Quantitative analysis

•Download as PPT, PDF•

5 likes•2,461 views

Report

Share

Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

PPCE unit 2 (ME8793 – PROCESS PLANNING AND COST ESTIMATION )

PPCE unit 2 (ME8793 – PROCESS PLANNING AND COST ESTIMATION )

FUNDAMENTALS OF CNC & PART PROGRAMMING - UNIT - 4 CAD&M

FUNDAMENTALS OF CNC & PART PROGRAMMING - UNIT - 4 CAD&M

Viewers also liked

Viewers also liked (18)

Importance of quantitative techniques in managerial decisions

Importance of quantitative techniques in managerial decisions

Similar to Quantitative analysis

Similar to Quantitative analysis (20)

Write a program in C or C++ which simulates CPU scheduling in an opera.pdf

Write a program in C or C++ which simulates CPU scheduling in an opera.pdf

Lab 3 of 7 Process Management Simulation L A B O V E R V I E W.docx

Lab 3 of 7 Process Management Simulation L A B O V E R V I E W.docx

An Algorithm for Optimized Cost in a Distributed Computing System

An Algorithm for Optimized Cost in a Distributed Computing System

Lot Completion Estimation Using Self-Configuring Equipment Model-based Applic...

Lot Completion Estimation Using Self-Configuring Equipment Model-based Applic...

DESIGN OF ROBUST CELLULAR MANUFACTURING SYSTEM FOR DYNAMIC.pptx

DESIGN OF ROBUST CELLULAR MANUFACTURING SYSTEM FOR DYNAMIC.pptx

Recently uploaded

Mehran University Newsletter is a Quarterly Publication from Public Relations OfficeMehran University Newsletter Vol-X, Issue-I, 2024

Mehran University Newsletter Vol-X, Issue-I, 2024Mehran University of Engineering & Technology, Jamshoro

This presentation was provided by William Mattingly of the Smithsonian Institution, during the fourth segment of the NISO training series "AI & Prompt Design." Session Four: Structured Data and Assistants, was held on April 25, 2024.Mattingly "AI & Prompt Design: Structured Data, Assistants, & RAG"

Mattingly "AI & Prompt Design: Structured Data, Assistants, & RAG"National Information Standards Organization (NISO)

This presentation was provided by William Mattingly of the Smithsonian Institution, during the third segment of the NISO training series "AI & Prompt Design." Session Three: Beginning Conversations, was held on April 18, 2024.Mattingly "AI & Prompt Design: The Basics of Prompt Design"

Mattingly "AI & Prompt Design: The Basics of Prompt Design"National Information Standards Organization (NISO)

APM Welcome

Tuesday 30 April 2024

APM North West Network Conference, Synergies Across Sectors

Presented by:

Professor Adam Boddison OBE, Chief Executive Officer, APM

Conference overview:

https://www.apm.org.uk/community/apm-north-west-branch-conference/

Content description:

APM welcome from CEO

The main conference objective was to promote the Project Management profession with interaction between project practitioners, APM Corporate members, current project management students, academia and all who have an interest in projects.APM Welcome, APM North West Network Conference, Synergies Across Sectors

APM Welcome, APM North West Network Conference, Synergies Across SectorsAssociation for Project Management

Recently uploaded (20)

Measures of Central Tendency: Mean, Median and Mode

Measures of Central Tendency: Mean, Median and Mode

Mattingly "AI & Prompt Design: Structured Data, Assistants, & RAG"

Mattingly "AI & Prompt Design: Structured Data, Assistants, & RAG"

Mattingly "AI & Prompt Design: The Basics of Prompt Design"

Mattingly "AI & Prompt Design: The Basics of Prompt Design"

Presentation by Andreas Schleicher Tackling the School Absenteeism Crisis 30 ...

Presentation by Andreas Schleicher Tackling the School Absenteeism Crisis 30 ...

ICT Role in 21st Century Education & its Challenges.pptx

ICT Role in 21st Century Education & its Challenges.pptx

APM Welcome, APM North West Network Conference, Synergies Across Sectors

APM Welcome, APM North West Network Conference, Synergies Across Sectors

Russian Escort Service in Delhi 11k Hotel Foreigner Russian Call Girls in Delhi

Russian Escort Service in Delhi 11k Hotel Foreigner Russian Call Girls in Delhi

Quantitative analysis

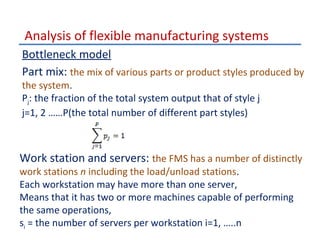

- 1. Analysis of flexible manufacturing systems Bottleneck model Part mix: the mix of various parts or product styles produced by the system. Pj: the fraction of the total system output that of style j j=1, 2 ……P(the total number of different part styles) Work station and servers: the FMS has a number of distinctly work stations n including the load/unload stations. Each workstation may have more than one server, Means that it has two or more machines capable of performing the same operations, si = the number of servers per workstation i=1, …..n

- 2. Analysis of flexible manufacturing systems Bottleneck model Process routing: it defines the sequence of operations, the workstations where operations are performed and the associated process time. tijk: the processing time that a production unit occupies a given workstation server (without any waiting) i : refers to the station j : refers to the part or the product K: refers to the number of the operation in the product process plan

- 3. Analysis of flexible manufacturing systems Bottleneck model Work handling system: the handling system used to transport parts with the FMS it can be considered as a special case of workstations (n+1). the number of carriers is analogous to the number of servers Transportation time : the mean time required to transport parts from one station to another one. It can be more convenient to use average transport time for all moves

- 4. Analysis of flexible manufacturing systems Bottleneck model Operation frequency: the expected number of times a given operation in the process routing is performed for each work unit. fijk: operation frequency for operation k in process plan j at station i.

- 5. Analysis of flexible manufacturing systems Bottleneck model Average workload for a given station: the mean total time spent at a station per part. tijk: processing time for operation k in process plan j at station i. fijk: operation frequency for operation k in process plan j at station i. pj: part mix fraction for part j. Workload of handling station: the mean transport time multiplied by the average number of transports required to complete the processing of a part. mean number of transports (nt) :

- 6. Analysis of flexible manufacturing systems Bottleneck model System performance measure: a)Production rate of all parts, b)Production rate of each part style, c)Utilisation of the different workstations, d)Number of busy servers at each work station. These measures will be computed based on the assumption of: The FMS is producing at its maximum possible rate. Which is constrained by the bottleneck station in the system. The bottleneck is the station with the highest workload per server.

- 7. Analysis of flexible manufacturing systems Bottleneck model System performance measure: a)Maximum production rate of all parts (pcs/min), S* number of servers at the bottleneck station WL* is the workload at the bottleneck station b) Maximum production rate of each part style (pcs/min),

- 8. Analysis of flexible manufacturing systems Bottleneck model System performance measure: c) utilization of each work station Ui, Average station utilization , Overall FMS utilization

- 9. Analysis of flexible manufacturing systems Bottleneck model System performance measure: d) Number of busy servers at each workstation (BSi), Example 19.5 Example 19.6

- 10. Analysis of flexible manufacturing systems Bottleneck model System performance measure: d) Number of busy servers at each workstation (BSi), Example 19.5 Example 19.6