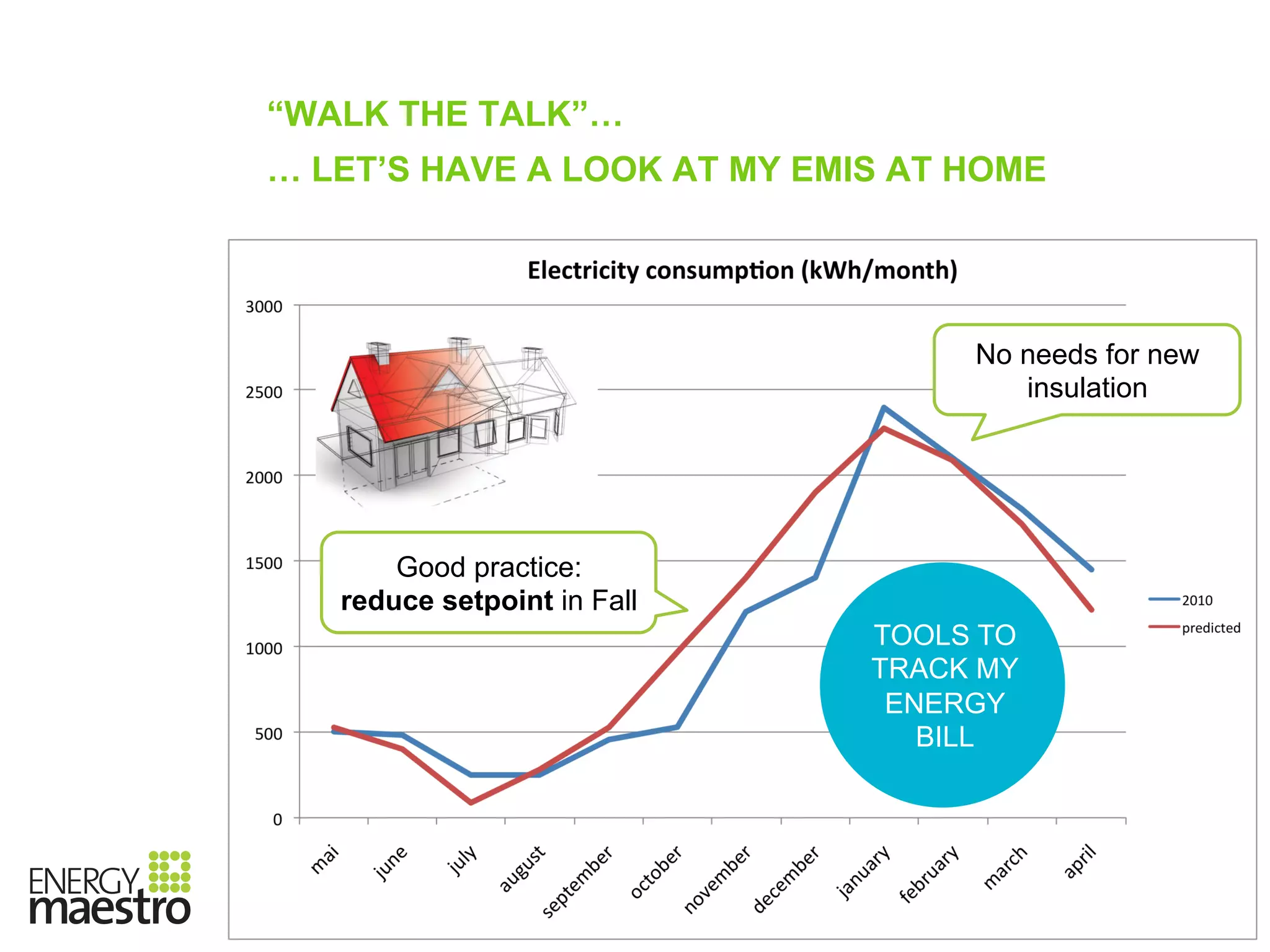

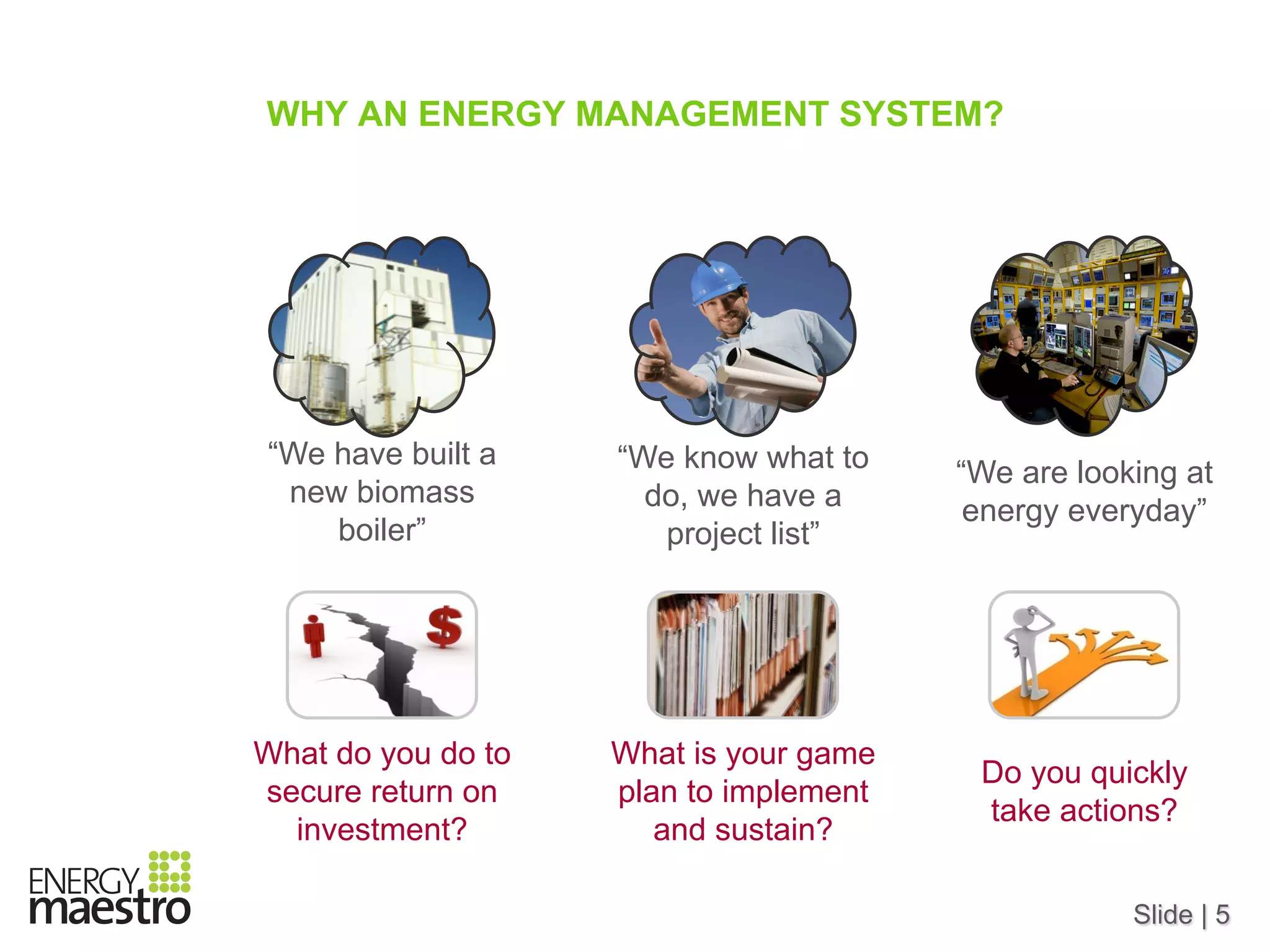

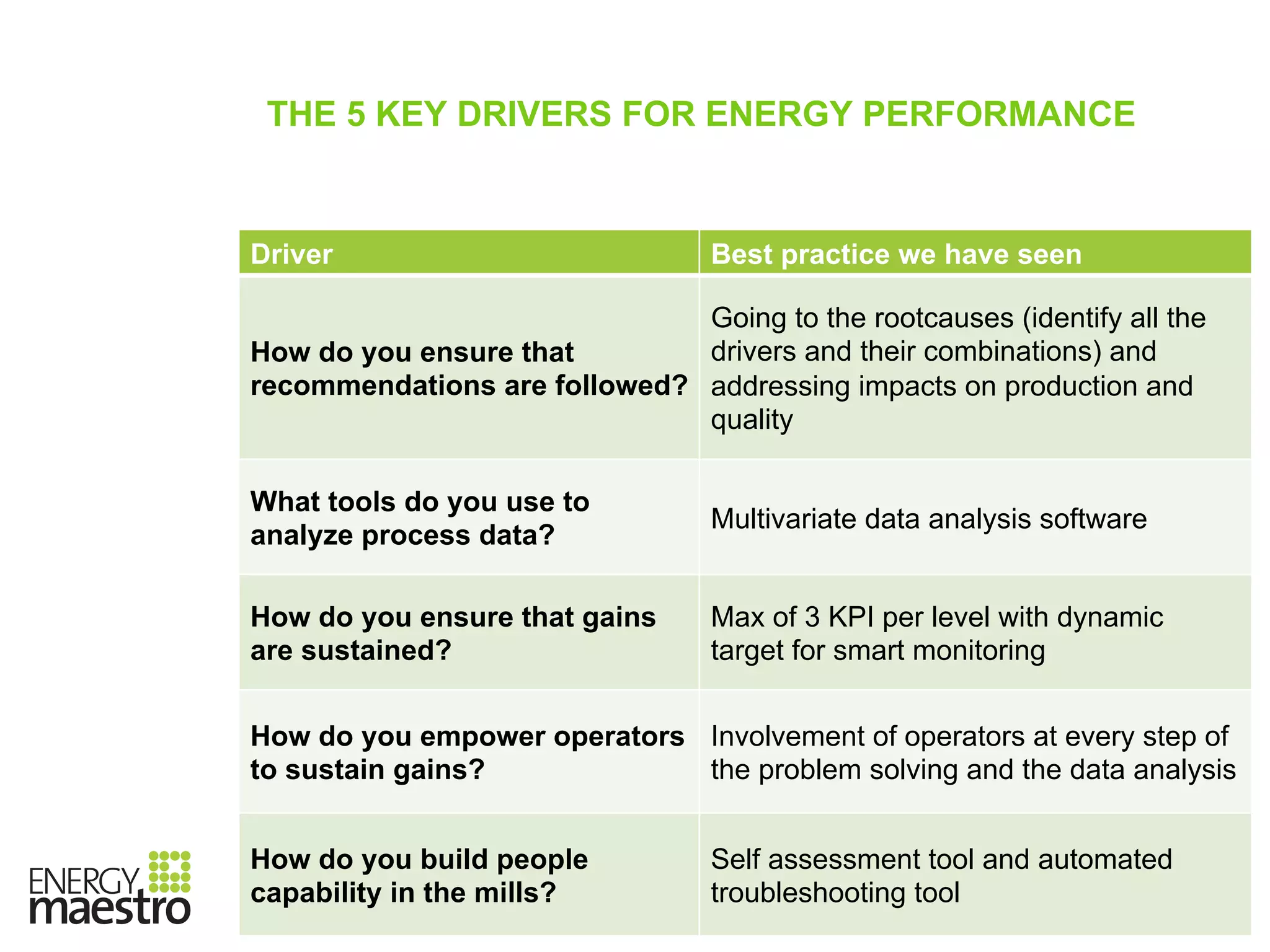

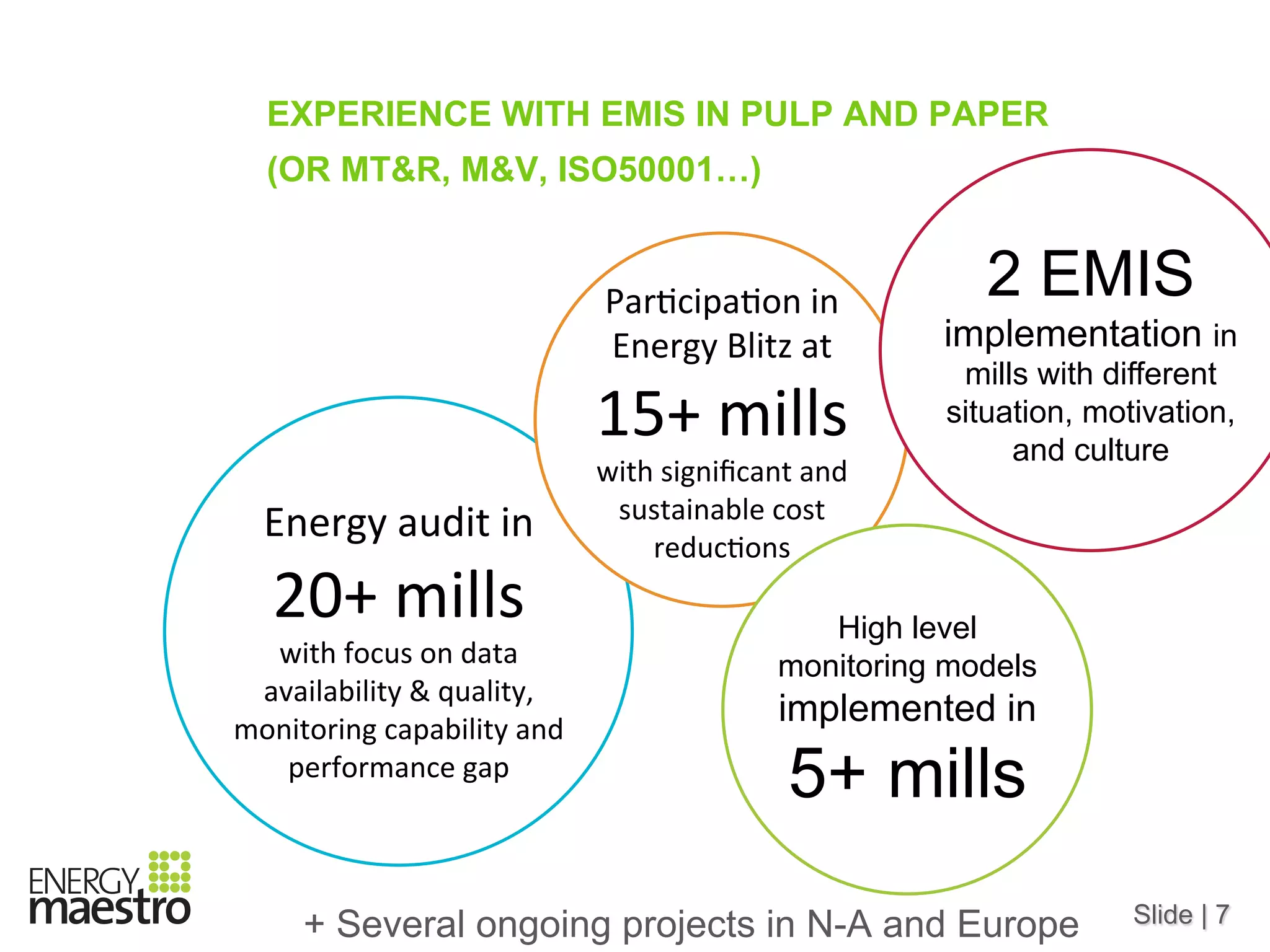

