English

1.2 Export Markets

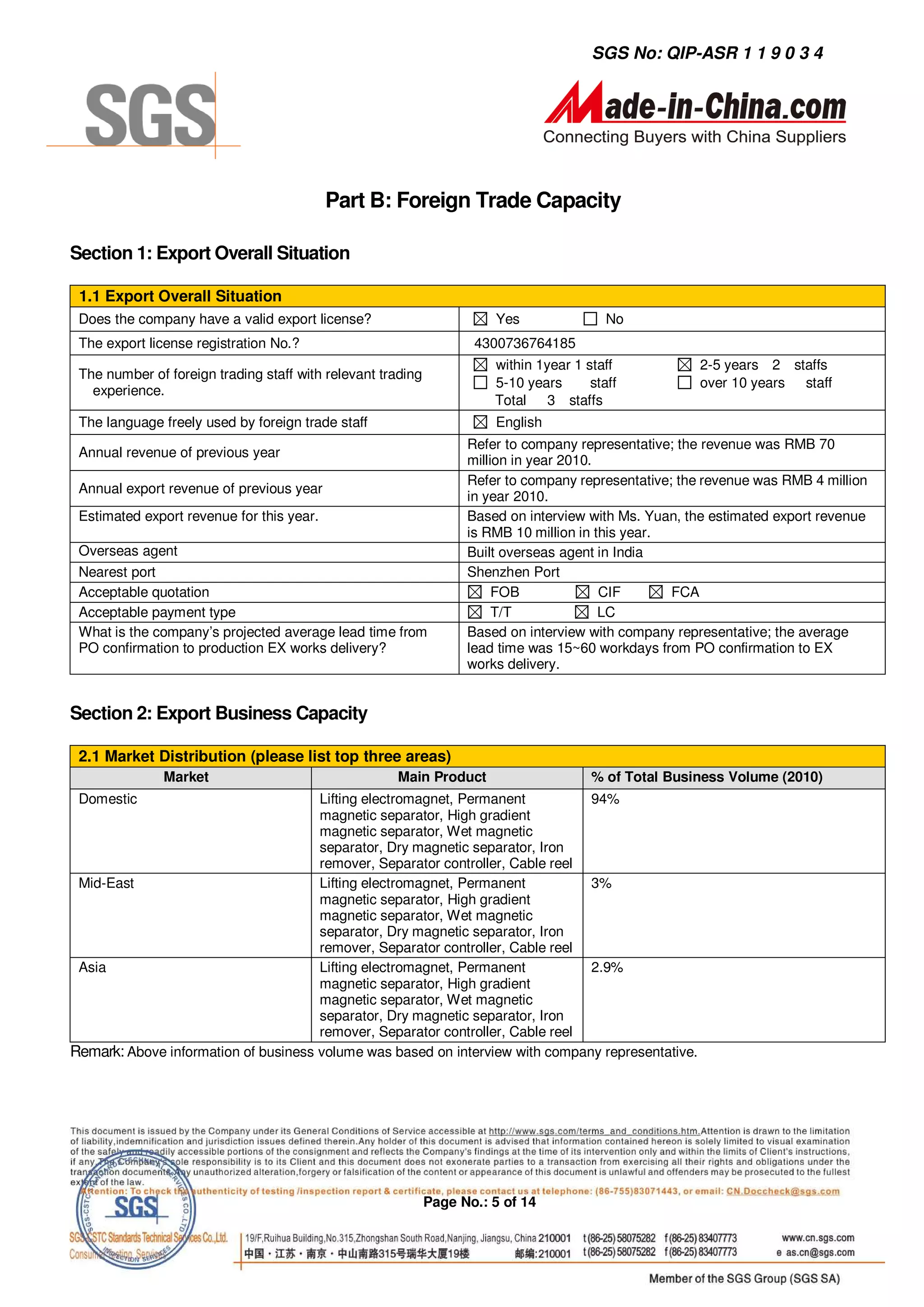

Main export markets (Top 5) and percentage of total export:

1. Middle East: 30%

2. Southeast Asia: 25%

3. Africa: 20%

4. South Asia: 15%

5. Europe: 10%

Total export amount in the last 3 years:

