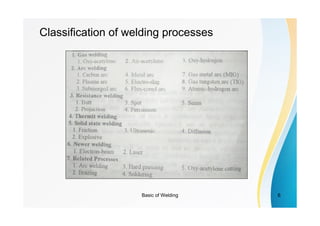

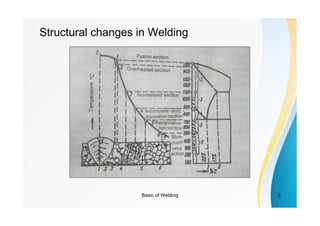

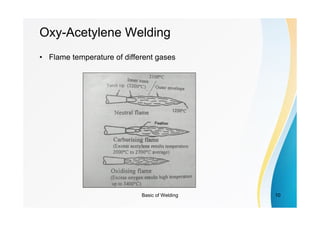

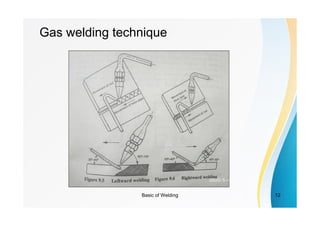

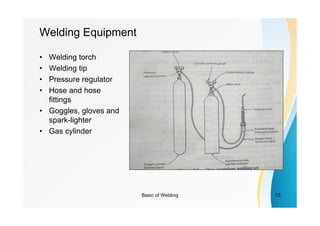

This document provides an introduction to welding and related processes. It discusses weldability, the different types of welding including plastic, fusion and cold welding. It classifies welding processes and discusses the metallurgy and structural changes involved in welding. Specifically, it describes gas welding and oxy-acetylene welding in detail, including the flame types, welding technique and required equipment. The document serves as an overview and introduction to various welding concepts and processes.