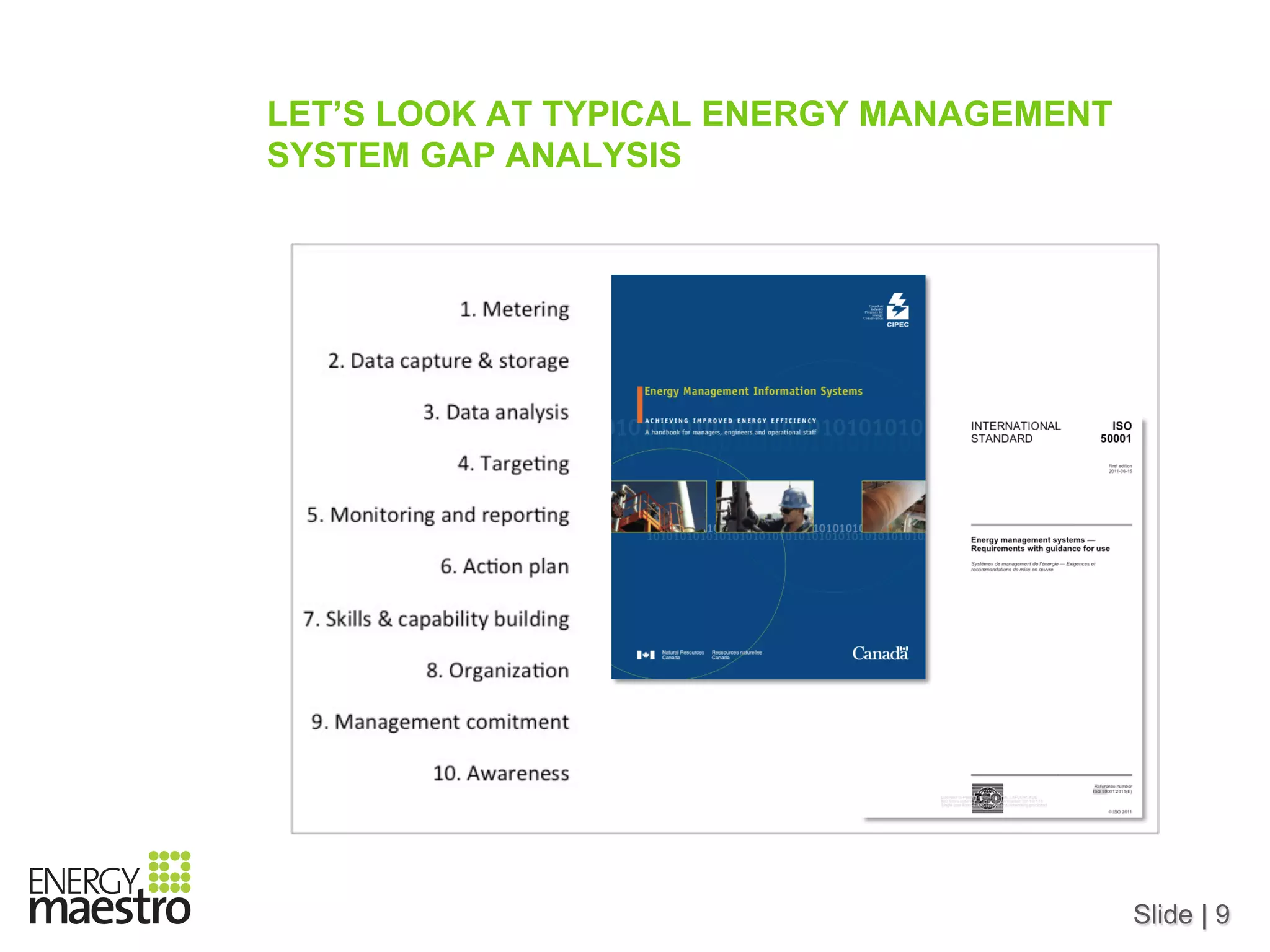

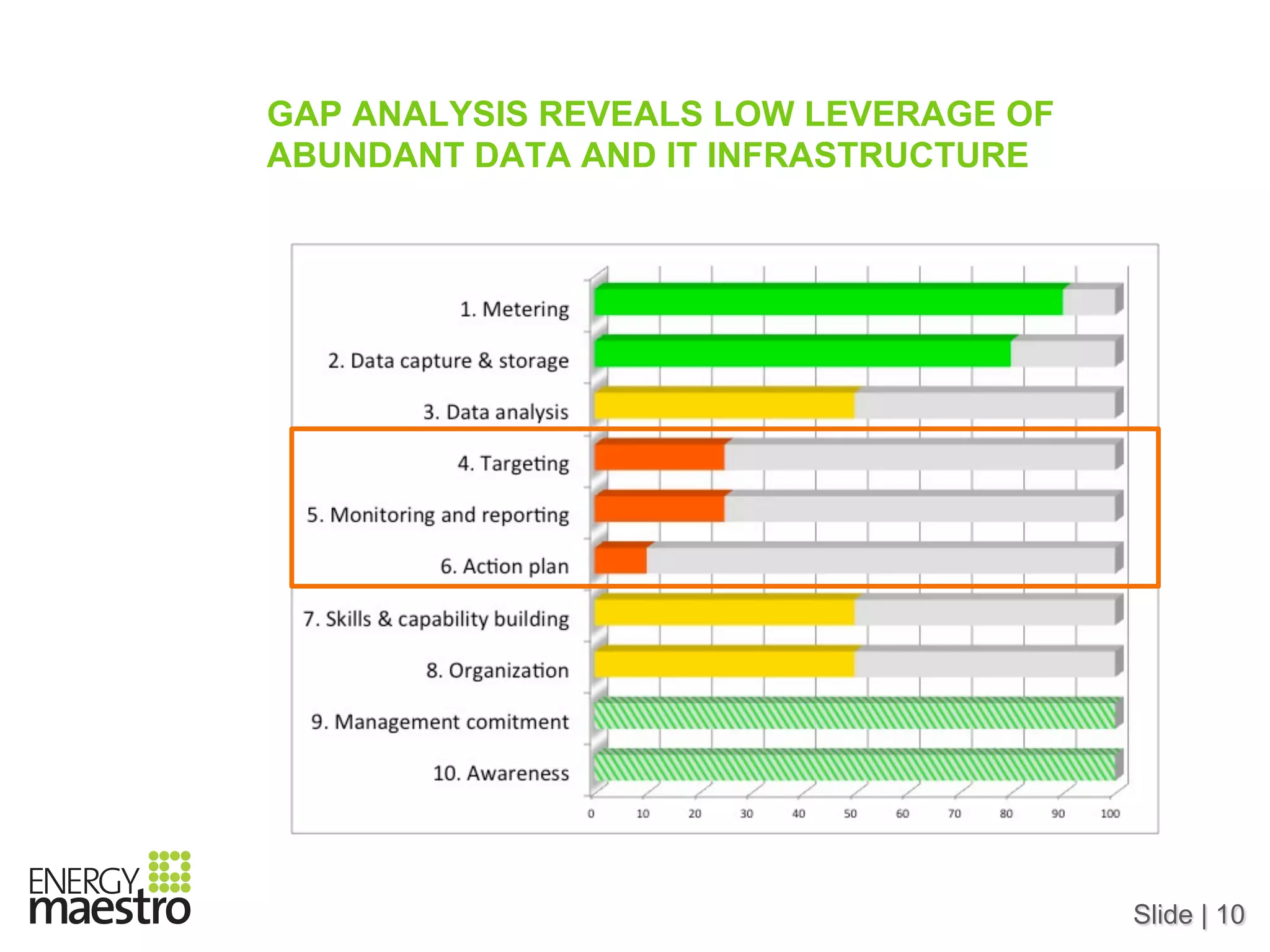

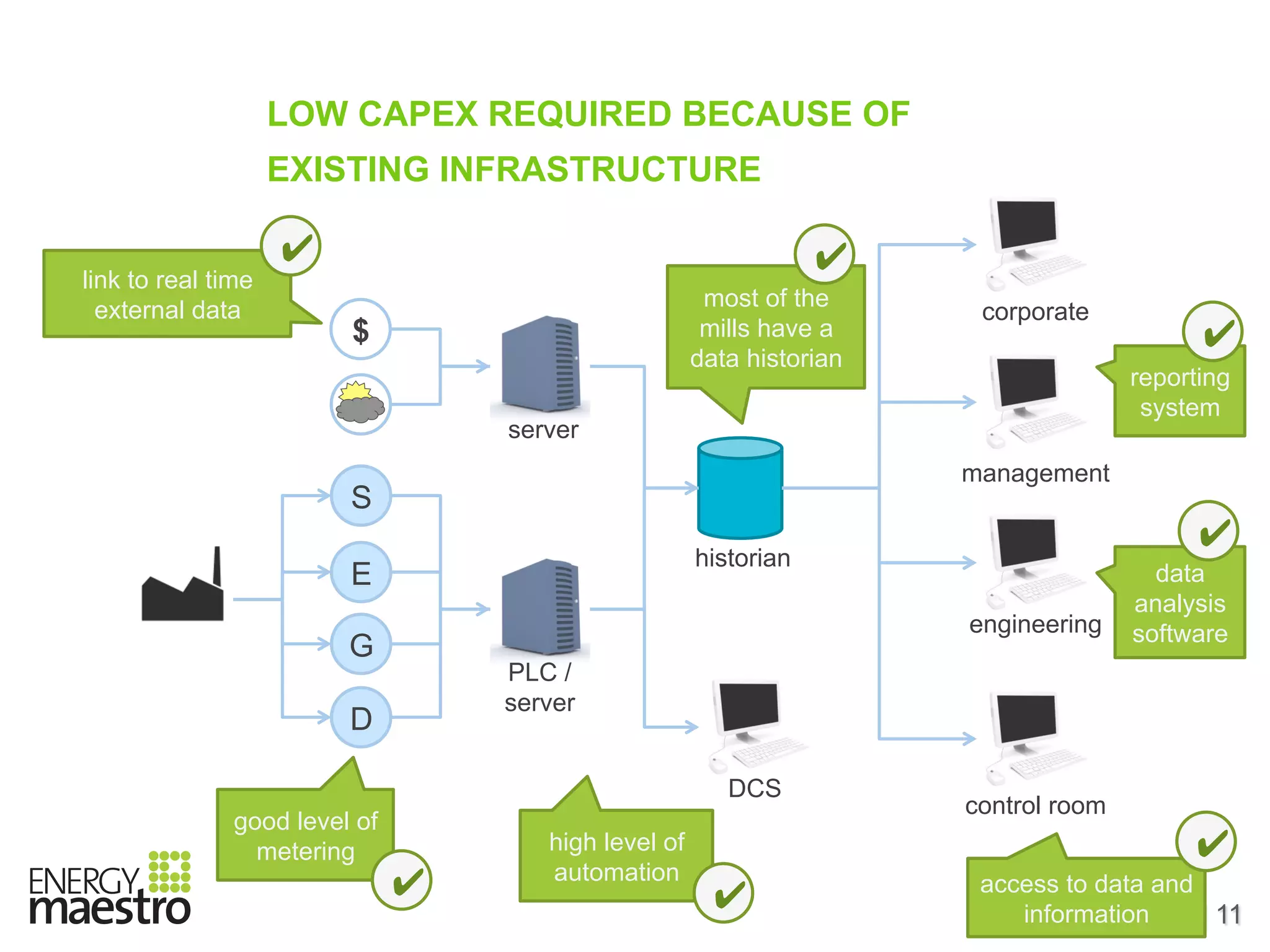

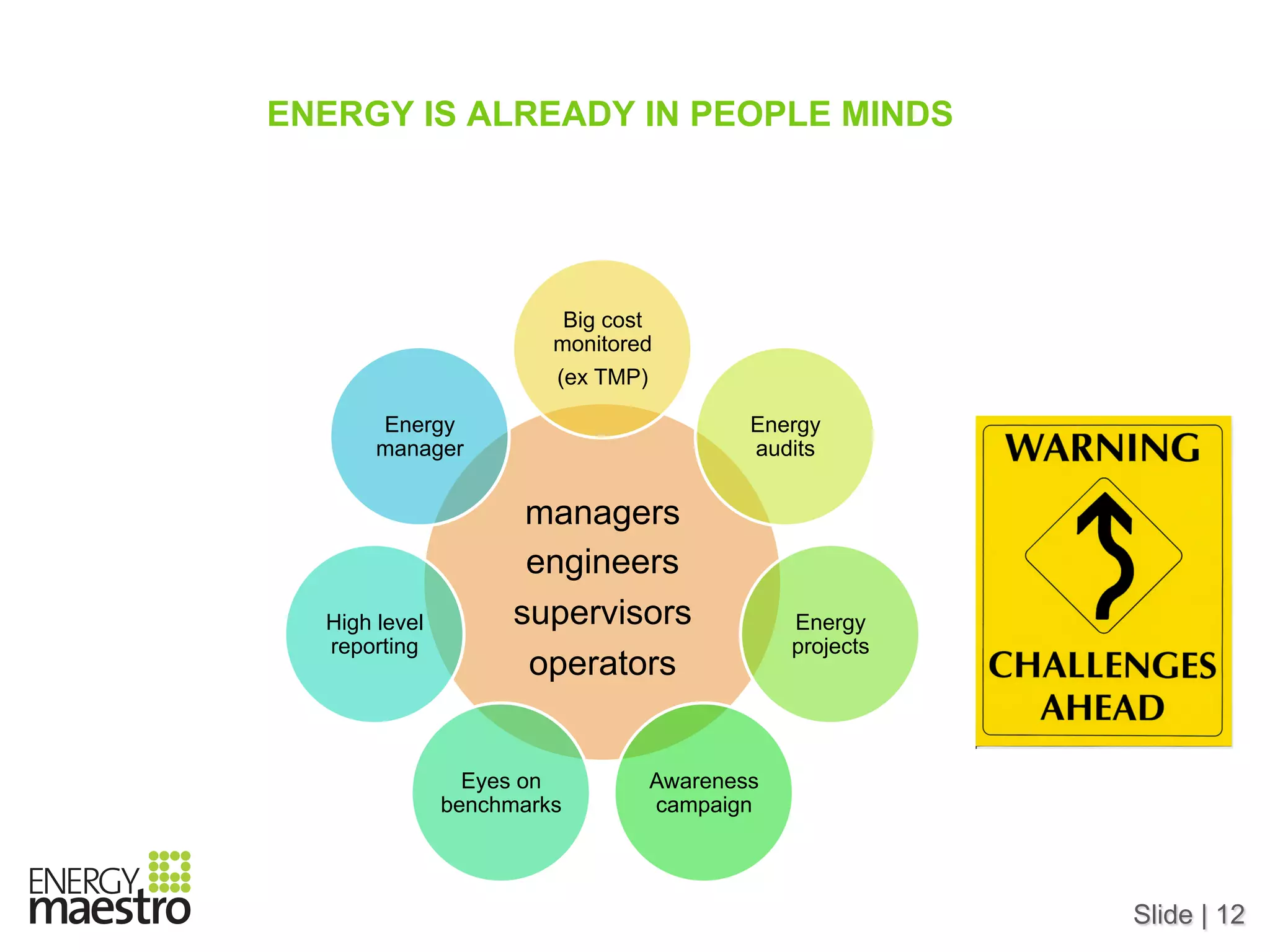

