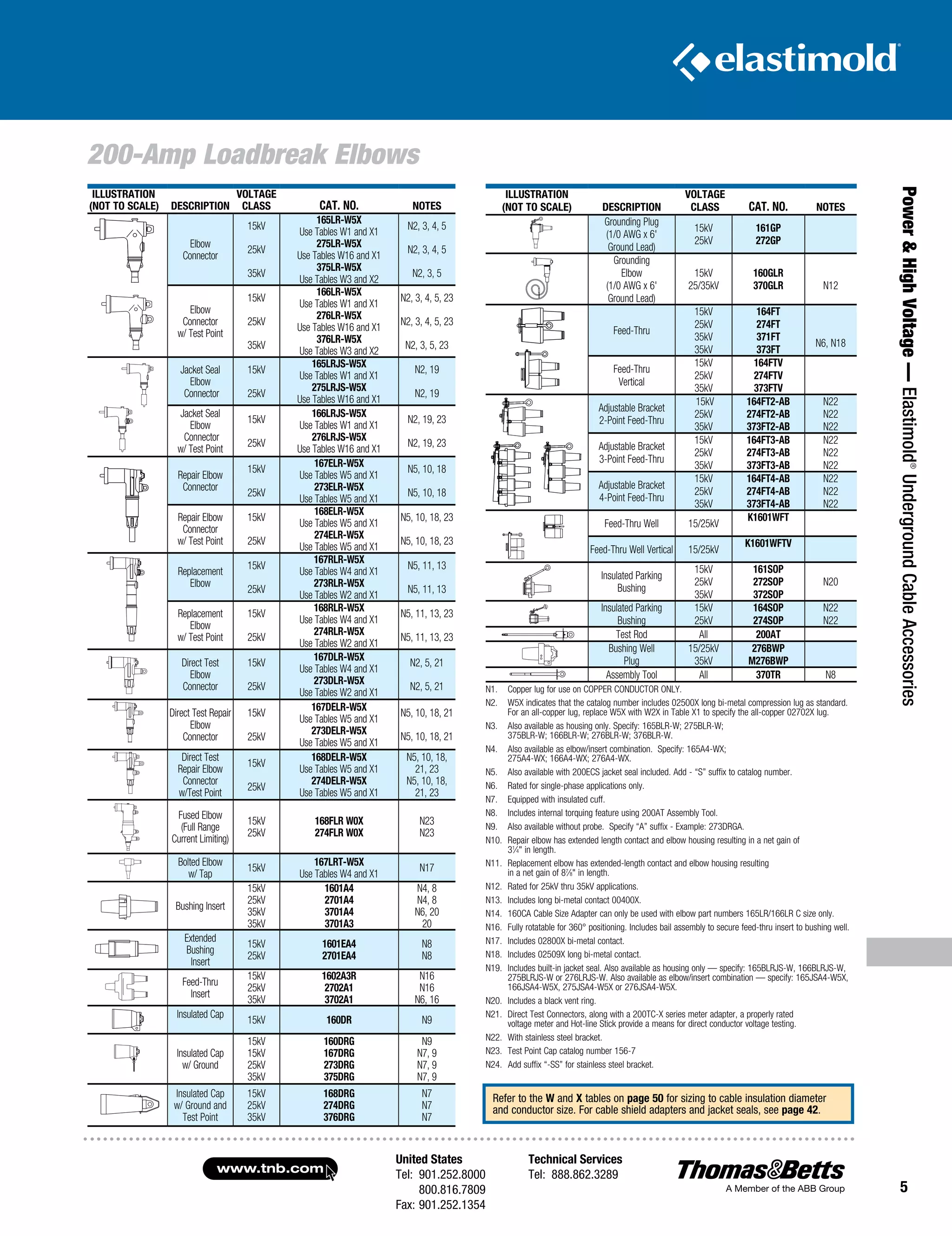

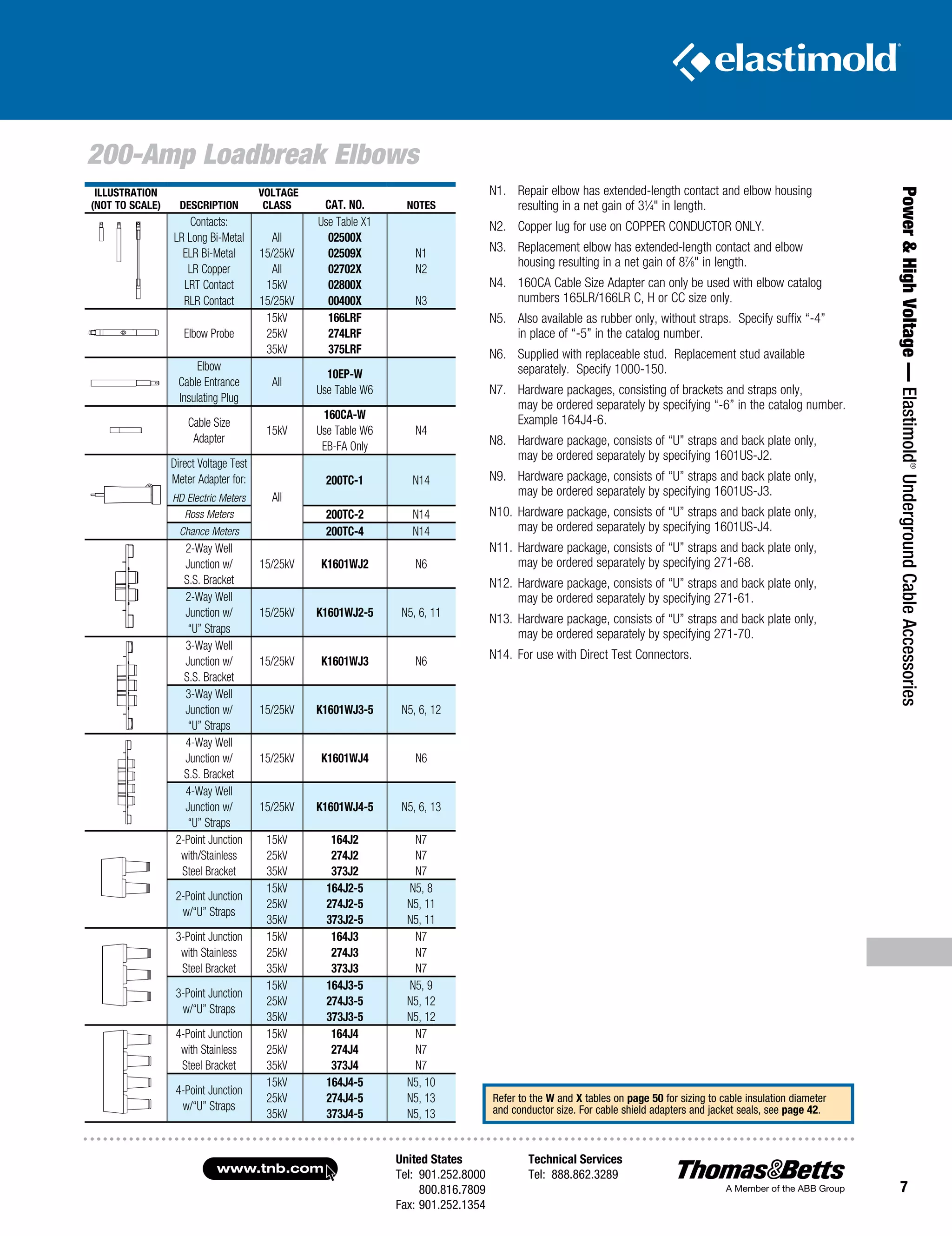

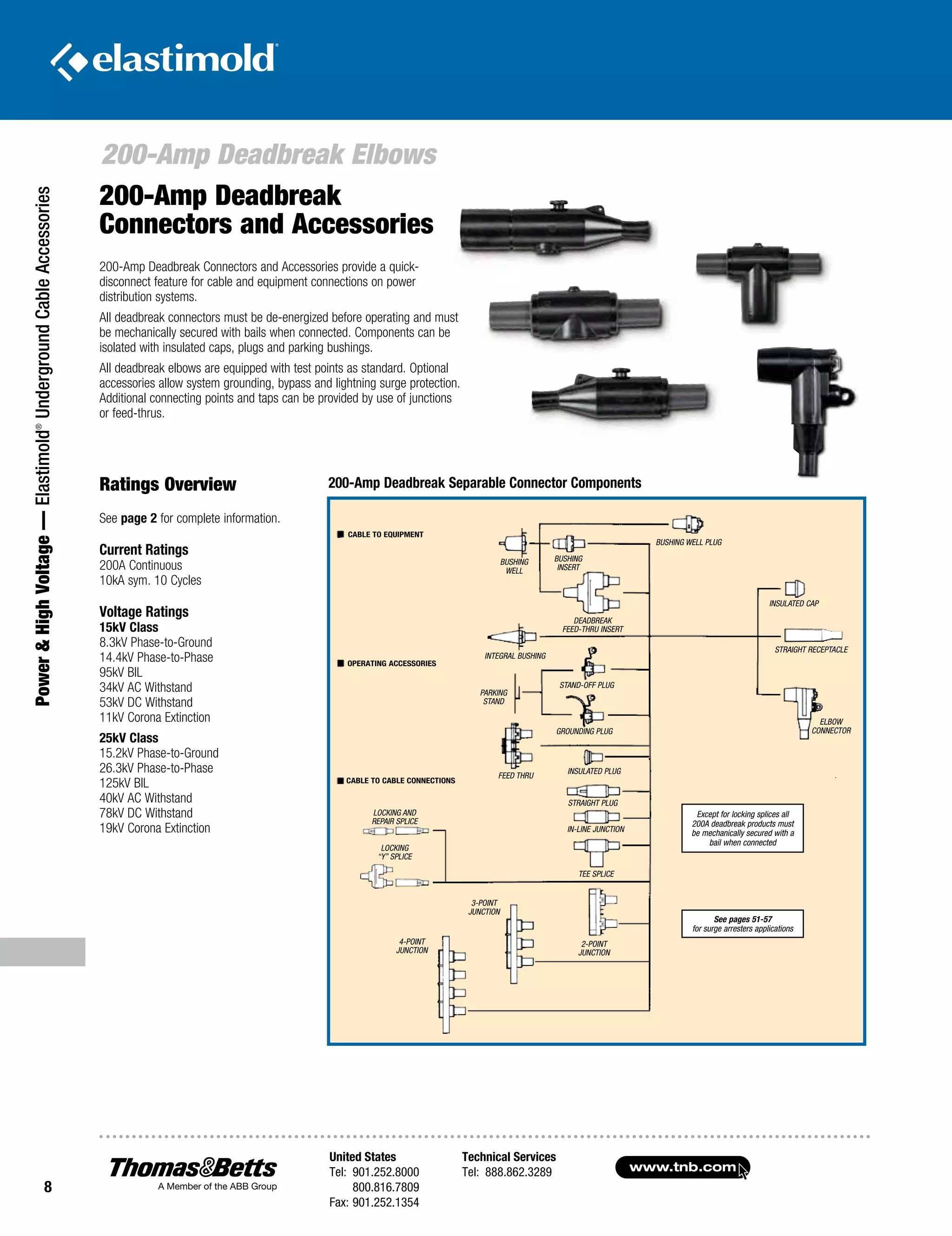

