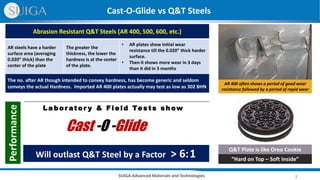

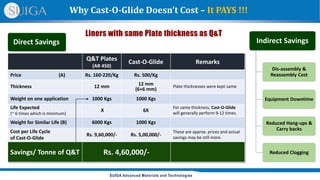

Cast-O-Glide is a chromium carbide overlay wear plate that offers unprecedented advantages over traditional quenched and tempered steel plates and weld clad plates. It provides the highest wear resistance, lowest maintenance needs, and highest productivity. Laboratory and field tests show Cast-O-Glide can last 5-6 times longer than quenched and tempered plates and 2-3 times longer than the best weld clad plates. Its extremely smooth surface and negligible dilution provide laminar flow and maximum carbide concentration for superior performance.