Vestas is exploring trends and needs in blade technology to further industrialize the wind industry. Some key areas of focus include:

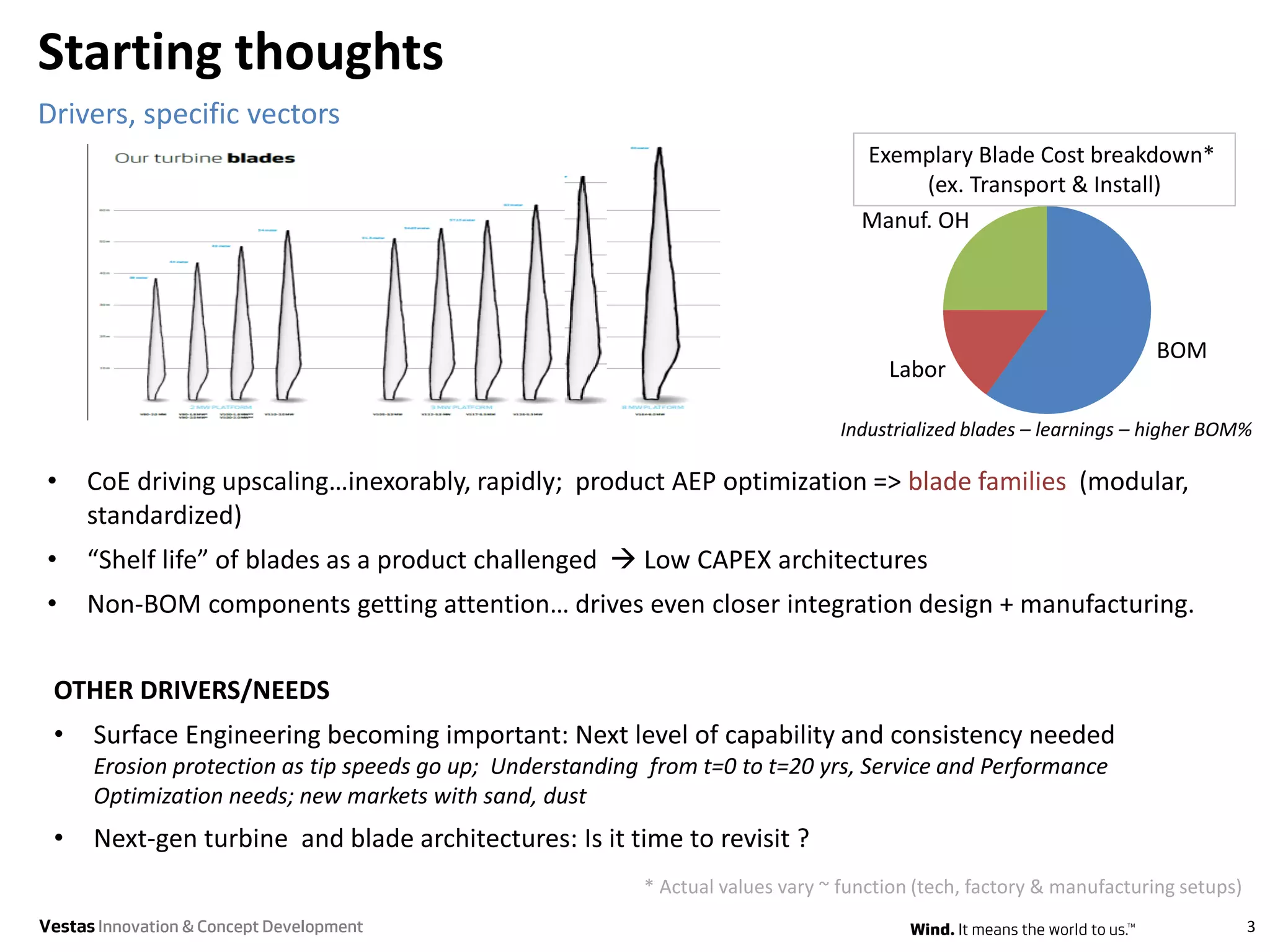

1. Driving full exploitation of the learning curve to reduce costs and achieve grid parity prices while scaling turbines larger.

