CV Ahmed Adel Inservice AIM and RBI manager 2016

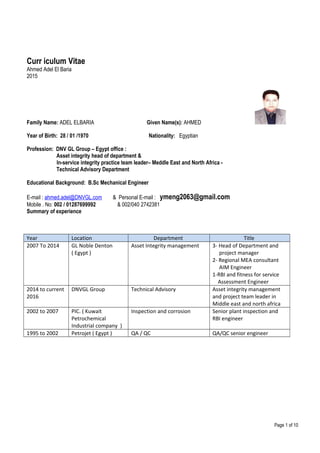

- 1. Curr iculum Vitae Ahmed Adel El Baria 2015 Family Name: ADEL ELBARIA Given Name(s): AHMED Year of Birth: 28 / 01 /1970 Nationality: Egyptian Profession: DNV GL Group – Egypt office : Asset integrity head of department & In-service integrity practice team leader– Meddle East and North Africa - Technical Advisory Department Educational Background: B.Sc Mechanical Engineer E-mail : ahmed.adel@DNVGL.com & Personal E-mail : ymeng2063@gmail.com Mobile . No: 002 / 01287699992 & 002/040 2742381 Summary of experience Year Location Department Title 2007 To 2014 GL Noble Denton ( Egypt ) Asset Integrity management 3- Head of Department and project manager 2- Regional MEA consultant AIM Engineer 1-RBI and fitness for service Assessment Engineer 2014 to current 2016 DNVGL Group Technical Advisory Asset integrity management and project team leader in Middle east and north africa 2002 to 2007 PIC. ( Kuwait Petrochemical Industrial company ) Inspection and corrosion Senior plant inspection and RBI engineer 1995 to 2002 Petrojet ( Egypt ) QA / QC QA/QC senior engineer Page 1 of 10

- 2. Curr iculum Vitae Ahmed Adel El Baria 2015 Qualificationans and Certification : - ASNT Level II in Radiography Testing. - ASNT Level II in Ultrasonic Testing. - ASNT Level II in Magnetic Particles Testing. - ASNT Level II in Liquid Penetrant Testing - Certified welding inspector ( CWI ) . - NACE ICP internal corrosion pipeline certificate - Certified piping inspector (API 570) - Certified Pressure Vessel Inspector (API 510) - Certified Above Ground Storage Tank Inspector (API 653) - Certified for (API 580) : Supplemental inspection certification program tests Inspectors knowledge and expertise in the field of risk based inspection - Certified for( API 577) Advanced Knowledge of Welding Inspection And Metallurgy - Certified For (API 571) Refinary deteriation and failure mechanism - Cathodic Protection Level – I - Dupont Safety Resources For ( Action Employess Can Taken ) - Modified Dow Fire & Explosion Index Workshop - Plans and Process of Emergency & Evacuation - Livelink Software for Business Users - Ultrapipe Software Corrosion monitoring different modules - ESAB Arc Welding Technology Cirtificate - Galiom RBI and Asset Integrity manmagemt software -GL office at Malyzia (KL - API RBI software training ( E2G ) certificate - RBI Synergi software training certificate Language(s): Arabic, English Traning Course Training Courses :None DistrractiveTesting methods (RT,UT,MT,PT) Level II Training course in,Mar.2005: Safety Audit Hour Training course in OCT.2004: Fire Protection training &Coaching. Training course in MAY.2005 :(PSM) Process Safety Management Training course in JAN.2004: (PHA) Process Hazard Analysis Training course in FEB..2004:(RBA) Risk Base Analysis Training course in May ,03 ISO 14001 – Environmental Management System Training course in JAN,06 : PSM Procedure awareness Training course in DEC.2002 : CWI Training course in MAY.2004 : API 570 Training course in FEB, 2006 API 653 Training course in 15 June to 24 June/2003 : Modified Dow Fire & Explosion index workshop Training course in 9 Jul to 16 Jul /2003 : Modified Dow Fire & Explosion index workshop Training course in 5 May 2003 : Emergency and Evacuation Plan Page 2 of 10