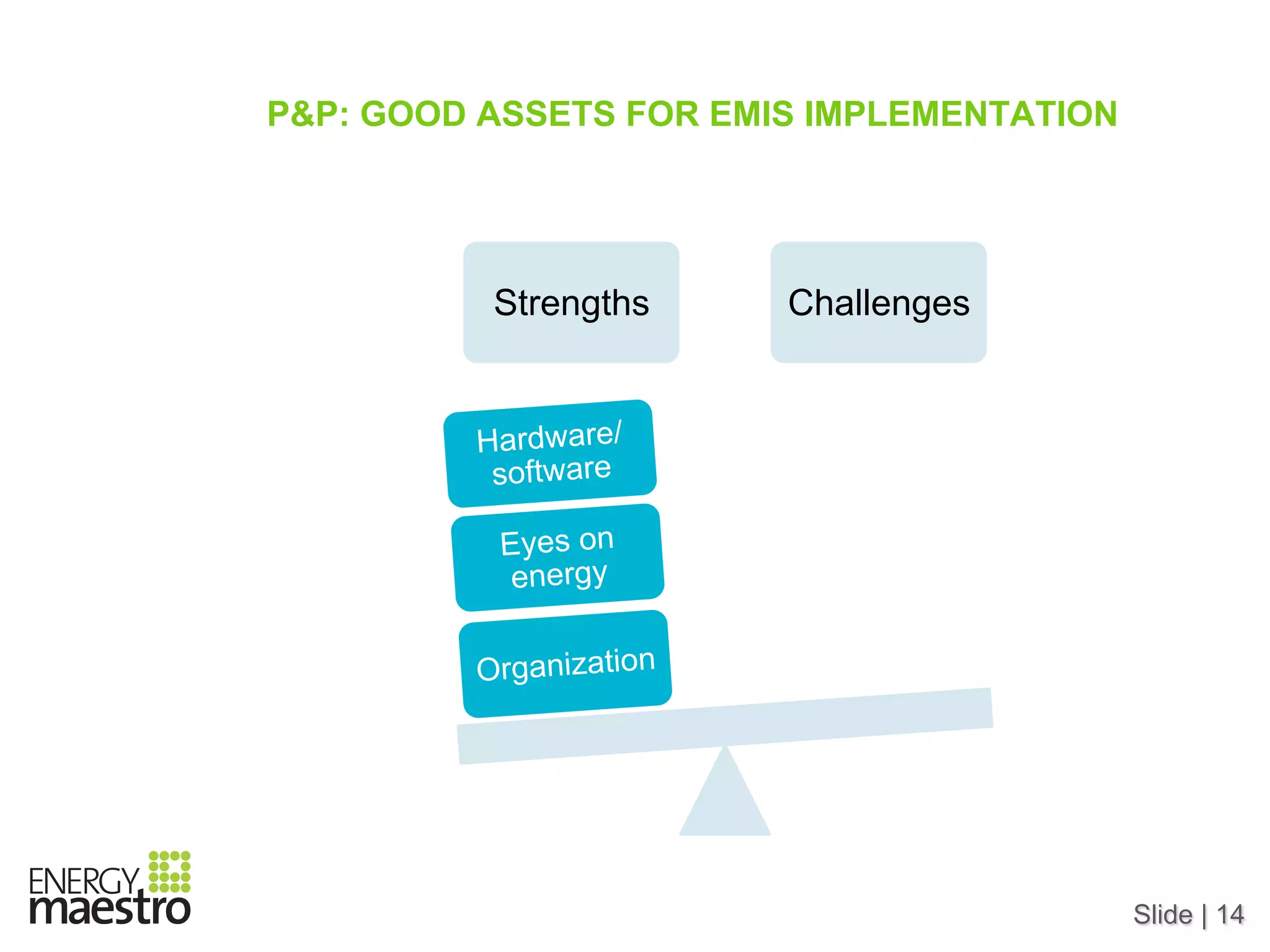

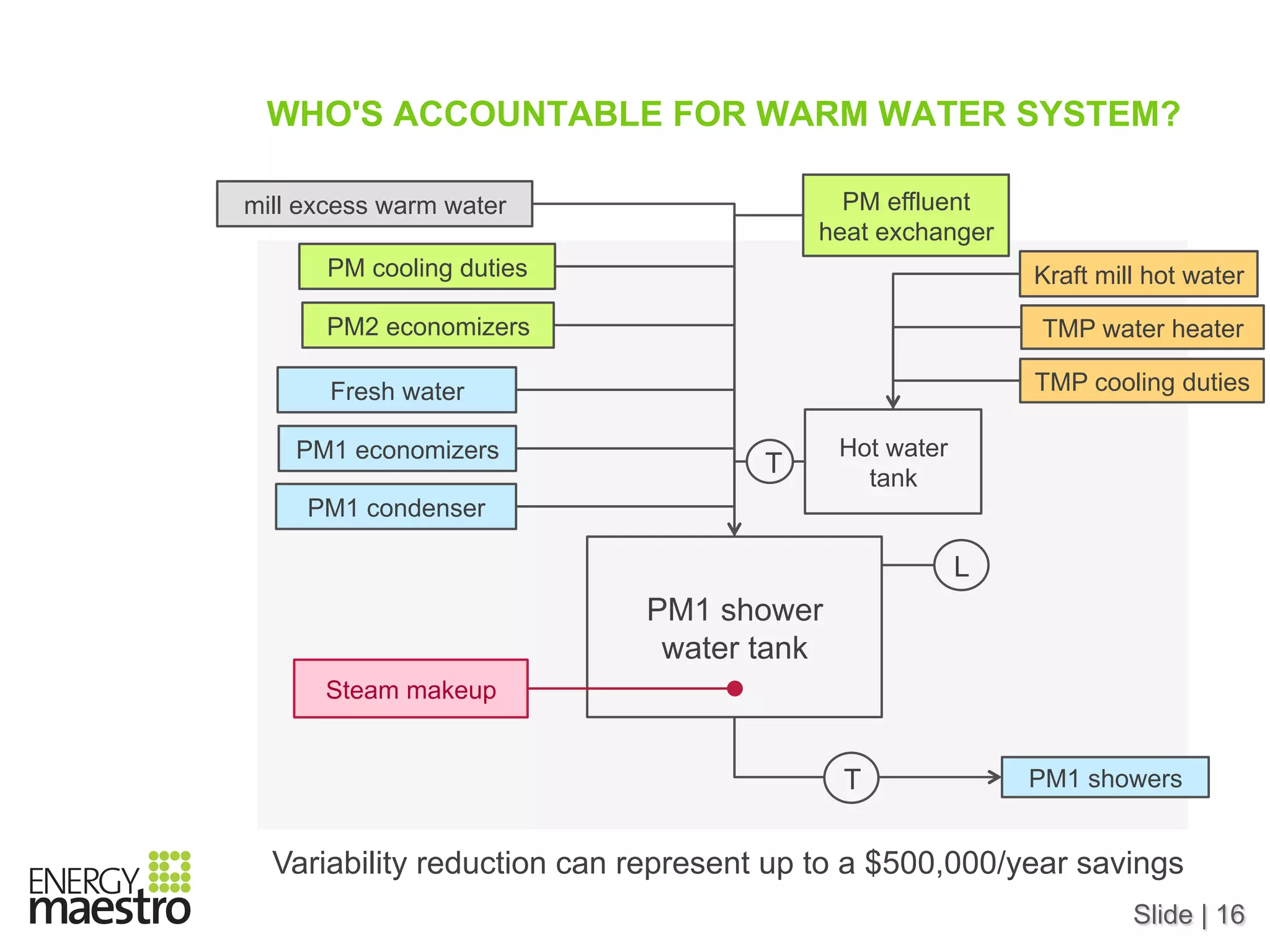

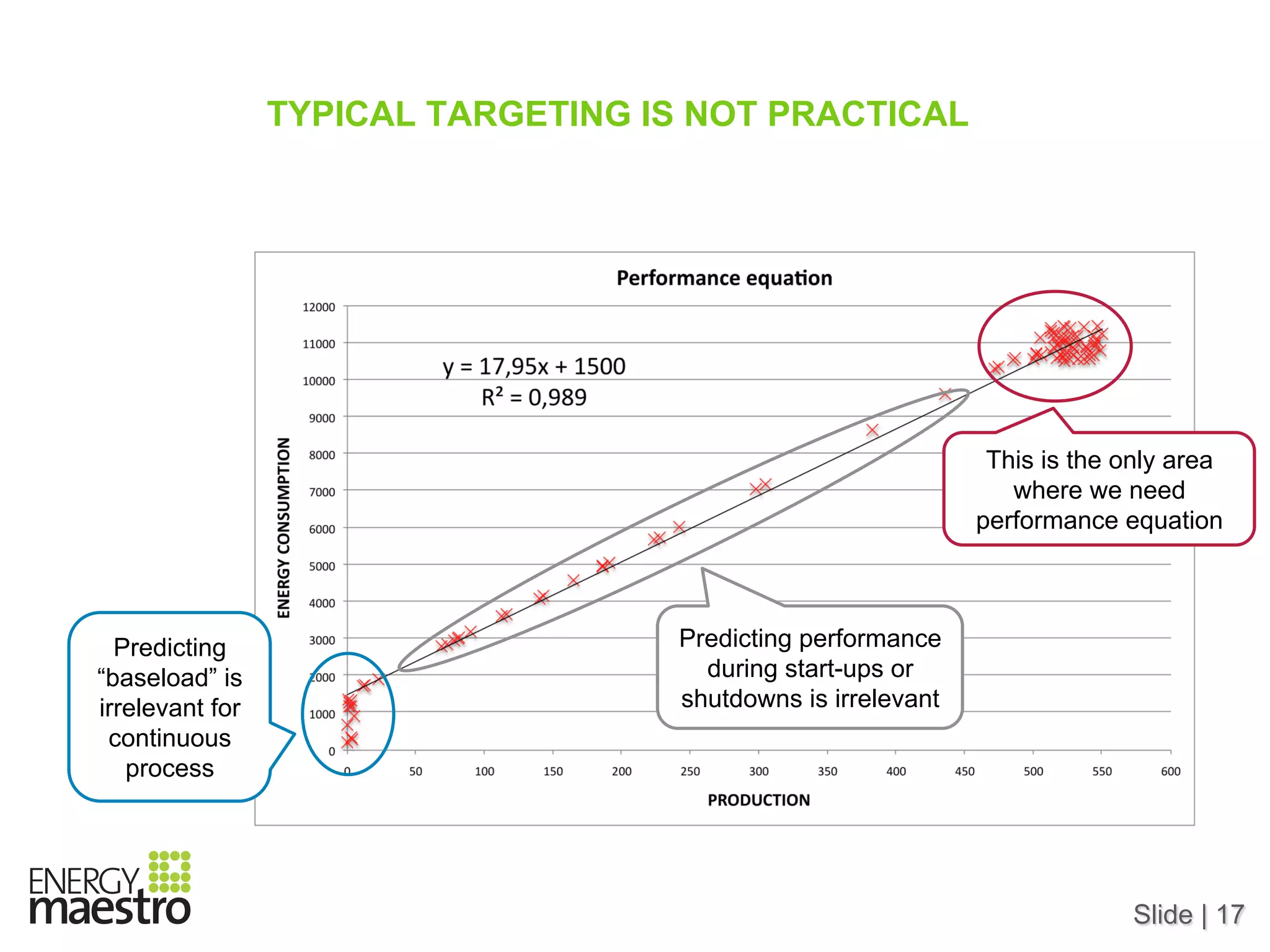

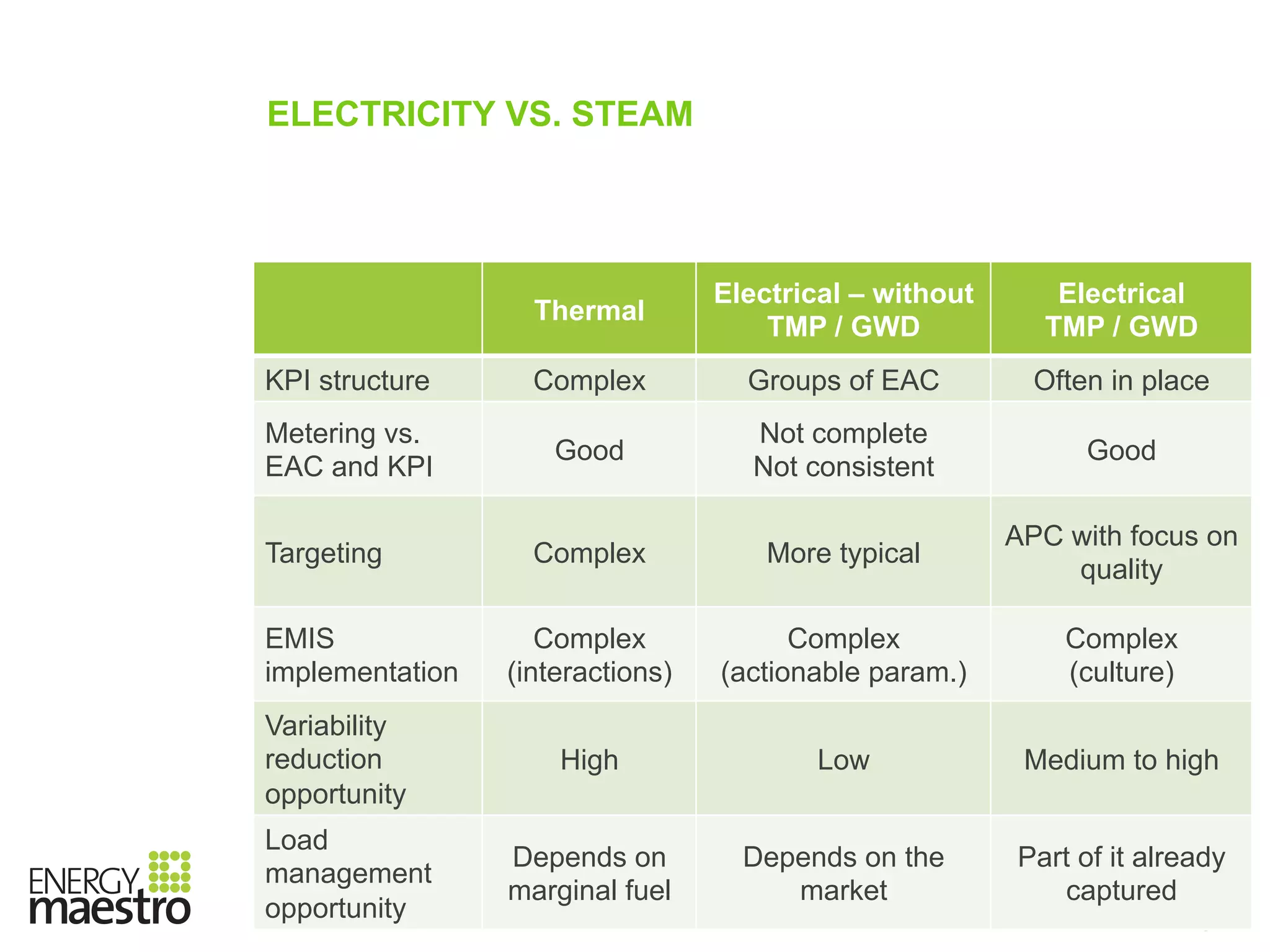

