Embed presentation

Download as PDF, PPTX

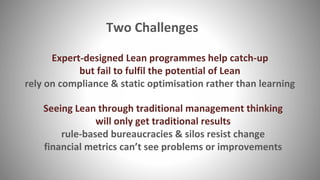

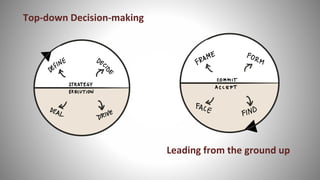

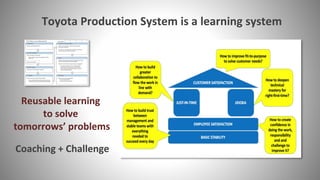

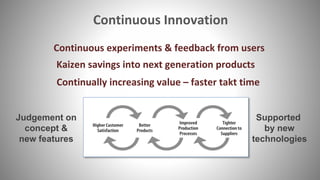

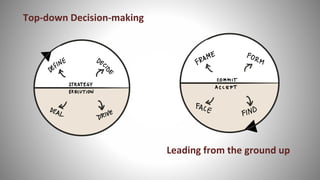

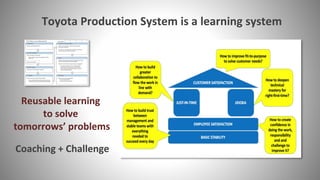

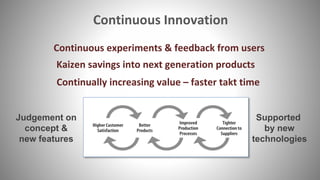

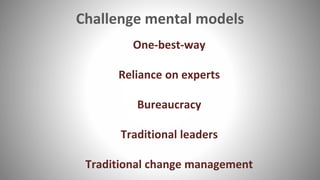

The document discusses the future potential of Lean and challenges with current Lean approaches. It argues that expert-designed Lean programs rely on compliance and static optimization rather than learning. True Lean potential requires active leadership, engaging employees in collaborative problem solving and continuous learning. Pioneering CEOs applying Lean as a strategy saw superior results by focusing on people and cumulative learning to solve problems and translate gains to the bottom line.