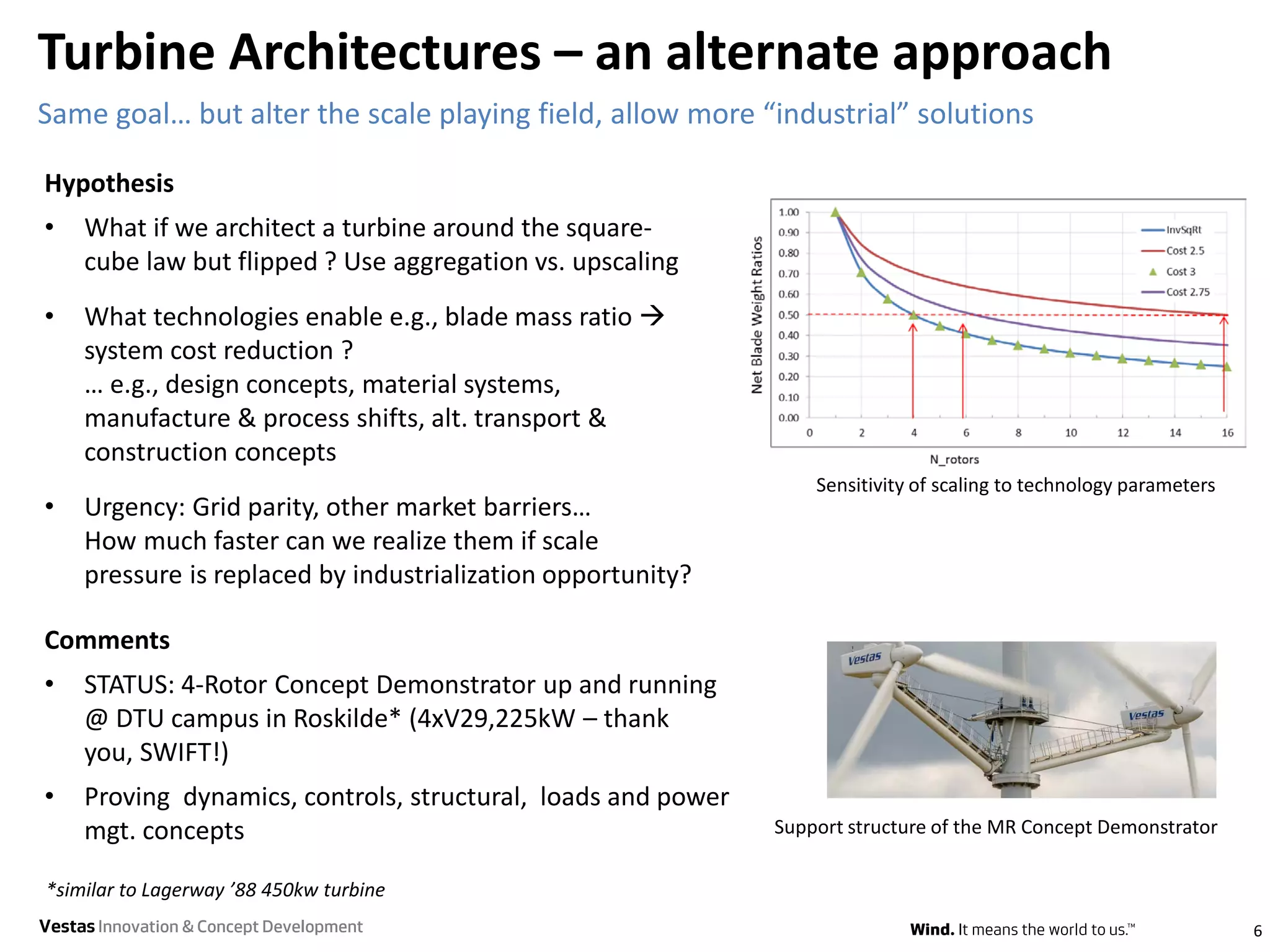

2. Developing next-generation turbine and blade architectures that are more modular, standardized, and have lower capital costs.

