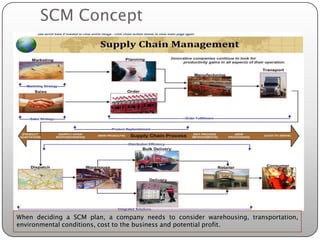

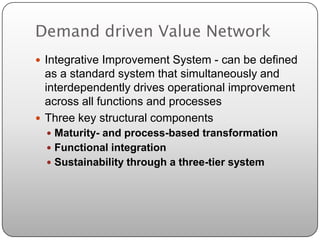

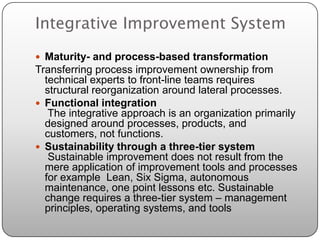

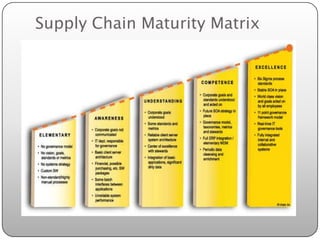

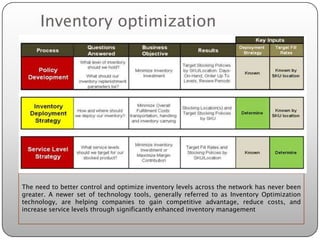

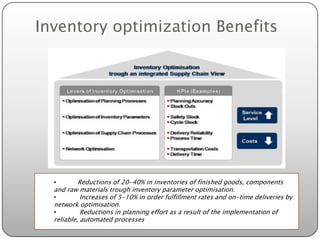

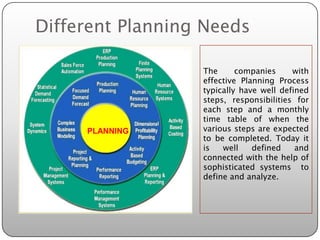

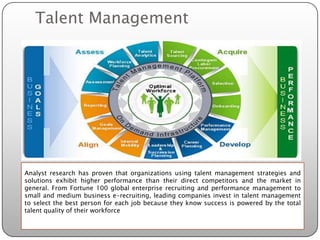

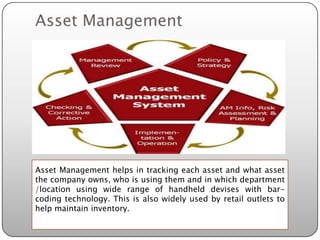

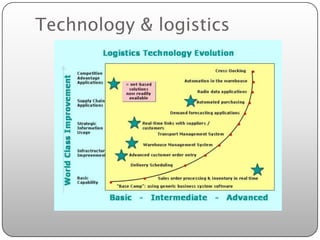

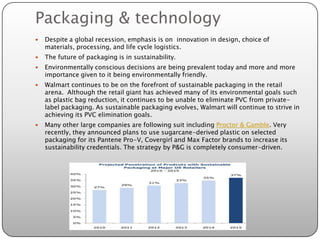

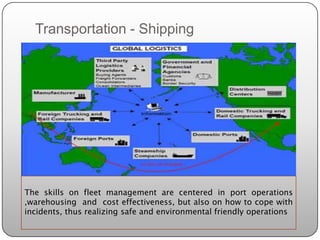

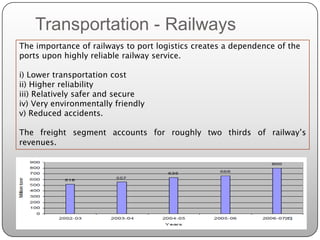

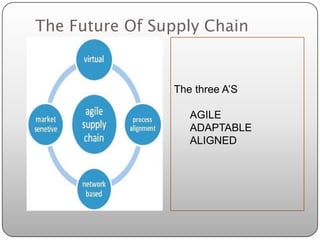

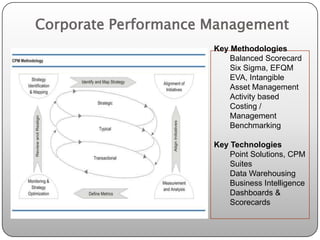

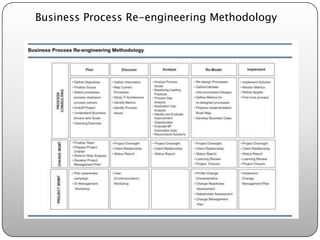

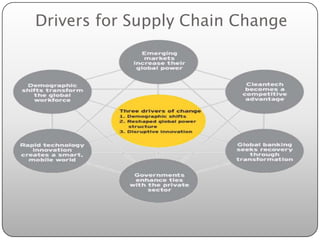

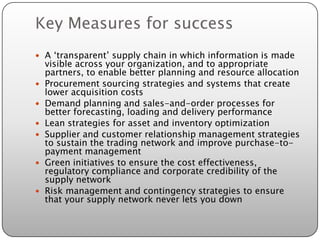

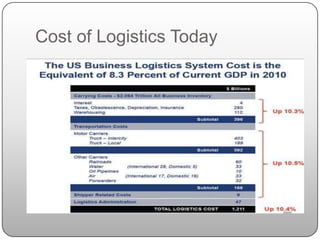

This document discusses supply chain management and the future of logistics. It covers key factors for supply chain success like route optimization, inventory management, and technology. It discusses concepts like demand driven value networks, integrative improvement systems, and supply chain maturity. It addresses topics such as inventory optimization, different planning needs, talent management, asset management, transportation methods, warehousing, packaging, and the roles of technology. It outlines principles of asset management and discusses the future of supply chains, challenges, and measures for success.