- 3. Curr iculum Vitae Ahmed Adel El Baria 2015 Training course from 18/7/2004 to 21/7/2004 : Cathodic Protection Training course in 25 Sept.2004 : Action Employees Can Take (from Dupont safety resources) Training course in Des,06 : Policy of information technology Training course in June,05 : Ultrapipe Asset management software Training course in Des,05 : Live link software programmer ( User training) Training course in Des,03 : Maximo software programmer ( User training) Training cource on Galiom software -GL office at Malyzia (KL) API RBI software ( E2G) Membership : -TWI : The welding Institute , World Center for materials joining Technolog - AWS : American welding society - NACE : # 677624 Present Assignment: Since Oct. 2009 DNV GL GROUP – EGYPT Asset integrity Head of Department / Project manager / Counsaltant/Practice team leader Since April/2008 Germainscher Lloyd Industrial Services Asset Management Consultant Engineer Middel East and Africa Regional office Since Dec. /2008 Germanischer LIoyd Industrial Services Asset integrity management Head of Department Since Jun. / 2008 Germanischer LIoyd Industrial Services Asset integrity Project Manager Since Apr. /2007 Germanischer LIoyd Industrial Services Asset integrity and Reliability Engineer Past Assignments: Since Oct./2002 Petrochemical Industries Co.( PIC ) , located in State of Kuwait Senior Plant Inspection Engineer Since May./1995 Petrojet Co. Egypt Page 3 of 10

- 4. Curr iculum Vitae Ahmed Adel El Baria 2015 Lead QA/QC Engineer Detail of Experience ( 1 ) From April 2007 Till Now : Permmenenant employer with Germanischer LIoyd Industrial Services Egypt (Currently DNV GL GROUP) in Position Held: Asset Integrity Head of Department. : Reference project as follows: Title Location/ Project Period Senior Reliability Engineer Gupco Rehabilitation Badri complex Project :( RBI and FFS Assessment) April. 2007 – Oct. 2007 Asset integrity Project Manager Gupco Rehabilitation July 10 complex Project. And Gupco Saqqara Project –Egypt (RBI and FFS Assessment) Nov. 2007 – Oct. 2008 Regional Asset Integrity management and consultant Engineer Middle East and Africa Regional office 2009 to 2010 Asset Integrity project team leader UGDC project : RBI and FFS Project Jan. 2010 to Dec 2010 Asset integrity head of department GL Noble Denton –Egypt from 2010 – Jun 2013 Project team leader in-service inspection and FFS assessment project at Amerya Jan 2011 - May.2011 RBI senior engineer and project team leader Rashpetco Company RBI project Jun.2011 - Dec. 2011 RBI senior engineer and project team leader Saudi ARAMCO [safaniya offshore producing RBI project] April 2012 - Oct.2012 Senior Asset Integrity engineer OSI optimization ARAMCO Project standard for :Tanageb plant (G54, G80 ) and Safaniya plant ( G74 , G486, R90 ) May. 2013 - Oct. 2013 RBI senior engineer and project team leader Provide written scheme of examination for all assets in Rachpetco Company ( Rosetta and WDDM Plants ) Jan. 2014 And current. Senior Asset Integrity engineer Enppi / Khalda plant FFS assessment project April 2014 – and current Regional Practice team Leader – Medill east and North Africa DNV GL Group – Egypt office ( Promotion ) Current title Responsibilities Asset Management Head of Department [Since Oct. 2009 till now] - Completion of the company budget and policy - Provide all AIM procedure and project technical proposal Page 4 of 10

