Final lab report for thermos 2(mech)

•Download as DOC, PDF•

7 likes•6,944 views

CAPE PENINSULA UNIVERSITY OF TECHONOLOGY DEPARTMENT OF MECHANICAL ENGINEERING THERMODYNAMICS 2 LAB

Report

Share

Report

Share

Recommended

More Related Content

What's hot

What's hot (20)

Pressure distribution along convergent- divergent Nozzle

Pressure distribution along convergent- divergent Nozzle

Thermodynamic Chapter 4 Second Law Of Thermodynamics

Thermodynamic Chapter 4 Second Law Of Thermodynamics

To investigate Fourier’s Law for the linear conduction of heat along a homoge...

To investigate Fourier’s Law for the linear conduction of heat along a homoge...

Presentation on Calculation of Polytropic and Isentropic Efficiency of natura...

Presentation on Calculation of Polytropic and Isentropic Efficiency of natura...

Viewers also liked

With the demand for propylene outpacing the current supply levels, the supply assurance for propylene has become challenging. There are issues concerning the shortage of propylene and its impact on the industry. The paper discusses various feasible alternatives with emphasis on the production of GREEN propylene.Propy-LENE Supply! Go Green! On-Purpose Technologies for the Future

Propy-LENE Supply! Go Green! On-Purpose Technologies for the FutureBeroe Inc - Advantage Procurement

Viewers also liked (20)

Propy-LENE Supply! Go Green! On-Purpose Technologies for the Future

Propy-LENE Supply! Go Green! On-Purpose Technologies for the Future

Similar to Final lab report for thermos 2(mech)

Energy crisis is one of the most important problems

the world is facing now-a-days. With the increase of cost of

electrical energy operating cost of cold storage storing is

increasing which forces the increased cost price of the

commodities that are kept. In this situation if the maximum

heat energy(Q) is absorbed by the evaporator inside the cold

room through convective heat transfer process in terms of –

heat transfer due to convection and heat transfer due to

condensation, more energy has to be wasted to maintain the

evaporator space at the desired temperature range of 2- 8

degree centigrade. In this paper we have proposed a theoretical

heat transfer model of convective heat transfer in cold storage

using Taguchi L9 orthogonal array. Velocity of air (V),

Temperature difference (dT), Relative Humidity (RH) are the

basic variable and three ranges are taken each of them in the

model development. Graphical interpretations from the model

justify the reality through anova and s/n ratio calculation.OPTIMIZATION OF CONVECTIVE HEAT TRANSFER MODEL OF COLD STORAGE USING TAGUCHI ...

OPTIMIZATION OF CONVECTIVE HEAT TRANSFER MODEL OF COLD STORAGE USING TAGUCHI ...International Journal of Technical Research & Application

Similar to Final lab report for thermos 2(mech) (20)

CAPE PENINSULA UNIVERSITY OF TECHONOLOGY DEPARTMENT OF MECHENICAL ENGINEERIN...

CAPE PENINSULA UNIVERSITY OF TECHONOLOGY DEPARTMENT OF MECHENICAL ENGINEERIN...

Photovoltaic thermal (PV/T) collectors with nanofluids and nano-Phase Change ...

Photovoltaic thermal (PV/T) collectors with nanofluids and nano-Phase Change ...

Soil Lab Powerpoint consolidation lab presentation

Soil Lab Powerpoint consolidation lab presentation

THEORETICAL AND EXPERIMENTAL STUDIES ON STEPPED SOLAR STILL

THEORETICAL AND EXPERIMENTAL STUDIES ON STEPPED SOLAR STILL

THEORETICAL AND EXPERIMENTAL STUDIES ON STEPPED SOLAR STILL

THEORETICAL AND EXPERIMENTAL STUDIES ON STEPPED SOLAR STILL

CH EN 3453 Heat Transfer 2014 Fall Utah Homework HW 01 Assignment

CH EN 3453 Heat Transfer 2014 Fall Utah Homework HW 01 Assignment

Title of the ReportA. Partner, B. Partner, and C. Partner.docx

Title of the ReportA. Partner, B. Partner, and C. Partner.docx

OPTIMIZATION OF CONVECTIVE HEAT TRANSFER MODEL OF COLD STORAGE USING TAGUCHI ...

OPTIMIZATION OF CONVECTIVE HEAT TRANSFER MODEL OF COLD STORAGE USING TAGUCHI ...

Recently uploaded

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Process of Integration the Laser Scan Data into FEA Model and Level 3 Fitness-for-Service Assessment of Critical Assets in Refinery & Process IndustriesFEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced LoadsArindam Chakraborty, Ph.D., P.E. (CA, TX)

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call Girl Aurangabad Indira Call Now: 8617697112 Aurangabad Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Aurangabad Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Aurangabad understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Recently uploaded (20)

DC MACHINE-Motoring and generation, Armature circuit equation

DC MACHINE-Motoring and generation, Armature circuit equation

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Hazard Identification (HAZID) vs. Hazard and Operability (HAZOP): A Comparati...

Hazard Identification (HAZID) vs. Hazard and Operability (HAZOP): A Comparati...

