This document provides an overview and table of contents for the book "Wiring Complete" by Michael Litchfield and Michael McAlister. It details the book's contents which include instructions for various residential wiring projects like installing electrical boxes, running cable, wiring devices, installing lighting fixtures, troubleshooting appliances, and working with service panels. The book provides a start to finish guide for home electrical systems with expert advice on wiring, tools, materials and safety.

![Text by Michael W. Litchfield and Michael McAlister,

© 2008 by The Taunton Press, Inc.

Photographs © 2008 by The Taunton Press, Inc., except as noted.

Illustrations © 2008 by The Taunton Press, Inc.

All rights reserved.

I

T ITh

eTau

n

to

nPress

]nspira(;on for hand.oon living"

The Taunton Press, Inc.,

63 Sout h Main Street, PO Box 5506,

Newtown, CT 06470-5506

e-mail: tp@taunton.com

Editors: Matthew Teague, Helen Albert

Copy editor: Candace 8. Levy

Indexer: Jay Kreider

Jacket/Cover design: Kimberly Adis

Interior design: Kimberly Adis

Layout: Cathy Cassidy

Illustrator: Trevor Johnston

Photographer: Michael Litchfield, except where noted.

Library of Congress Cataloging-in-Publication Data

Litchfield, Michael.

Wiring complete / Michael Litchfield and Michael McAlister. -- Rev. ed.

p. em.

Includes index.

ISBN 978+6008S ~256 ~5

1. Electric wiring, Interior. 2. Dwellings-'Electric equipment. I. McAlister, Michael.

II. Title.

TK3285.L542008b

62I.3F24~~dc22

200B054144

Printed in the United States of America

1098765432

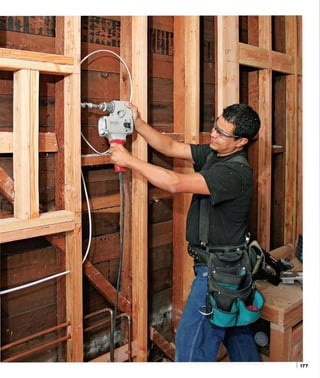

Dozens of people made this book possible. We are

especially indebted to the electricians and builders

who got us onto job sites and allowed us to photoqraph

them at work. Thanks to old friend Rafael Maldonado

of Blue Electric in Berkeley, California, for sharing his

vast knowledge and his crew, particularly Isaac Castro,

Jorqe Dominquez, and Carios GUerrero. Huqe thanks to

the unflappable Daniel Kealey, Nathan Parker, and Din

Abdullah of MRM Electrical, Berkeley. LIkewise, Kevin

McCarthy, Simon Jordan, Ki Soo An, and Jimmy Stuart.

A million thanks to Mike Zelinka and colleagues at Laner

Electric in Richmond, California.

We are qrateful to Jana Olson, Karen Cornell, and John

Nicoles of Omega Too Lighting In Berkeley for the excel-

lent sequences of lamp and chandelier repair. Thanks

also to Nowell's Antique Lightinq in Sausalito, California.

Hats off to Jamie Carlen and Chris D'Andrea of

Jamie Carlen & Co., Berkeley; and Chip Harfey, Jesus

Beltran, and Gelber Guzman of Holfand-Harley. Thanks

to supremely talented architect Gary Earl Parsons of

Berkeley and his associate Cecil Lee.

Thanks to Roqer Robinson of the Star inspection

Group, Oakland, California, for letting us cherry-pick his

photo archiVe of code violations; Casablanca Fans for

product shots; Muffy Kibbey for photos of the handsome

kitchen in the planninq chapter; and Ken Gutmaker for

photos that first appeared in Renovation, 3rd Edition

(Taunton, 2005).

Thanks to homeowners Catherine Moncrleff and

Stuart Brotman, Martha and Dean Rutherford, Judith

and Stanley Lubman, Laurie Case, and Andy Baker.

Finally, high-fives to the Taunton Press family and

friends, Including Executive Editor Helen Albert, Wendl

Mijal, Matthew Teaque, Jennifer Peters, Nicole Palmer,

Julie Hamilton, Sandor Naqyszalanczy, Rex Cauldwell,

Clifford Popejoy, Joseph Truini, Mike Guertin, and

Fernando Paqes Rulz.

-Michael Litchfield and Michael McAlister

The following manufacturers/names used in Wiring Complete are trademarks: Adapt-Touch™

, American Aldes™, BernzOmatic™

, Broan-NuTonesM, Capsylite®,

Casablanca® Fan Co., Channeliock®, Clikstrip®, Code Check®, Condulet®, COPALUM®, Cutler'Hammer®, Decora®, DeWALT®, Fantech®, Federal Pacific®,

Fluke®, Greenlee® Nail Eater™, Grip-lok™, Halogen Capsylite®, Hubbell®, Hunter®, Ideal®, InSinkErator®, International Code Council®, Juno®, Kelvar®,

Klein ToolsTM

, Knipex®, Kobe®, Legrand®, lemnis®, Leviton®, Ughtolier®, lutron®, Milwaukee®, National Electrical Code®, Nouvelie® fan, Panasonic®,

Panduit®, Philiips®, PowerFast®, Romex®, Roto-Spilt®, Rotozip®, Scandia® fan, Seatek®, Snap-Tite®, Speed® Square, Square D®, Strap Gun®, Tech

Ughting®, Tech lightingS

"I, Vol'Con® lite, Watt Stopper®, WD-40®, Wiggy®, Wire'Nut®, Zinsco®

Wiring is inherently dangerous. Using hand or power tools improperly or ignoring safety practices can lead to permanent injury or even

death. Don't try to perform operations you learn about here (or elsewhere) unless you're certain they are safe for you. If something

about an operation doesn't feel right, don't do it . Look for another way. We want you to enjoy wor king on your home, so please keep

safety foremost in your mind.](https://image.slidesharecdn.com/wiringcompletegnv64-211128021253/85/Wiring-complete-gnv64-4-320.jpg)