- 5. Curr iculum Vitae Ahmed Adel El Baria 2015 - Ensure smooth execution of the project as per project schedule - One of the project team Team leader & team member Project Manager: GAPCO Company and UGDC Company - Liaison person for all contractual matters pertaining to the project - Shall ensure smooth execution of contact as per contract and project schedule - Assign the asset integrity project execution plan - Provide and deliver all assessment report to client Senior Site Asset Integrity Engineer: Ensure that Inspection Strategies, techniques and analysis are developed and managed in accordance to the company policy. Focal point for Asset Integrity Management internal assessments and Verification & Measurement. Assure timely execution and follow-up of remedial studies. Ensure that updated & proven inspection/NDT techniques, etc. are applied to achieve overall cost optimization associated with inspection in general and increased availability of plant and facilities for safe production. Ensure the development of Risk Based schemes to provide the required level of assurance of fitness for continued operation. Participates in the establishment of integrity performance indicators that will serve in achieving shareholders KPIs. Monitor the PM schedule and compliance for all the defined HSECES. Audit the facility as a Level-1 Audit for all asset Integrity related areas. Monitoring the inspection work sheets, weekly report etc and follow up the actions to reduce the integrity concerns and timely closures of the required action items. Ensure that technical inspection and corrosion procedures are reviewed and updated in compliance to the Organization Inspection procedures and AIRMS requirements. Custodian of anomaly tracking and management of change register as applicable to Asset Integrity Management. Reliability Engineer: • Prepare & issue the work packs required for corrosion monitoring & base line inspections. • Compile and Issue Inspection Workpacks and associated drawings to the Inspection Engineer/Plant • Inspector • Analyze Inspection reports and initial review of anomalies by the Inspection Engineer/Plant Inspector • Perform Fitness for Purpose evaluations • Development of Maintenance Recommendations based on the Fitness for Purpose evaluation according to API 579& B31.G • Monitor and Report Workpack Status • Identify data that is missing to perform a Fitness for Purpose evaluation • Use trends, where available, to develop the periodic re-inspection program • Liaise with Client personnel to source Drawings, Design Data and Process Data required to perform Fitness for Purpose evaluations • Highlight to the Project Site Coordinator and Deputy Project Manager issues that require external • resources, Corrosion Engineering, Software Specialist, etc • Part of the team to asses the conditions of the equipments as per the established procedures based on RBI. Page 5 of 10

- 6. Curr iculum Vitae Ahmed Adel El Baria 2015 • Record and Assess the detailed inspection findings for fitness for purpose (FFS) based on remaining thickness as per API 510- API 570, API 653. and API 579 • preparing Assessment procedures for pressure vessels, Platform piping and risers and carrying out and implementation of Assessment Process through Galiom software • RBI Engineer : - Assign P&ID corrosion loops - Assign P&ID inventory groups - Assign failure mode and failure mechanisms per each corrosion loop - Assign susceptibility and severity for all deterioration mechanisms - Assign probability of failure per each corrosion loop - Assign consequence of failure per each inventory group - Manage of the risk result - Assign the written scheme of examination based for risk criticality - Manage of the inspection interval based of risk criticality ( 2 ) From OCT.2002 To April 2007 : Inspection consultant engineer o Provide inspection Plan o Liaison person for all inspection contractual and agency o Provide all inspection manual and procedure o Direct to all inspection engineers o Provide inspection section annually budget o Ensure smooth execution of all inspection activities o Provide internal audit o Review and approve all inspection reports o Provide inspection section objective and execution plan o Completion of all inspection tools and devices o Provide training and certification program for all section employer o Development of Maintenance Recommendations based on the Fitness for Purpose evaluation o Monitor and Report Workpack Status o Identify data that is missing to perform a Fitness for Purpose evaluation o Use trends, where available, to develop the periodic re-inspection program INSPECTION ENGINEER : {Petrochemical Industries Company PIC Kuwait}. From 2002 up to 2007 Responsibility : Page 6 of 10

