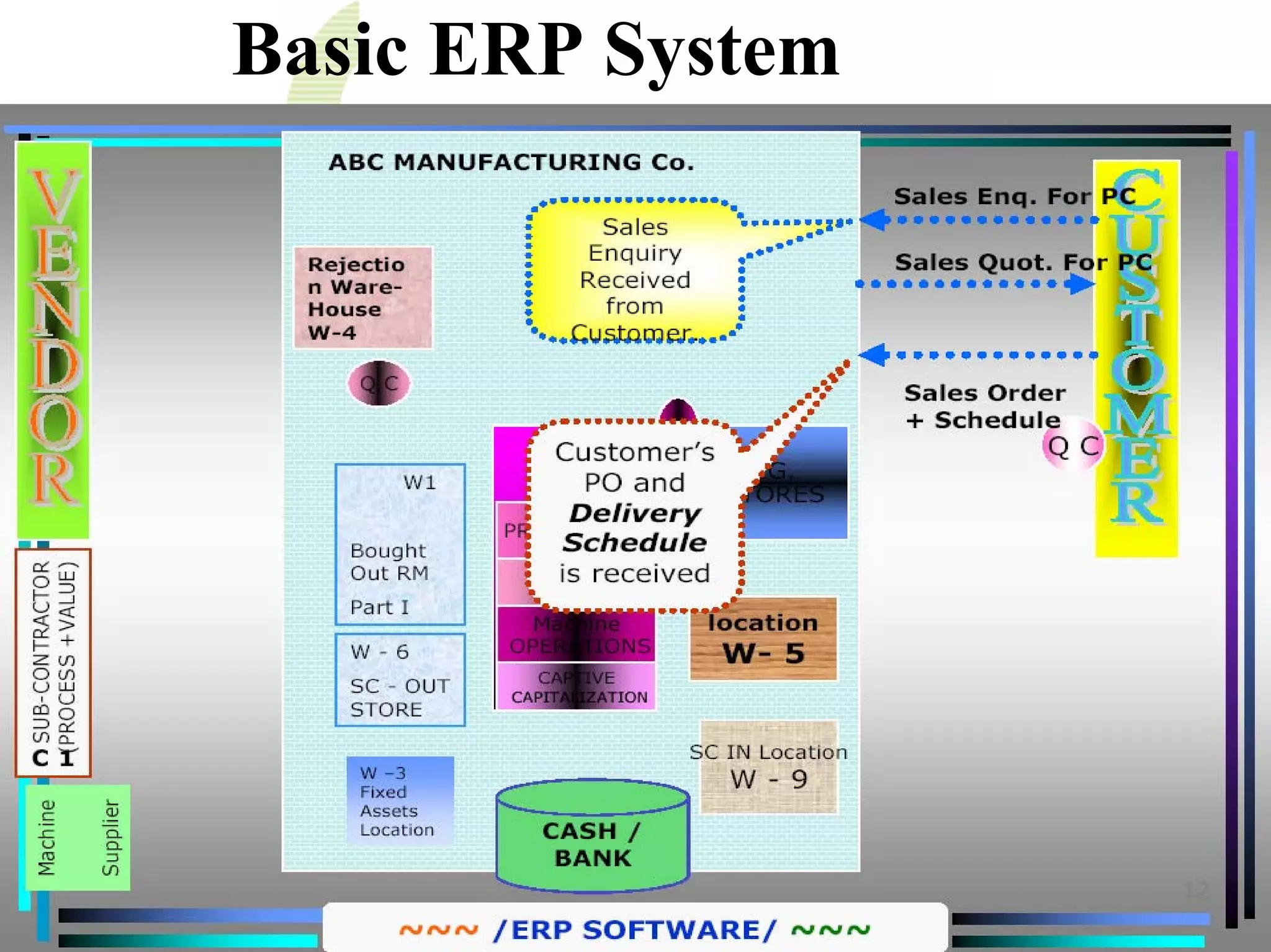

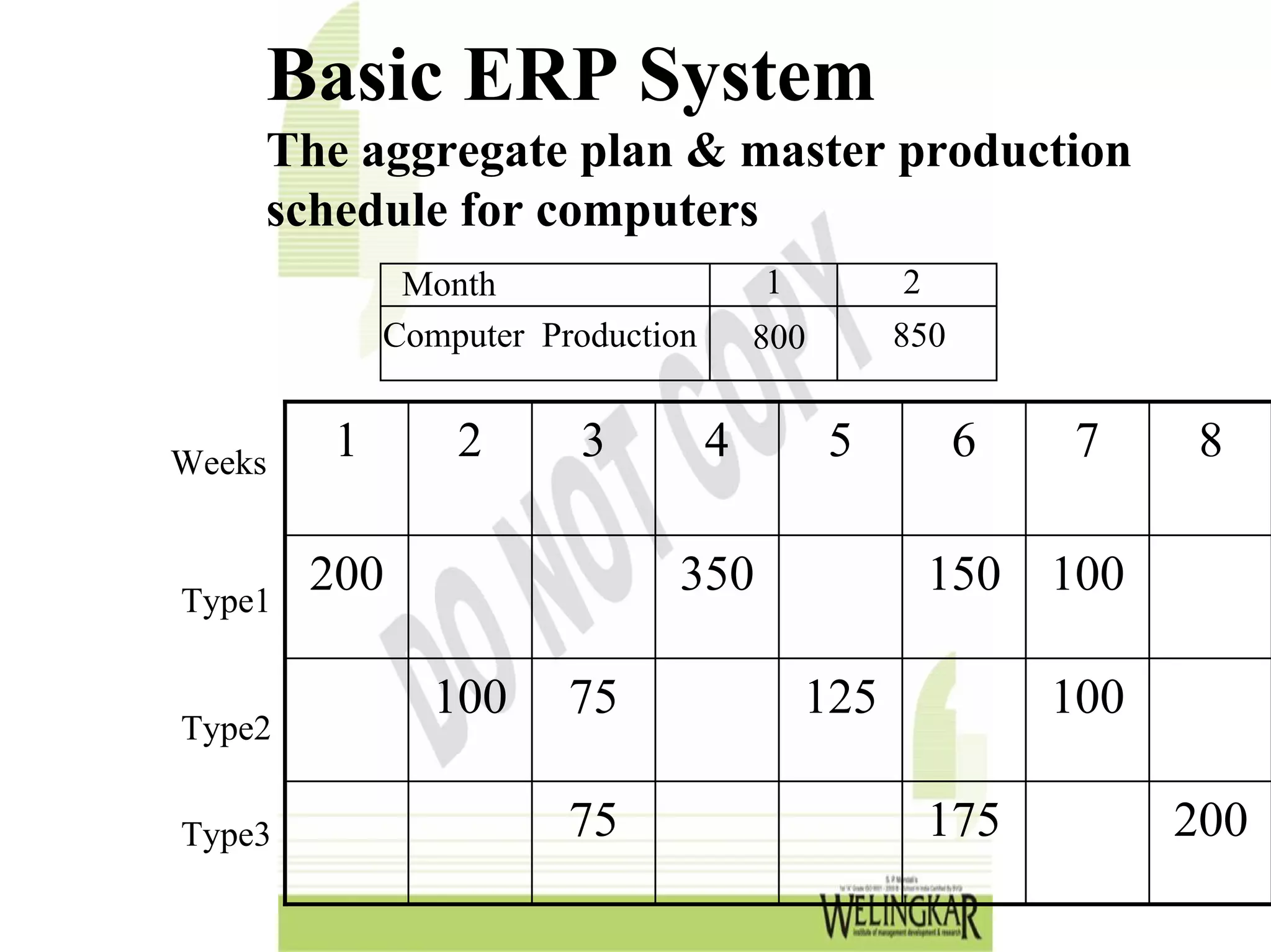

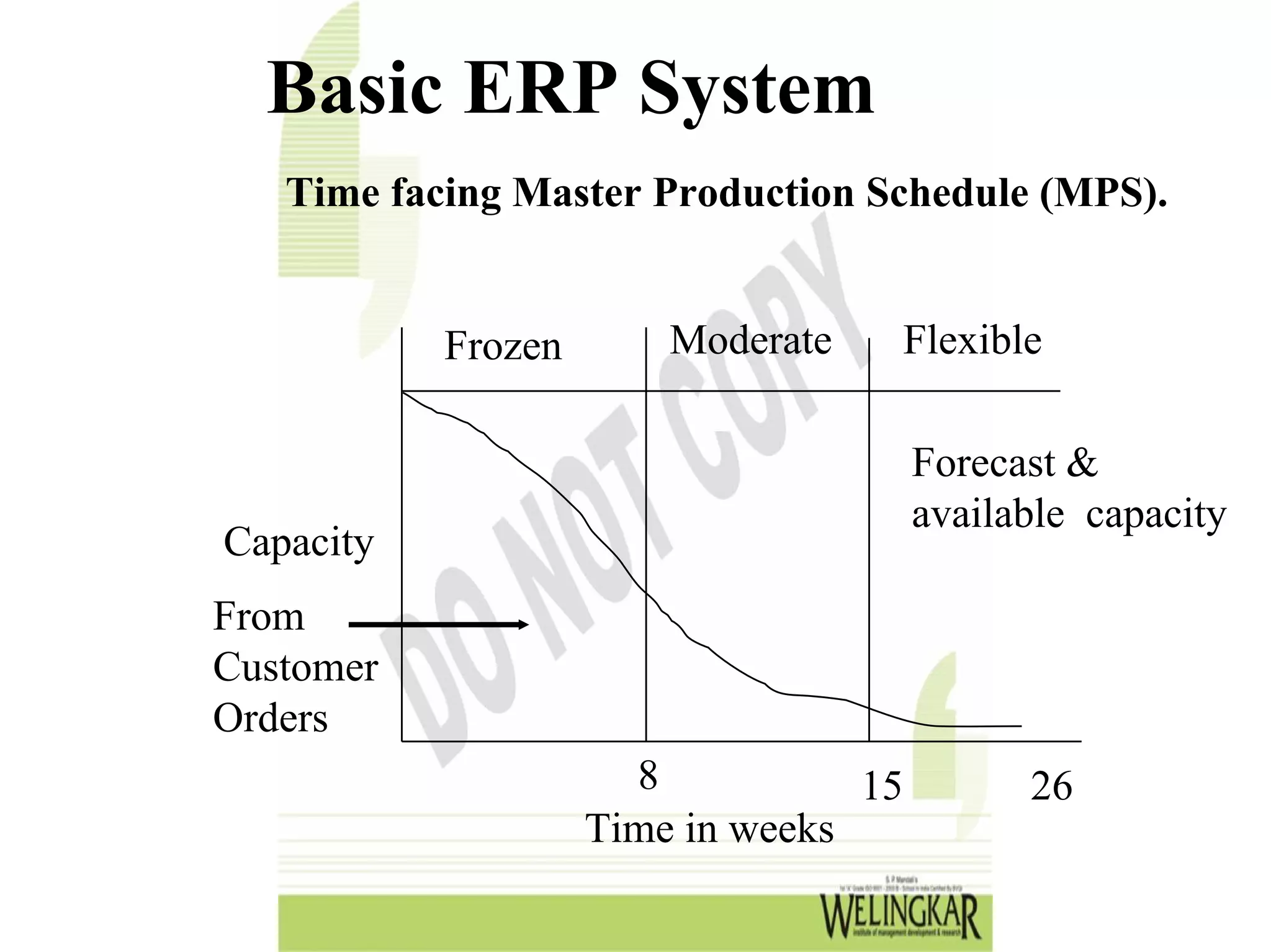