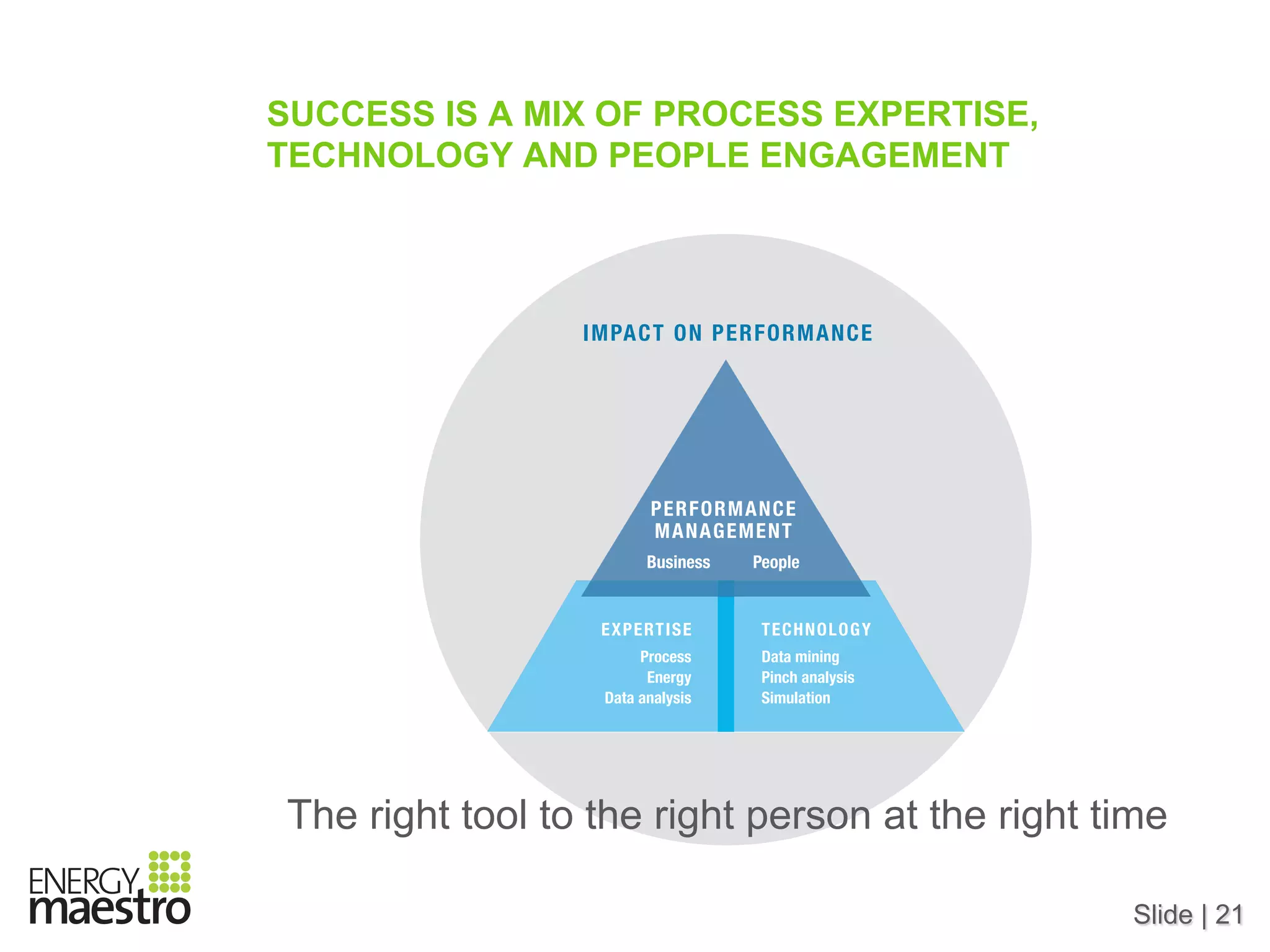

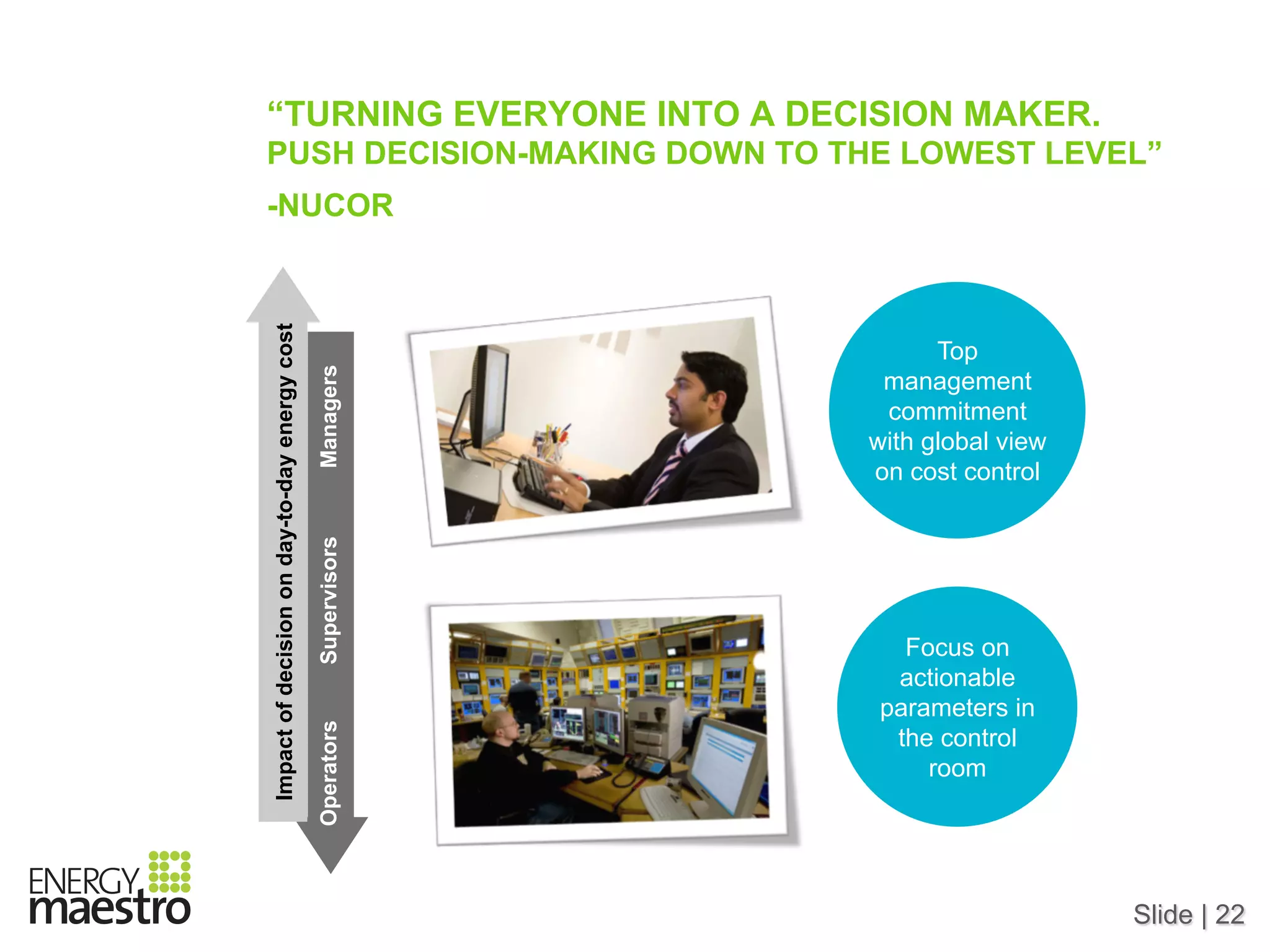

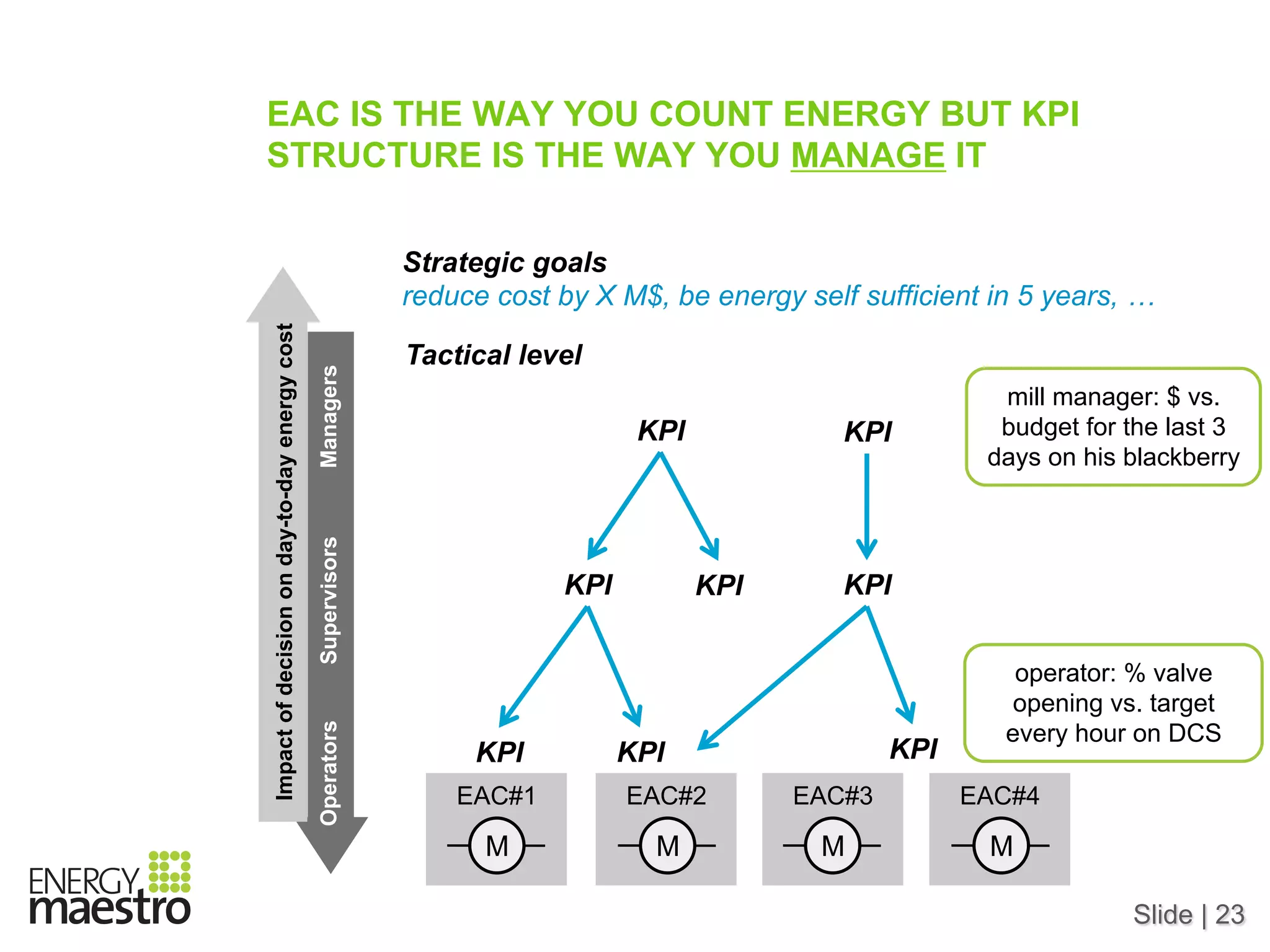

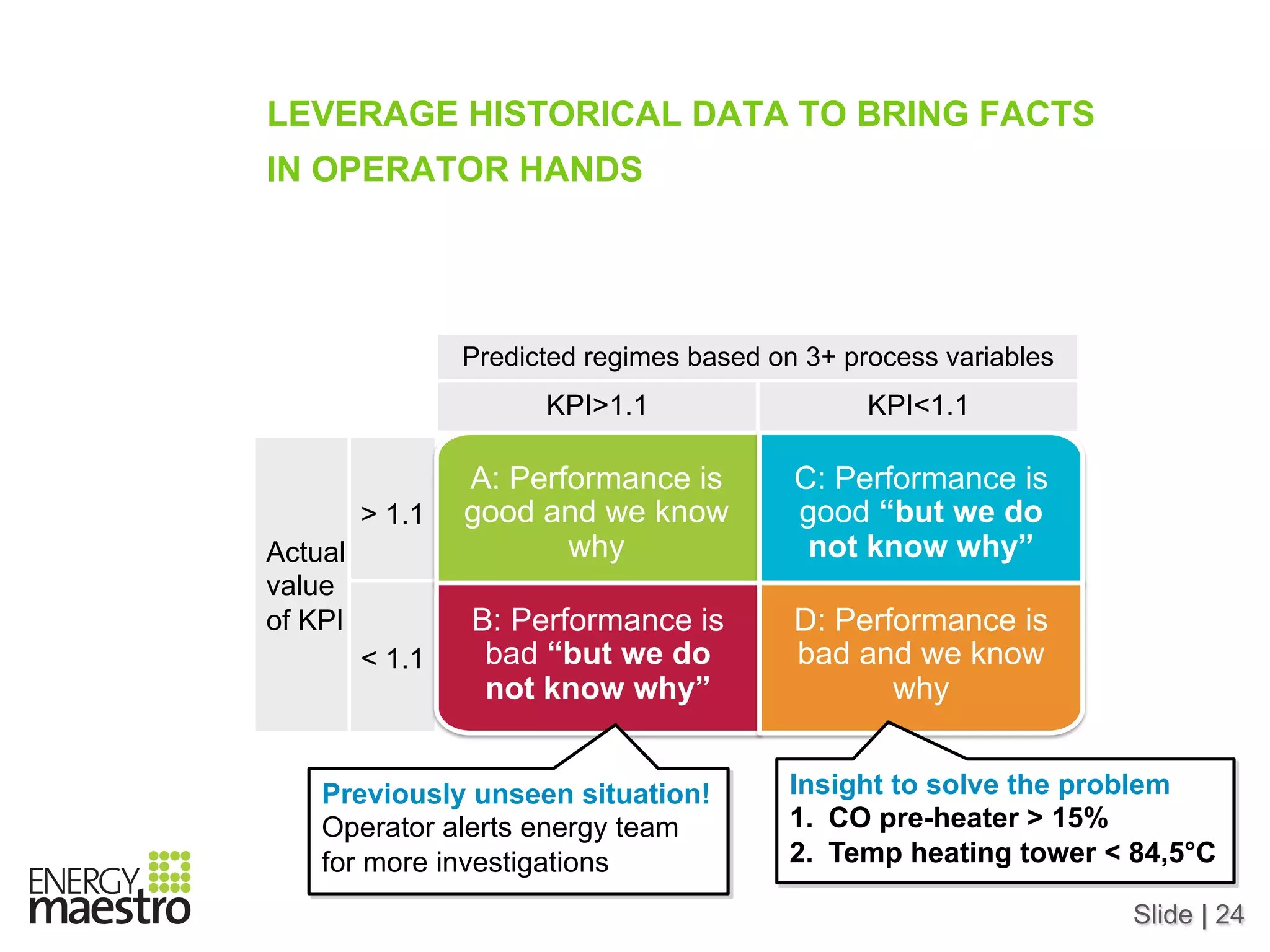

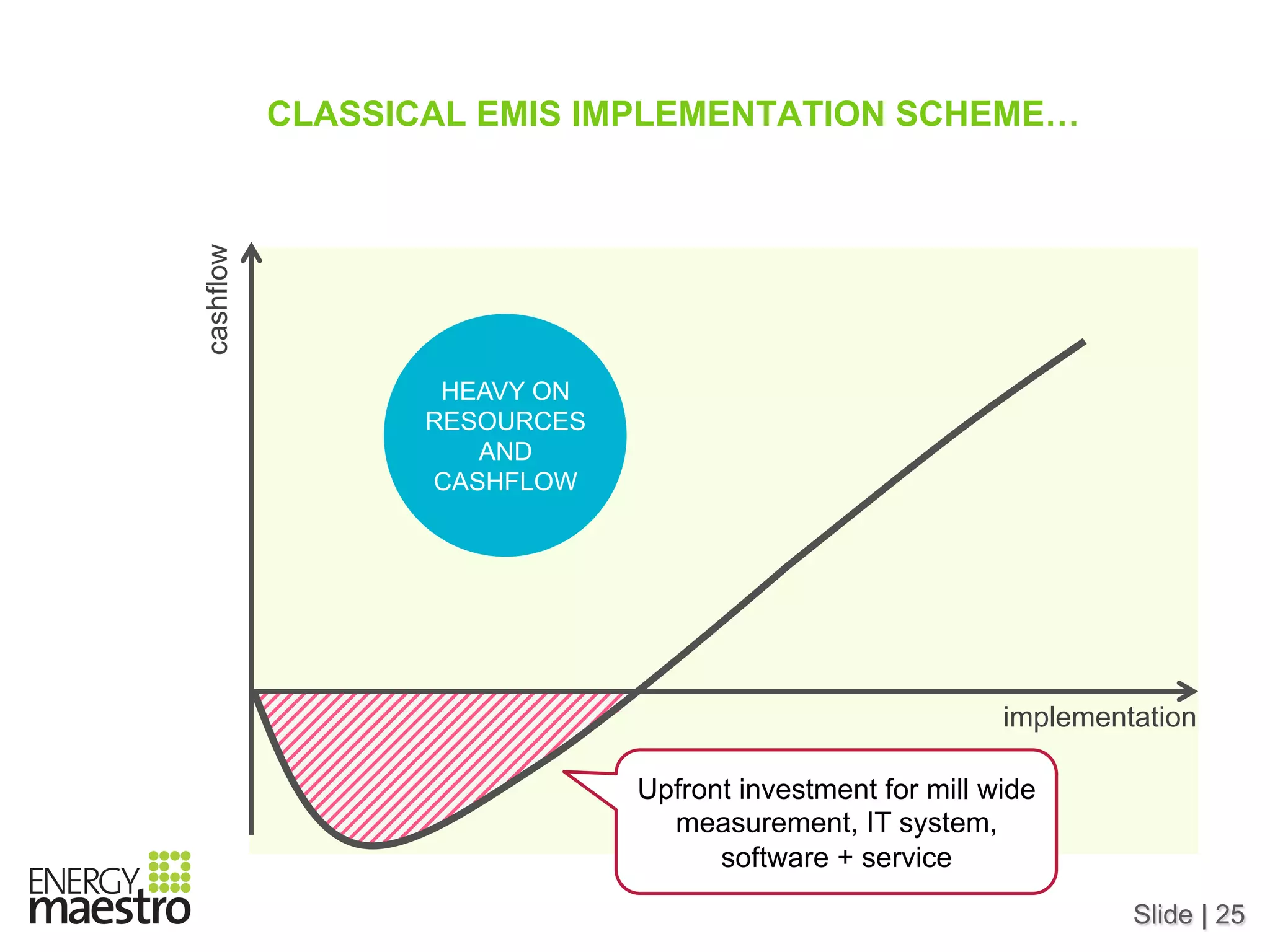

