- Heating rate and peak temperature

- Cooling rate

- Composition of filler metal

- Pre/post heating of base metal

- Stress relieving heat treatment

Controls the microstructure and properties of the weld.

41

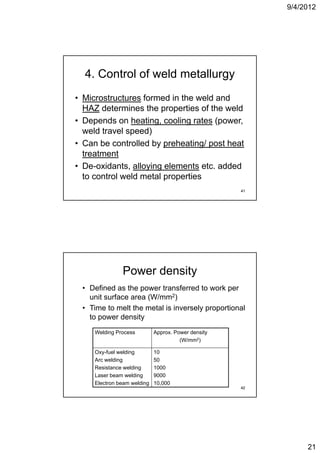

Heat transfer in welding process

- Heat input to the weld is from the energy source

- Heat is conducted away from the weld zone into the base metal

- Heat flow depends on thermal properties of base metal and weld metal

- Heat affected zone experiences thermal cycle due to heat input

- Rapid heating and cooling rates in welding leads to non-equilibrium

microstructures

- Control of heat input and cooling rate is important to control weld

metallurgy

![9/4/2012

Example 1-Solution

Rate of heat input to the weld bead = 3500 × f1 × f2

= 3500 × 0 7 × 0 5 = 1225 J/s

0.7 0.5

Heat input = Energy used for heating to Tm + Energy used

for melting

1225 = [Cp(Tm-T0) + Lm ] × A × v

1225 = [480(1760 300) + 247 ×103] × 7860 × 20 ×10-6 × v

[480(1760-300) 10 10 6

Travel speed v = 0.0082 m/s = 8.2 mm/s

45

Summary: Lectures 1-3

• Overview of welding, applications,

ad a tages

advantages

• Welded Joint types

• Fusion & Solid state welding

• Elements of weld setup, Heat Balance,

Power density y

• N.B: Characteristics, micro-structural

zones and concept of lattice continuity in

fusion & solid state welding

46

23](https://image.slidesharecdn.com/weldinglectures1-4-121005013434-phpapp02/85/Welding-lectures-1-4-23-320.jpg)