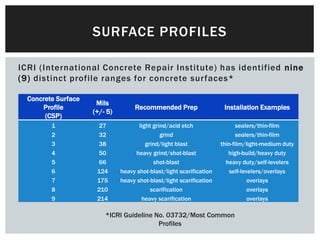

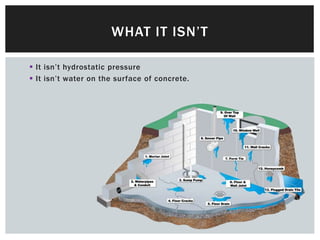

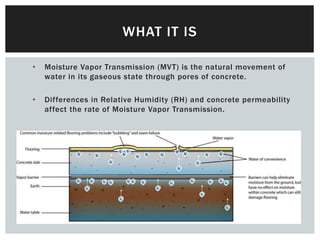

The document discusses why coatings fail on concrete surfaces. The main reasons for failure are poor surface preparation or insufficient bond profile (73% of failures), and excessive moisture or water vapor transmission through the concrete (16% of failures). Proper surface preparation through methods like grinding, shot-blasting or scarifying is critical to ensure proper bonding between the coating and concrete substrate. The document also discusses testing and solutions for eliminating issues caused by moisture vapor transmission through the concrete.