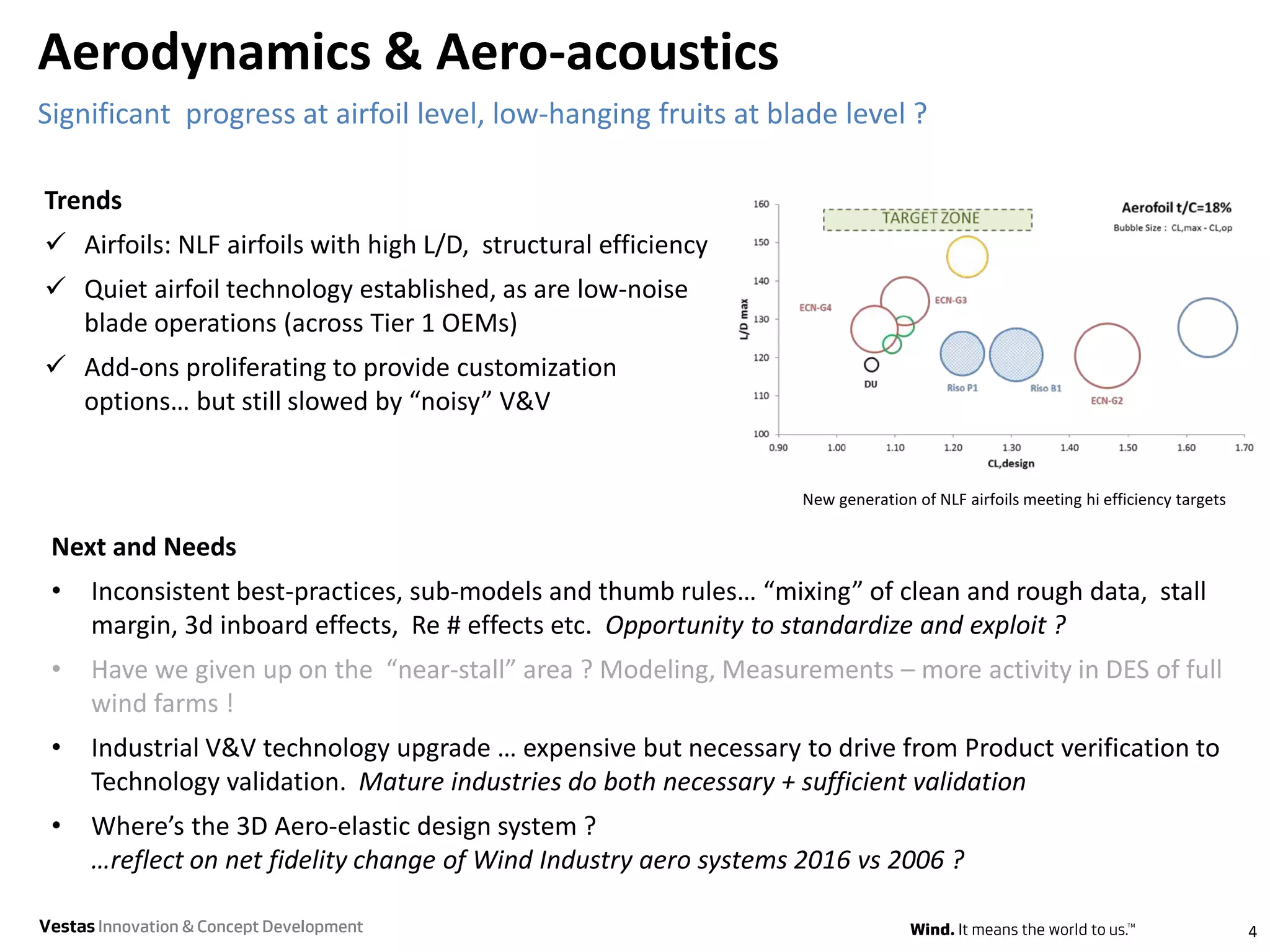

3. Advancing aerodynamic and aeroacoustic models and validation techniques to improve blade and system-level design optimization.

