .

- 19. WORK HOLDING DEVICES 1. COLLET CHUCKS :- A collet is a cylindrical steel bush having three or four equally speed slits along the length . These slit give the spring action . The collet nose is made thicker to from the jaws , The outer surface of nose fits in the taper hole of the hood . The bore of collet may be circular hexagonal etc , depending upon the shape of work . Collets chucks are used for holding the bar stock quick setting and accurate centering is done using collet chucks . Different types of collets chucks used in the capstan lathe are :- 1. Draw back collet 2. Push out collet 3. Dead weight collet

- 20. Collets

- 21. 2. JAW CHUCKS The jaw chucks are used in capstan lathes having two or three or four jaws depending upon the shape of the work. The jaws are used to support odd sized jobs or jobs having larger diameter , which cannot be introduced though the head stock spindle and gripped by collet chucks . Different types of chuck used are :- Self centering chuck Independent chuck Combination chuck Air operated chuck Soft jaws chuck

- 22. Chucks

- 23. 3. FIXTURES A fixture may be described as a special chuck built for the purpose of holding ,locating and machining a large number of identical pieces , which cannot be easily held number of identical pieces , which cannot be easily held by conventional gripping devices . Fixtures also serve the purpose of accurately locating the machining surface The main function of a fixture are as follows :- They accurately locate the work . They grip the work properly , preventing it from bending or slipping during macching operations . They permit rapid loading and un loading workpieces.

- 24. Turning Fixtures

- 25. TOOL HOLDING DEVICES The wide variety of work performed in a capstan or Turret lathe in mass production . Different types of tool holders are used for holding tools for typical operations . These tools are held in the six faces of the turret , on the four position of the front tool post and in the rear tool post . Special tool holders are also sometimes designed for special purpose .

- 26. The important and widely used for tool holders are listed below:- 1. Straight cutter holder 2. Multiple cutter holder 3. Adjustable angle cutter holder 4. Offset cutter holder 5. Sliding tool holder 6. Knee tool holder 7 . Box tool holder 8. Bar ending tool holder 9 . From tool holder 10.Tap holder 11. Die holder 12 .V –steady box tool holder 13 Roller steady box tool holder 14 . Balanced tool holder

- 28. Tool and Tool-Layout Tools for capstan and turret lathe are similar in construction to those of centre lathe tools, except material. The tools used are made of H.S.S. or tungsten carbide because the machines are more rigid and also operated at higher cutting speeds. The tools mounted on cross-slide are used for tuning, facing, necking, parting etc. and those mounted on the turret head are used for drilling, boring reaming, etc.

- 29. Tool Layout The tool layout for a job constitutes the pre- determined plan for machining operation of a particular component. The layout is dependent upon the number of pieces to be manufactured, i.e. lot size. As a general rule, standard tools should be used as much as possible and also for small batches of work, the layout should be simple.

- 30. For large quantities and long run special tools should be used as they minimize machining time and retain their cutting qualities for the maximum period. The accuracy and cost of component largely depends upon the tool layout. For preparation of the tool layout, it is necessary to have the finished drawing of the part to be machined and if it is a forging or casting, the forged, or cast blank will determine how much machining has to be done on various faces.

- 31. Tool Layout for Hex. Headed bolt

- 32. The sequence of operation to be done for the manufacture of hexagonal bolt is illustrated as below :- •Hexagonal bar stock is used in the turret faces bar stop ,box turning tool and forming tool and self opening dia. head mounted •For each tool position the length of travel of the turret is set by feed stop screws •Chamfering tool is held in the front tool post and the parting off tool is held in the rare tool post . •Bar stop in the turret face is brought position •The coller opens and bar stock is pulled out by the bar feeding mechanism till it butt against the bar stop collar closes. •Turret goes back and is indexed.

- 33. -Box turning tool comes into position .The turret head moves towards the head stock. The bar is turned down to 16mm dia. for a length of 50mm. -The turret returns to starting position and is indexed. End forming tool comes into position. The turret moves forward. The end forming tool, machines the bolt end. -The turret returns to starting positions and is indexed. The self opening die head comes into position. The turret moves forward. - The end forming thread is cut for 37mm length. The die opens our. The turret goes back the starting position. -The chamfering tool in the front slide moves forward and chamfer is machined. The front slide is withdrawn to original position. -The parting off tool post moves forward and cuts off the component. The cycle is repeated.