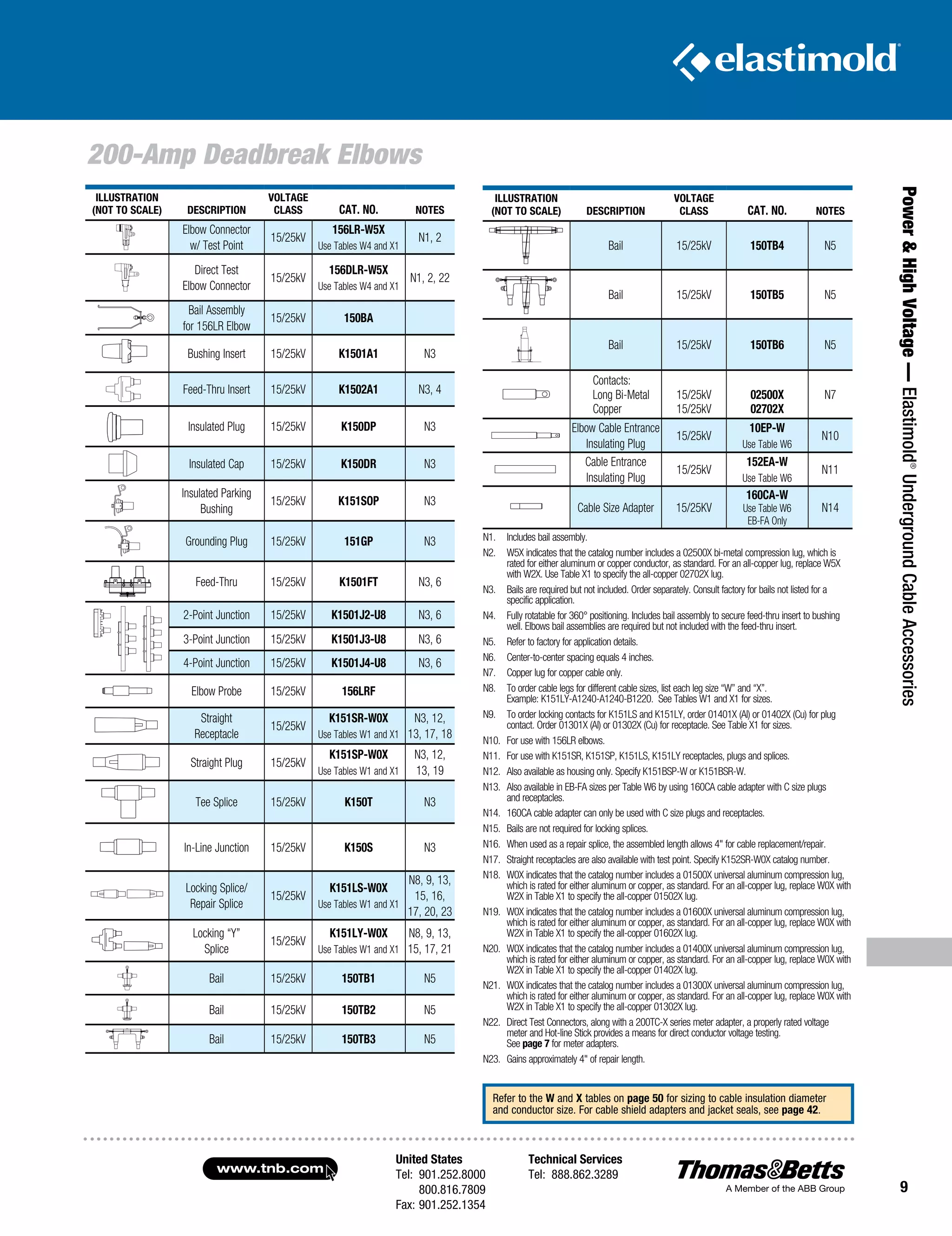

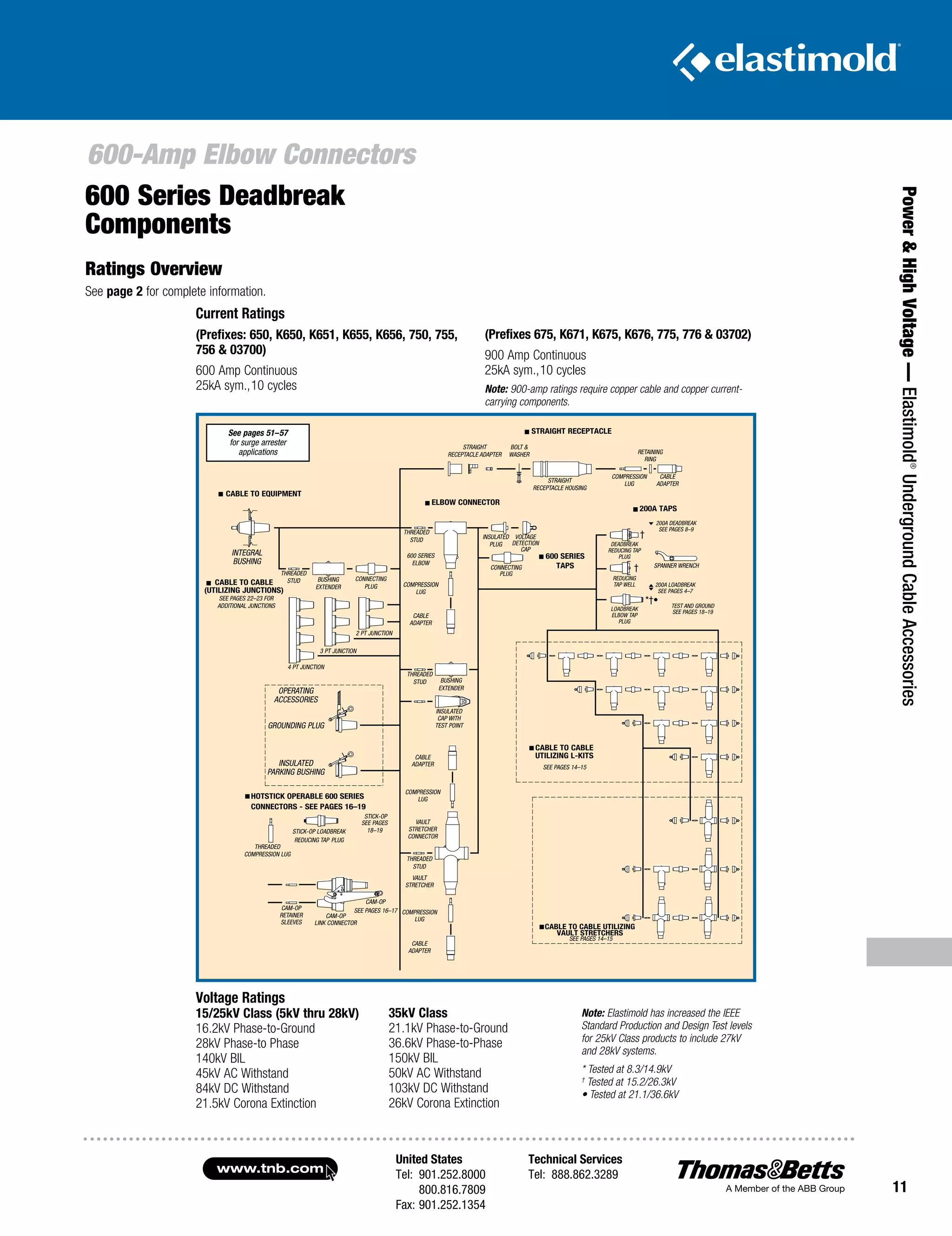

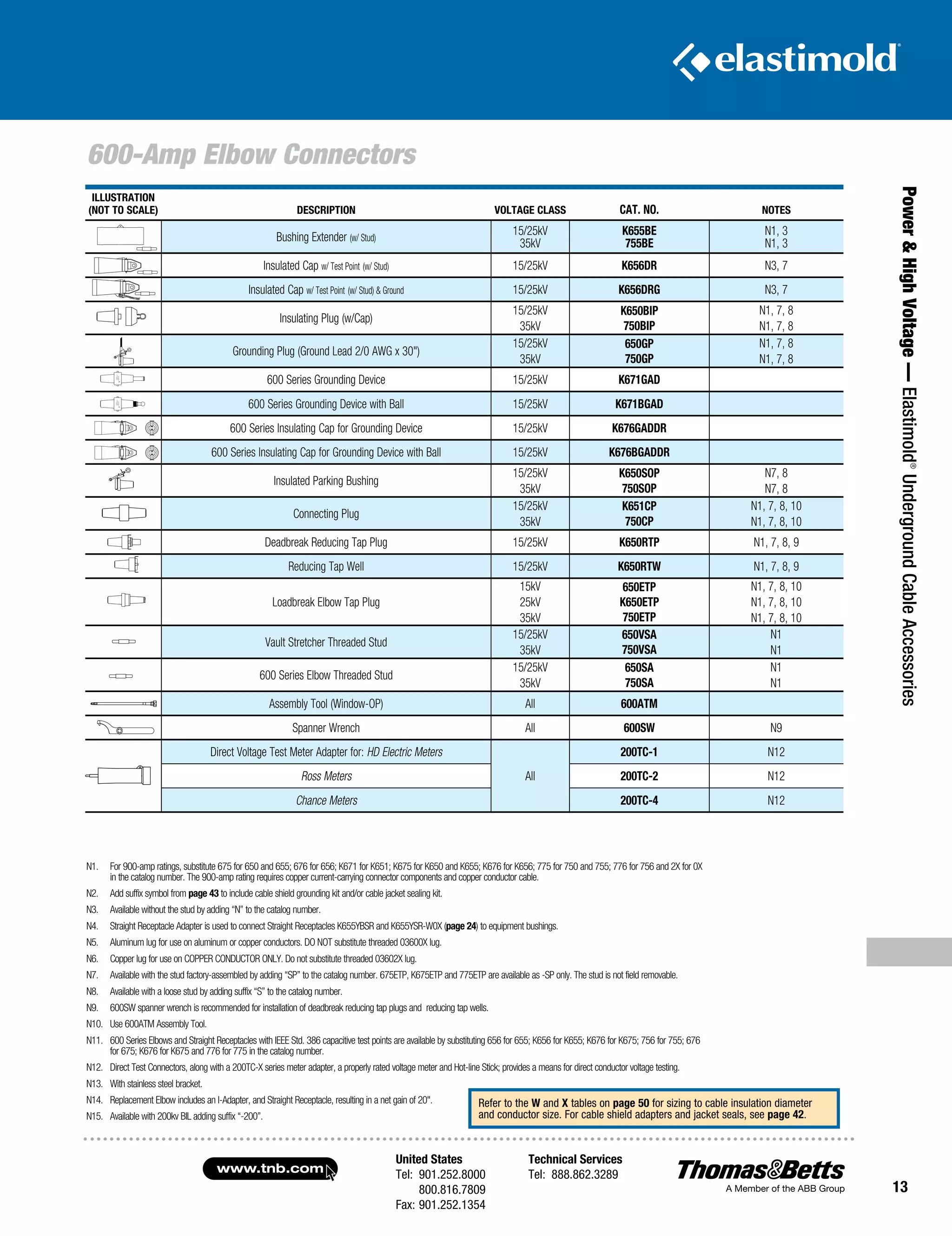