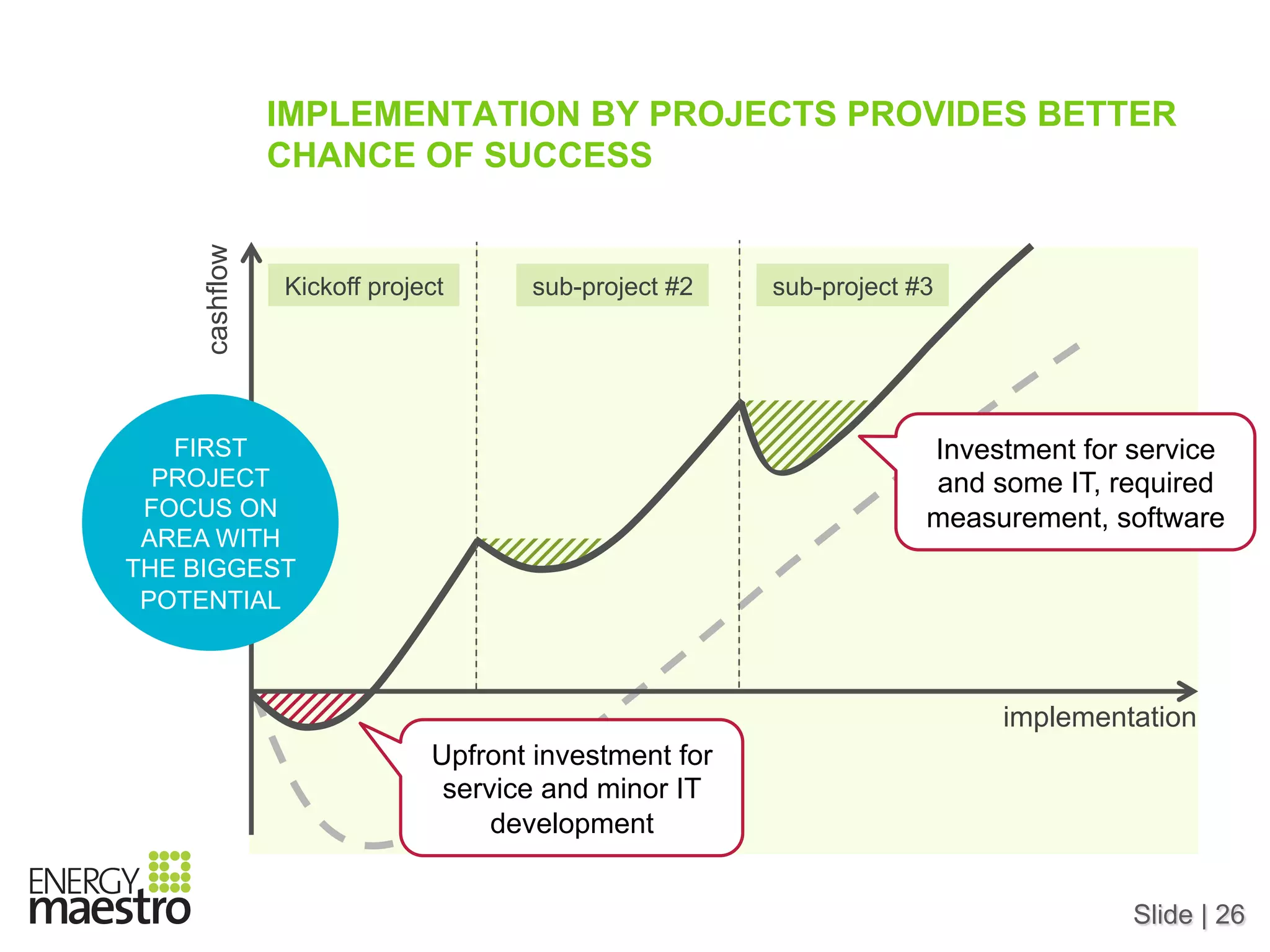

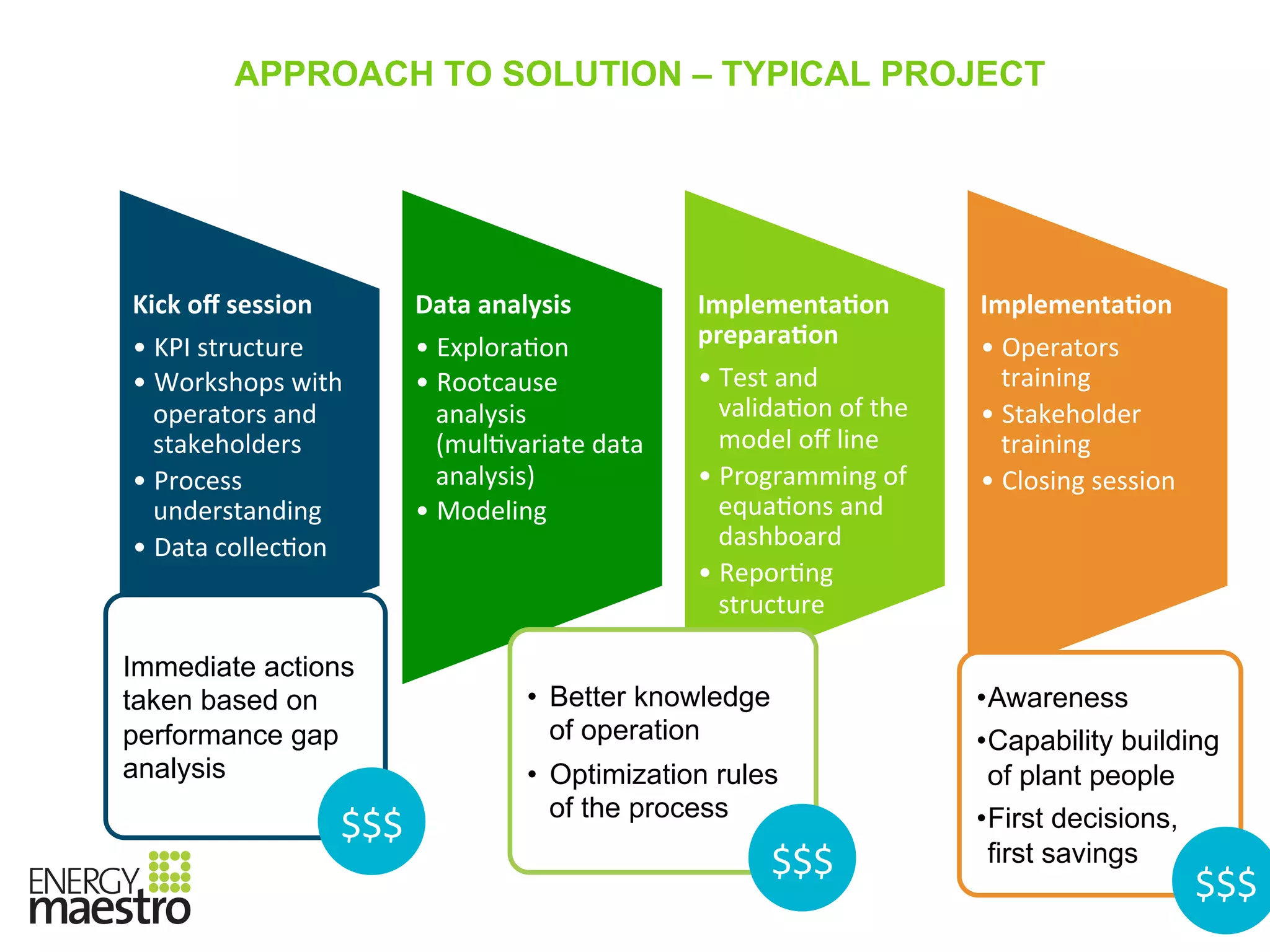

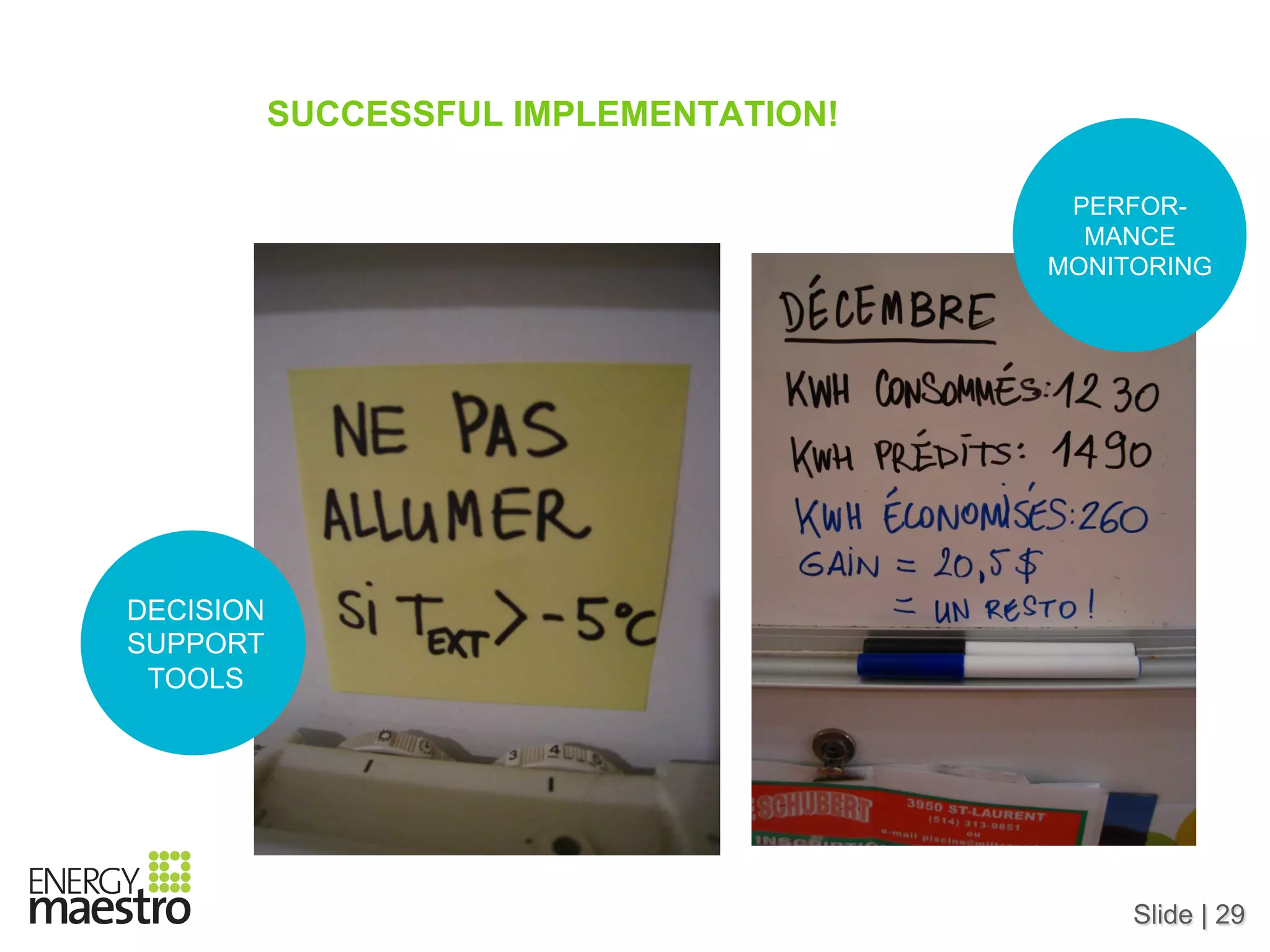

The document outlines the importance and implementation of Energy Management Systems (EMS) in industrial settings, particularly pulp and paper mills. It discusses key success factors, human challenges, and the gap between data and actionable insights, emphasizing the need for a mix of technology, process expertise, and employee engagement to optimize energy performance. Additionally, it highlights the significance of using historical data and establishing clear KPIs to drive accountability and improve decision-making at all levels within organizations.