- 7. Curr iculum Vitae Ahmed Adel El Baria 2015 Inspection of equipment in Ammonia ( 2000 mt / d ), Urea (2500 mt / d ) plants equipment such as columns , heat-exchangers, pressure vessels, boilers, heaters, reactors, strippers, safety valves & valves, storage tanks , piping & pipelines , etc . - Co-ordinate and following up on inspection and related activities carried out by specialized independent inspection authorities and surveyors for critical inspection or for insurance purposes. - Supervise and controls the activities of inspection technicians and give instructions related to critical inspections to be implemented on plants equipment. - Approves and / or recommend methods of repairs necessary to be implemented on plant equipment has shown unsatisfactory conditions and or advise on or approve materials, welding procedures, heat treatment and inspection methods related to repair work and follows up to ensure they are carried out satisfactory. - Review / prepare welding ( WPS,PQR & WPQ ), heat treatment and NDT procedures for different metals such carbon steel, stainless steel and non -ferrous as well as solving problems related to the welding and materials. - Review the thickness survey and calculate corrosion rate and remaining life for piping and equipment according to API 570&510andAPI 653 code through ultrapipe soft ware system in our company - Prepare piping , equipments and safety valves due list for inspection through ultrapipe system - Prepare equipments and piping shut down list - Conduct failure analysis and recommended to change or Modify materials operating conditions based on investigation result. - Inspect in site received critical new plant equipment and review related inspection test certificates for acceptance. - Gives advice and direction to technicians as necessary in carrying out any highly technical, specialized or critical works involved with studies projects, trouble shooting, inspection procedures / methods, etc. Participated as a member in various teams constituted by management like Process Hazard Analysis Team: The team will study the concern segment from all the points of view process,engineering,inspection and maintenance to make the area of concern with safe running and reliable without affecting all the process activity and efficiency. Further more the team will submit to the management report about team studding with high lighting to any recommendations required to the concern section for implementing. Page 7 of 10

- 8. Curr iculum Vitae Ahmed Adel El Baria 2015 Root Cause Analysis Team : Management constitutes a team of members from different backgrounds to study and find the root causes of sporadic incidents like fire accident of gas preheater, multiple leaks in boiler,…etc.,and recommend practical steps to avoid such incidents in future. Duties include: The team will study the failure of the concern equipment from all the points of view it may leads to this failure using all facilities of research to find out the roots of failure causes and will submit a report to the manager including the recommendations to avoid such failures. - Inspection and clearance of inwards goods including plates, pipes, exchangers, vessels, ETC. Duties include: i) Obtain relevant test certificates from manufacturer/supplier and check their data and authenticity. ii) Conducting necessary tests as per standard codes on the test specimens and analyzing the data. iii) Arranging and supervising preliminary examination like dimensions of received equipment tests for approximate chemical analysis, hardness measurements, and ultrasonic examination for different materials. iv) Preparing the final certificates for accepted/not accepted items and routed to all concern departments. - This will be arrangement and coordinating with third part inspection agency for insurance renewal of boilers , heaters and lifting appliances and the duties include i) Prior information to process about date of expiry. ii) Co-ordinate with process and third part agency for date inspection. iii) Raise inspection work request, after visual inspection to all the Components of the boiler if required iv) Witness the hydrostatic pressure test and steam tests for the boiler in Presence of third party inspection representative ( 3 ) From MAY. 1995 to OCT, 2002 : Lead QA/QC ENGINEER I had been worked Worked in M/S petrojet as Projects QA/QC Engineer and leader QA/QC Engineer . M/S Petrojet specialists in fabricating pressure vessel, heat exchangers, heaters, all steel structure works & Contracture for all petroleum plants . My pre-tender duties directe all the QA/QC and ISO work jobs as well as preparing Welding procedure specification WPS and Procedure qualification record PQR as per ASME Sec.IX for all fabrication and contracture jobs and direct and interpretation for all non distractive examination ( NDE) and distractive test in all projects as well as welders test and preparing for welders certificates . Main duties • Functional responsibility for Quality Management, Quality Assurance and Quality Control activities on the Project. • Develops, Implements, maintain & update QMS procedures & Programs of EPC Projects. Page 8 of 10