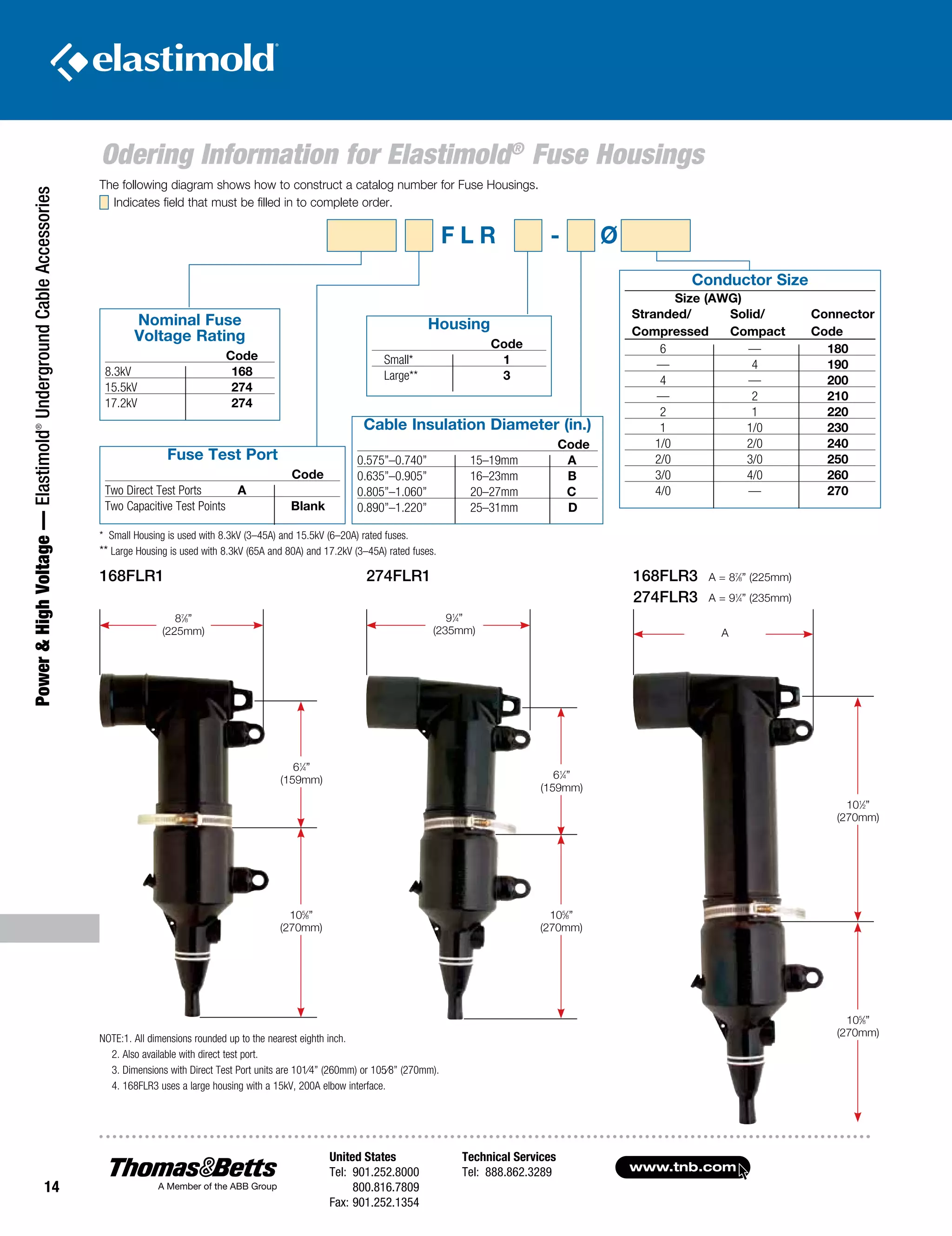

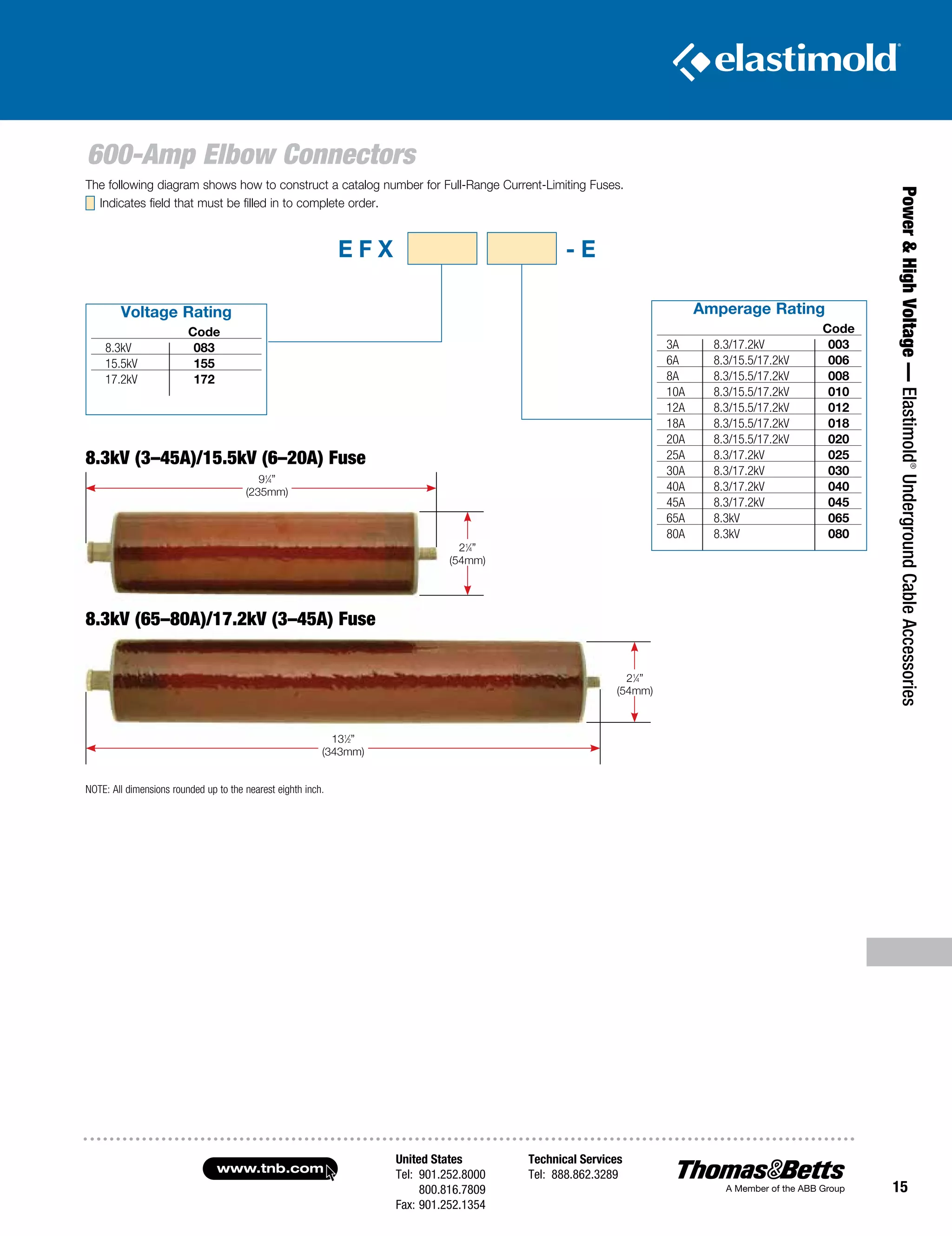

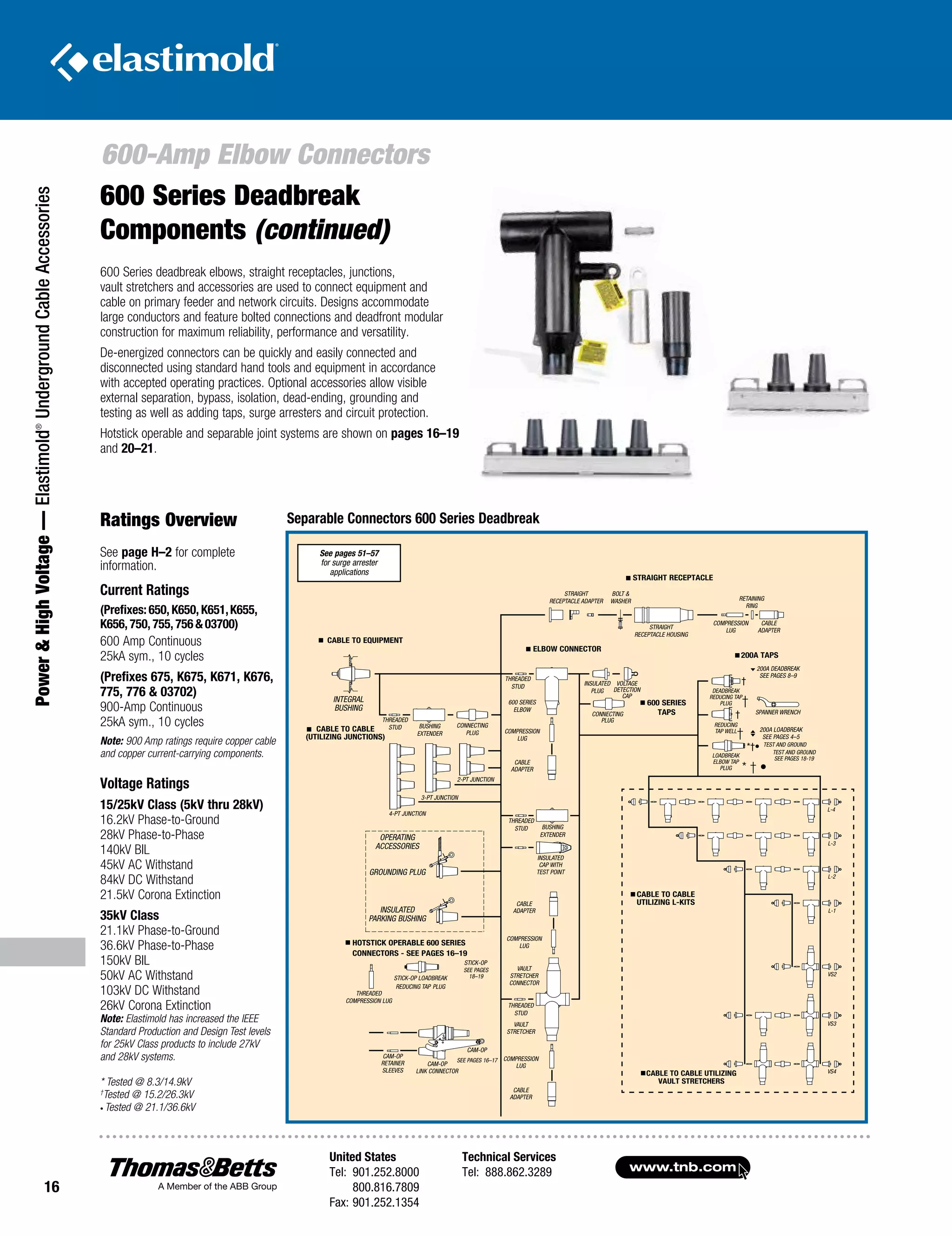

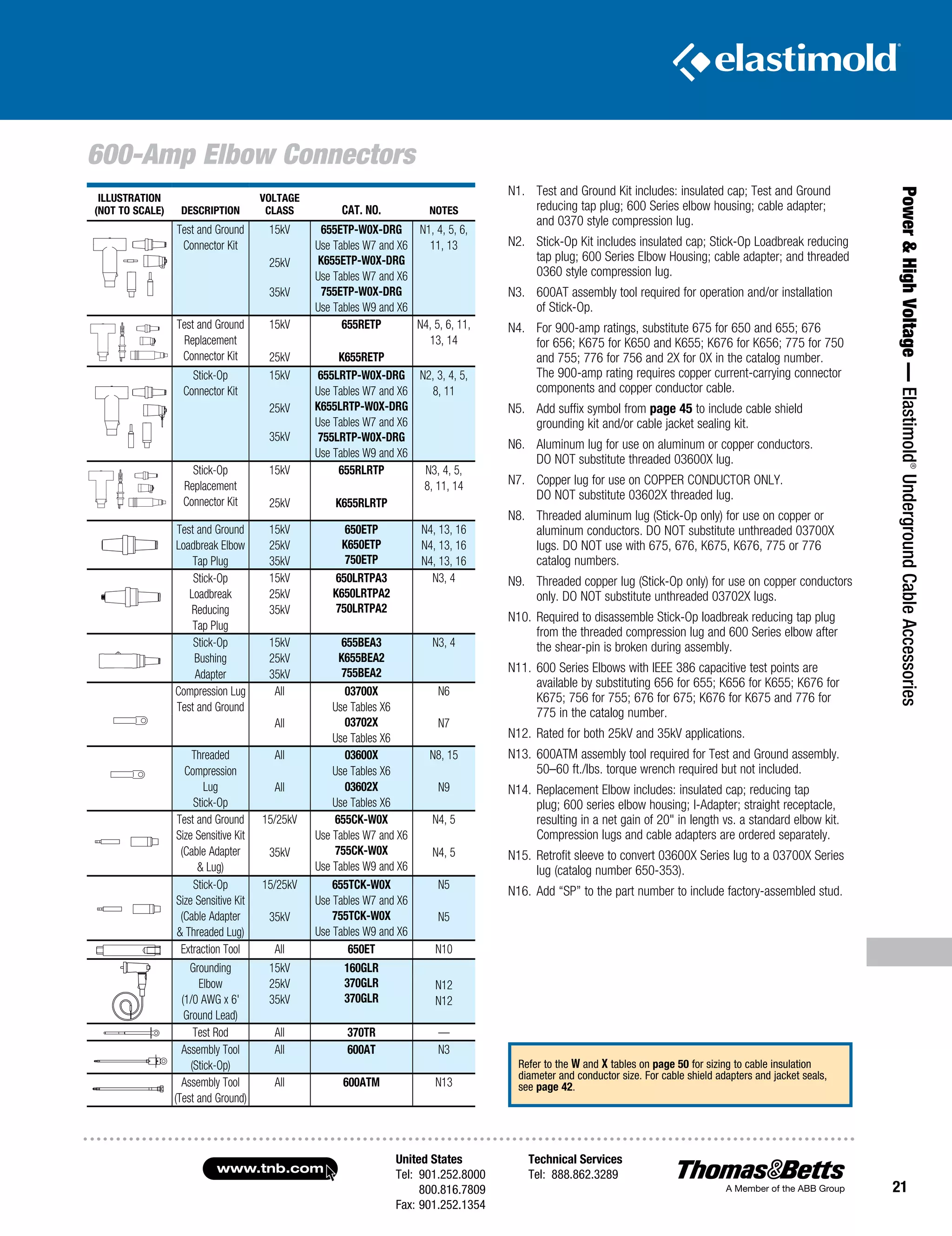