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

Standard vs Custom Battery Packs - Decoding the Power Play

Standard vs Custom Battery Packs - Decoding the Power Play

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Final lab report for thermos 2(mech)

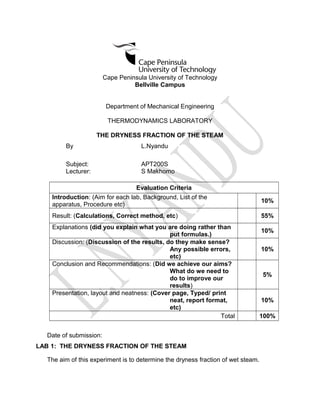

- 1. Cape Peninsula University of Technology Bellville Campus Department of Mechanical Engineering THERMODYNAMICS LABORATORY THE DRYNESS FRACTION OF THE STEAM By L.Nyandu Subject: APT200S Lecturer: S Makhomo Evaluation Criteria Introduction: (Aim for each lab, Background, List of the apparatus, Procedure etc) 10% Result: (Calculations, Correct method, etc) 55% Explanations (did you explain what you are doing rather than put formulas.) 10% Discussion: (Discussion of the results, do they make sense? Any possible errors, etc) 10% Conclusion and Recommendations: (Did we achieve our aims? What do we need to do to improve our results) 5% Presentation, layout and neatness: (Cover page, Typed/ print neat, report format, etc) 10% Total 100% Date of submission: LAB 1: THE DRYNESS FRACTION OF THE STEAM The aim of this experiment is to determine the dryness fraction of wet steam.

- 2. 1. Apparatus • Steam boiler plant. • Separating and throttling calorimeter. • Measuring beaker 2. Theoretical background According to Philip (1998) the separating calorimeter is a vessel used initially to separate some of the moisture from the steam, to ensure superheat conditions after throttling. The steam is made to change direction suddenly; the moisture droplets, being heavier than the vapor, drop out of suspension and are collected at the bottom of the vessel. The throttling calorimeter is a vessel with a needle valve fitted on the inlet side. The steam is throttled through the needle valve and exhausted to the condenser. Suppose M kg of wet steam with a dryness fraction of x enters the separating calorimeter. The vapor part will have a mass of x M kg and the liquid part will have a mass of M kg. In the separating calorimeter part of the liquid, say1 kg will be separated from the wet steam. Hence the dryness fraction of the wet steam will increase to x1 which will pass through the throttling process valve. After the throttling process the steam in the throttling calorimeter will be in superheated state. 3. Procedure 1. Start the boiler and supply steam to the separating and throttling calorimeter unit. 2. Start the cooling water flow through the condenser. 3. Open steam valve and allow the steam to flow through the calorimeters to warm through the steam. 4. Open the throttle valve and adjust to give a pressure at exhaust of about 5cm Hg measured on the manometer. 5. Drain the separating calorimeter. 6. Start the test and take readings at 2-3 minutes intervals. 7. When a reasonable quantity of condensate is collected measure the quantity of separated water and the quantity of condensate.

- 3. Figure2. T-S diagram of the separating and throttling calorimeter. From the steady flow energy equation: Q – W = hC - hB Since throttling takes place over a very small distance, the heat transfer is negligible Q = 0. Then the steady flow energy equation for the throttling process becomes, hC = hB Hence, enthalpy after throttling = enthalpy before throttling hC=hf + xhfg If the pressure of the steam before throttling, the pressure and temperature of the steam after throttling, are known the value of x can be calculated using steam tables. Dryness Fraction = Therefore, ws s o mm m x + = Where, Ms the mass of dry steam and Mw is the mass of suspended water separated from the calorimeter. Results ● C A B ● ● P2 P1 T2 T1 T S

- 4. Absolute Pressure = Gauge Pressure + Atmospheric pressure = = = 841.33 KPa and = 30 KPa = 112.5 and = 69.06 The above written values were calculated using interpolation method and values from the steam tables. Separating calorimeter only (xo): Ms: 1830mL = 1.83L = 1.83 Mw: 94mL = 0.94L= 0.94 = = = 0.95 Throttling calorimeter only x1 Specific enthalpy before throttling at P1 = specific enthalpy after throttling at P2 (Using interpolation) = + = =

- 5. This means it lies outside the dome = = 0,951 Table 1: Lab readings Reading Units Volume of Steam (Vs) 0.00183 m3 Volume of Water (Vw) 0.000094 m3 Pressure before throttling (P1) 840 kPa Pressure After throttling (P2) 30 kPa Temperature of steam before throttling (t1) 112,5 o C Temperature of steam After throttling (t2) 69,06 o C 4. Discussion Using the readings that were recorded in the lab the dryness fraction of the steam could be found, using the theoretical equations. From the results obtained the dryness fraction is 0.957 at x0 and 1.0064 at x1. The combined separating and throttling calorimeter was found by using equation 7 where both x0 and x1 were multiplied to get 0.951. 5. Conclusion It can be concluded that the experiment was successful. The dryness fraction of the steam was found using the readings found in the lab. 6. Recommendations The equipment in the lab should be either replaced or maintained in order to get more accurate readings. The students should be given the opportunity to record more than one value per reading so a mean can be obtained or so that there can be more certainty for each reading.

