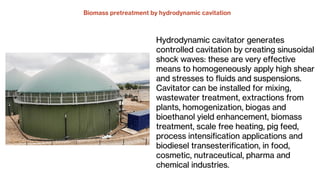

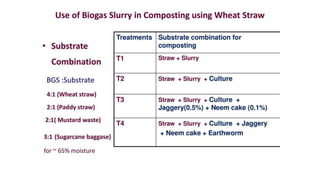

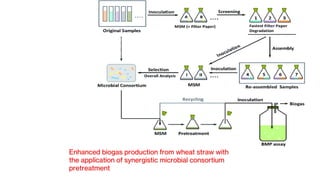

The document discusses various methods for pretreating wheat straw to enhance biogas production through anaerobic digestion, including using solvents like NMMO and ethanol, alkaline treatments with NaOH, and thermal pretreatments at different temperatures. Pretreating the wheat straw improves biogas yields by breaking down the hard lignocellulosic structure and increasing the cellulose content. The abstracts also examine how different pretreatment methods impact the chemical composition of the wheat straw and kinetics of biomethane production.