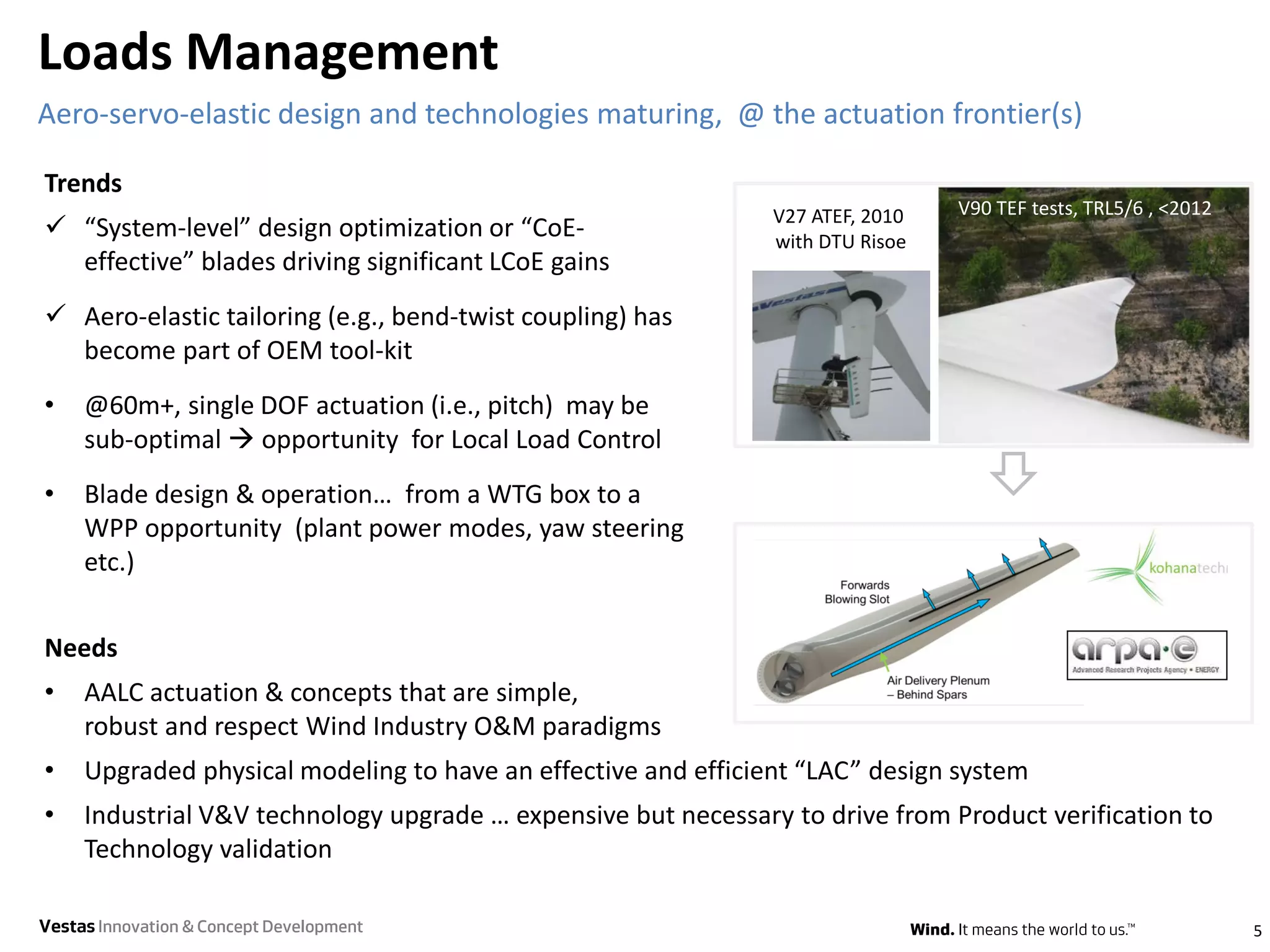

4. Maturing aero-servo-elastic design and loads management technologies, especially developing simpler yet robust actuation concepts.

5. Exploring alternative turbine architectures that use aggregation rather than