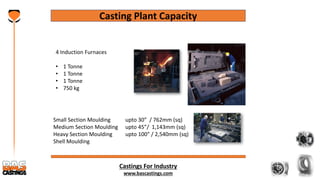

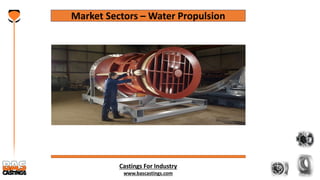

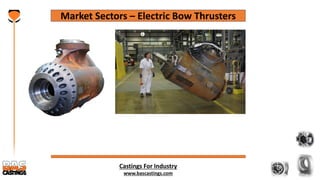

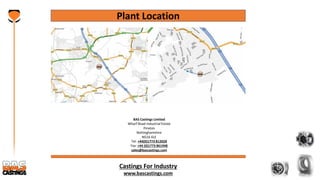

Bas Castings Limited is a UK foundry established in 1973, specializing in high integrity iron and steel castings for industrial applications, with a focus on modern manufacturing techniques and quality management systems. The company has a diverse product range, serving multiple sectors including defense, marine, and renewable energy, and emphasizes cost-effective solutions with extensive post-casting operations. With a workforce of over 200 employees and a turnover of £25 million, Bas Castings maintains rigorous quality control and has received various international accreditations.