2008: USD 2 million

2009: USD 3 million

2010: USD 4 million

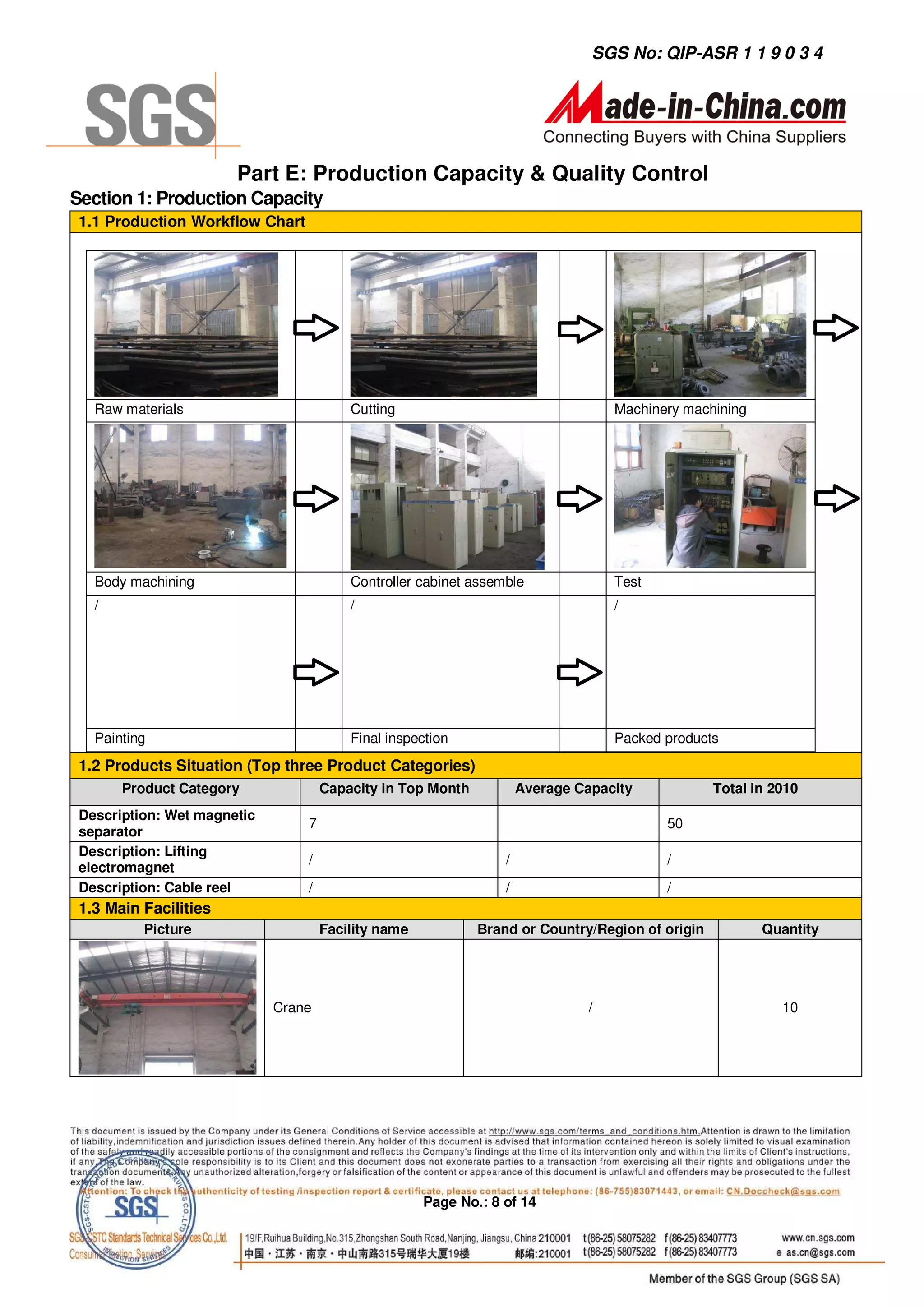

1.3 Export Products

Main export products (Top 5) and percentage of total export:

1. Lifting electromagnet: 30%

2. Permanent magnetic separator: 25%

3. High gradient magnetic separator: 20%

4