- 6. Cape Peninsula University of Technology Bellville Campus Department of Mechanical Engineering THERMODYNAMICS LABORATORY THE ENTHALPIES AND ENTROPIES By Student name Student no Signature L. Nyandu Subject: APT200S Lecturer: S Makhomo Evaluation Criteria Introduction: (Aim for each lab, Background, List of the apparatus, Procedure etc) 10% Result: (Calculations, Correct method, etc) 55% Explanations (did you explain what you are doing rather than put formulas.) 10% Discussion: (Discussion of the results, do they make sense? Any possible errors, etc) 10% Conclusion and Recommendations: (Did we achieve our aims? What do we need to do to improve our results) 5% Presentation, layout and neatness: (Cover page, Typed/ print neat, report format, etc) 10% Total 100% Date of submission: LAB 2. THE ENTHALPIES AND ENTROPIES

- 7. (a) = 740 + 101 = 840 KPa = 0.841 MPa = 6.835688 = + x.Sfg = 0.2821 + x (8.40686) X = 0.78 @ = . 4.187 x 18 = 75.366 KJ/Kg = 75,36 + 0.78 (2458,26) = 1987,89 KJ/Kg = = 2382,89 KJ/Kg = 6.835688 @ =210 (b) @ =

- 8. = 0.2677 + 0.78(8,334) = 6.835 KJ/Kg @ (C) = - = 1987.89 -75.366 = 1912.526 KJ/Kg = - = 2382.89 – 75.366 = 2307.53 KJ/Kg = - = 2860.29 – 75.366 = 2785.03 KJ/Kg (d) = - = 6.835 – 0.2677

- 9. = 6.557 KJ/Kg = 8.1763 – 0.2677 = 7.9086 KJ/Kg = 6.8345 – 0.2677 = 6.567KJ/Kg (e) = - = 2382.89 – 1987.89 = 395 KJ/Kg = - = 2860.296 – 1987.89 = 872.405 KJ/Kg

- 10. (f) = 8.1263 – 6.83 = 1.341 KJ/Kg = 6.835688 – 6.835688 = 0KJ/Kg Lab 2 readings Readings Units Boiler Pressure 841 kPa Temperature of feed water (to) 18 o C Temperature of superheated steam (tf) 210 o C

- 11. Cape Peninsula University of Technology Bellville Campus Department of Mechanical Engineering THERMODYNAMICS LABORATORY BOILER EFFICIENCY & CONDENSERS By Student name Student no Signature L.Nyandu Subject: APT200S Lecturer: S Makhomo Evaluation Criteria Introduction: (Aim for each lab, Background, List of the apparatus, Procedure etc) 10% Result: (Calculations, Correct method, etc) 55% Explanations (did you explain what you are doing rather than put formulas.) 10% Discussion: (Discussion of the results, do they make sense? Any possible errors, etc) 10% Conclusion and Recommendations: (Did we achieve our aims? What do we need to do to improve our results) 5% Presentation, layout and neatness: (Cover page, Typed/ print neat, report format, etc) 10% Total 100% Date of submission:

- 12. LAB 3. THE EFFICIENCIES Boiler efficiency Equivalent Evaporation Rackine efficiency

- 13. Lab 3 readings Readin g Units Volume of fuel 5.9 x10-4 m3 Time 2.22 min Mass flow rate of steam 318.18 kg/h CV of fuel 45.5 MJ/kg Density of fuel 0.84 kg/L Cape Peninsula University of Technology Bellville Campus Department of Mechanical Engineering THERMODYNAMICS LABORATORY BOILER EFFICIENCY & CONDENSERS

- 14. By Student name Student no Signature L.Nyandu Subject: APT200S Lecturer: S Makhomo Evaluation Criteria Introduction: (Aim for each lab, Background, List of the apparatus, Procedure etc) 10% Result: (Calculations, Correct method, etc) 55% Explanations (did you explain what you are doing rather than put formulas.) 10% Discussion: (Discussion of the results, do they make sense? Any possible errors, etc) 10% Conclusion and Recommendations: (Did we achieve our aims? What do we need to do to improve our results) 5% Presentation, layout and neatness: (Cover page, Typed/ print neat, report format, etc) 10% Total 100% Date of submission:

- 15. LAB 4. THE CONDENSERS Pressure inside the condenser Dryness fraction of turbine exhaust steam entering condenser (a) Condenser efficiency(ηc) Vacuum efficiency (ηvac) Pa = ρmghm = 13.6 x 9.81x hm(m) / 1000

- 16. Note: Relative density of mercury is 13.6 PA = Pg + 0.133h (kPa) or PA = Pg + hm / 7.5 (kPa) Lab 4 readings Readin g Units Mass flow rate of cooling water (Mc/w) 5.09 kg/min Inlet temperature to condenser of cooling water (tw1) 21 o C Outlet temperature to condenser of cooling water (tw2) 27 o C Condenser Pressure (Pc) 75 kPa Condensate Temperature (tk) 46 o C