- 9. Curr iculum Vitae Ahmed Adel El Baria 2015 • Work towards achievement of TE QUALITY Objectives & compliance to Codes, Standards & client specifications. • Internal Auditing of QMS procedures and programs & prepare MRM inputs to ensure effectiveness of QMS. • Raise, track & analyze NCR’S, CAR’S & Audit findings for continuous improvement of QMS. • Supplier / sub-contractor audits • Assist and advise Project / Operational Management on Quality Issues in relationship to Technical integrity of desired output. • Lead a team of QA/QC/ WELDING / NDT / Painting Inspectors • Review and implement Quality & Inspection test plans , Method statements, Procedures . • Plan and schedule stage & final inspection including client and TPI. • Co-ordinate Project / contract Quality Kick-off Meetings • Co-ordinate Qualification of welding procedures and certification of welders. • Quality Training / Meetings • Ensure compilation and submission of final Quality Documentation. • Assist & provide Quality Inputs for Pre-Qualification and Registration • Maintain Quality Documentation / information management system, reports and records • Provides quality support and guidance in managing contractors, subcontractors and vendors in ensuring that work is performed safely and consistent with the project procedures. • Preparation and presentation of Project Inductions and Quality guidance for the project team. • Preparation of Project Quality Documents including Policy, Plan, Audit Schedule and associated Quality specific procedures, specifications and guidelines. • Ensures that engineering activities are executed as per the approved schedule plans. • Ensures all project information related to design, procurement and construction is accurate and timely. • Ensures quality of all required drawings, specs, and procedures necessary for field installation. • Implements procedures to ensure standards and practices are followed on all project work. • Establishes acceptance criteria for engineered equipment. Page 9 of 10

- 10. Curr iculum Vitae Ahmed Adel El Baria 2015 • Reviews contractors' and subcontractors' quality plans and ensures these support the overall project plans and goals. • Reviews all execution plans and ensures these comply with company's quality control objectives and engineering standards. • Works closely with the procurement staff in developing efficient materials issuance processes and accountabilities. • Works with Company and contractor to resolve all quality control related issues and engineering questions. • Assures that all project closeout reports are completed. • Projects: Quality Control & Quality Assurance in all the following pipelines and plants projects PIPE LINES • ELfayom—Bani Sweef 12"Pipe line Petroleum Products (clint:P.P.C) • Quaron – El-tebeen Pipe line 22''/16" oil ( Clint : P.P.C) • Dahshor – ELKorimat Pipe Line 22" gas ( Clint : Gasco ) • Mostorod – Banha Pipe line 16" oil (Clint: P.P.C) • ElKorimat – Bani Sweef pipe line 30" gas ( Clint: Gasco) • ELmax – Damanhor Pipe line 12" Products ( Clint : P.P.C) • Midor – Elmax pipe line 22" Solar ( Clint : P.P.C) • Midor – Wastern Desert Gasa Complex plant 12: pipe line (Clint: Gasco) • Batra – talkha 6' pipeline gas (Clint: Petropel CO.) • Merlon pipe line 12" gas (Clint: merlon) PLANTS • Khalda ELsalam Plant (Clint: Khalda Co.). Location : Egyptian west Dissert • Western Desert Gas Complex Plant ( Clint : Gasco) Alameria – Alexandria • Sid bic ( SIDI KARIR Petrochimical Co. ) Ethylene Plant ( Clint: sid bic) Alameria – Alexandria • Sid bic ( SIDI KARIR Petrochemical Co. )Poly Ethylene Plant (clint: sid bic) Alameria – Alexandria • Middle East Petroleum Company (MIDOR) Plant (Clint: Meditab Co.).ALexandria • ELtemsah Plant ( Clint : Petropel).Location Port Saed Extend of Alexandria Petroleum Co. (Clint: Alex. Petroleum Co.) Page 10 of 10