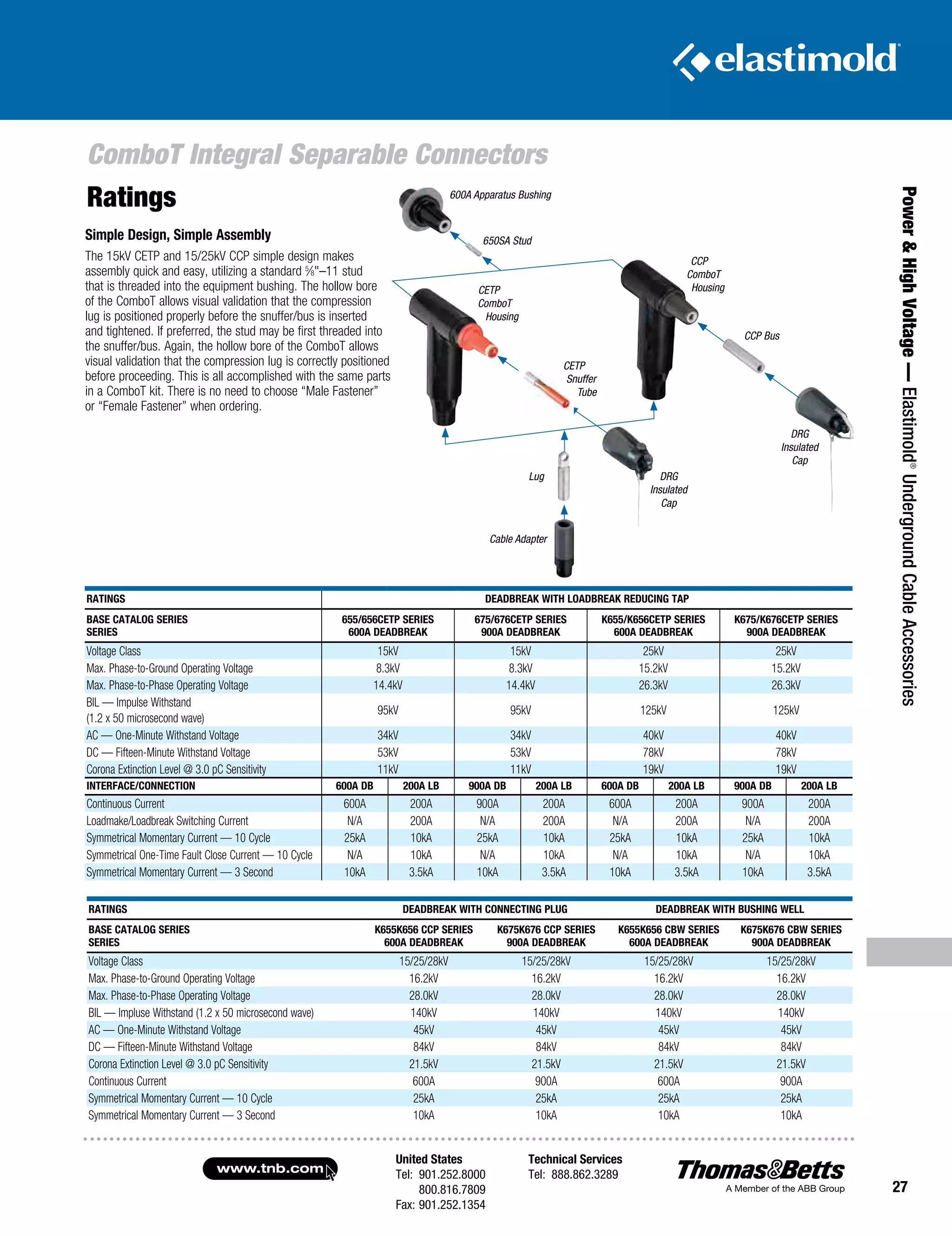

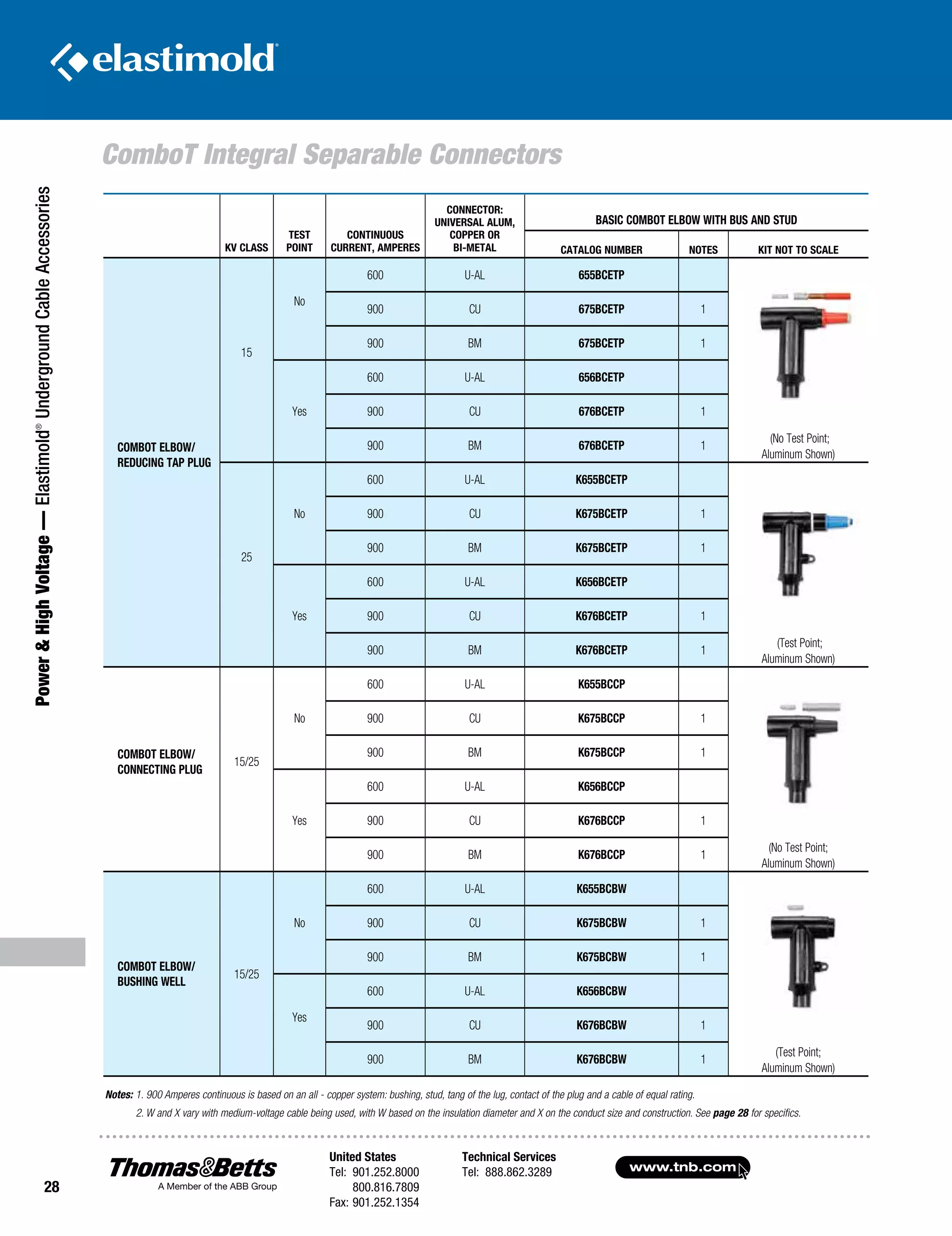

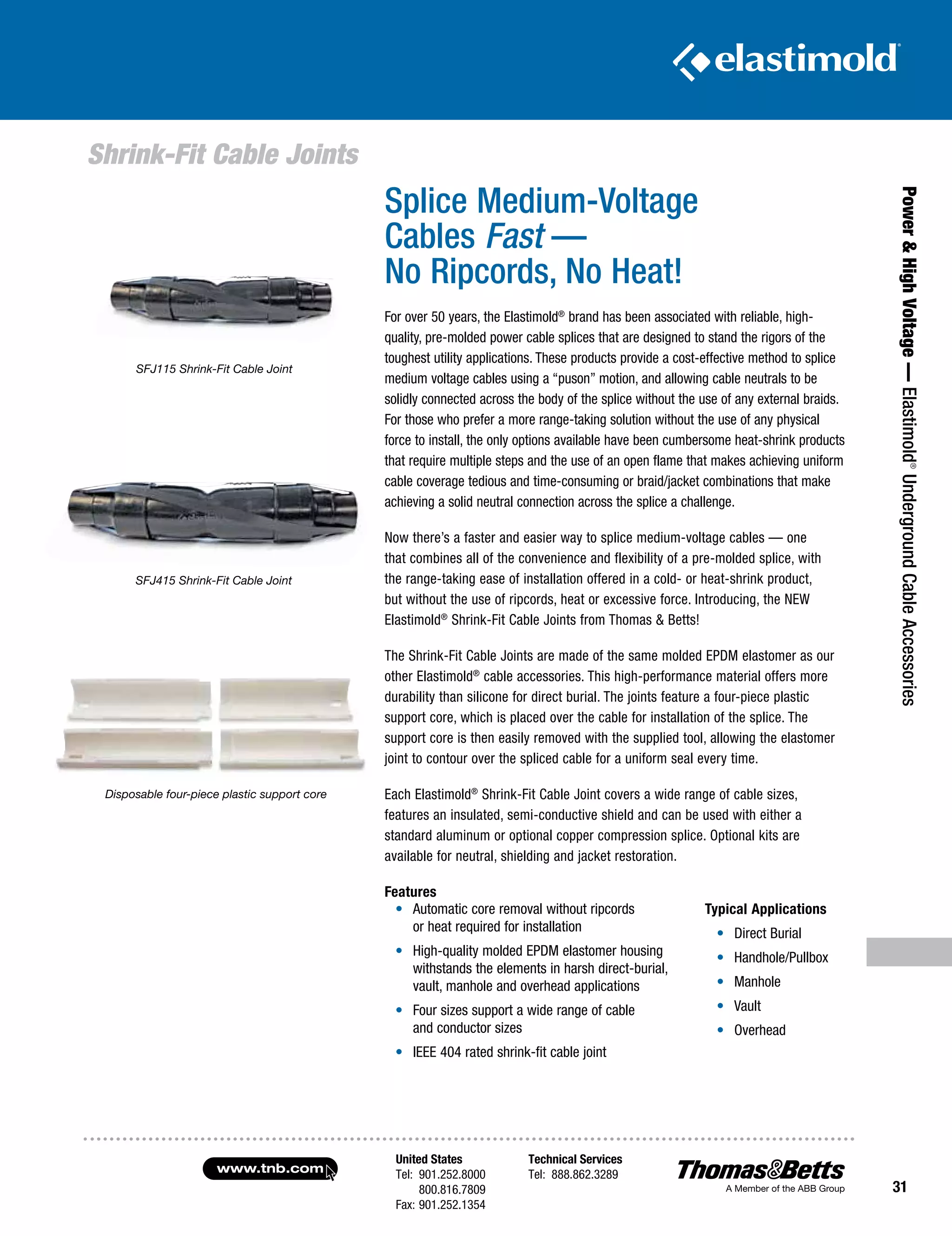