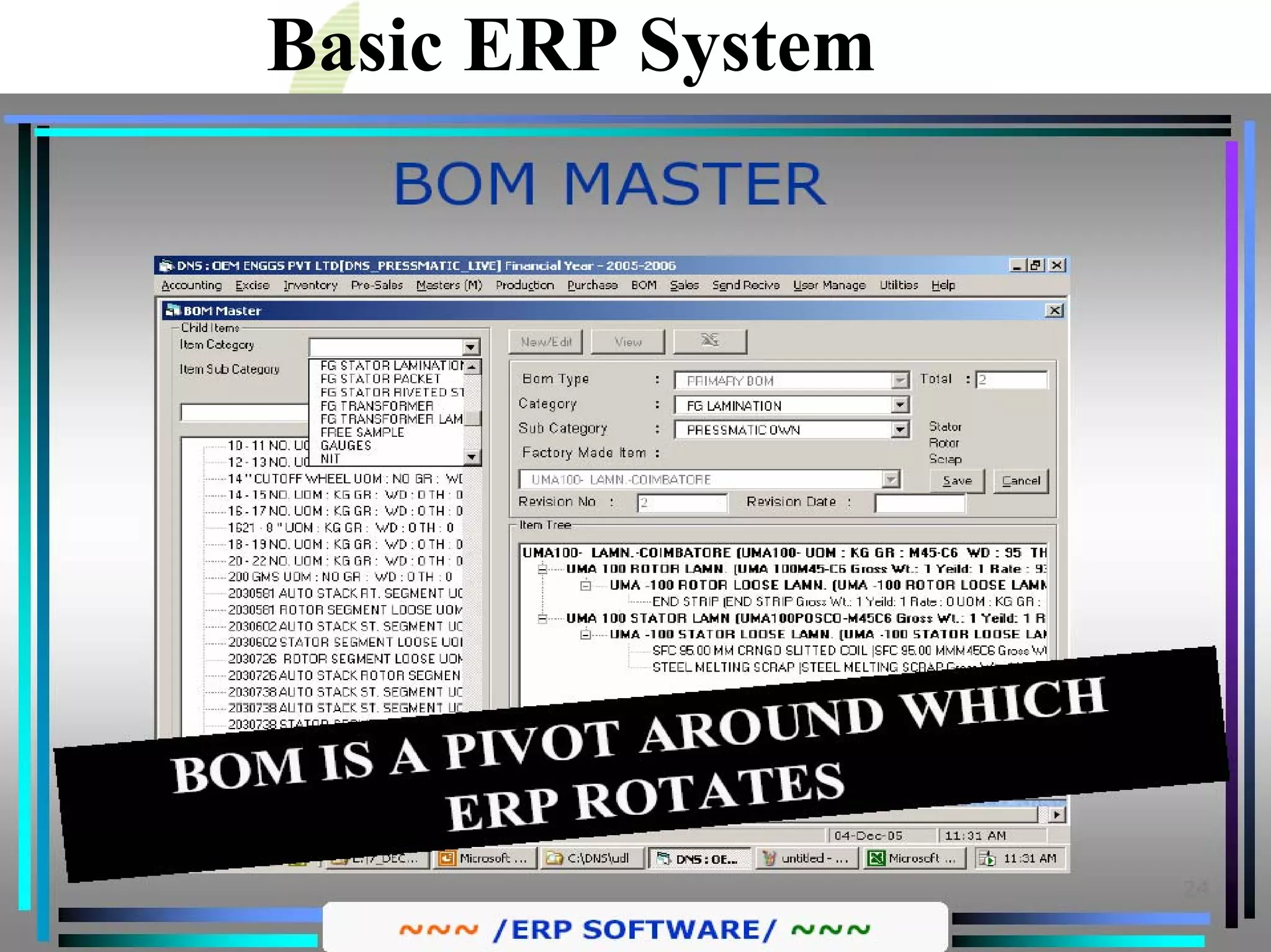

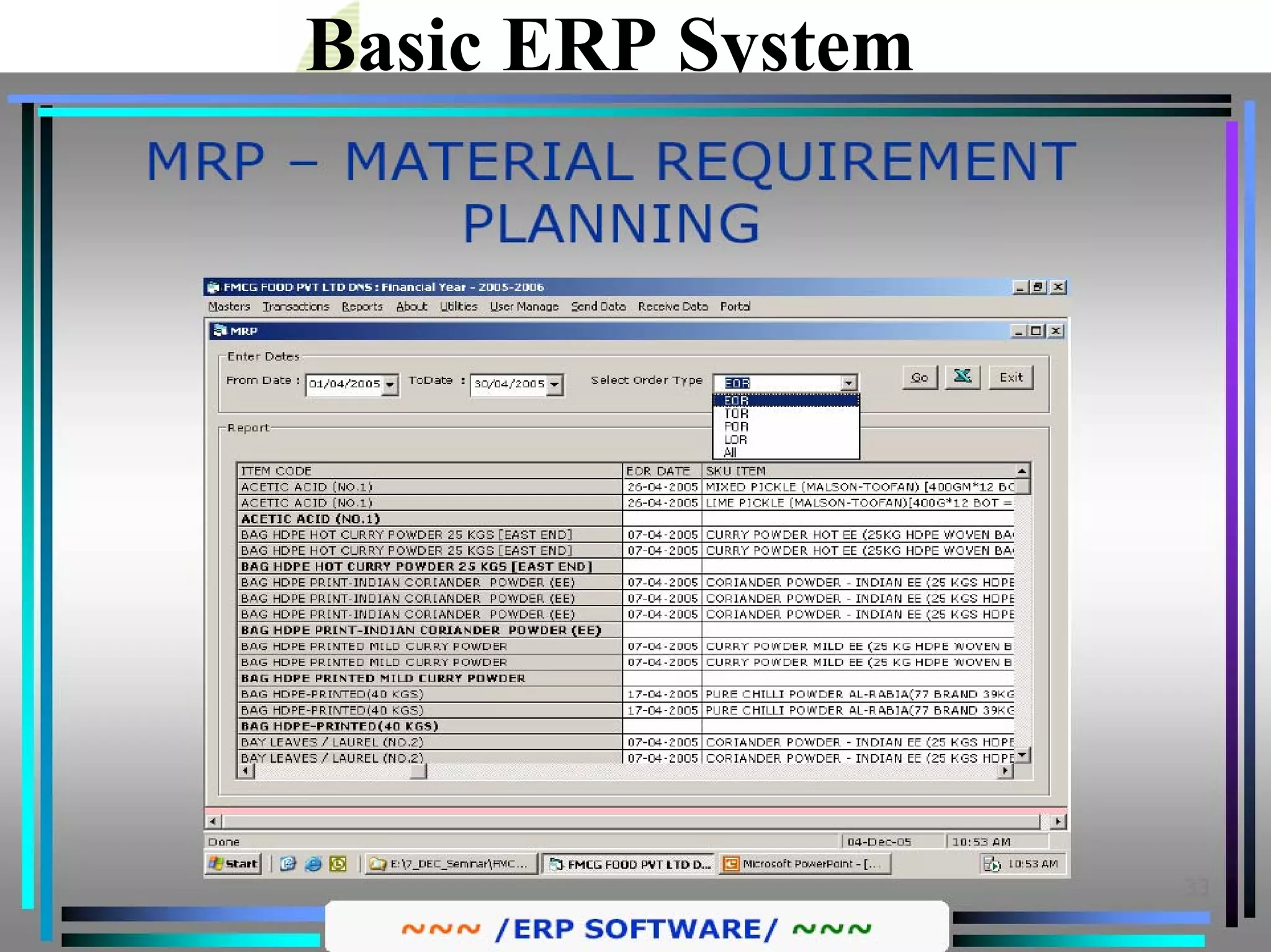

