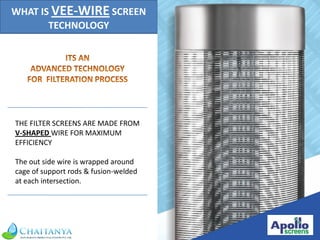

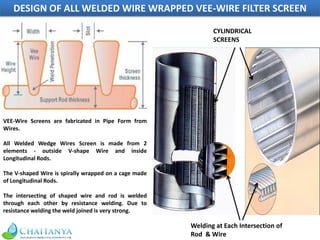

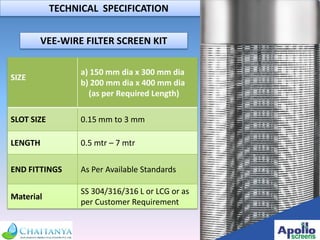

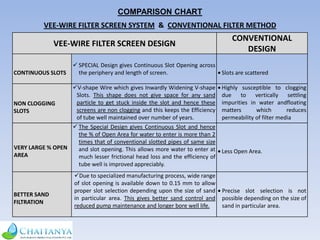

This document provides information on Vee-wire filter screens used for rainwater harvesting and borewell applications. Vee-wire screens have continuous slots that provide over 2x the open area of conventional slotted pipes, preventing clogging. They are made of stainless steel through a welding process and come in various diameters and slot sizes. Vee-wire screens provide a more efficient alternative to traditional gravel filtration systems by eliminating maintenance costs and space requirements while allowing easy cleaning and sustained recharge rates.