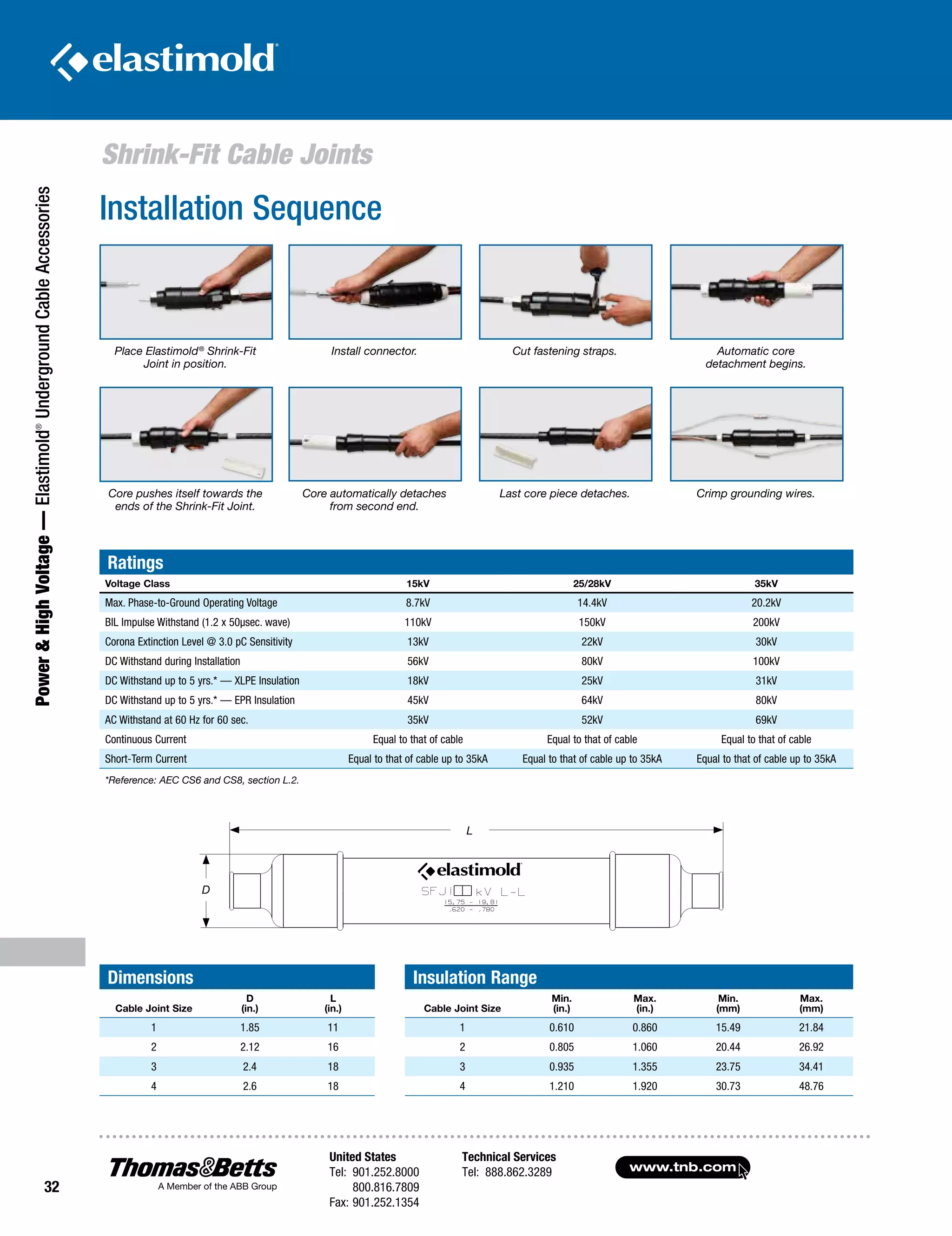

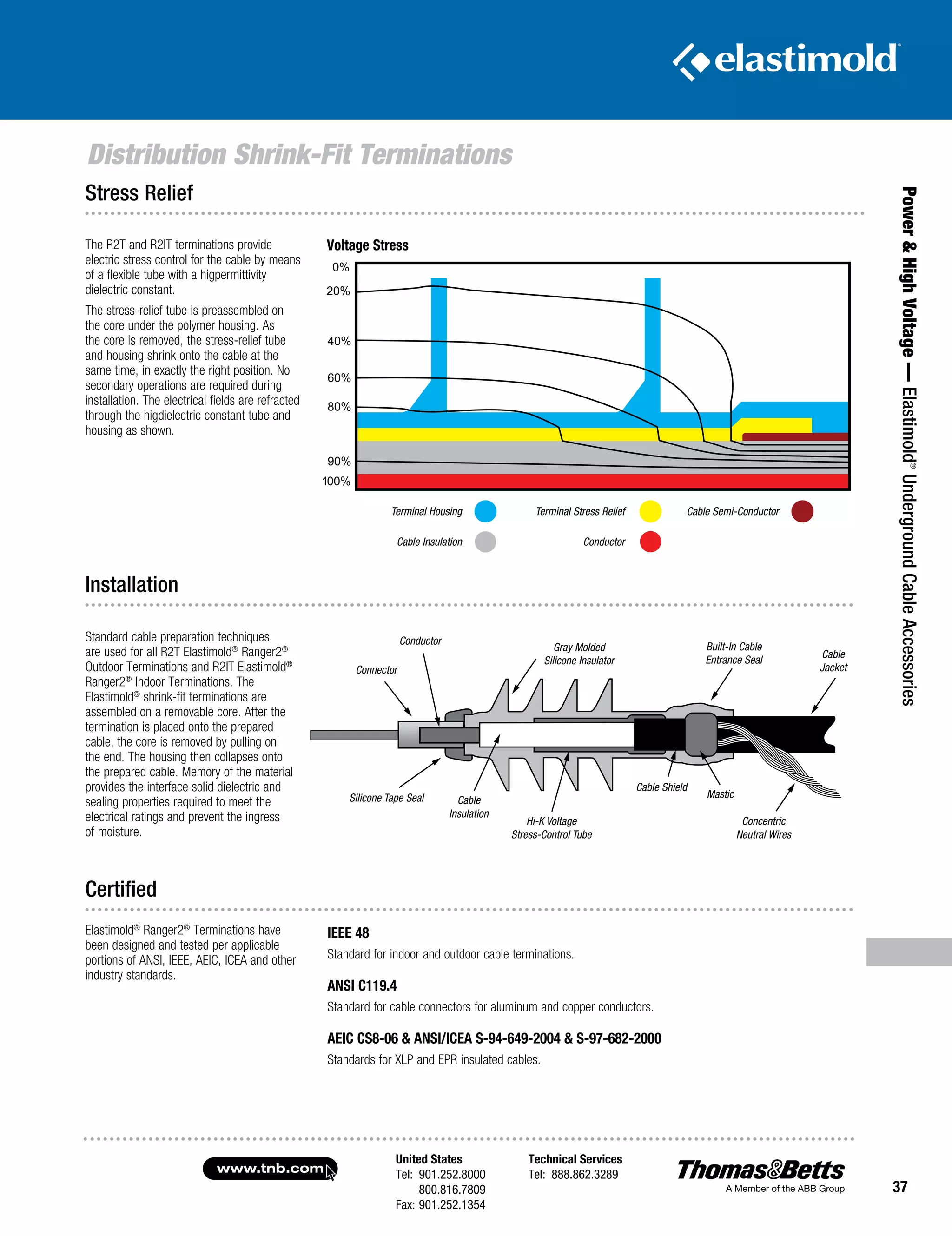

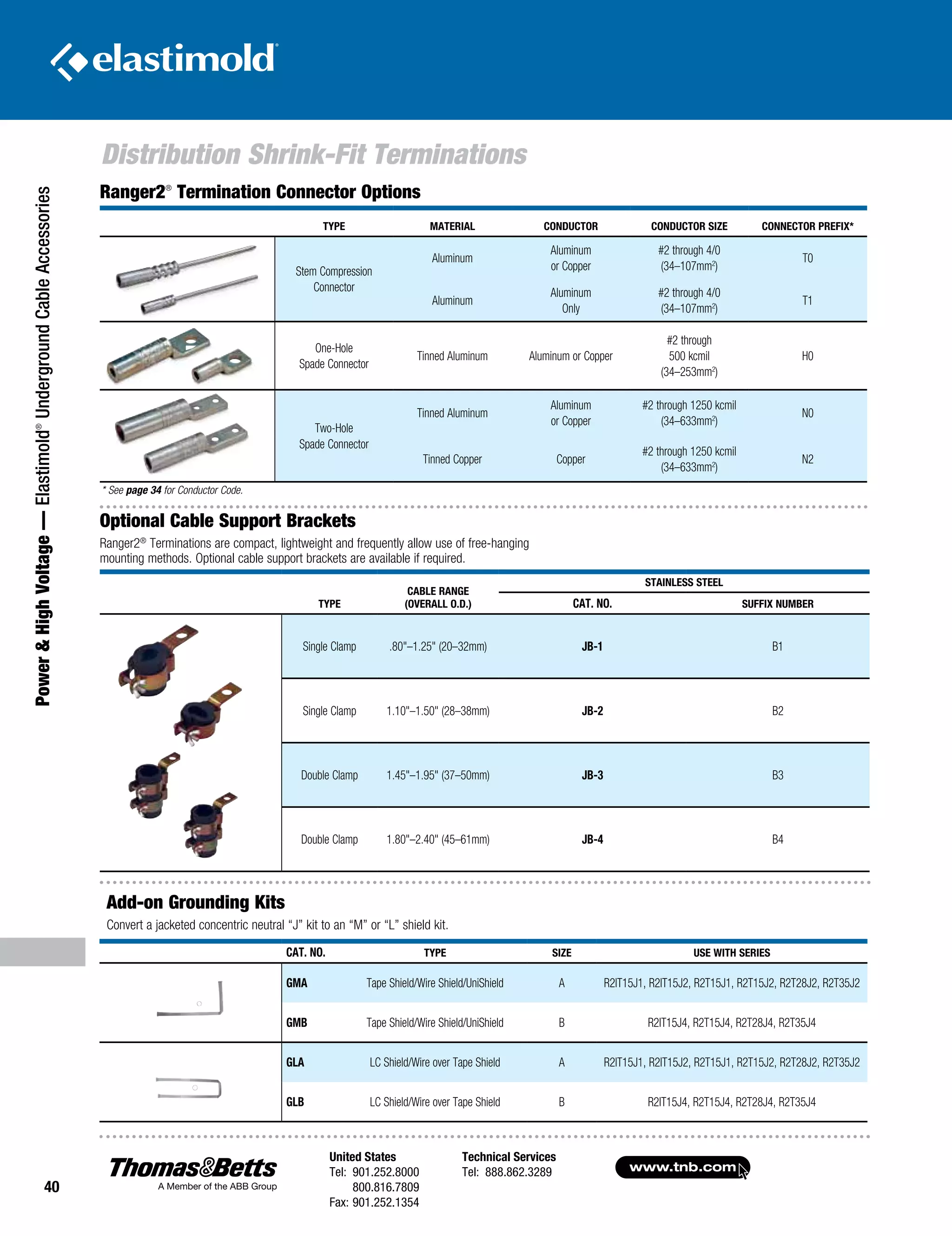

This document provides an overview of Thomas & Betts' Elastimold underground cable accessories product line. It lists the voltage and current ratings for various separable connectors, cable joints, and terminations. It also covers applicable industry standards and notes that the products are designed for ambient temperatures from -40°C to +65°C in all underground applications including direct burial and submersion.