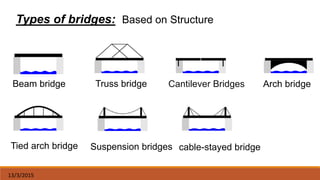

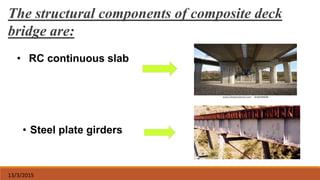

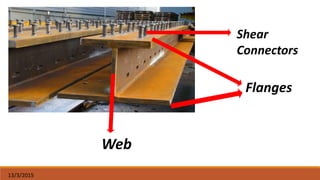

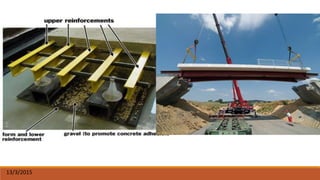

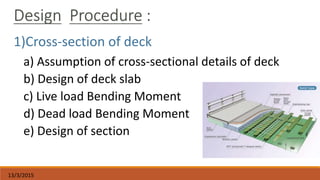

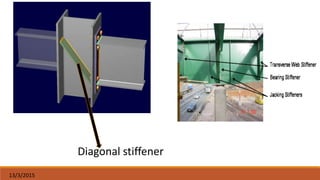

This document provides information about the design of a composite deck bridge. It includes an abstract describing the key components of a composite deck bridge. The introduction defines different bridge types. The main body describes the structural components of a composite deck bridge, including the RC slab, steel girders, and shear connectors. It outlines the design procedure and provides literature references. The conclusion indicates that site data will be collected and a composite deck bridge will be analyzed and designed using MIDAS software.