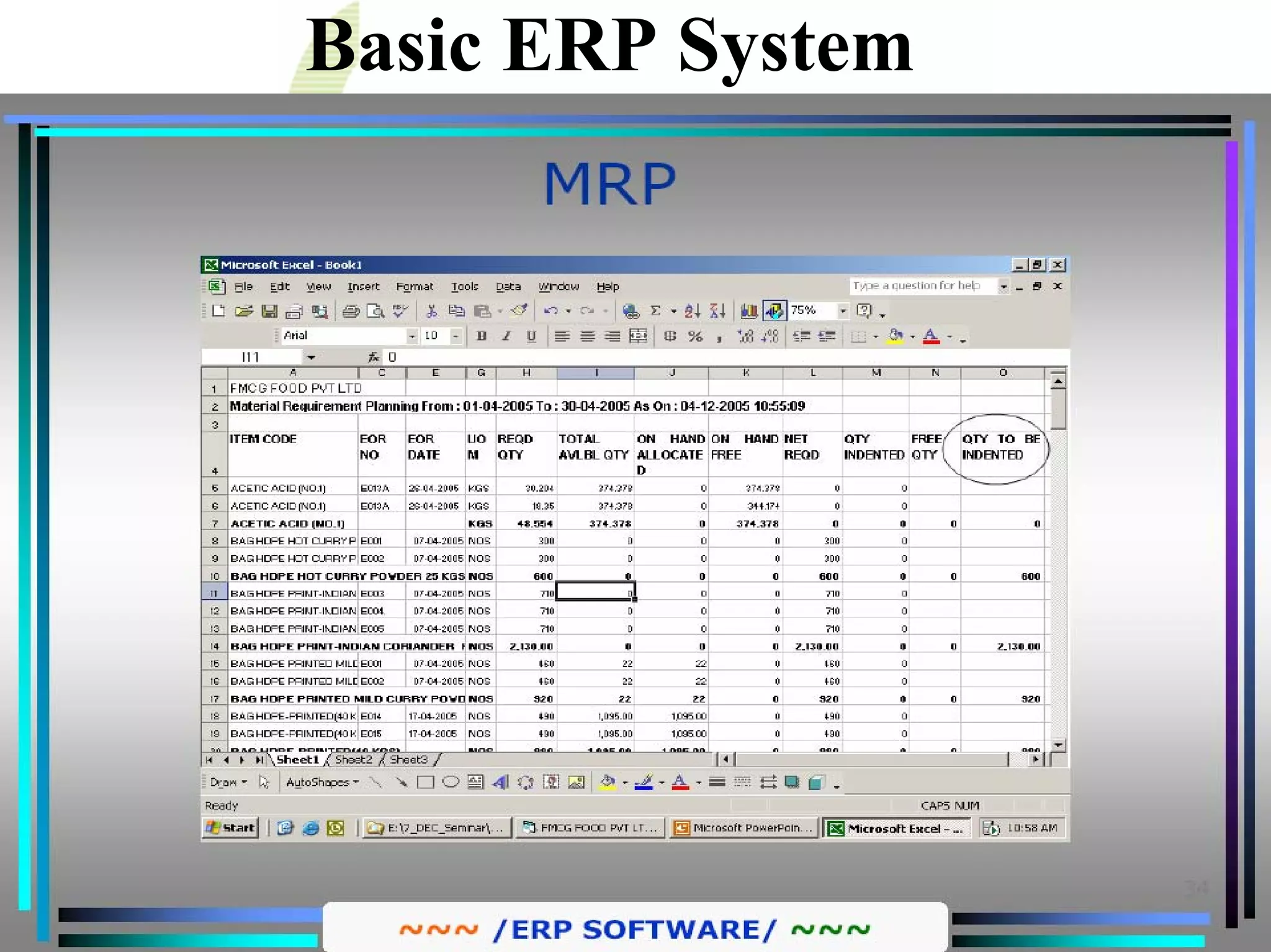

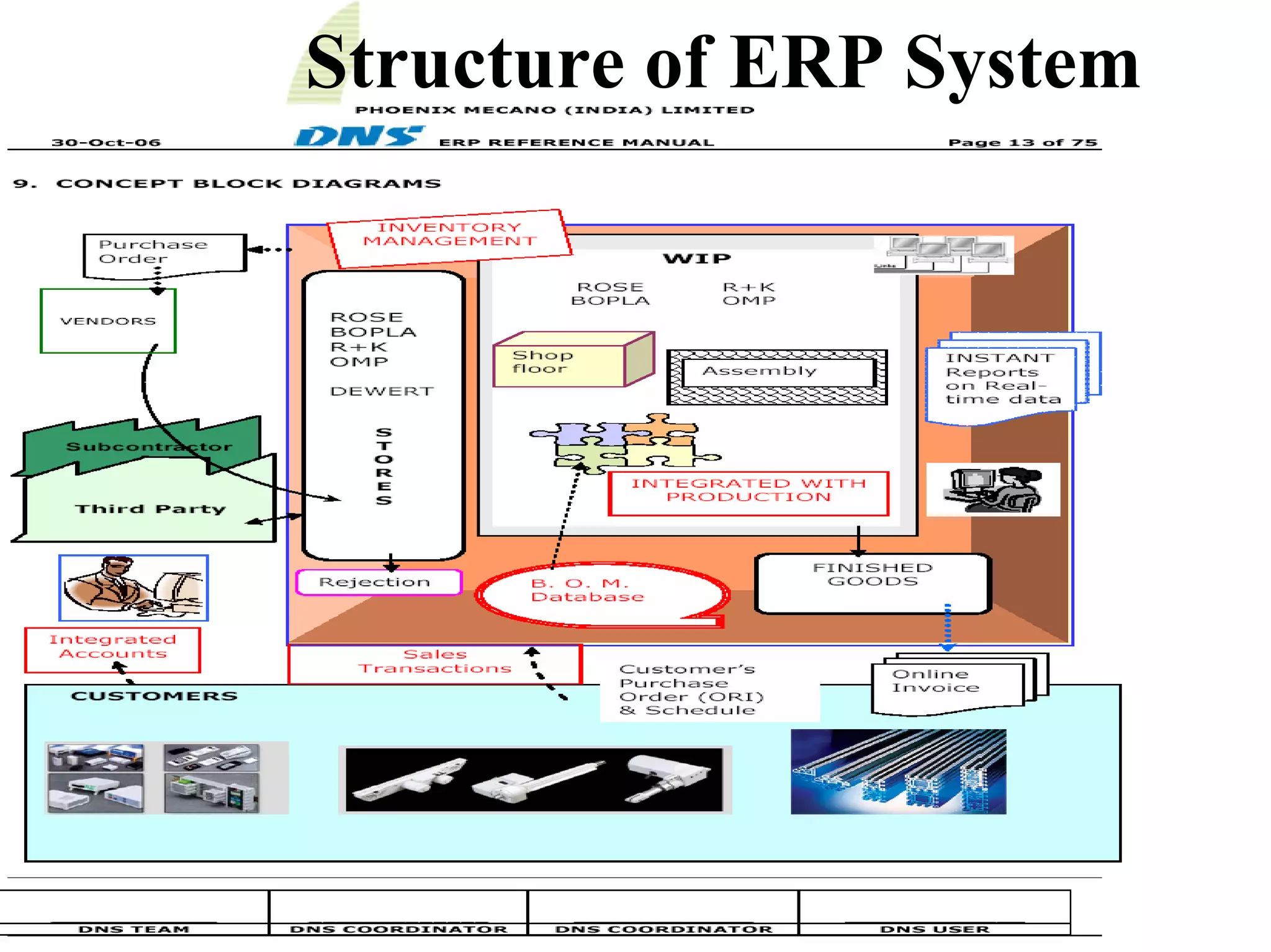

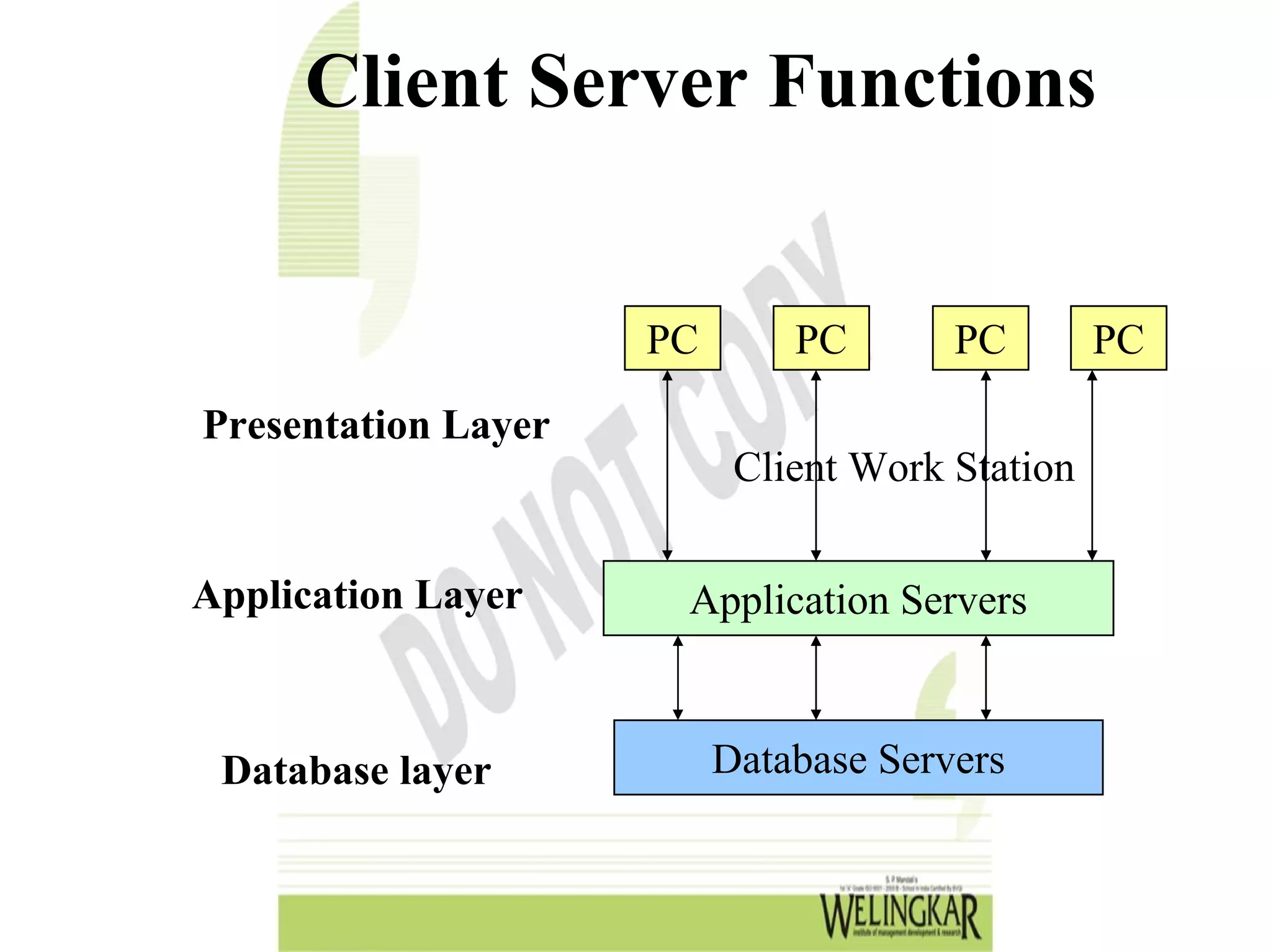

Chapter 3 provides an overview of ERP systems, highlighting their central database which integrates various applications including financial, manufacturing, and HR management. It outlines the four key elements of a basic ERP system: strategic and business planning, sales and operations planning, master production scheduling, and material requirement planning. The chapter also describes the structure of ERP systems, emphasizing the importance of client-server architecture and the roles of different software layers.